Time is precious when it comes to product development. When you need to generate small batches of functioning prototypes or production units over a period of two to four weeks, the upfront expense of traditional steel molds and months-long production runs really are considerable delays hamstringing innovation and responsiveness to the market.

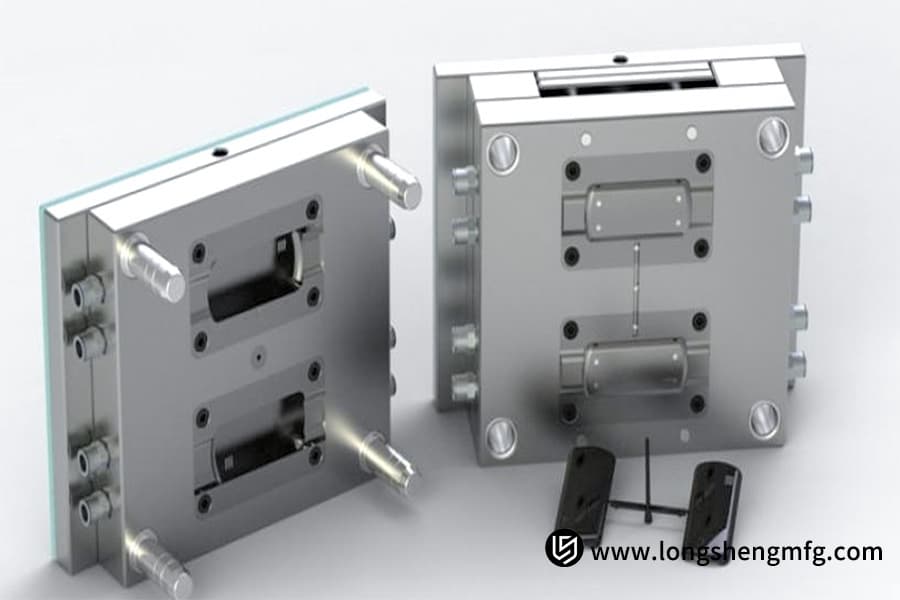

This is where rapid injection molding comes in as an extremely plausible strategic option. So, what is rapid injection molding, anyway? It’s pretty much a technology that makes use of soft molds, like aluminum alloy molds, and small-tonnage injection molding machines in attempting to quickly make small quantities of plastic parts.

Its value lies in its ability to hugely accelerate the process of time-to-market, allowing teams to undertake intensive product validation, market testing, and design refinement prior to attempting large-scale manufacturing, effectively reducing initial investment and development costs. This article will examine the advantages of rapid injection molding, its most applicable contexts, and when to use it. To save you time, here’s a quick overview of the core conclusions.

Rapid Injection Molding Core Quick Reference

| Project | Core Content |

| Core Definition | Mass rapid manufacturing technology in small batches of injection parts according to flexible molds, such as aluminum alloy made, and small-tonnage injection molding machines. |

| Application Scenarios | Small-batch production (tens to thousands of pieces), functional prototypes, pilot manufacturing, and test markets. |

| Typical Mold | Aluminum molds and mild steel molds are common molds, which have short manufacturing cycles and are low in cost. |

| Production Cycle | Overall cycle (mold + production) is typically 2-4 weeks. |

| Relative Cost | Mold and unit cost is significantly less than with steel molds, but unit cost for mass production is greater. |

| Core Benefits | Quick market introduction, low development risk, verification of design, flexibility in material and surface treatment. |

| Main Limitations | Mold life is short (thousands to tens of thousands of cycles) and therefore not suitable for quantity production of the finished product. |

Rapid injection molding fills the existing gap between the prototyping and mass production perfectly. With rapid iteration and test production, it provides timely assistance to companies to mitigate risk and take advantage of market opportunity.

Rapid injection molding is a strategic choice for balancing speed, cost, and quality in the process of design in production.

Why Trust This Guide? Practical Experience from LS Manufacturing Experts

The information in this manual is not scholarly, but the culmination of more than a decade’s worth of actual hands-on experience in the rapid injection molding business at LS Manufacturing. As a small batch and rapid response manufacturer, we are very close to the intense time, cost, and quality pressures at every stage of the process of product creation.

The depth of expertise for LS Manufacturing is in over 5,000 successful rapid injection molding jobs completed to startups and Fortune 500 companies working within diversified high-precision markets like consumer electronics, medical devices, and auto components. We do not simply provide machinery; we provide complete product development, mold optimization, and material selection solutions.

For example, LS Manufacturing helped a customer get 200 sets of functional parts out to market test within 10 working days with the help of fast-moving aluminum molds, before they made their final product design. This first-time decision not only solidified the client’s design, but also earned them early orders in advance, with a solid foundation to launch a winning product. That site experience is the foundation of our trustworthy team.

What exactly is rapid injection molding?

Briefly, “rapid” injection molding is not just “rapid” injection molding; it’s a structured engineering practice to achieving successful time to market. At its core is the inherent combination of speed and efficiency, cutting short the entire process from design through to proven parts by creative means.

So then, what is “rapid injection molding” exactly? Its general deviation from traditional injection molding is in two aspects:

- Simplified and efficient rapid tooling: It eliminates the long and costly manufacturing process of traditional steel molds and turns to rapid tooling with materials such as aluminum alloy. Its extremely short processing cycle is the primary requirement for achieving “speed.”

- Highly optimized production processes: It combines small-tonnage injection molding machines with specially tested process parameters to provide rapid turnaround and stable production of small lots.

We reverse this concept around in a professional end-to-end service at LS Manufacturing: From your design drawings, we expedite mold design and manufacturing, then follow through with a series of intense mold trial and parameter adjustment, and lastly provide injection molded parts ready for production quality within 2-4 weeks with verification and testing.

In its essence, rapid injection molding is a revolution in efficiency in product development. Through innovative marrying of processes and molds, it transforms long waits into effective market opportunities.

Why can rapid injection molding significantly shorten lead times?

Rapid injection molding is capable of producing delivery times of weeks. It is not a matter of accelerating one process, but the outcome of LS Manufacturing’s methodical optimization of three aspects: molds, processing, and processes.

1. Mold Simplification: Saving Time from the Start:

LS Manufacturing uses aluminum rapid molds in its facility. Aluminum, compared to steel molds, is easier to cut, and our CNC equipment can increase processing efficiency multiple times, thus saving significant front-end time.

2. Parallel Processing and Scheduling for Seamless Integration

As mold processing goes, the production staff at LS Manufacturing has already completed production parameter library and scheduling. As soon as the mold is complete on the production line, it’s sent directly to the designated set-up injection molding machine to go into trial production, eliminating the “wait time” from traditional manufacturing.

3. Internal Collaboration: The Ultimate Guarantee of Efficiency

LS Manufacturing’s extremely interactive design, mold, and production team maintains a consistent, fast response process. That is, the decision-making trail is extremely short, communication cost is minimized, and all steps are focused on one goal: getting qualified parts out the door as soon as possible.

It is this system, so thoroughly integrating effective molds, concurrent engineering, and co-operative processes, that is the solid foundation for LS Manufacturing’s staggering speed, to ensure your projects get completed at high speed end-to-end.

Is speed the main advantage of rapid injection molding just speed?

Speed is, without a doubt, the most daunting advantage of rapid injection molding, but its value surpasses even that. It’s a strategic choice that reduces overall project risk and optimizes development resources.

1. Significant Cost Benefits:

For low-volume injection molding, it significantly reduces initial mold investment. You do not have to bear the prohibitive cost of steel molds for production runs in hundreds or thousands of units so you can more meaningfully invest valuable capital on market validation and core innovation.

2. Extremely Low Design Validation Risk:

Before going into mass production, it allows you to pilot produce parts with material and performance characteristics similar to the finished product. What this means is that design flaws can be realized and corrected before they cost tens of thousands of dollars in the long run.

3. Unparalleled Flexibility:

Due to its rapid moldability, both the time and cost investment of converting, changing, or re-designing a design is significantly lower than in traditional methods. This allows for the iteration cycle to be more agile and allows for fast reaction to comments from the market or the tests.

At LS Manufacturing, we like to think of ourselves as a partner who helps customers reduce overall project risk. We provide more than the ability to produce quick parts; with low-volume injection molding solutions, we help you bring your ideas to market for less money and with higher potential for success.

Rapid injection molding creates a loop of “speed, cost-effectiveness, and stability.” The central strength of its power lies in providing unparalleled flexibility and security in product development beyond simple increments of speed.

Which industries and products are best suited for rapid injection molding?

The applications of rapid injection molding are fairly self-evident. It is ideally suited for high speed to market, iterative agility, and cost control industries. Typical among these industries is the need for proofing and testing with real parts before full-scale manufacture.

1. Medical Devices and Life Sciences:

Surgical instrument handles, device cases, diagnostic equipment, and numerous other uses subject the biocompatible material and tight tolerances to extremely demanding requirements. Low-volume injection molding can be used to create functional product prototypes for clinical trials before filling demanding regulatory approvals at a cost-effective manner, significantly reducing R&D risk.

2. Consumer Electronics and Smart Hardware:

Earphone shells, intelligent wearables, and sensor components require constant product refinement and constant appearance and design optimization. Rapid injection molding has the capability to provide the high-precision, low-quantity components needed for user testing, crowdfunding, and pre-sales to become a valuable tool to leverage market opportunities.

3. Automotive and Aerospace:

Non-core but functionally critical components such as interior buttons, cable wraps, and ventilation ducts. This technology allows on-board road testing or functional testing before mold freeze, ensuring ideal design and material performance and avoiding expense recalls due to minor component failure.

Whether for the medical fraternity requiring compliance validation, the consumer electronics business driven by trends, or the automobile business preoccupied with safety and redundancy, rapid injection molding has become a key element of product innovation process owing to its unique value in risk reduction and rapid development.

When should I consider rapid injection molding for my project?

Explain when to use rapid injection molding on project planning milestones and your development speed and cost will be directly impacted. The best time to utilize rapid injection molding is when your project faces any of the below conditions. Especially, you should give this solution top priority when the below mentioned critical indications occur:

1. Time-Driven Projects:

When the market window is short and you need to produce functional parts for demonstration, testing, or sale in 2-4 weeks, then the long lead times of traditional molds are not sufficient. This is the most severe situation for the use of rapid injection molding.

2. Uncertain Requirements:

If your design for the product isn’t yet fully determined or requires real-world market feedback to validate requirements, this technology allows you to manufacture in small lots at a very low cost, without facing the significant cost of scrapping traditional molds due to design modifications.

3. Budget and Production Constraints:

If your project budget is tight, or the final required volume is a few hundred pieces or a few thousand pieces, it is not economical to invest in expensive traditional molds. Low-cost mold injection molding is the best option for small-batch production needs.

When your project is defined by cost-effectiveness, uncertainty, and speed, the choice of rapid injection molding is not merely a technical decision but a strategic one in an effort to ensure project agility and success.

How significant is the cost difference between rapid injection molding and traditional injection molding?

While comparing the prices of rapid injection molding and traditional injection molding, do not simply compare unit cost; instead, look at it in terms of “total cost of ownership.” Rapid injection molding, with its unique strengths, has phenomenal overall cost advantages for small lot injection molding and at the conceptual and early phases of product development. The comparison that follows is done on the basis of key parameters:

| Cost Dimension | Rapid Injection Molding | Traditional Injection Molding |

| Mold Investment | Extremely Low (with rapid tooling such as aluminum molds) | High (the manufacturing of steel molds can cost tens to hundreds of thousands of yuan) |

| Production Cycle | Brief (the entire process for small-volume production might be as short as 2-4 weeks) | Lengthy (even mold manufacturing alone can last weeks or months) |

| Cost Per Part | Cheaper for small batches | Extremely competitive for large batches |

| Design Iteration Risk | Low, low remake or mold modification cost | High, high re-opening or mold repair cost |

1. Mold Investment:

Rapid injection molding uses rapid tooling such as aluminum molds, and the molds cost much less than traditional steel molds. This means that you don’t need to bear the enormous cost of mold investment at the start of a project.

2. Time Cost:

Time equals money. Rapid injection molding can reduce production cycles to 2-4 weeks, to the market sooner. For those products that have to catch a market window, the cost of missing a market window can easily be more than the price differential in the mold.

3. Control of Risk:

During the product development phase, design changes are unavoidable. With traditional injection molding, each change can trigger costly mold reworks and project delays. But rapid injection molding allows multiple design validations at decreased costs, eliminating the huge losses of large-scale production failure due to design flaws.

While cost per part for rapid injection molding is perhaps higher than for traditional molding in mass production, benefits to mold investment, time savings, and risk management reduce the overall cost at the low-volume, high-uncertainty development phase.

What should you consider most when selecting a rapid injection molding partner?

While choosing rapid injection molding services, you are not merely deciding on a vendor; you are also making a partner selection that will decide the success of your project. A good partner must provide end-to-end assistance in four areas: technology, quality, communication, and service. The most critical factors to evaluate in assessing a partner are listed below:

1. Technical Experience and Expertise:

A good partner should possess extensive experience in speedy injection molding projects and the ability to foresee and address potential issues from design to production. In LS Manufacturing, for example, our combined experience working on thousands of projects guarantees that your designs are translated into qualified products with maximum efficiency.

2. Comprehensive Quality Assurance System:

From raw material receipt through shipment, there must be standardized quality control processes.LS Manufacturing’s established inspection system of IQC/IPOQ/FQC makes certain that all lots of parts conform to settled-up requirements.

3. Efficient Communication and Project Management:

An immediate response is necessary to expediting projects. An assigned project manager with open information and frequent reporting on progress is necessary to make sure that projects are on schedule and issues are fixed on time.

4. One-Stop Service Capabilities:

LS Manufacturing provides turnkey solutions ranging from design optimization consulting and tooling to post-molding manufacturing injection. The turnkey solution eliminates communication cost and risk in managing multiple vendors, hence ensuring smooth project delivery.

Selecting a speed-up injection molding partner is a general evaluation process. In addition to cost, the partner’s technical capability, core quality, communication efficiency, and integration ability should be evaluated as well.

How to deliver medical prototype housings in 45 days and save 40% in costs?

In the health care technology industry, time and capital are usually a primary constraint to innovation. One startup firm producing intelligent infusion pumps had a problem: they needed to present 50 functional prototypes to investors within 60 days. Standard injection molding without any special procedure required 12 weeks in molding, well outside their schedule and budget.

1. Customer Dilemma:

The client’s fundamental issue was that traditional mold-making processes took too long and could not handle their time-critical needs of creating the fundraising presentations. On top of that, the price of molds at this point was out of the question. That left them with a dilemma: either delay their presentation or charge much more.

2. LS Manufacturing Solution:

Having analyzed their needs, we offered a high-end program for acceleration injection molding immediately. The Special LS Manufacturing solutions are:

- Utilizing aluminum molds in small-shot injection molding, reducing mold production time from 12 weeks to 3 weeks.

- Concurrent mold design and medical-grade material ordering provide smooth process integration.

- DFM analysis reports are delivered within the first part trial phase to ensure best-in-class structural design.

3. Results and Value:

With this business-critical rapid injection molding solution, the customer created 50 high-quality medical prototype housings in 45 days, 15 days faster than their schedule. This efficient process enabled the customer to present a key financing presentation and complete their next round of funding. Compared to typical mold-building solutions, the customer could save over 40% of initial investment, reserving precious capital for subsequent versions of the product.

Choosing the right rapid injection molding partner not only precludes time and cost liabilities but is also critical to project success and attaining marketplace advantage. LS Manufacturing’s skills in rapid injection molding are intended to provide a viable avenue for breakthrough projects like these.

Can the quality of rapid injection molded parts meet mass production standards?

This is one of the basic queries the majority of clients have before they choose rapid injection molding: Will they be compromising on quality for speed? At LS Manufacturing, we always hold to the fact of “fast does not mean compromise.”

With meticulous quality control, we ensure that the quality of the parts is completely consistent with the stringent standards required for functionality, beauty, and even low-batch selling. In particular, we ensure quality conformance through the following three dimensions:

1. Material Performance Consistency with Mass Production:

LS Manufacturing employs exactly the same quality high-performance engineering plastics (i.e., ABS, PC, and PA) for the finished product to ensure that quickly injection molded components are identical with mass produced components in key performance characteristics such as mechanical strength, temperature resistance, and biocompatibility.

2. Strict Process Control System:

In LS Manufacturing, each mold goes through meticulous process parameter adjustment and optimization. We monitor key parameters such as temperature, pressure, and time during the injection molding process in order to ensure part dimensional stability and cosmetic appearance are to design tolerance and the tolerance is consistently controlled with reliability.

3. Comprehensive Quality Verification Process:

From first-article inspection to batch sampling, LS Manufacturing has integrated a full quality tracing system. We conduct multi-dimensional part quality inspection using meticulous test methods such as coordinate measurement and colorimetry to ensure every batch of deliverables meets mutually agreed specifications.

The track record of LS Manufacturing shows that experienced rapid injection molding not only meets mass production standards but also provides valuable process references for eventual large-scale production. We have supplied a number of medical, automotive, and consumer electronics clients with quality parts ready for marketing testing and functional testing.

Rapid injection molding has a partner that possesses a comprehensive quality system in order to supply consistent parts of production quality, not “temporary” prototypes. That is one of the core beliefs that LS Manufacturing provides to clients.

How do I get a preliminary quote for rapid injection molding from LS Manufacturing?

A prompt quote for LS Manufacturing’s rapid injection molding is simple and efficient. We understand that the fastest, most concise, and simple quote is of greatest importance in your consideration in the early stages of a project. Therefore, we simplified the quoting process to give you efficient reference data in the shortest lead time available. All we need from you are the following three basic pieces of information in order to begin the quote process:

1. 3D Design Files:

Share your 3D model (ideally in STEP/IGS format). This is the foundation for LS Manufacturing to analyze the structure of the part, conduct rapid injection molding process analysis, and offer recommendations for design optimization.

2. Material and Process Requirements:

Let us know your chosen plastic material (e.g., ABS, PC, PP), along with any special color, surface finish (e.g., texture, paint), or certification requirements.

3. Quantity and Timeline:

Informing us of what your target quantity is (tens to thousands of units) and your desired schedule will enable us to create the best production schedule.

As soon as you submit your request, LS Manufacturing’s seasoned project staff will get started right away with a review. Not only will we give you a clear and accurate quote, but we will also give you an initial process analysis so you’ll know for sure your proposal.

Contact us today for a personalized quote and select LS Manufacturing as your trusted rapid injection molding provider to propel your success.

FAQs

1. What is the typical lead time for rapid injection molding?

From concept validation to parts shipment, LS Manufacturing’s quick injection molding processes typically take 2-5 weeks. Turnaround is contingent upon part complexity and quantity: plain structure parts can ship in 2-3 weeks, complex structure parts and custom surface finishes can ship in 4-5 weeks. We use standard processes and concurrent engineering to reduce wait time and optimize product development.

2. What production batch size is suitable for rapid injection molding?

High-speed injection molding is optimally suited for small quantities of tens to thousands of pieces. For that quantity range, LS Manufacturing helps customers achieve cost and productivity balance through aluminum mold technology and flexible scheduling. For over tens of thousands of units of volume demand, we will evaluate and recommend traditional steel mold solutions to offer best return on investment during the product life cycle.

3. What are the commonly used mold materials for rapid injection molding?

Aluminum alloy is the simplest material to make rapid injection molding molds. Its better cutting power increases the processing speed by 3-5 times compared to steel molds, without losing a life long enough to conduct thousands of injection molding cycles. LS Manufacturing also offers coated aluminum molds or mild steel molds for special needs, achieving the best compromise between speed and durability.

4. My product design is still very rough. Can you provide support?

We definitely can. LS Manufacturing has expert Design for Manufacturability (DFM) analysis resources. Our designers and engineers will help refine draft angles, wall thickness distribution, and structural details based on the unique nature of the injection molding process. In addition to improving the quality of the part, this avoids follow-up mold rework cost by ensuring your designs are properly translated into manufacturable solutions.

Conclusion

Rapid injection molding is more than technology for manufacturing; it’s a strategic choice for accelerating product innovation and reducing early-stage risk. Its blend of processes optimally balances velocity, cost, and quality, and therefore is most suited to critical applications such as pilot production of a product, market testing, and low-volume manufacturing.

Working with LS Manufacturing is not just a manufacturing solution but also a dedicated partner who well understands your R&D requirements and is dedicated to helping your project succeed from inception to delivery. With our rich technical competence and complete quality management system, we guarantee that your concepts can be rapidly and dependably converted into successful market solutions.

Contact LS Manufacturing and upload your 3D design files now to receive a personalized rapid injection molding solution quote and free Design for Market (DFM) analysis from LS Manufacturing. Let’s get started on your project the next business day and work together to accelerate your creative vision to market success!

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.