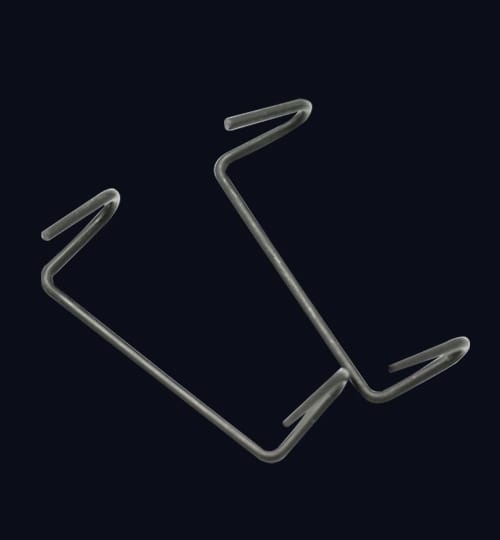

Custom Spring Manufacturing

World-class metal springs are delivered to your door in days. A wide variety of springs materials and secondary finishes are available from us. Trim your production time and launch products faster with us from prototypes to assemblies to finishing options.

- Customization of springs to your exact specifications

- Precision cutting of springs to required lengths

- Stress relieving and shot peening to improve spring performance

- Heat treatment services for increased durability and reliability

- All uploads are secure and confidential

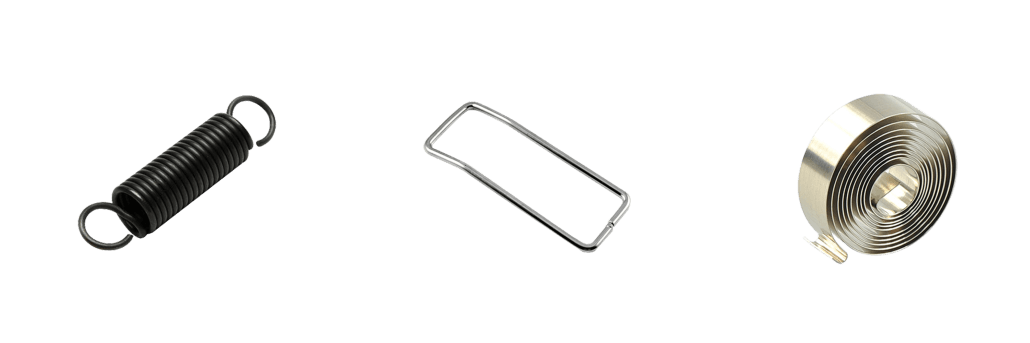

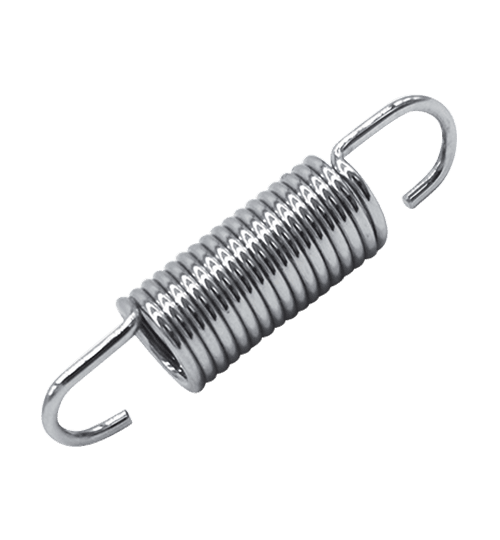

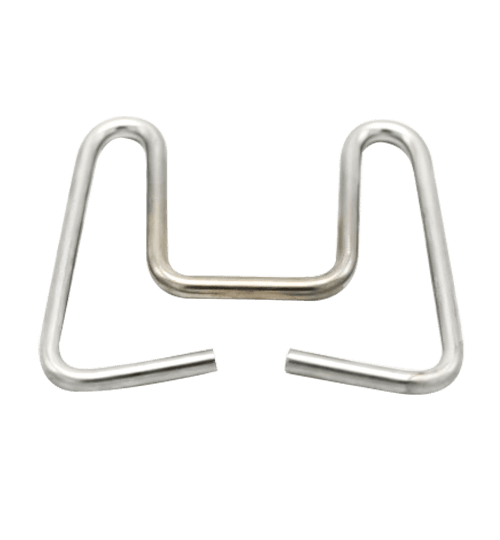

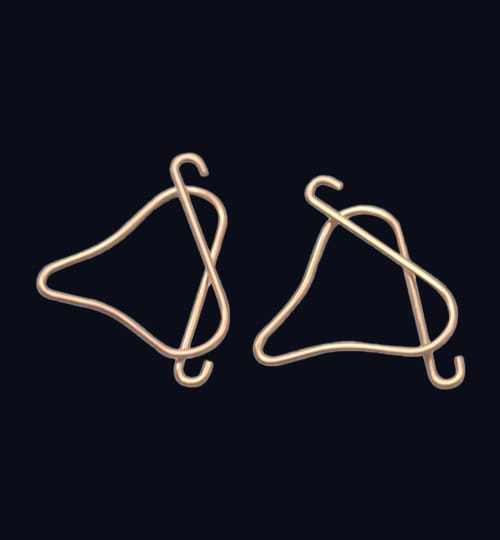

Types Of Springs

Get quality custom metal Spring all type for rapid prototyping and end-use production. Lead times are as fast as 3 day.

Our Custom metal all type Spring Manufacturing Services

We have advanced metal spring manufacturing setup and perfect inspection equipment to meet your various needs, we offer only the best metal spring manufacturing services and the ability to refine that even more. So if you are looking to have parts turned in with a high level of accuracy and need parts made right the first time, you have come to the right place.

You can always get more competitive pricing at higher quantities. We also offer DFM, first article inspection (FAI) reporting, and material certifications.

Longsheng Metal Spring Manufacturers

- Instant Pricing

- Free DFM analysis

- Parts as Fast as 1 day

- Tight Tolerances

- ISO 9001 Certificated

- ISO 14001 Certificated

- IATF 16949 Certificated

The metal springs we often process now include compression springs, extension metal springs, torsional metal springs, and custom metal springs, which are often used in various industries such as automobile hardware parts, Electrical equipment, Electronic products, Medical equipment, Gym equipment parts, Industrial equipment, Mechanical parts, Office equipment, Children’s toys, Etc.

Put your parts into production today

- All information and uploads are secure and confidential.

Custom Spring Parts Material

Longsheng supplies most of the industry standard materials. If you do not find the materials you want in the list, please contact us

| Aluminum alloy material | Stainless Steel | Alloy Steel | Copper alloy | Other alloy |

|---|---|---|---|---|

| Aluminum alloy 6061 | Stainless steel 303 | Q235 (A3 steel) | Bronze-H59 | Electrician pure iron-DT4C |

| Aluminum alloy 5052 | Stainless steel 304 | 45 steel | Bronze-H62 | Electrician pure iron-DT4E |

| Aluminum alloy 2A12 | Stainless steel 316 | Cr12 | Copper-T2 | Titanium alloy-TC4 |

| Aluminum alloy 7075 | Stainless Steel 316L | 3Cr13 | Oxygen Tu2 | Magnesium alloy -AZ91D |

| - | Stainless steel 420 | Spring Steel-65MN | Tin Bronze-QSN-6-6-3 | - |

| - | Stainless Steel-17-4PH | Mold Steel-SKD11 | Beryllium copper-C17200 | - |

Different Types Of metal spring Parts

Check out our extensive gallery that shows precision manufacturing prototypes and spring parts from our valued customers.

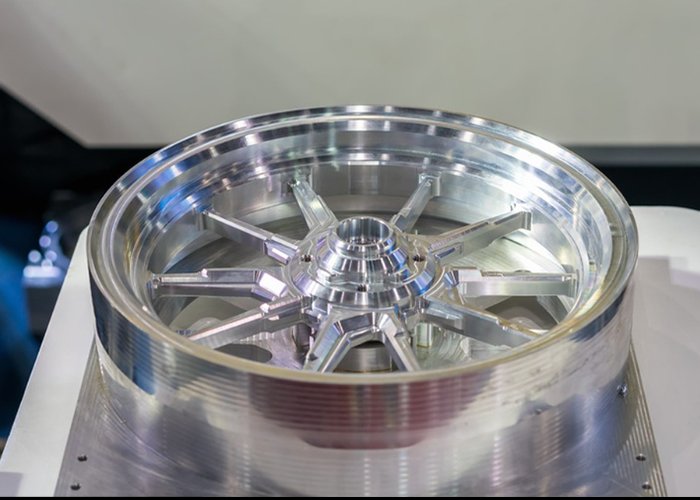

Our Machining Service For Various Industrial Applications

No matter what industry you’re in, Longsheng’s machining service are the perfect solution for all your needs. Our commitment to quality and customer satisfaction means that we always deliver on our promises, ensuring that you get the best parts at the best prices.

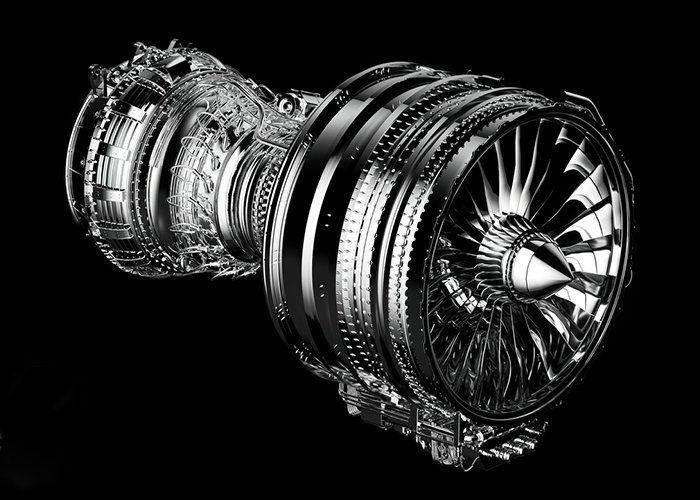

Aerospace

Our precision parts machining services provide durability and precision to meet the complex requirements required at different stages of the aerospace industry.

Automotive

From prototyping to production, our precision parts machining services are the ideal manufacturing solution for on-demand automotive parts.

Electronics

We specialize in providing high-quality machining services for a wide variety of electronics.

Medical Devices

We provide high-quality custom precision parts for various medical equipment, including surgical instruments, beds, monitoring equipment, and more.

Frequently Asked Questions about Spring Parts Manufacturing

We provide new product developers with engine processing parts suitable for functional testing or final use of engineering -level materials. Get your required spring parts machining services support by reading FAQ.

Spring manufacturing is the process of designing, producing, and testing springs. Springs are used in everything from cars to pens to medical devices. They are an important component in many products because they help regulate motion and force.

Springs can be made from a wide variety of materials, including steel, titanium, and even plastic. The choice of material depends on the specific application and the desired properties of the spring, such as flexibility, resistance to corrosion, and strength.

There are many different types of springs, including compression springs, extension springs, torsion springs, and flat springs. Each type of spring has different properties and is used in different applications.

Our spring manufacturing company has been in business for over 00 years and has a reputation for producing high-quality springs that meet or exceed industry standards. We use the latest technology and employ skilled technicians to ensure that our springs are precisely engineered and manufactured to the exact specifications of our customers.

We have a rigorous quality control process that involves multiple inspections and tests throughout the manufacturing process. We use advanced inspection and testing equipment to ensure that all parts meet or exceed industry standards.

We do not have a minimum order quantity. Whether you need a single part or thousands of parts, we are happy to work with you.

Our pricing is based on the complexity and quantity of the parts being manufactured. We will provide you with a detailed quote when you submit your order.

Yes, we have a team of experienced engineers who can assist you with design and prototyping. We can work with you to optimize your designs for manufacturability and efficiency.

We offer a warranty on all of our products. If you experience any issues with our products, please contact us and we will work with you to resolve the issue.

You can submit an order by contacting us directly or through our website. We will work with you to ensure that your order is submitted correctly and that you receive the parts you need on time and within budget.

Put your parts into production today

- All information and uploads are secure and confidential.