Your sole supplier for purchasing custom parts

Your Design, Our Precision!

From raw material control to product inspection, we always adhere to the pursuit of excellent quality and deliver impeccable results for you.

- All uploads are secure and confidential

Our Manufacturing Capabilities

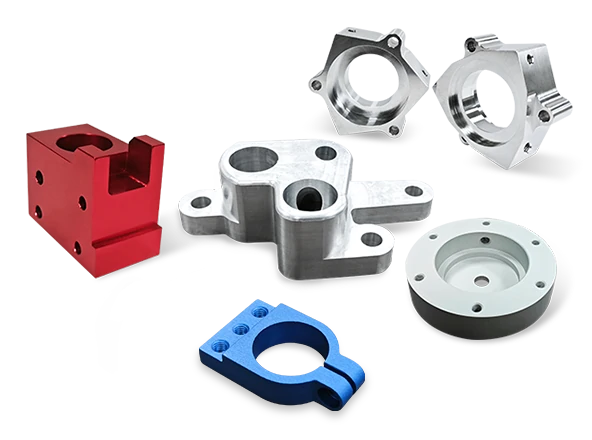

With over 15 years of manufacturing experience, we handle cnc parts with tolerance of up to 0.005mm, same day quotation, and 72 hours delivery. We have produced over 80,000 different parts of different quantity. Our aim is to provide top quality and high efficiency metal parts machining services for prototyping as well as mass production customers.

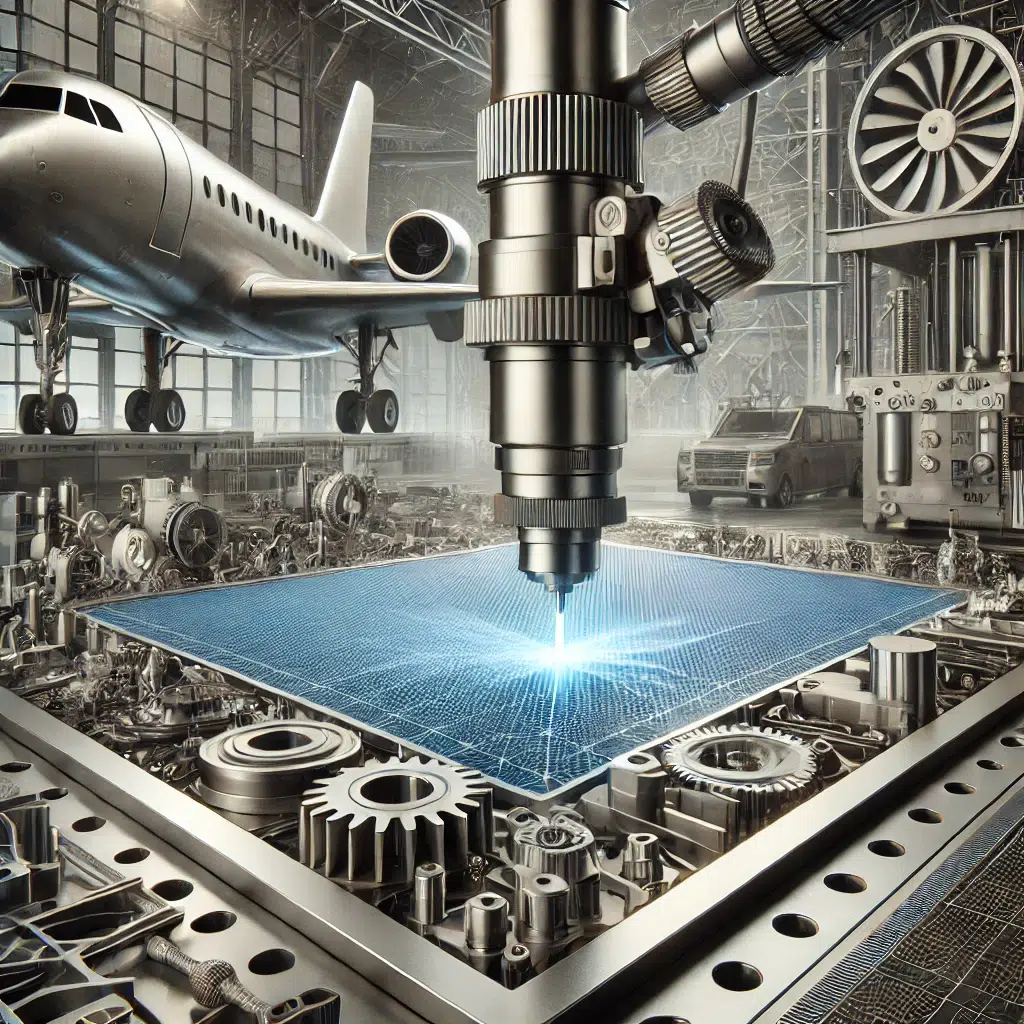

CNC machining is a manufacturing process that utilizes state-of-the-art 4-axis and 5-axis equipment for rapid and accurate CNC machining.

Whether it’s simple parts or complex structures, we can accurately process them to ensure that every detail is perfectly presented.

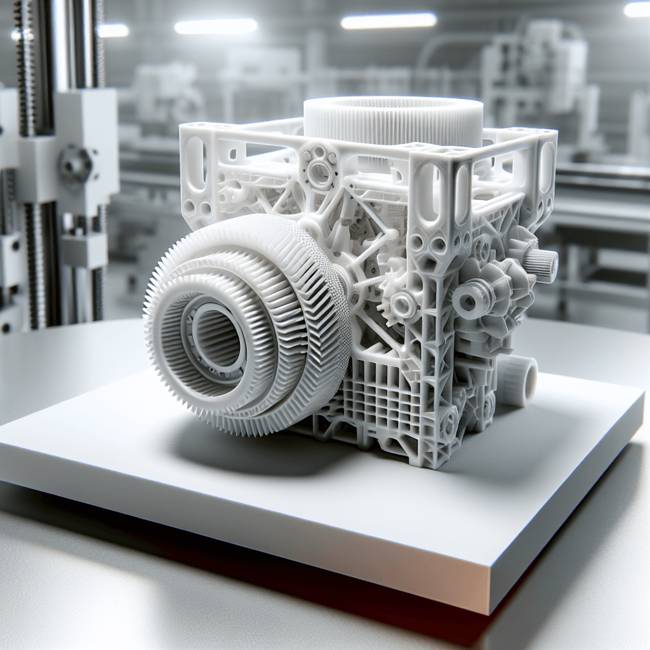

Our 3D printing technology can quickly create prototypes of objects, accelerating the product development process.

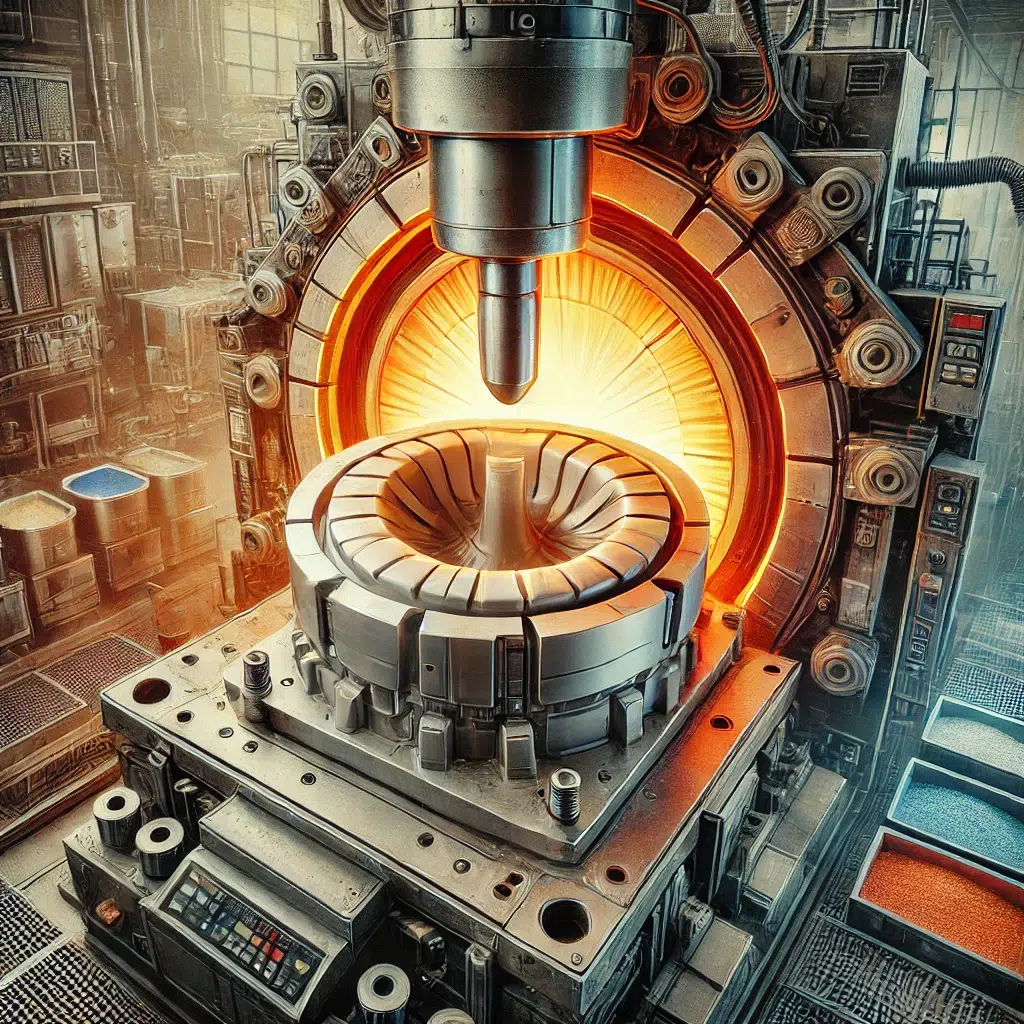

Advanced injection molding technology and equipment provide you with high-quality and precision molding products.

It involves shaping metalinto different forms with the help of cutting, bending,and pressing machines.

Quickly validate design concepts, reduce development cycles, and provide better product visualization and cost savings.

How LongSheng Works

Your time is precious, and we are well aware that you want efficient delivery. We streamline the innovation cycle into four simple but effective steps. In just 3 days, you can have flawless parts! Start your machining project now!

Upload CAD file

Multiple designs for different parts can be uploaded and we will send you a single quote along with detailed cost.

Start Production

When you review the quote and place your order, we will start manufacturing. It also provides sorting options.

Your Parts Shipped

You will receive your order in just a few days, and it will be shipped directly to the shipping address you fill in.

Why Choose LongSheng

Turn your ideas into reality with our excellent on-demand manufacturing services to produce simple and complex prototypes and final parts, all of our products meeting strict tolerances and quality requirements.

Production Workshop

Our manufacturing factory is equipped with advanced production lines that can handle a variety of materials, including metals, plastics, and composites. We utilize computer-aided design (CAD) and computer-aided manufacturing (CAM) software to program our machines, ensuring high precision and accuracy in every product we create.

International Accreditation

At our manufacture factory, quality is paramount. We are proud to hold various industry certifications, including ISO 9001:2015, which ensures our processes and products meet international quality standards. We also follow strict quality control measures throughout the production process to ensure the final product is of the highest quality.

24/7 Engineering Support

Longsheng provides you with an experienced team of service engineers to solve all your manufacturing problems. Not only can we help you optimize your design and reduce costs, but our senior engineers also provide professional guidance and beneficial DFM feedback, and achieve higher quality and more consistent quality control through standardized practices to ensure that your project achieves the best results.

From Prototyping to Production

Rapid Prototyping

Our prototype production service quickly transforms your design concepts into actual samples, helping you test, validate, and improve your creativity.

On-Demand Production

On demand production solutions ensure that your products are manufactured on demand when needed, reducing inventory and waste. Everything is accurate to your specifications and schedule.

Mass Production

When the product is ready and validated through prototype and small batch production, we can manufacture it on a large scale to meet market demand.

High Quality On Time Delivery

Experience our commitment to unparalleled precision and superior quality control. We utilize cutting-edge inspection equipment in our CNC machining process to ensure every part meets rigorous industry standards and exceeds customer expectations. Take a closer look at our leading-edge inspection tools that make our precise, reliable, and efficient manufacturing possible.

Quality Control and Testing

The Longsheng team ensures quality, so you can deliver parts on time and to specifications every time.

- Advanced facilities

- On-site quality engineers

- Inspection reports for every

Professional Engineering Team

We are proud to have a professional engineering team working closely with you to help quickly solve problems and provide excellent solutions to ensure your success.

- Customized solutions

- Professional support 24/7

Refund and Repair Policy

To ensure that each custom part you order meets the highest manufacturing standards, we can rework or refund if the order does not meet your specifications.

- Handle issues within 3 days

- Professional after-sales service team

Our Collaborate With Numerous Industries

Crossing numerous industries, Longsheng uses highly advanced technology, from prototype production to on-demand manufacturing, and then to large-scale production, to ensure the excellent quality and reliable performance of parts, ensuring the success of your project.

Automotive

Whether it’s engine components, chassis components, or interior parts, our material selection and manufacturing technology can meet your needs, helping you create safer, more efficient, and reliable automotive products.

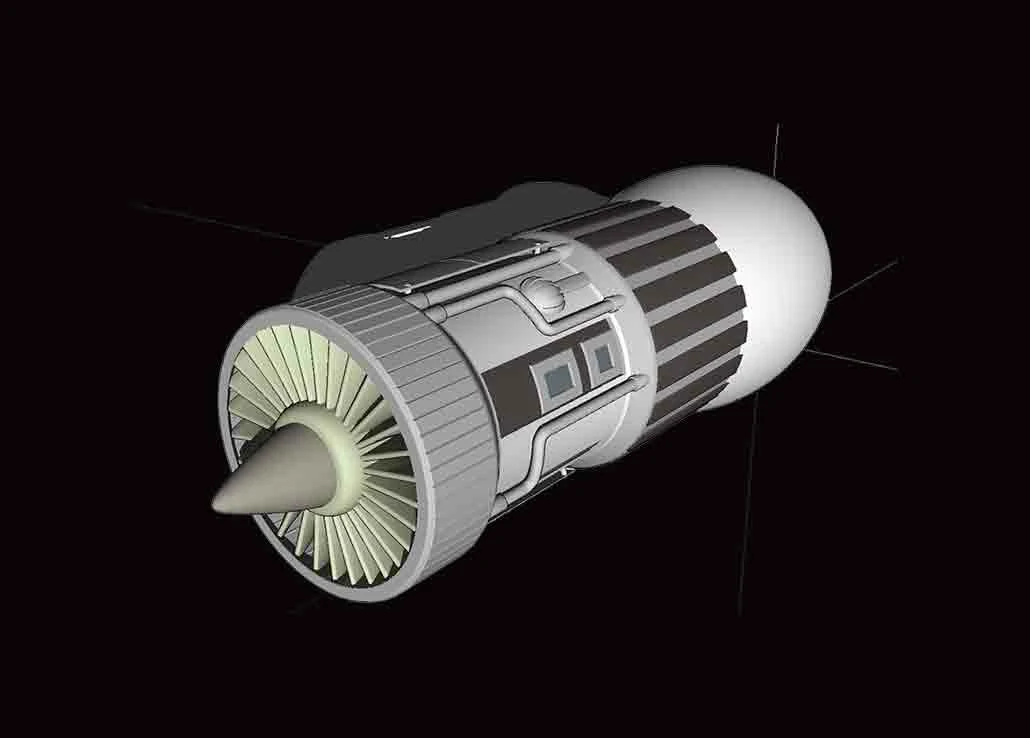

Aerospace

Our precision machining services provide higher corrosion resistance and durability for precision parts in the aerospace industry to meet the strict requirements of various stages.

Medical Devices

Longsheng is an ideal solution for manufacturing customized parts for diagnostic and medical equipment. You can prototype, innovate, and influence human life faster.

Electronics

We provide professional design support to strengthen your supply chain and obtain customized parts for every prototype, production, and assembly requirement.

Industrial Equipment

Longsheng provides industrial equipment manufacturers with sturdy and durable components, making it easier for you to prototype and produce a large number of parts to maintain smooth machine operation.

Customer Satisfaction Evaluation

Listen to our customers’ voices! We have received praise and satisfactory evaluations from many customers.

They highly recognize our professional services and high-quality results.

I couldn’t be happier with this order. The quality is as quoted and the lead time was very not only very fast and it was done on schedule. The service was absolute world-class.Compared to most European CNC suppliers, Longsheng’s customer service is far ahead. Stronglyrecommended.

Katie Robinson

— Aerospace R&D engineer

Hi Gloria,I appreciate the efforts. If we can get just 50 pieces out that will help the customer until the remaining parts are delivered so their inventory does not run out.

Allison Jackson

— Engineer

Dear Gloria,the parts were successfully received by our customer yesterday. There were no damages, all in good quality. He gave a very big praise to the packaging master. He has never received such well packed sheet metal parts. Thank you for a great job!

Michael Anderson

— Mechanical Designer

Put your parts into production today

- All information and uploads are secure and confidential.

News & Blog

Deep understanding of industry knowledge and real-time updates at any time.