Surface Finishing Services

If you need post-processing on precision parts, just state your requirements in the “Upload Your Design” with a few clicks.

- Manufacturing on demand

- ISO 9001:2015 certified

- Get rapid quotes within 2 hours

- All uploads are secure and confidential

Surface finishing can give your finished product a unique or desired appearance and feel through different processes. Whether you need to improve appearance, enhance adhesion, enhance weldability, or enhance corrosion resistance and hardness, Longsheng provides excellent surface finishing services for you. Contact our customer service team and you will receive fast and accurate online quotes.

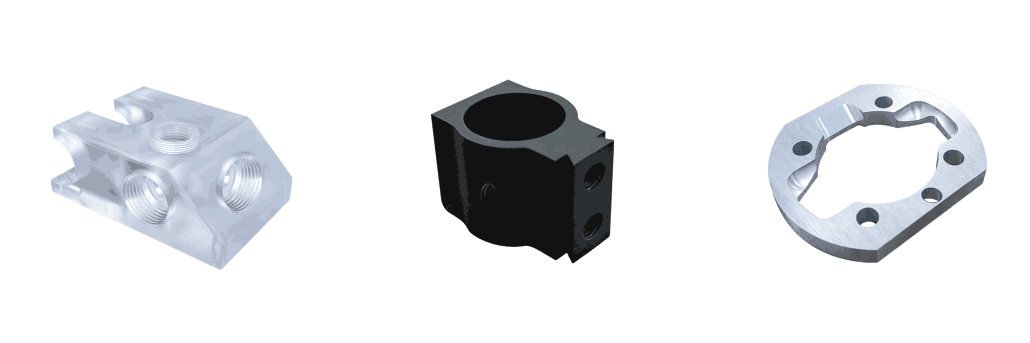

Strengthen, protect, and improve appearance of parts with post-process finishing

Please take a look at the finishing options to understand how we can customize the most suitable solution for you to meet your unique needs.If you have more complex surface finishing requirements, please contact gloria.wu@longshengmfg.com

| Name | Description | Material | color | Machining marks | Link |

|---|---|---|---|---|---|

| Anodizing | Anodizing process involves creating a layer of oxide on the surface of the product, which enhances its durability and resistance to corrosion. | Aluminum | Clear, black, grey, red, blue, gold | Visible under anodizing | Learn More>> |

| Powder Coating | powder coating process involves applying a dry powder to the surface of the product, which is then heated to create a smooth and durable finish. | Metal | White, Black, RAL and Pantone | Parts are powder coated directly after machining | Learn More>> |

| Polishing | Polishing can create a smooth and glossy surface on the product surface. We offer different types of polishing, such as mechanical polishing and chemical polishing. | Metal | Silver gray | Removed on primary surfaces | Learn More>> |

| Chromate | Chromate, commonly known as a chemical thin film, is a conversion coating used as a corrosion inhibitor on aluminum. | Aluminum | Clear/ Slight yellow tint | Machining marks are visible | Learn More>> |

| Bead blasting | Bead blasting can be used to create a textured surface, remove rust or paint, or prepare a surface for further finishing. | Metal | N/A | - | Learn More>> |

| As machining | Our machined finish can be machined to Ra 3.2 μ M/Ra 126 μ Surface roughness of in and removal of sharp edges and burrs from the parts. | Metal | N/A | Slightly visible | Learn More>> |

| Vapor polishing | Vapor polishing is a surface finishing technique used to improve the smoothness and clarity of a variety of materials, particularly plastics | Plastics | N/A | Smooth | Learn More>> |

| Black Oxide | Black oxidation is a conversion coating used for metals. Can provide a black smooth appearance and slightly improve corrosion resistance. | Metal | Black | Visible | Learn More>> |

| Alodine | Alodine, also known as chemical conversion coating or chromate conversion coating, involves applying a conversion coating solution to a metal surface, usually containing chromate compounds. | Metal | True qualities | Tool marks visible | Learn More>> |

| Fine machining | Fine machining manufacturing process involves processing raw materials into parts or products with high precision, smooth surfaces, and fine size control through a series of fine machining steps. | Metals, Plastics | N/A | Slightly visible | / |

| Brushing | Brushing can effectively remove sharp edges, burrs, and unwanted protrusions from machined parts, ensuring that they are safe to handle and minimizing the risk of injury. | Metals, Plastics | N/A | Remove main surfaces | / |

| Wire drawing | Wire drawing is used to improve the quality and appearance of metal surfaces, which involves scraping, grinding, or polishing the surface of metal materials to create a surface effect with specific textures and appearances. | Metal | N/A | Removed on Primary surfaces | / |

Latest Blog Posts

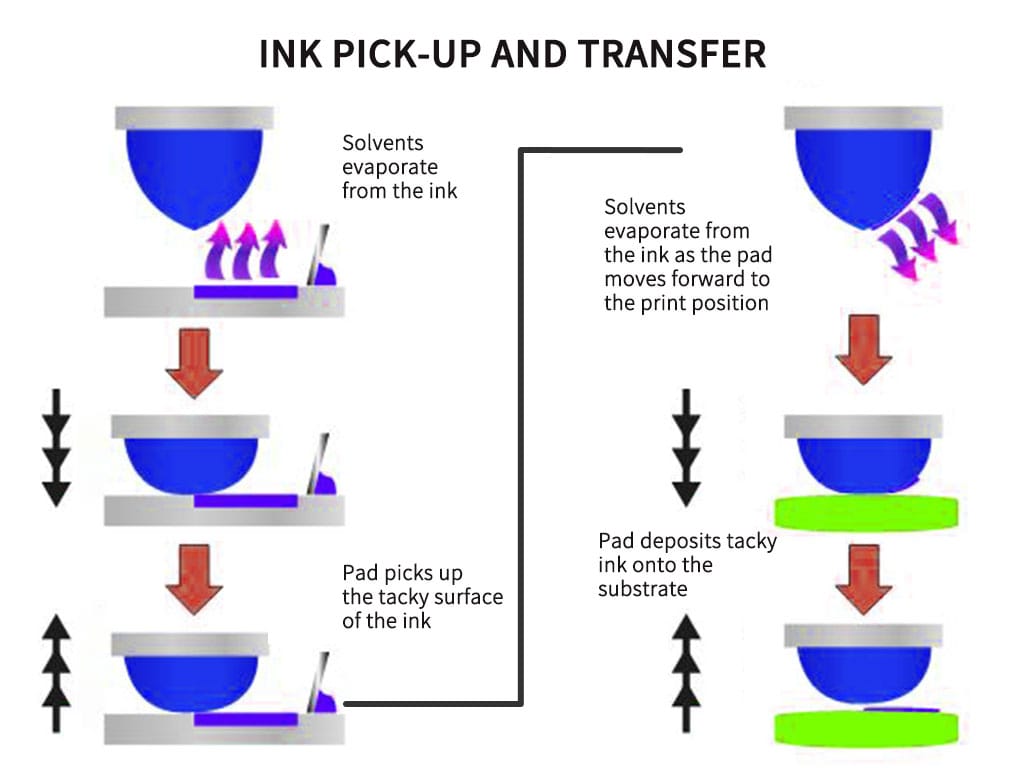

Pad Printing: Know Its Process and Advantages

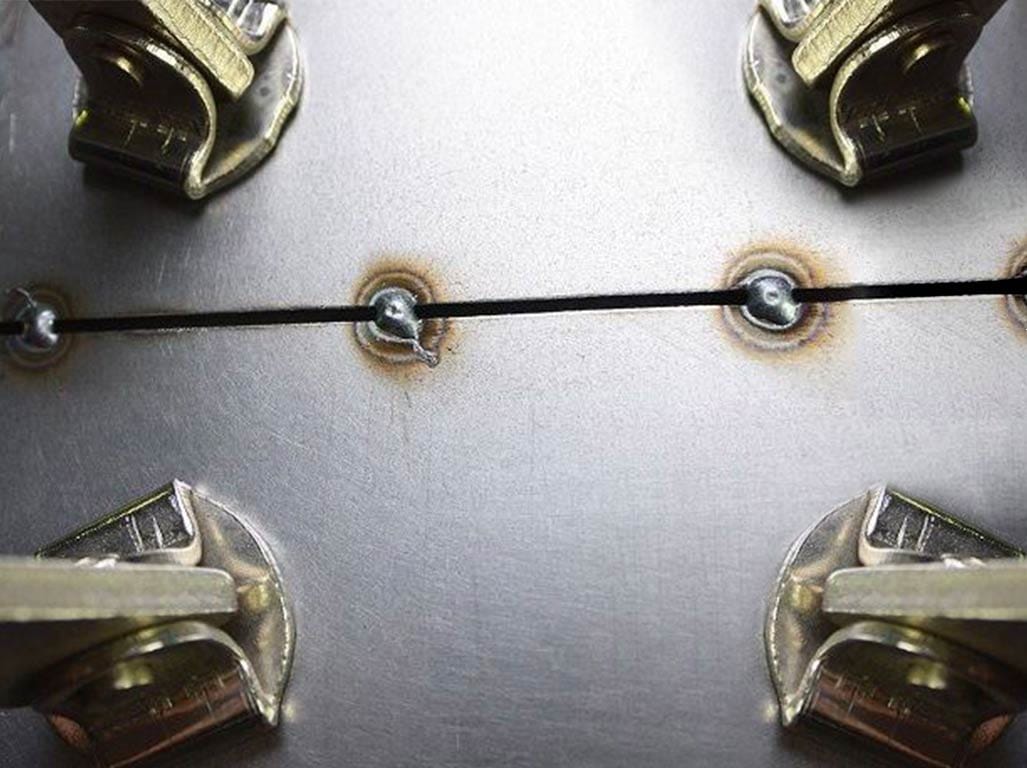

What Is Tack Welding? Understanding Its Purpose and Importance (Explained)

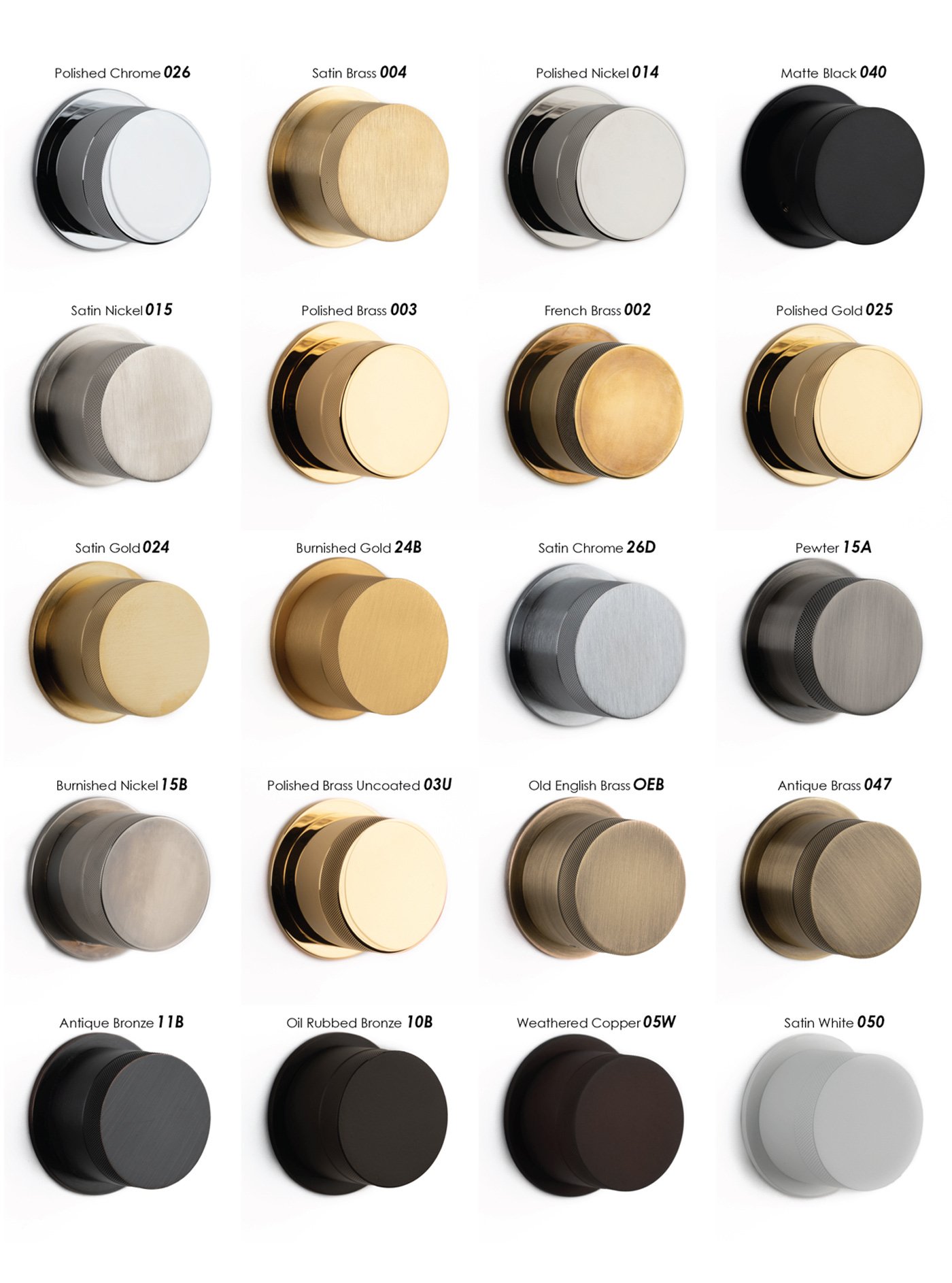

Hard Anodized Aluminum Colors Guide: All you need to know

Put your parts into production today

- All information and uploads are secure and confidential.