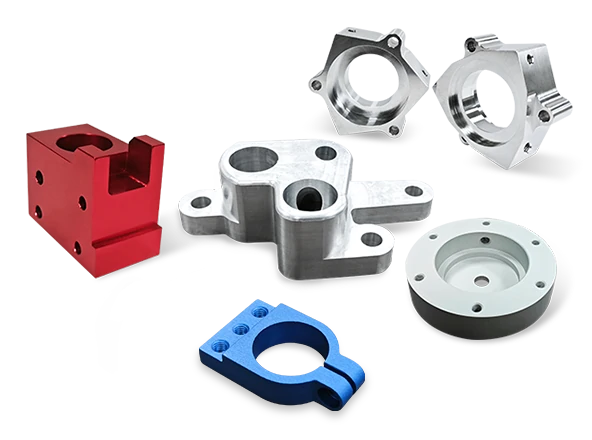

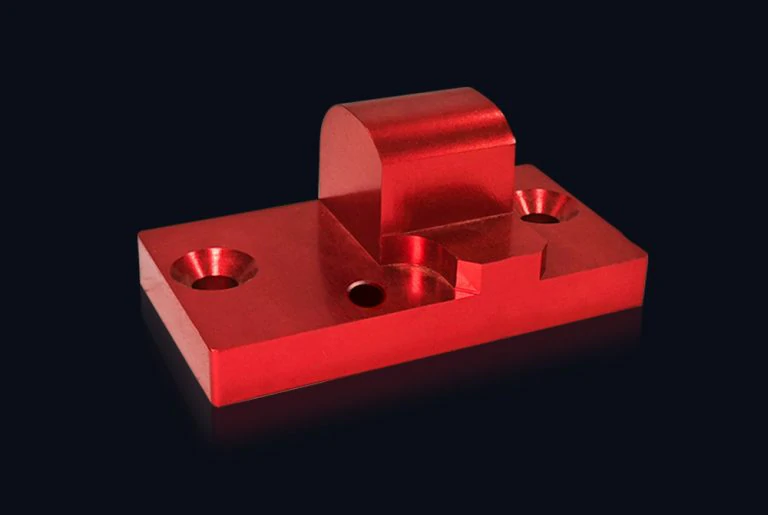

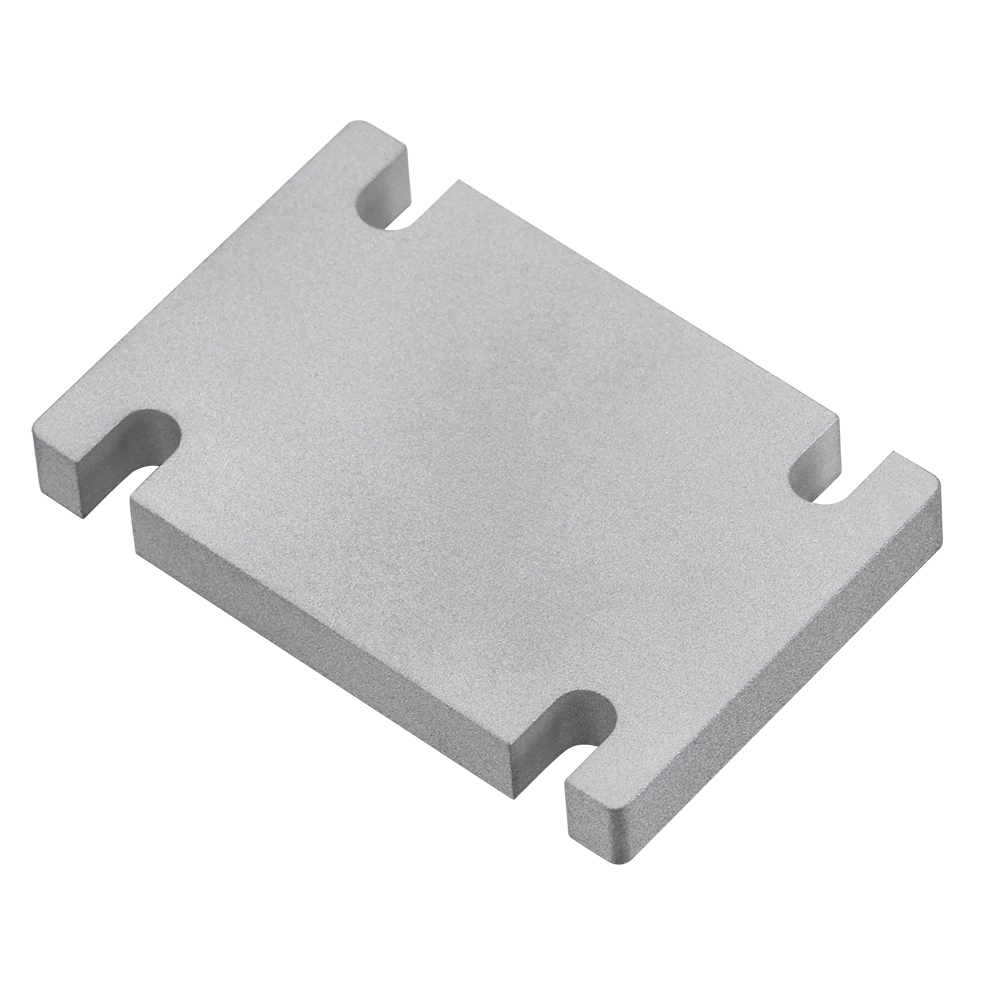

Gallery of CNC Machined Parts

Dive into longsheng’s extensive gallery that showcases some of our completed custom CNC parts and take confidence that we can create your CNC machining project according to your strict specifications.

DEPENDABLE QUALITY

ISO 9001:2015 Certified. With 2 self owned factories ensure quick-turn capabilities. Start ordering your custom metal and plastic parts today.

Looking for reliable and fast turnover suppliers for machined plastic and metal components? We have hundreds of CNC machine tools and unparalleled production capacity to ensure that your parts are shipped on time every time. Whether you need machined prototypes or low-volume production parts, simple or incredibly complex geometries, aesthetic or functional parts, machined prototypes and production parts in as fast as 3 day.

Our advanced milling technology enables us to produce high-precision parts such as gears, brackets, enclosures, and mechanical components. Mastery across materials spectrum.

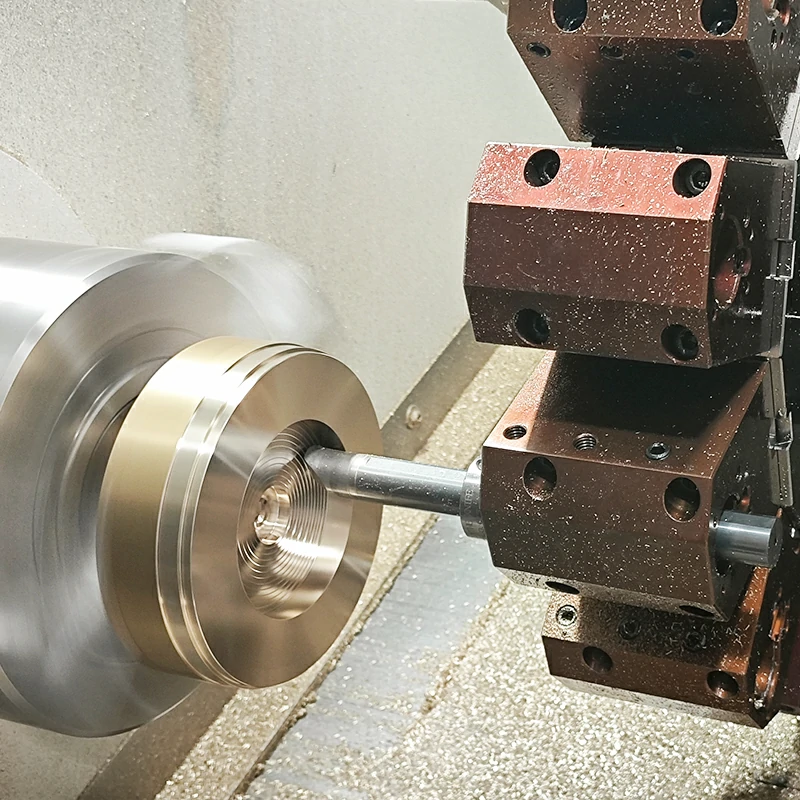

We can create highly accurate, any symmetrical cylindrical, or spherical parts in line with your stringent requirements.. Expertise in both hard and soft materials.

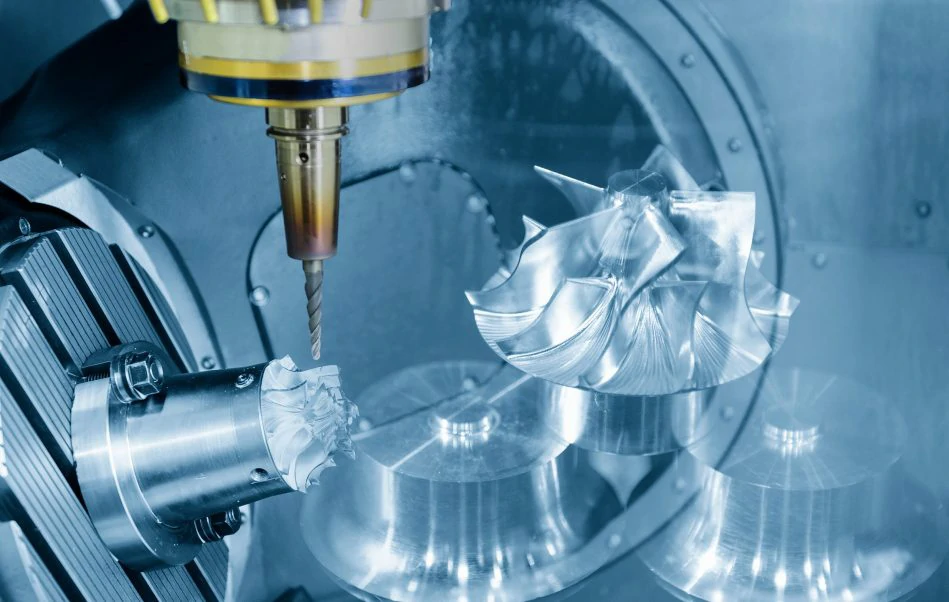

Leveraging 5-axis technology for crafting complex, multi-sided components such as impellers, turbine blades, mold cores, and aerospace parts. Unparalleled across a wide range of materials.

Dive into longsheng’s extensive gallery that showcases some of our completed custom CNC parts and take confidence that we can create your CNC machining project according to your strict specifications.

We can be your exclusive partner for creating precision machined prototypes and batch parts, we guarantee that all parts will be manufactured according to your specifications, as long as you specify the requirements on the drawings, we can also achieve special tolerances.

| Abilities | CNC Milling | CNC Turning |

|---|---|---|

| Maximum Part Size |

1300mm × 800 mm × 300mm 51.2in. × 31.5in. × 11.8in. |

300mm × 500mm 11.8in. × 19.7in. |

| Minimum Part Size |

1mm × 1mm 0.04in. × 0.04in. |

1mm × 1mm 0.04in. × 0.04in. |

| Minimum Feature Size |

+/- 0.3mm +/- 0.11in. |

+/- 0.3mm +/- 0.11in. |

| Standard Tolerances |

+/- 0.005mm +/- 0.0002in. |

+/- 0.005mm +/- 0.0002in. |

| Radii | Sharp inside corners on a part will be radiused (rounded) as a natural result of the CNC machining process. | |

| Linear Dimension |

+/- 0.005mm +/- 0.0002in. |

+/- 0.005mm +/- 0.0002in. |

| Hole Diameters (Not Reamed) |

+/- 0.005mm +/- 0.0002in. |

+/- 0.005mm +/- 0.0002in. |

| Shaft Diameters |

+/- 0.005mm +/- 0.0002in. |

+/- 0.005mm +/- 0.0002in. |

| Edge Condition | Sharp edges are broken and deburred by default. | |

| *longsheng can produce threads of any specification and size required by our customers. | ||

| Threads and Tapped Holes | Diameter: Φ 1.5-5 mm, depth: 3×diameter | Diameter: Φ 1.5-5 mm, depth: 3×diameter |

| Laser Etching | Minimum width of 0.5 mm, depth of 0.1 mm | use laser marking to create standard text for CNC turned parts |

| Lead Time | 3 Business Days | 3 Business Days |

* Maximum CNC parts size varies by material.We are able to offer a precision CNC machining service with a wide array of tolerances.Contact our team if you need further information.

Longsheng can source any other material on request for prototyping and production runs of custom parts. If you have special material needs, please contact us to provide you with a reliable solution, you can even compare the processing prices of different materials.

Offers excellent machinability, high strength-to-weight ratio, and superior corrosion resistance, making it perfect for lightweight, durable machined parts.

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

Stainless steel offers superior corrosion resistance, high strength, excellent toughness and ease of fabrication, ideal for demanding machining operations.

Titanium It’s a metal with excellent strength-to-weight ratio, low thermal expansion, high corrosion resistance; sterilizable and biocompatible for machining.

Plastics are also very popular option for CNC machining because of its wide choices, relatively lower price, and significantly faster machining time needed.

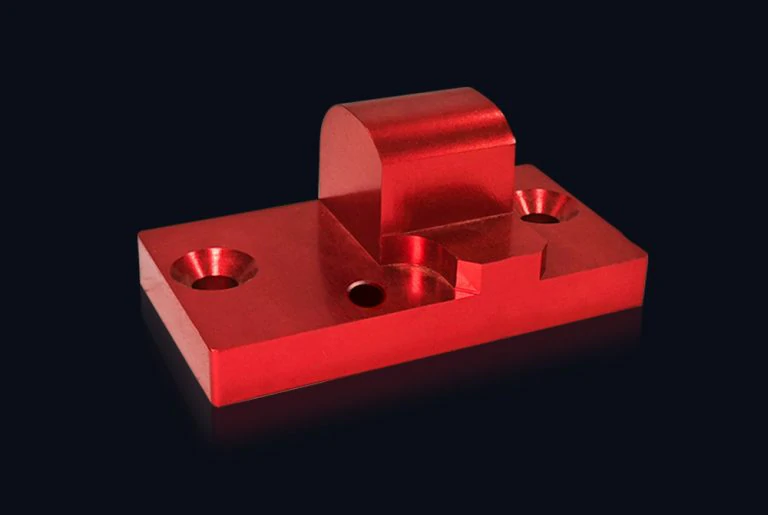

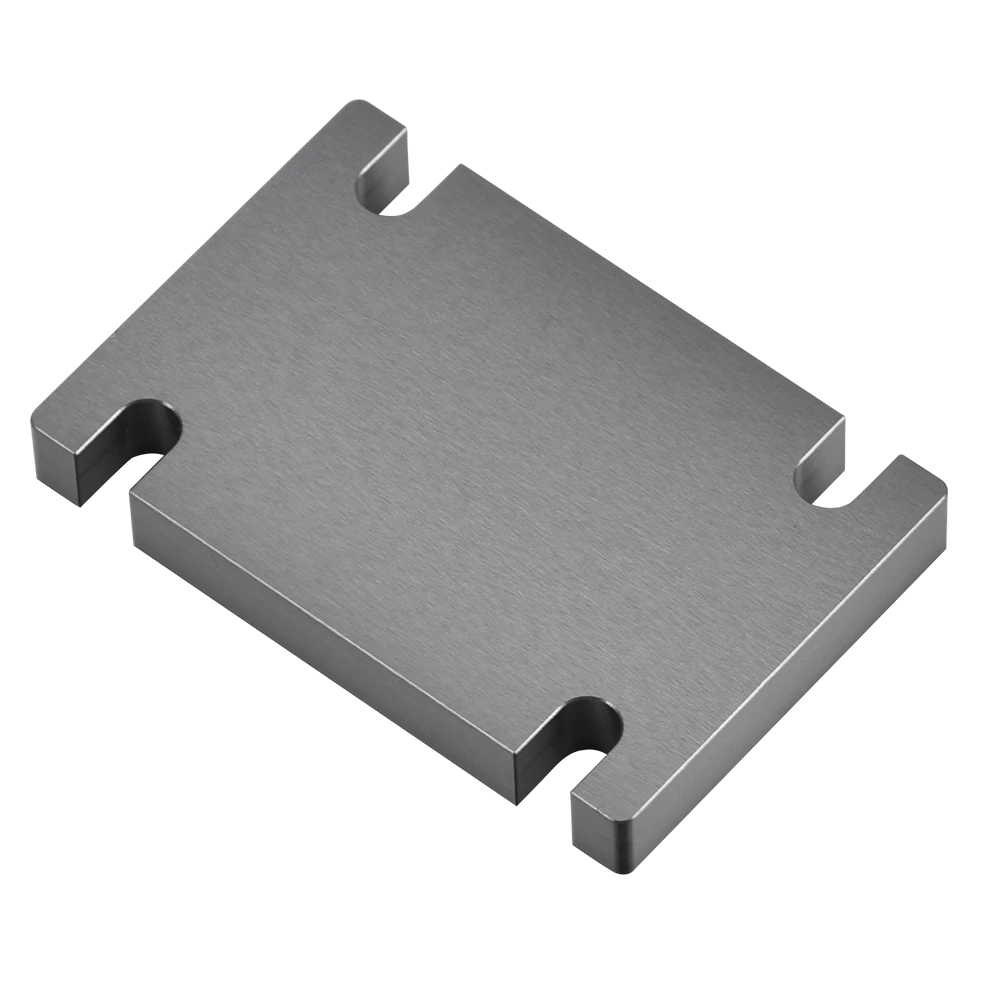

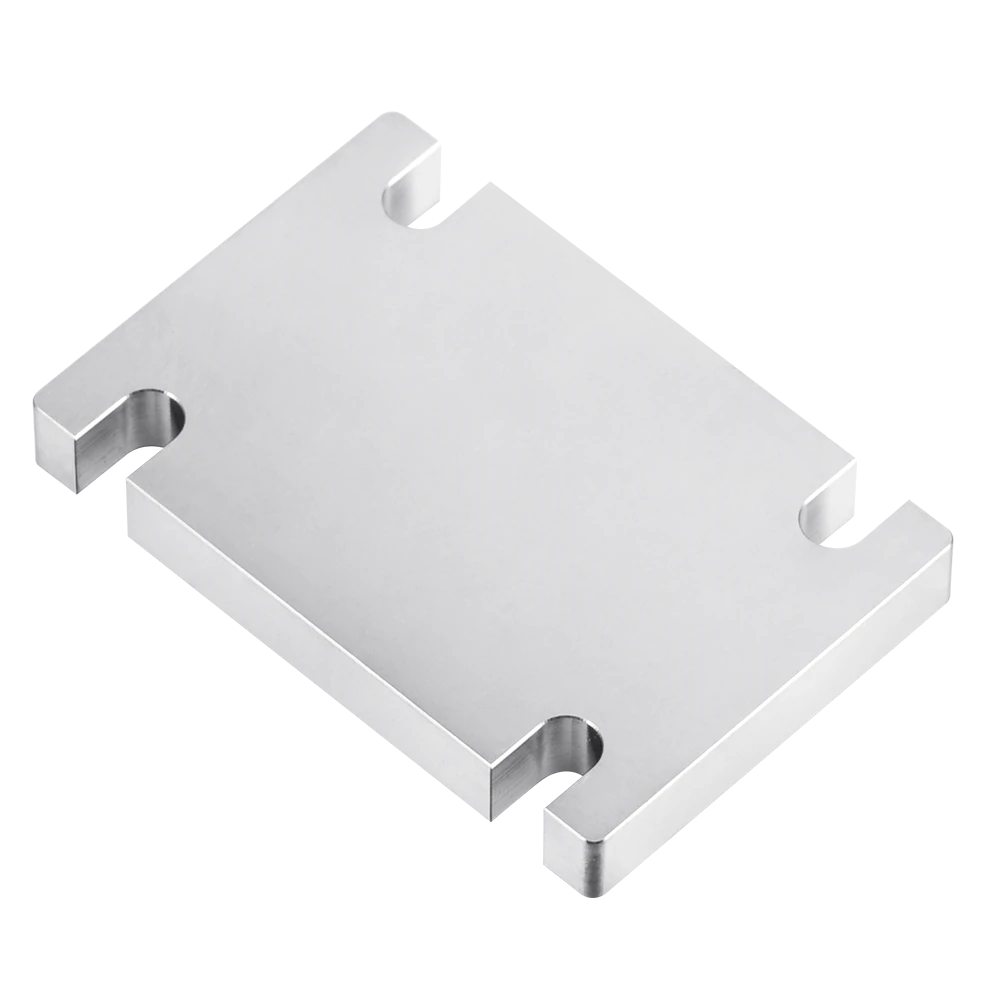

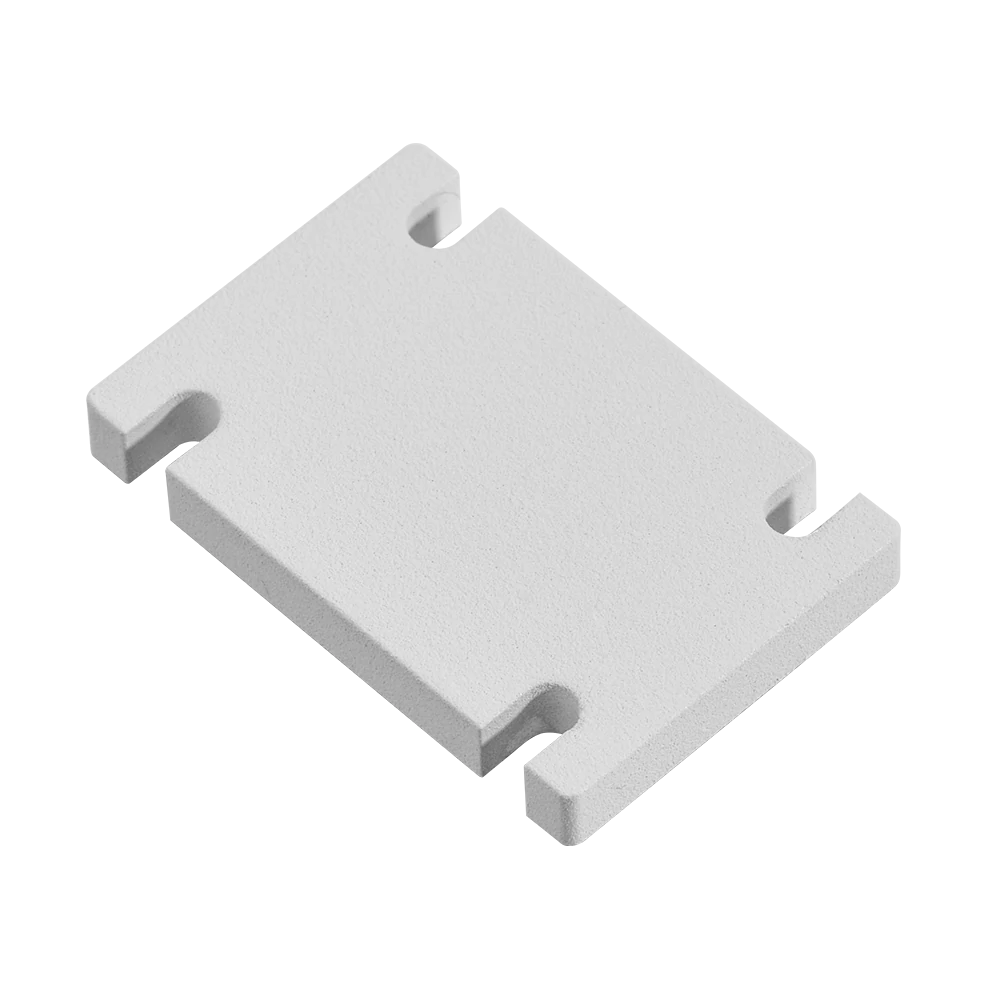

CNC machining leaves visible tool marks during the process of removing portions of the block’s surface to create desired shapes.Longsheng offer wide variety high level surface finishes. We only list some of the common finishing options. There are more options for your CNC prototyping and production parts.

| Name | Materials | Colors | Machining marks | Texture | |

|---|---|---|---|---|---|

|

Anodizing | Aluminum | Clear, Black, Red, Blue, Orange, Gold | Visible under anodizing | Smooth with possible fine texture |

|

Polishing | Metals | N/A | Removed on primary surfaces | Smooth, without roughness |

|

Powder coating | Aluminum, Stainless steel, Steel | Black, any RAL code or Pantone number | Removed | Gloss or semi-gloss |

|

Bead blasting | Metals | N/A | Removed for non-cosmetic, removed on primary surfaces for cosmetic | Rough, resembling sandpaper |

* We only list some of the common finishing options. There are more options for your CNC prototyping and production parts.Contact our team if you need further information.

Experience our commitment to unparalleled precision and superior quality control. We utilize cutting-edge inspection equipment in our CNC machining process to ensure every part meets rigorous industry standards and exceeds customer expectations. Take a closer look at our leading-edge inspection tools that make our precise, reliable, and efficient manufacturing possible.

We have a team of dedicated and competent engineers and technicians who provide 24-hour technical support to help solve your problems.

The Longsheng team ensures quality, so you can deliver parts on time and to specifications every time.

If the parts do not meet the requirements, please contact us within 5 days after receiving the order, and we will resolve your issue within 3 days.

Simply upload your design file to get a CNC quote. Our engineers analyze your part geometry and provide real-time and competitive pricing as well as comprehensive DFM feedback.

We provide you with design assistance. Whether you need to optimize an existing design or create a new one from scratch, we will help you achieve the best design and production results.

We have over 100 engineering grade materials suitable for various CNC parts applications and industries. The material range ranges from plastic to aluminum, stainless steel, platinum, and copper.

We provide you with custom sample manufacturing, allowing you to check and verify the quality, adaptability and performance of your products prior to mass production.

Listen to our customers’ voices! We have received praise and satisfactory evaluations from many customers.

They highly recognize our professional services and high-quality results.

You can contact our sales team directly (+86 185 6675 9667). Or provide the relevant design documents, specifications and your contact information through the form on the right, and we will communicate with you and start processing your order within 2 working hours.

Yes, we can provide samples or prototype production services according to customer requirements. We can process according to design drawings or samples to verify and confirm the quality and applicability of the parts.

We have a rigorous quality control process that involves multiple inspections and tests throughout the manufacturing process. We use advanced inspection and testing equipment to ensure that all parts meet or exceed industry standards.

The delivery time varies depending on the complexity, quantity, and machining technology of the parts. We will provide accurate delivery times based on customer order requirements and strive to deliver on time.

No matter if your are looking for one-off prototypes or large-scale batch manufacture, we can deliver repeatedly on quality and lead time to make your ideal real, and let your custom parts quickly enter the market.