Automotive Industry

If you are looking for a reliable and experienced automotive manufacturer, Contact us today to learn more about our capabilities and how we can help you meet your automotive manufacturing needs.

- Tolerances down to +/- 0.005mm

- ISO 9001:2015 certiified

- 24/7 technical support

Why Choose Us for Automotive Manufacturing

At Longsheng, whether you need the manufacturing of prototype parts or mass production, we have the corresponding capabilities and experience to meet your needs. We are committed to providing reliable and high-quality components to assist you in achieving success in the fiercely competitive automotive market.

Quick Quotation

Simply upload CAD files and you can quickly understand manufacturing costs within 2 hours. You can also keep up with the latest information on order status at any time.

Rapid Prototyping

Longsheng has extensive experience in prototype manufacturing, ensuring that your components are completed with high quality in the later stages of the design and manufacturing process.

ISO Certification

Longsheng is a manufacturing company certified by ISO 9001, which means we adopt internationally recognized best practices to develop your products and ensure they meet standard requirements, regardless of the complexity of the design.

On Demand Custom

Our automotive parts manufacturing process is fully customizable, based on your specifications, dimensions, materials, and surface requirements to ensure that your unique needs are met.

Fast Delivery

We are committed to providing fast manufacturing and delivery to meet your production needs, while also providing you with greater flexibility to quickly respond to market changes. Longsheng is your partner for automotive parts needs.

Quality Control of Automotive Parts

Order quantity

We do not have a minimum order quantity. We can accommodate orders of any size, including single-piece orders.

100% full inspection shipment

- material report

- Hardness test report

- Dimension inspection report

- Salt Mist test report

Mass production

We are capable of mass production and can accommodate orders of any size, including large-volume orders.

80000 + customers trust

- 98% on-time delivery rate

- Delivery in one day at the earliest

- Quick proofing of parts

- One-stop machining

Automotive Manufacturing Capabilities

At Longsheng, we are committed to providing high-quality automotive parts suitable for road use. Our quality control process ensures that you obtain parts that meet your quality requirements at a low cost. Longsheng is your trusted partner, providing excellent service for your automotive parts needs.

Suitable for Automotive Parts Materials

Longsheng can source any other material on request for prototyping and production runs of custom parts. If you have special material needs, please contact us to provide you with a reliable solution.

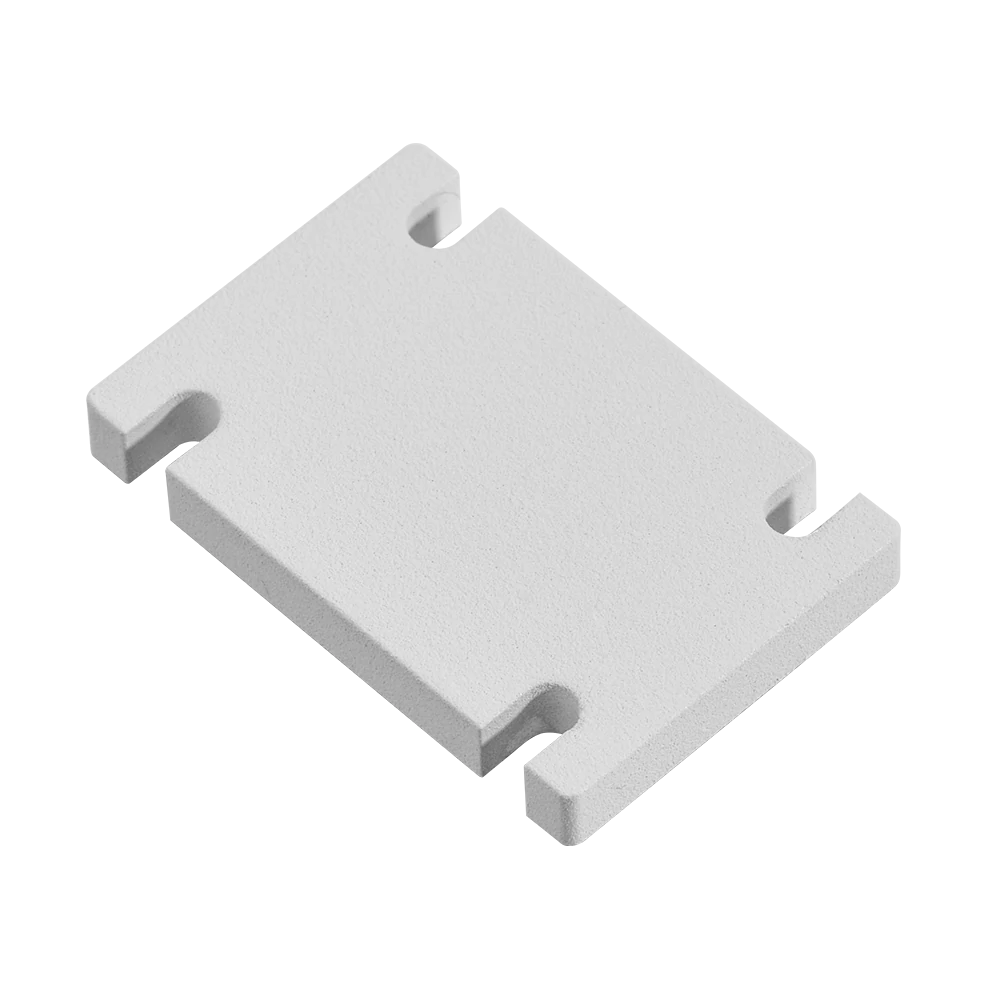

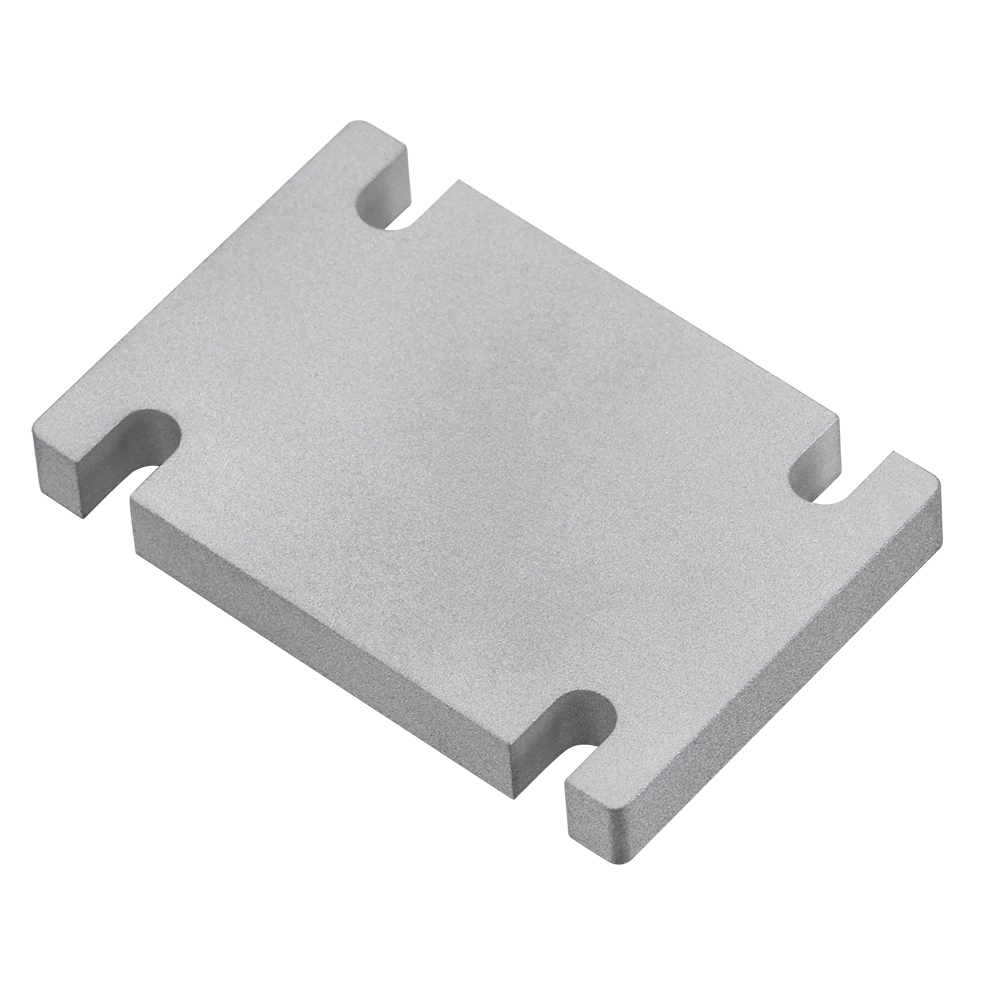

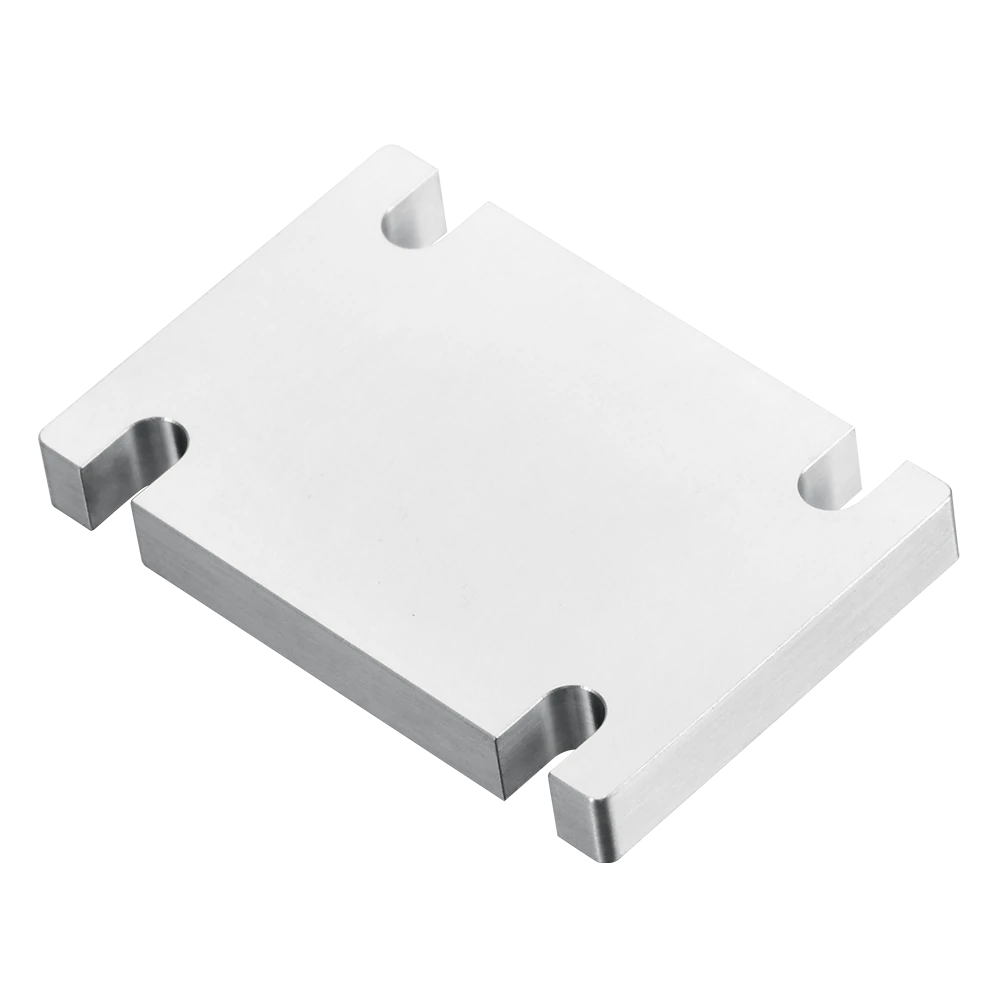

Aluminum

Offers excellent machinability, high strength-to-weight ratio, and superior corrosion resistance, making it perfect for lightweight, durable machined parts.

- Price: $

- Lead Time: < 3 days

- Finishing Options: Alodine, Anodizing Types II, III, III + PTFE, ENP, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing.

- Alloys:6061-T6, 7075-T6, 7050, 6061-T651, 3.3211, 65028 , 2024, 5052, 6063, MIC6, 6082-T651

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

- Price: $

- Lead Time: < 3 days

- Finishing Options: Available as-machined, media blasted, or hand-polished

- Alloys: Copper C110, 101, CU ETP, CU OFE

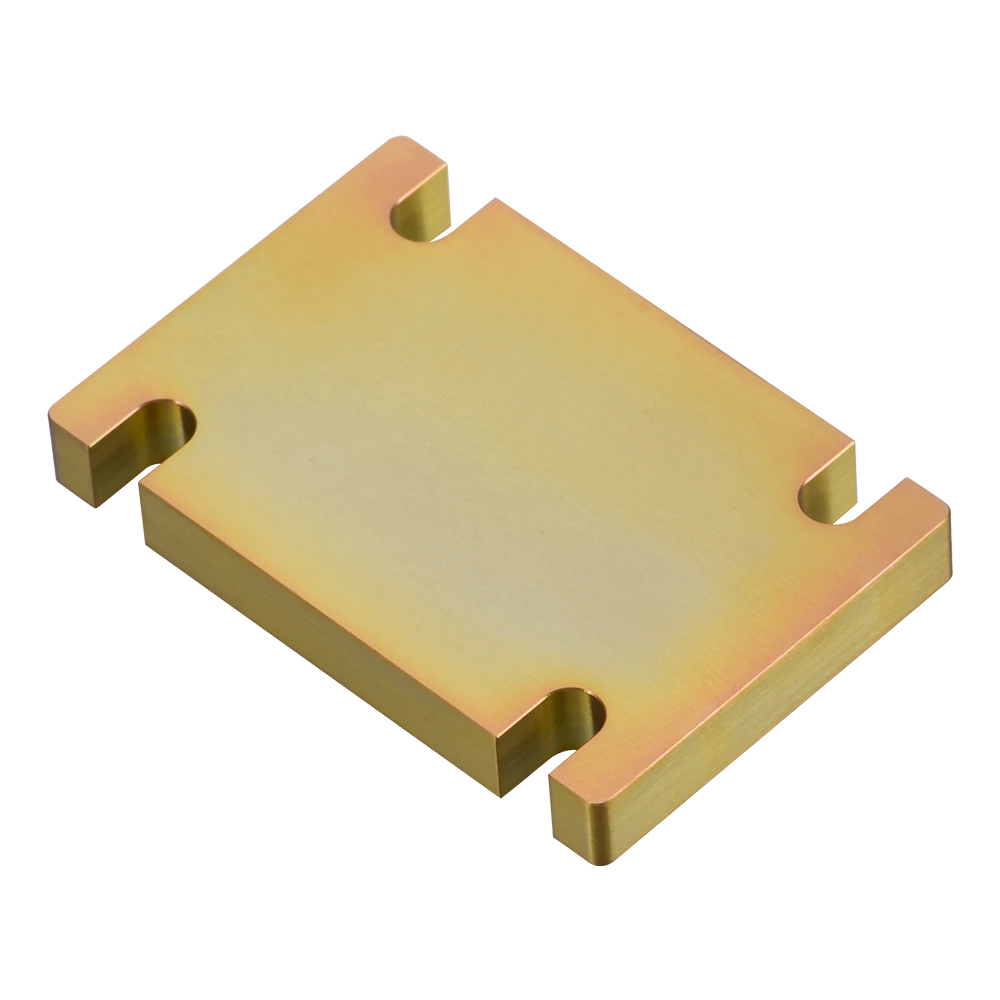

Brass

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

- Price: $

- Lead Time: < 3 days

- Wall Thickness: 0.75 mm

- Finishing Options: Media blasting

- Alloys:Brass Cz121, C38500, 2.0401, CuZn39Pb3, Brass C360, 2.0375, CuZn36Pb3, 319 grade 2

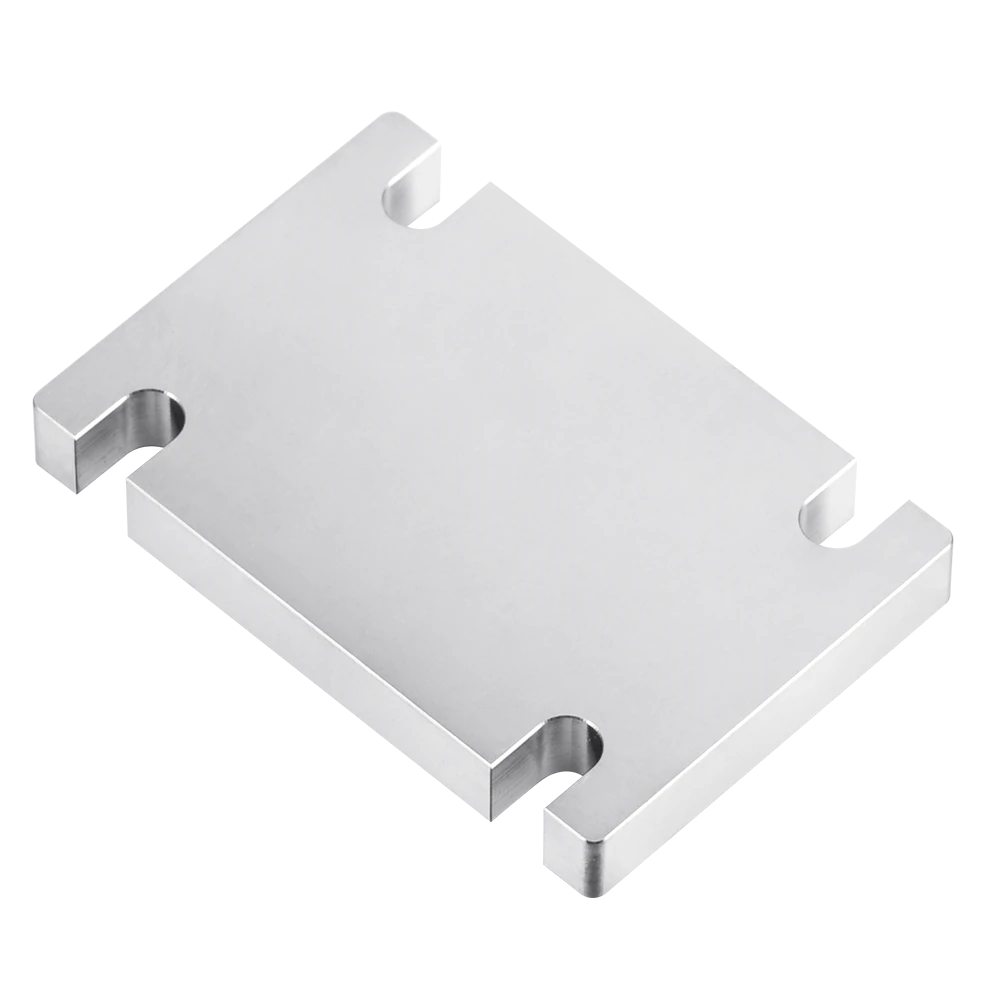

Stainless Steel

Stainless steel offers superior corrosion resistance, high strength, excellent toughness and ease of fabrication, ideal for demanding machining operations.

- Price: $

- Lead Time: < 3 days

- Wall Thickness: 0.75 mm

- Finishing Options: Black Oxide, Electropolishing, ENP, Media Blasting, Nickel Plating, Passivation, Powder Coating, Tumble Polishing, Zinc Plating, Vibratory Tumbling

- Alloys:301, 303, 430, 304L, 316L, 15-5, 410, 416, 440C, 17-4PH, Nitronic 60

Titanium

Titanium It’s a metal with excellent strength-to-weight ratio, low thermal expansion, high corrosion resistance; sterilizable and biocompatible for machining.

- Price: $

- Lead Time: < 3 days

- Wall Thickness: 0.70 mm

- Finishing options: Media Blasting, Vibratory Tumbling, Passivation, Powdercoating

- Alloys:Titanium Grade 1, 2, 5, Ti6Al4V, 3.7164, 3.7035, 3.7025

Plastics

Plastics are also very popular option for CNC machining because of its wide choices, relatively lower price, and significantly faster machining time needed.

- Price: $

- Lead Time: < 3 days

- Color: Opaque beige, Black, neutral matte finish, Optically clear, opaque, White, brown, Green, yellow, Clear, glossy, Natural (off-white), Naturally translucent amber color, frosted when machined

- Plastic:ABS, PMMA, PC, POM, PCGF30, PA, PC+ABS, PAGF30, PPGF30, PP, PTFE, PEI, PS, PPS, PE, PPSU, PET, PEEK, LDPE, G-10, HDPE, FR4, PVC, NYLON

Post-Processing For Automotive Parts & Accessories

Surface finishing for automotive parts are available in many materials and colors. Whether you want to protect your parts from corrosion, enhance their appearance, or add texture, there is a surface finish that will meet your needs.

| Name | Description | Material | Color | Texture | Link | |

|---|---|---|---|---|---|---|

|

Anodizing | Anodizing is an electrochemical process used to enhance the corrosion resistance, appearance, and surface properties of metal parts, particularly aluminum. | Aluminum, Metals | Clear, black, grey, red, blue, gold | Rough, smooth, metallic | Learn More>> |

|

Powder Coating | Powder coating is a popular and environmentally friendly method of applying a protective and decorative finish to various types of metal and even some non-metal surfaces. | Metals | White, Black, RAL and Pantone | Glossy, fine, hardness | Learn More>> |

|

Polishing | The primary goal of polishing is to create a smooth and reflective surface by removing imperfections, scratches, and irregularities. | Metals | Silver gray | Bright, mirror, silk | Learn More>> |

|

Chromate | Chromate, commonly known as a chemical thin film, is a conversion coating used as a corrosion inhibitor on aluminum. | Aluminum | Clear/ Slight yellow tint | Satin | Learn More>> |

|

Bead blasting | Bead blasting, also known as abrasive blasting, is a surface preparation technique used to clean, finish, or texture a surface by forcibly propelling small, spherical abrasive materials, called "beads" or "media," at high speeds onto the surface being treated. | Aluminum, copper, stainless steel, steel | N/A | Grainy, slightly matte texture | Learn More>> |

|

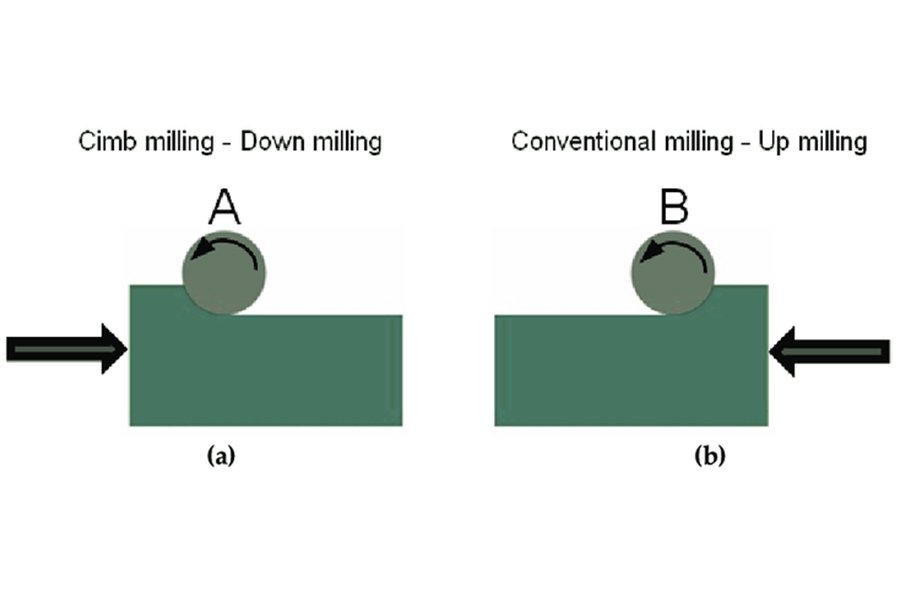

As machining | Machining is a subtractive manufacturing process in which a machine tool, typically a cutting tool, removes material from a workpiece to achieve the desired shape, dimensions, and surface finish. | Metals | N/A | Smooth, glossy finish | Learn More>> |

Automotive parts machining applications

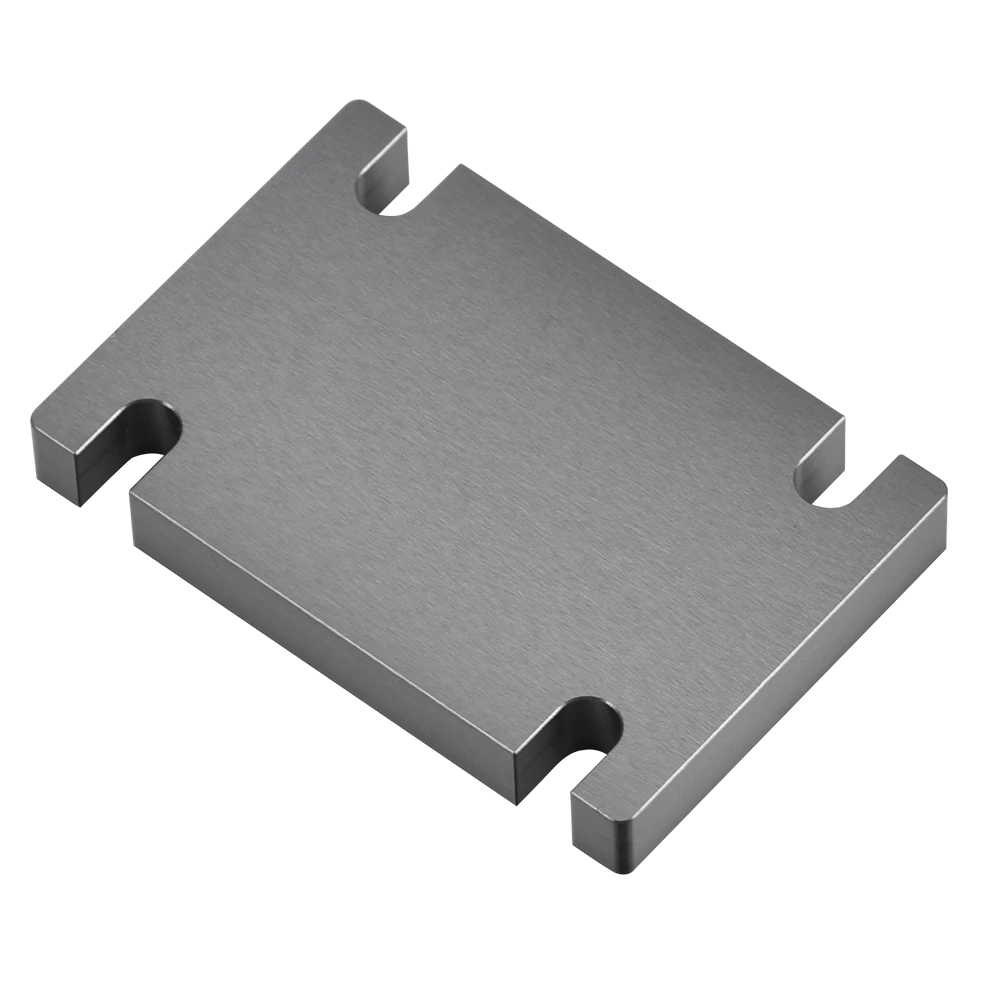

Whether you need custom parts or replacement parts for your vehicle, we can handle all your machining needs. From engine components to suspension parts, we have the expertise to manufacture parts that meet your exact specifications.

- Engine crankshafts

- Connecting rods

- Pistons

- Brakes

- Dashboards

- Wheels

- Suspension systems

FAQs About Automotive parts

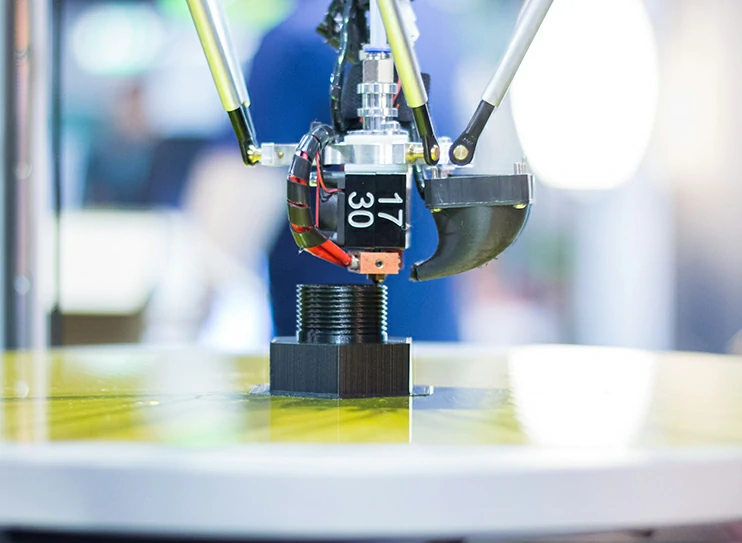

At our machining service, we specialize in the manufacturing of automotive parts using CNC machines. These machines are computer-controlled and can produce complex parts with high precision and accuracy.

We can work with a variety of materials, including aluminum, steel, and plastics. Our team is experienced in working with these materials to manufacture parts with high precision and accuracy. We use the latest technology and techniques to ensure that all parts meet our customers' requirements.

Our rigorous quality control process includes multiple inspections throughout the manufacturing process. We use state-of-the-art measuring equipment to ensure that all parts meet our high standards. Our team is committed to producing high-quality parts that meet our customers' specifications and regulatory requirements.

Our turnaround time varies depending on the complexity of the part and the quantity ordered. However, we strive to deliver parts as quickly as possible without compromising quality. Our team works closely with our customers to ensure that we meet their timelines and requirements.

Yes, we offer custom machining services to meet our customers' unique needs. Our experienced team can work with you to design and manufacture custom parts that meet your specifications. We use the latest technology and techniques to ensure that we produce high-quality parts that meet our customers' requirements.

Customer Satisfaction Evaluation

Listen to our customers’ voices! We have received praise and satisfactory evaluations from many customers.They highly recognize our professional services and high-quality results.

Custom Prototypes and Parts for Automotive Companies

We provide customized automotive prototype and component manufacturing solutions for automotive companies and component manufacturers in various production stages, from prototype design to mass production, and ensure that the produced parts meet industry performance and safety standards.

Put your parts into production today

- All information and uploads are secure and confidential.

More of The Industries We Support

Click on the links below to learn more about our services and case studies.