This article provides an overview of our company’s CNC machining services for custom machined parts. We use the latest technology and equipment to produce high-quality parts with precision and accuracy. Our team of experts has years of experience in the industry and can handle projects of any size and complexity. Contact us today to learn more about our services and how we can help you with your next project.

our custom machining parts offer several advantages over off-the-shelf options. With custom machining, you can design parts that are tailored to your specific needs and requirements, optimizing the performance of your equipment and improving efficiency. Additionally, custom parts can reduce the risk of breakdowns and downtime, leading to significant cost savings in the long run. If you are looking to improve the performance and reliability of your equipment, contact us today to get started on your next project.

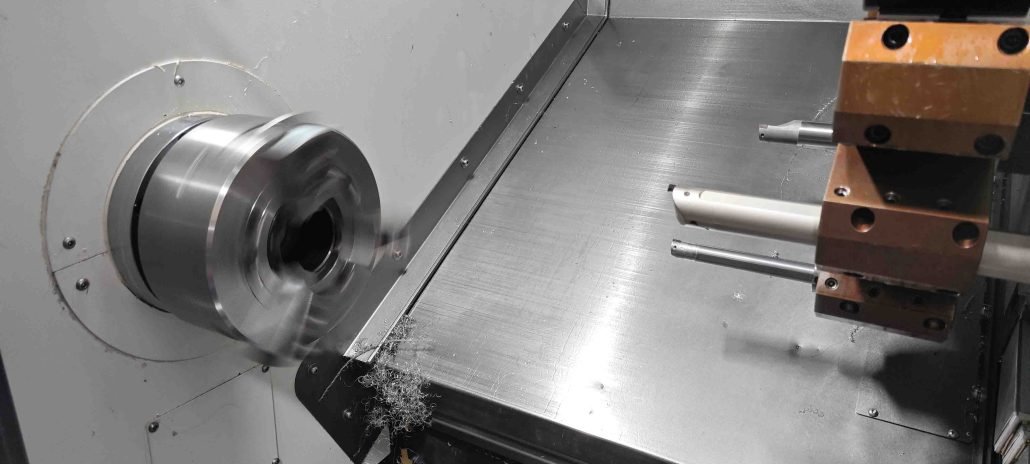

CNC Machining Services for Custom Machined Parts

Our company specializes in providing CNC machining services for custom machined parts. We use the latest technology and equipment to produce high-quality parts with precision and accuracy. Our team of experts has years of experience in the industry and can handle projects of any size and complexity.

We understand the importance of delivering projects on time, which is why we have streamlined our processes to ensure fast turnaround times without compromising on quality. We work closely with our clients to understand their requirements and provide tailored solutions to meet their specific needs.

Our services include CNC milling, turning, drilling, and grinding. We use a variety of materials, including aluminum, steel, titanium, and plastics, to produce parts that meet the highest standards of quality and durability. We also offer finishing services, such as anodizing, plating, and painting, to ensure that your parts look and perform their best.

At our facility, we maintain strict quality control measures to ensure that every part meets our clients’ exact specifications. Our team uses advanced inspection equipment to verify the accuracy and quality of every part we produce. We also have a dedicated customer support team that is available to answer any questions or concerns you may have.

If you are looking for reliable and precision CNC machining services for custom machined parts, look no further than our company. Contact us today to learn more about our services and how we can help you with your next project.

Benefits of Custom Machining Parts

Custom machining parts are created specifically to meet the unique requirements of a particular application. These parts offer numerous benefits over standard, off-the-shelf parts. Here are some of the key advantages of using custom machining parts:

Enhanced Precision

Custom machining parts are designed and manufactured to meet the exact specifications of the application. As a result, they offer enhanced precision and accuracy, which is crucial in many industries, such as aerospace, medical, and defense.

Improved Performance

Custom machining parts can be designed to perform specific functions, such as reducing friction or improving heat dissipation. This can lead to improved performance and efficiency compared to standard parts.

Increased Durability

Custom machining parts are often made from high-quality materials that are selected specifically for their durability and performance. This can lead to increased lifespan and reduced maintenance costs.

Greater Flexibility

Custom machining parts can be designed to fit unique or complex shapes, which is not possible with standard parts. This allows for greater flexibility in design and can help to optimize space and functionality.

Cost-Effective

While custom machining parts may have a higher upfront cost than standard parts, they can often provide cost savings in the long run. This is because they are designed to meet the specific needs of the application, which can lead to improved efficiency and reduced maintenance costs.

In summary, custom machining parts offer a range of benefits over standard parts, including enhanced precision, improved performance, increased durability, greater flexibility, and cost-effectiveness. If you require a part that is uniquely designed for your application, custom machining is the way to go.

Applications of Custom Machining Parts

Custom Machining Parts are customized machining parts that are widely used in various mechanical equipment and industrial production. Below, we will explore their main application scenarios.

1. Automotive Manufacturing

Automotive manufacturing is one of the main application areas of Custom Machining Parts. Custom Machining Parts are often used in the manufacturing process of important parts such as car engines, clutches, and transmission systems. These parts require high precision and high-quality machining, and Custom Machining Parts can provide reliable solutions for car manufacturers.

2. Aerospace

Custom Machining Parts are also widely used in the aerospace field. Aerospace equipment needs to withstand extreme environmental conditions and high precision requirements, so the high precision machining capability of Custom Machining Parts can provide stable performance and reliability for these equipment.

3. Medical Devices

In the field of medical device manufacturing, Custom Machining Parts also has important applications. Medical devices require high-precision and high-quality machining and manufacturing, so the high-precision machining of Custom Machining Parts can ensure the performance and stability of these devices.

4. Electronic Devices

Custom Machining Parts are also widely used in the field of electronic device manufacturing. For example, high-precision Custom Machining Parts can be used in the manufacturing of parts such as heat sinks, chassis, and circuit boards for electronic devices.

In summary, Custom Machining Parts have extensive applications in various mechanical equipment and industrial production, and can provide manufacturers with high-quality and high-precision solutions, improve equipment performance and reliability, and promote the development of industrial production.

Custom Machining Parts Service

Our custom machining parts service offers a wide range of solutions to meet your unique needs. We understand that every project is different, and we are dedicated to providing the highest quality and most cost-effective solutions.

Our team of experts utilizes the latest in technology and equipment to create custom parts that meet your exact specifications. Whether you need a single prototype or a large production run, we have the experience and expertise to deliver exceptional results.

Our services include CNC machining, milling, turning, drilling, and more. We work with a variety of materials, including aluminum, steel, brass, and plastics, to ensure that your parts are exactly what you need.

At our facility, we prioritize quality and accuracy above all else. We use only the best materials and equipment to create custom parts that meet your exact specifications. We also offer a variety of finishing options, including painting, powder coating, and anodizing, to ensure that your parts are finished to your exact specifications.

Our team is dedicated to providing exceptional customer service and support throughout the process. We work closely with you to understand your needs and provide the solutions that meet your requirements. We also offer competitive pricing and fast turnaround times to ensure that your project is completed on time and within budget.

Contact us today to learn more about our custom machining parts service and how we can help you with your next project.

FAQ

Yes, our team of experts has years of experience in the industry and can handle projects of any size and complexity.

Contact us today to learn more about our services and how we can help you with your next project. We work closely with our clients to understand their requirements and provide tailored solutions to meet their specific needs.

We offer finishing services such as anodizing, plating, and painting to ensure that your parts look and perform their best.