Sheet Metal Fabrication Services

On-demand production services from prototype to sheet metal parts and get custom flat and formed sheet metal parts within our standard 3-day lead time.

- Lead time as fast as 3 day

- Tolerances down to +/- 0.01mm

- Quick quote within 2 hours

- All uploads are secure and confidential

Our Sheet Metal Fabrication Services

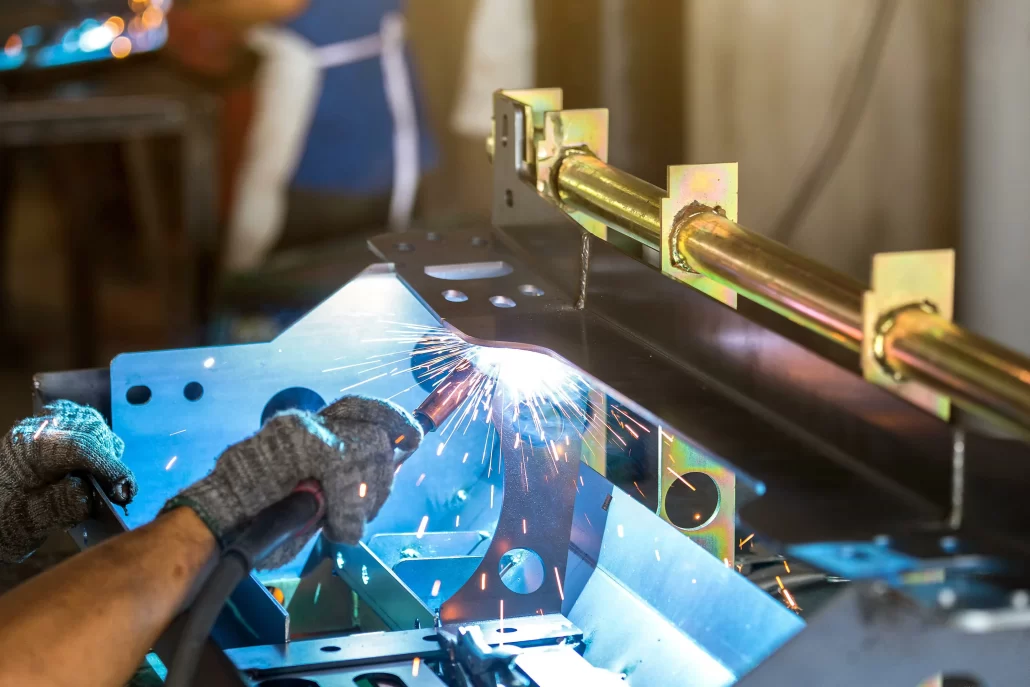

For metal parts with uniform wall thickness, sheet metal fabrication is more cost-effective than CNC machining, whether your project requires simple or complex cutting, stamping, bending, or welding services, we can present it perfectly.

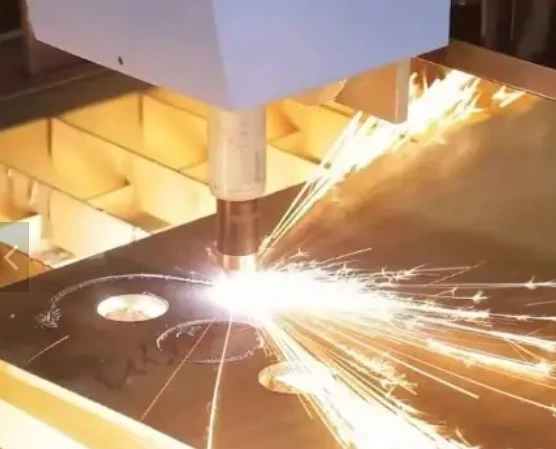

Laser Cutting

Whether thin or thick, our advanced cutting equipment enables accurate and efficient cutting of various materials.

Bending

Our bending technology can be used to accurately bend sheet metal parts to the angle and shape you need, ensuring perfect fitting of the parts.

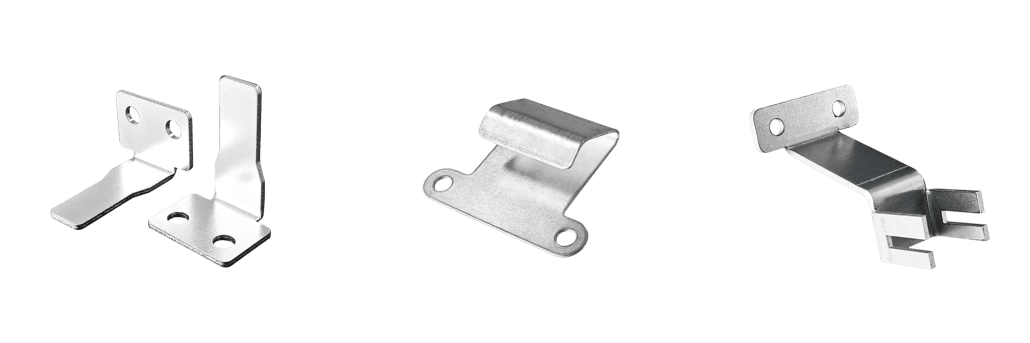

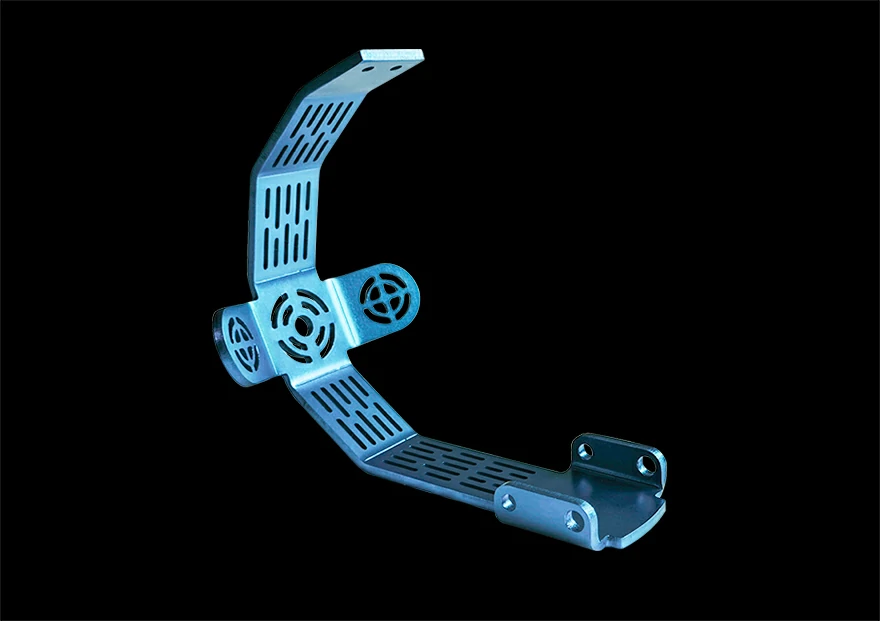

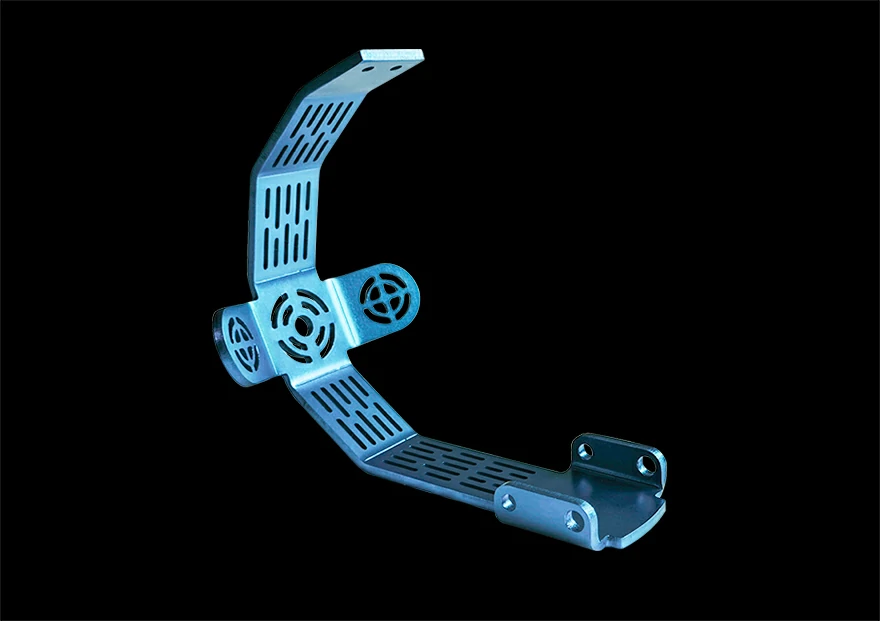

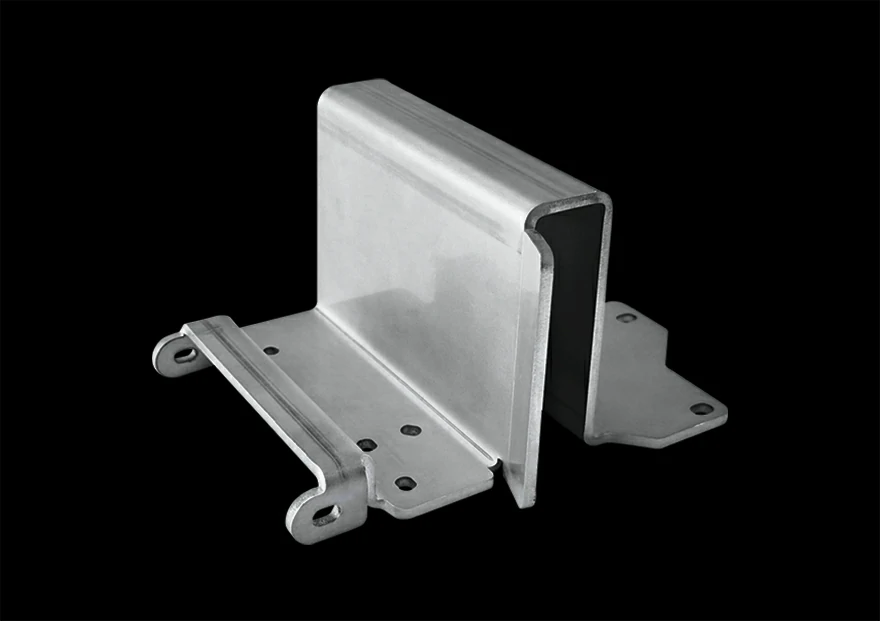

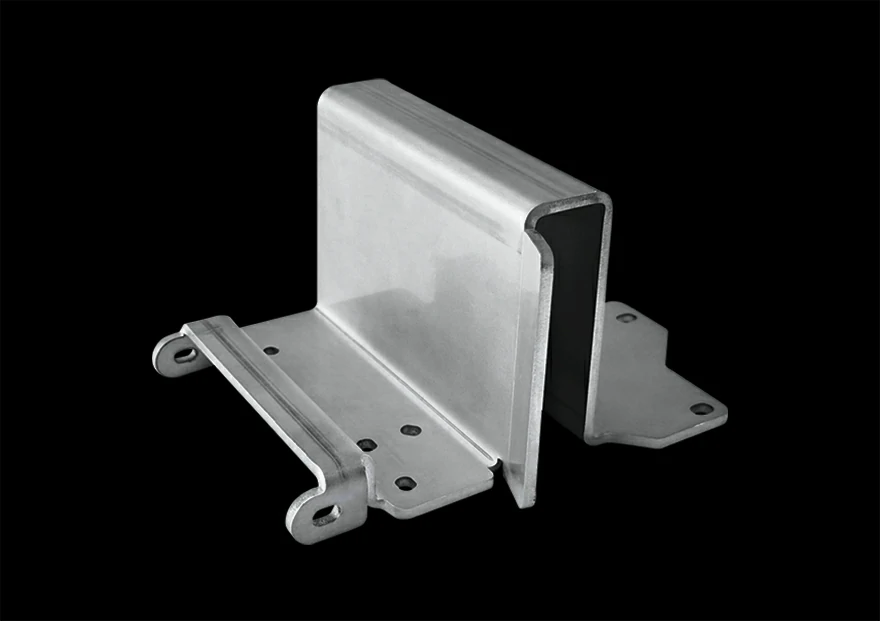

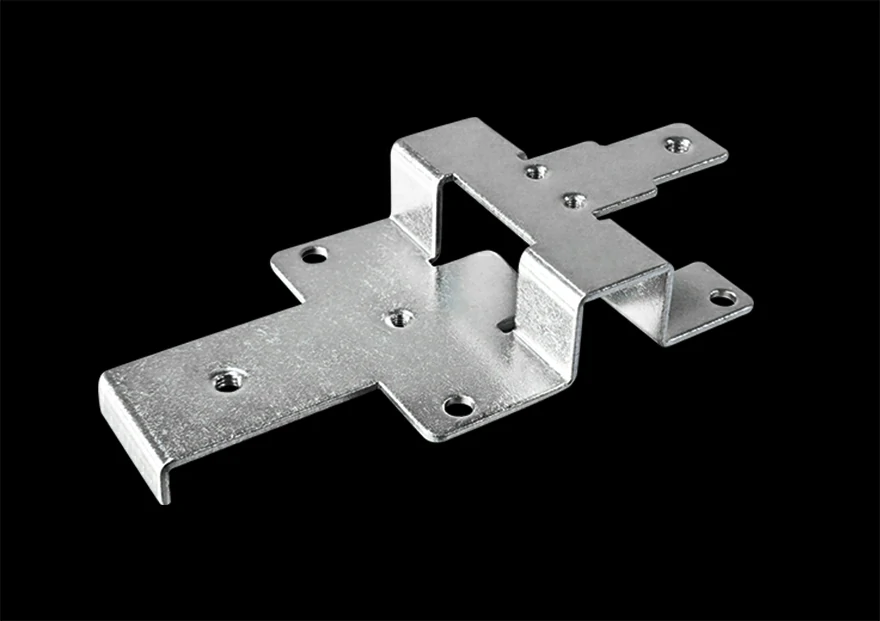

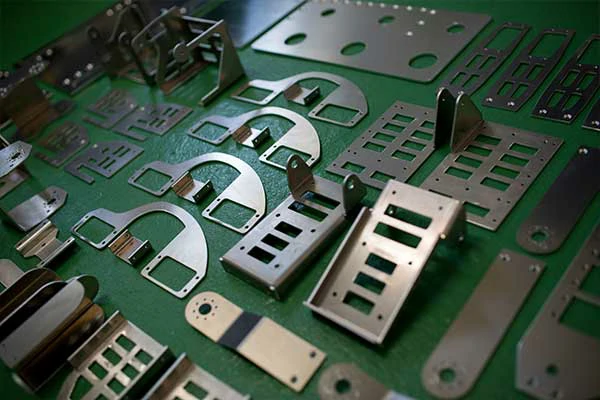

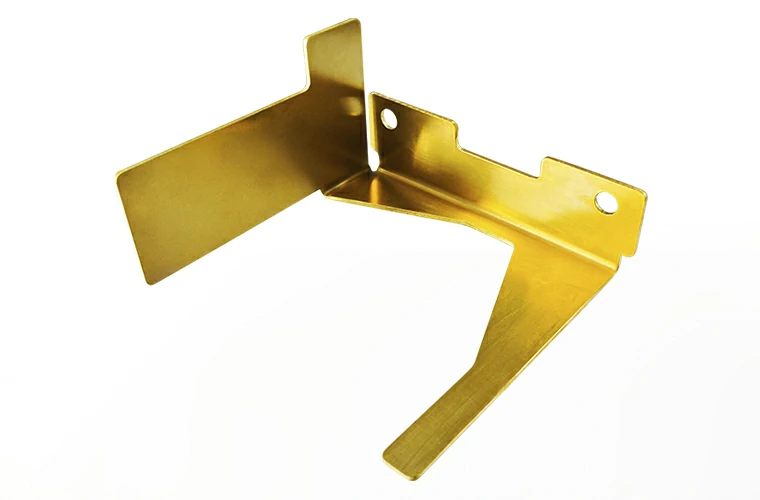

Gallery of Sheet Metal Fabrication Parts

We have been manufacturing various sheet metal fabrication parts, prototypes and various products for different customers. Whether simple or complex, here are the sheet metal fabrication parts we have made before.

Sheet Metal Parts in as Fast as 3 Day

Can’t wait to complete your sheet metal project? No need to wait for a long cycle, we promise to provide you with customized sheet metal parts as soon as 3 days! From prototype design to efficient production throughout the entire process, our efficient team will quickly respond to your needs, escort your project, and ensure that you take the lead in the market!

Sheet Metal Fabrication From Prototyping to Production

Sheet metal fabrication from prototype design to production can be used to produce various metal parts and products, and this manufacturing method is very flexible.

Rapid Prototyping

Manufacturing sheet metal prototypes at low cost in a short period of time, quickly validating design concepts and making design revisions, can help accelerate the product development cycle.

On-Demand Production

Produce the required quantity of sheet metal parts according to your specific needs, without the need for large-scale manufacturing and storage of large quantities of inventory.

Functional Prototype

A physical model or sample used to validate and test product design helps designers and engineers test and validate the design before the product enters actual production.

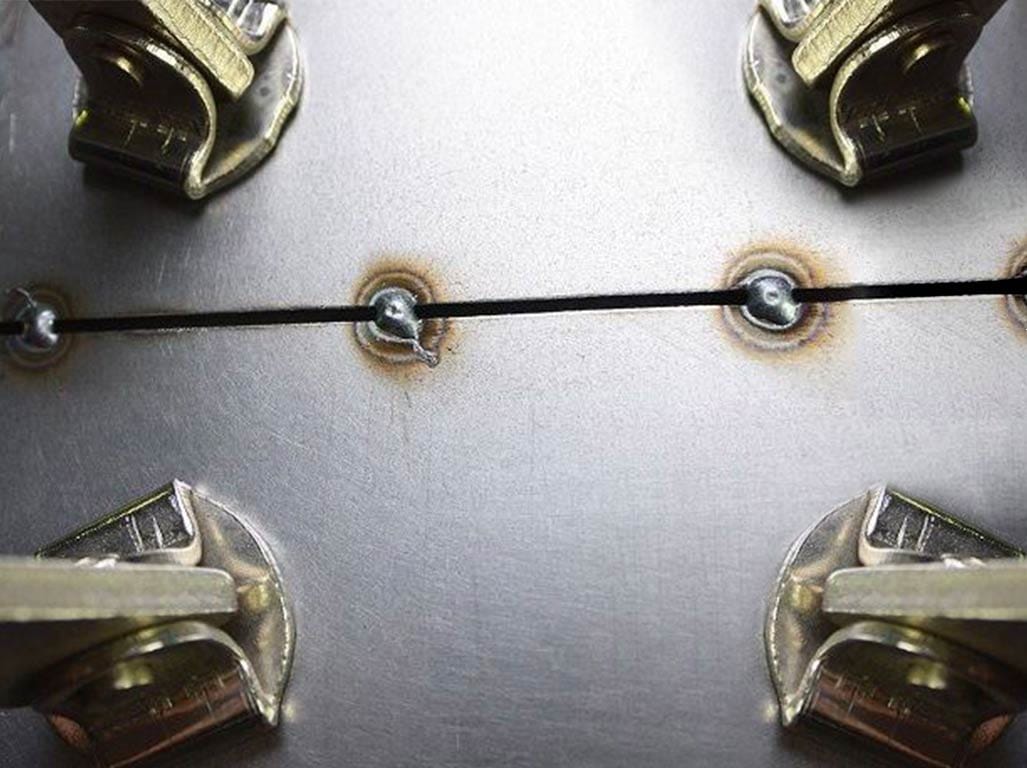

Sheet Metal Fabrication Tolerance Standard

By following the ISO 2768-m standard, your custom sheet metal fabrication service can more easily ensure the manufacturability and accuracy of parts, reducing errors and unnecessary manufacturing issues.

| Types | Tolerance |

|---|---|

| Bend edge straightness |

+/- 0.2 mm

+/- 0.008 inches |

| Edge to edge, single side |

+/- 0.1 mm

+/- 0.004 inches |

| Edge to hole, single side |

+/- 0.1 mm

+/- 0.004 inches |

| Hole to hole, single side |

+/- 0.1 mm

+/- 0.004 inches |

| Bend to edge/hole, single side |

+/- 0.2 mm

+/- 0.008 inches |

| Edge to feature, multiple sides |

+/- 1.0 mm

+/- 0.040 inches |

| Overformed parts, multiple sides |

+/- 1.0 mm

+/- 0.040 inches |

| Bend angle | +/- 1° |

| Weld joint location |

+/- 0.2 mm

+/- 0.008 inches |

| Surface finish thickness |

+/- 0.05 mm

+/- 0.002 inches |

Available Sheet Metal Fabrication Processes

Sheet metal fabrication involves multiple processes, each with its unique advantages. You can choose the appropriate process according to your specific customized parts needs.

| Optional Process | Description | Thickness | Cutting Area |

|---|---|---|---|

| Laser Cutting | Using high-power laser beams to cut metal materials can handle large-scale cutting tasks. | Up to 50 mm | Up to 4000 x 6000 mm |

| Bending | Used to bend flat metal parts into the desired shape after the cutting process, typically used to shape custom sheet metal prototypes. | Up to 20 mm | Up to 4000 mm |

| Laser Welding | Accurately weld sheet metal parts together using a laser beam. | Up to 15 mm | Up to 4000 mm |

| Stamping | Cutting, bending, and forming metal parts through stamping molds. | Up to 6 mm | / |

| Waterjet Cutting | Can handle large areas of workpieces and produce smooth cutting edges. | Up to 300 mm | Up to 3000 x 6000 mm |

Materials for Custom Sheet Metal Fabrication

The following are some common popular materials used for customized metal manufacturing. Regardless of the application and requirements of your sheet metal parts, you can find suitable materials at Longsheng.

Aluminum

Aluminum is popular in sheet metal fabrication due to its lightweight and thermal conductivity. It is suitable for applications that require lightweight components and can quickly dissipate heat, making it very useful in the electronics and aviation fields.

Alloys:6061-T6, 7075-T6, 7050, 6061-T651, 3.3211, 65028 , 2024, 5052, 6063, MIC6, 6082-T651

Copper

The conductivity and thermal conductivity of copper materials have made them widely used in electronic sheet metal fabrication. It can ensure the good performance of circuits and is used for manufacturing wires and connectors.

Alloys: Copper C110, 101, CU ETP, CU OFE

Brass

Brass is a multi alloy metal typically composed of a mixture of copper and zinc, and its low friction coefficient makes it very useful in applications that require reduced wear and tear.

Alloys:Brass Cz121, C38500, 2.0401, CuZn39Pb3, Brass C360, 2.0375, CuZn36Pb3, 319 grade 2

Stainless Steel

Stainless steel is a type of low-carbon steel that is highly favored in sheet metal fabrication due to its corrosion resistance and strength. It is commonly used in the production of food equipment, medical equipment, and chemical industry equipment.

Alloys:301, 303, 430, 304L, 316L, 15-5, 410, 416, 440C, 17-4PH, Nitronic 60

Steel

Steel is a sturdy and durable material with high strength and durability applications, making it very suitable for producing complex designs and parts that require extremely high precision, such as mechanical components and building structures.

Alloys:SPCC,1018

Why Choose Our Sheet Metal Fabrication Services

Quick quotation

Just upload your design file and configure the materials, finishing options, and requirements. Our engineers analyze your part geometry and provide real-time and competitive pricing as well as comprehensive DFM feedback.

Assured High Quality

We are a sheet metal fabrication factory certified by ISO 9001:2015 and can provide sheet metal component materials and full size inspection reports according to your requirements.

Reliable Delivery

From prototype design to efficient production, we deliver high-quality sheet metal parts within our standard delivery time of 3 days.

Readily available capacity

We have over 70 machines, and your sheet metal fabrication services can provide immediate and available production capacity.

Our Sheet Metal Fabrication for Various Applications

Longsheng’s sheet metal fabrication services provide critical support for enterprises in various industries, whether it is metal automotive components or electronic equipment components.

Sheet Metal Fabrication Overview

What is sheet metal fabrication?

Sheet metal fabrication is a manufacturing technique that encompasses the cutting and bending of metal sheets to create a variety of shapes and structures.

How Does Sheet Metal Fabrication Work?

In the sheet metal fabrication process, thin sheet metal stock is initially positioned on a flat bed. Here, a laser cutter ① follows pre-programmed patterns to cut out the desired parts. Depending on the specific part’s geometry, a sheet metal punch ② may also be employed to create additional features. After the parts are deburred to remove any sharp edges or imperfections, they proceed to the press brake ③where they are shaped into their final geometries. Frequently, additional secondary operations are employed to complete the finishing touches on the sheet metal parts.

Frequently Asked Questions about sheet metal fabrication

We provide new product developers with engine processing parts suitable for functional testing or final use of engineering -level materials. Get your required custom sheet metal fabrication service support by reading FAQ.

We provide customized sheet metal fabrication services, including sheet metal cutting, bending, punching, welding and assembly processes, to meet customer specific requirements.

Yes, we accept small batch orders. Our sheet metal fabrication equipment and processes can adapt to orders of various sizes, from small batches to large-scale production.

We can handle various common sheet metal materials, such as steel, stainless steel, aluminum, copper, etc. If you have special material requirements, we can evaluate and discuss them.

You can send us the design drawings in electronic format (such as CAD files). Our team will carefully review your design and work with you to ensure accuracy.Please provide detailed specifications and requirements, and we will produce customized parts or products according to your needs. Upload CAD files

Yes, we can make samples according to the customer's requirements. Sample production usually requires additional time and cost, but it can ensure that the final product meets your needs.

The delivery time depends on the size and complexity of the order. We will provide specific delivery time after order confirmation. We will do our best to meet the customer's requirements and inform you of the delivery progress in a timely manner.

You can contact us by phone, email, or online to provide detailed information about your project requirements. Our sales team will work with you to provide you with a quotation and assist you in completing the order process.

Latest Blog Posts

What Is Tack Welding? Understanding Its Purpose and Importance (Explained)

6 Ways To Reduce Sheet Metal Fabrication Costs

Explore the shaping mystery of sheet metal: the principle of sheet metal manufacturing

Put your parts into production today

- All information and uploads are secure and confidential.