3D Printing Services

- Over 70 materials to choose from

- Fast 3D printing parts in 1 days

- 1-on-1 Technical Support

- Multiple processes: SLS, HP MJF, FDM, SLA, Carbon DLS™, PolyJet and DMLS

- All uploads are secure and confidential

1 day

Lead time

15 +

Surface Finishes

1 pc

MOQ

20 +

Materials

Our unparalleled 3D printing capabilities

Whether you need a single prototype or a large production run, we can help. Our commitment to quality and customer satisfaction ensures that you receive the best possible service and results.If you have any questions or would like to learn more about our 3D printing capabilities, please don’t hesitate to contact us. We are always happy to help and look forward to working with you.

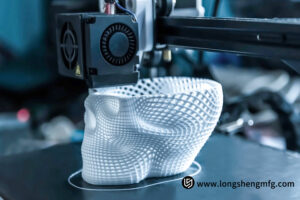

SLA

Stereolithography (SLA) is the use of UV lasers to cure liquid resin layer by layer to create 3D objects. The technology produces highly detailed and precise parts and is ideal for applications such as rapid prototyping, product design, and dental and medical modeling.

SLS

Selective Laser Sintering (SLS) is a 3D printing technology that uses a high-powered laser to fuse powdered material layer by layer to create a 3D object. This technology is ideal for creating complex geometries and functional parts with high strength and durability.

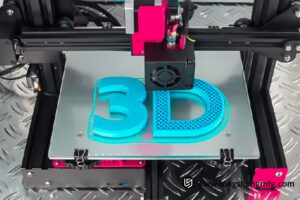

FDM

Fused Deposition Modeling (FDM) is a 3D printing technology that involves depositing melted thermoplastic material layer by layer to create a 3D object. This technology is widely used for rapid prototyping, as well as for creating functional parts and models.

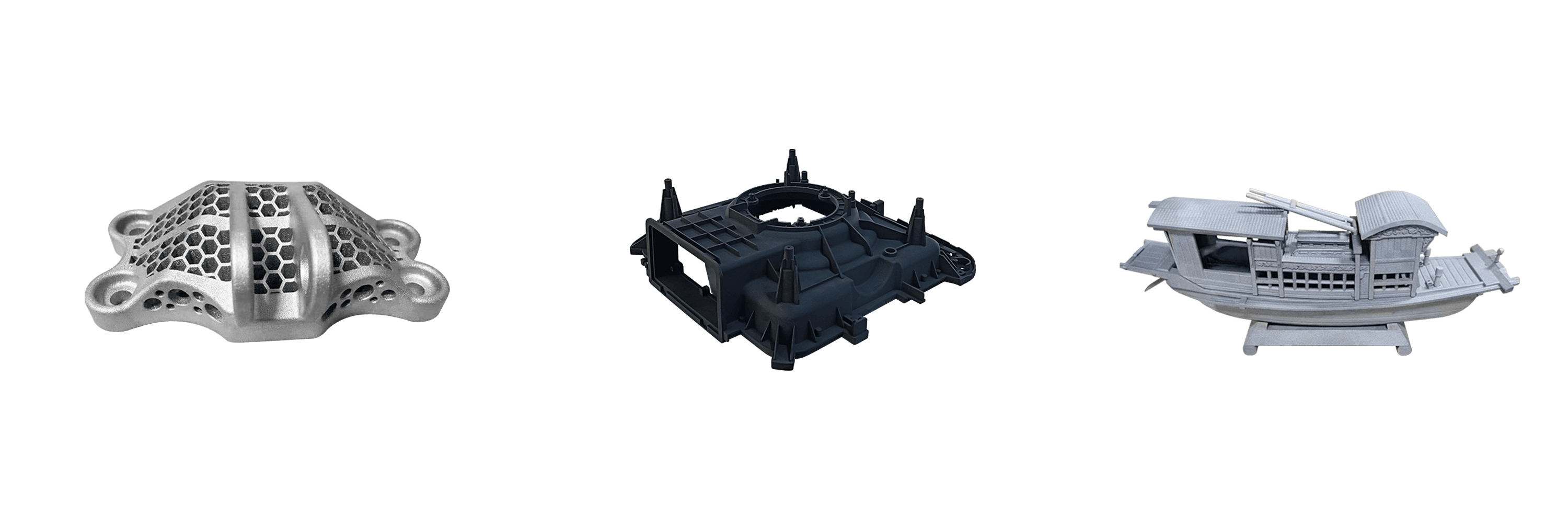

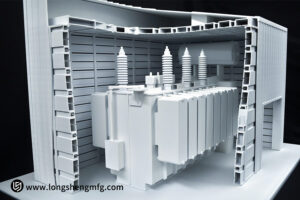

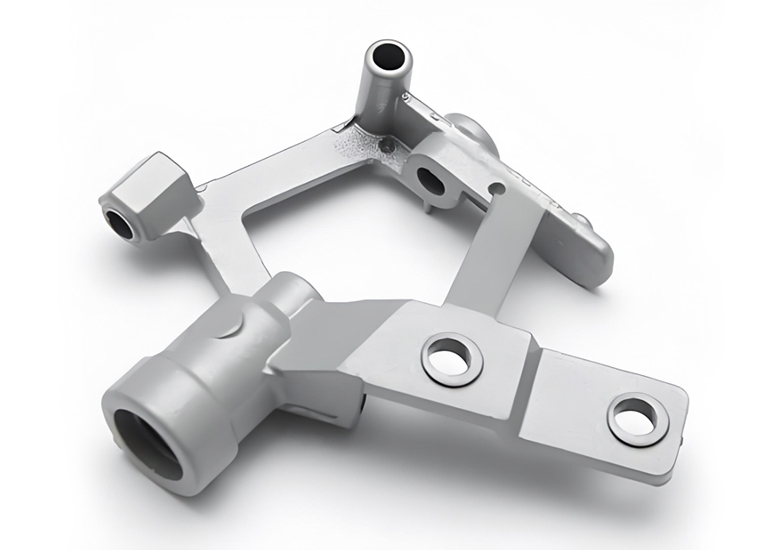

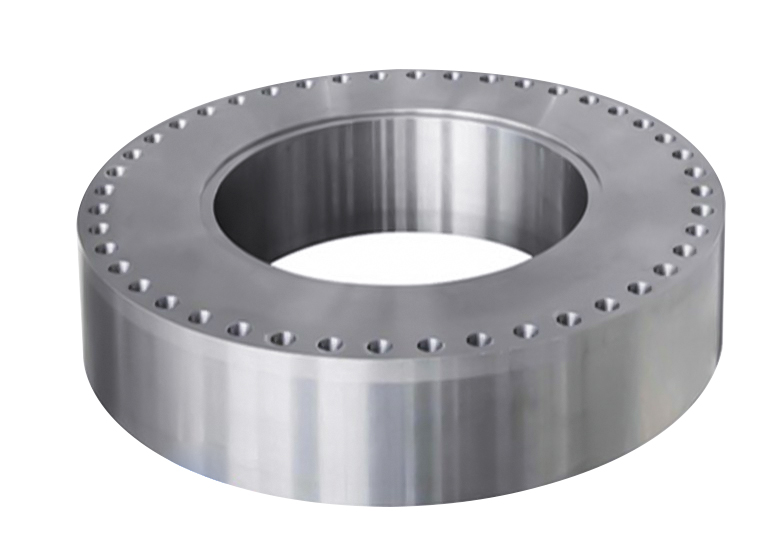

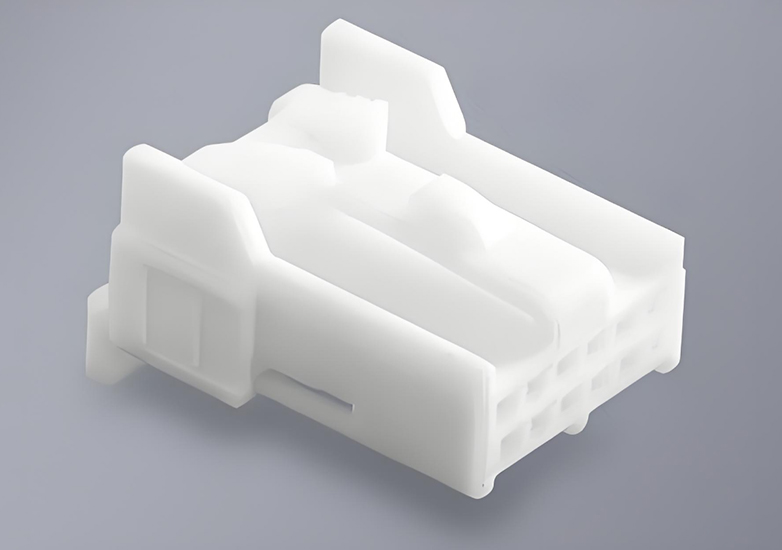

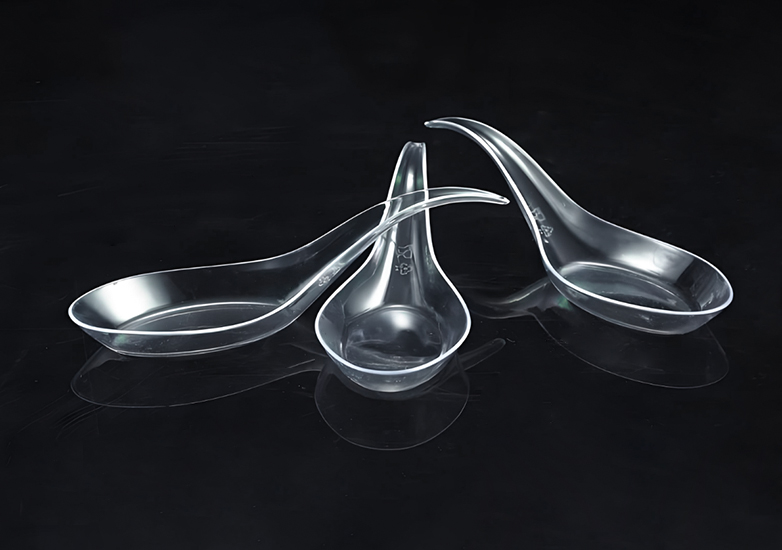

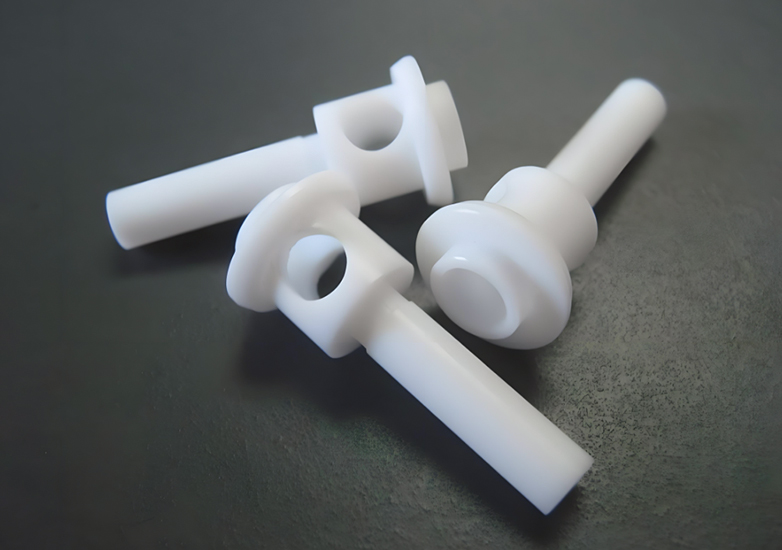

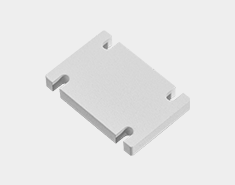

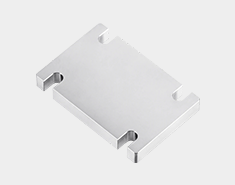

Gallery of 3D Printed Parts

3D Printing from Prototyping to Production

Transform your design and prototype into production grade 3D printed parts in just one day, allowing you to quickly bring outstanding products to the market.

On-Demand Production

On-demand production allows you to find the perfect match for your unique needs in our precision-driven processes, whether it's rapid prototyping or mass production.

Rapid Prototyping

We have the ability to quickly quote, allowing you to receive prototypes in a short period of time and test prototype parts in a timely manner to bring them to the market.

Production Parts

3D printing can quickly manufacture complex, customized, and small-scale production parts without the need for expensive tools.

Put your parts into production today

- All information and uploads are secure and confidential.

LS Manufacturing 3D Printing Tolerances

Thanks to our state-of-the-art facilities and rigorous testing processes, we are able to ensure that every 3D printed prototype and part is of impeccable quality and meets extremely strict tolerances.

| Process | Layer Height Range | Minimum Wall Thickness | Maximum Build Size | Dimensional Tolerance |

|---|---|---|---|---|

| SLA | 50 - 100 μm |

+/- 0.5 mm

+/- 0.019 in. |

600 x 600 x 600 mm

23.622 x 23.622 x 23.622 in. |

+/- 0.1 mm

+/- 0.003 in. |

| SLS | 100 - 200 μm |

+/- 1.0 mm

+/- 0.039 in. |

420 × 500 × 420 mm

16.535 × 19.685 × 16.535 in. |

+/- 0.3 mm

+/- 0.011 in. |

| FDM | 100 - 300 μm |

+/- 0.8 mm

+/- 0.031 in. |

1000 x 1000 x 1000 mm

39.370 x 39.370 x 39.370 in. |

+/- 0.2 mm

+/- 0.007 in. |

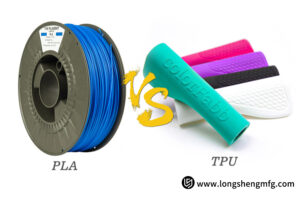

Materials for 3D Printing

Choosing the right materials is critical to creating custom prototypes and parts that meet the required mechanical properties, functions and appearance requirements. You can check out the basics of 3D printing materials at LS Manufacturing in order to choose the right material for your final part.

Metals

Plastics

We offer customization based on your specific material requirements. If you need a material not listed here, our team can source and process it to meet your exact needs.

These are just a few examples of the materials we work with. If you have a specific material requirement, please contact us to discuss your needs.

Surface Finishing for 3D Printing

| Category | Description | Material | Color | Texture |

|---|---|---|---|---|

Powder Coating

Powder Coating

|

Powder coating is a popular and environmentally friendly method of applying a protective and decorative finish to various types of metal and even some non-metal surfaces. | Metals | White, Black, RAL and Pantone | Glossy, fine, hardness |

Polishing

Polishing

|

The primary goal of polishing is to create a smooth and reflective surface by removing imperfections, scratches, and irregularities. | Metals | Silver gray | Bright, mirror, silk |

Bead blasting

Bead blasting

|

Bead blasting, also known as abrasive blasting, is a surface preparation technique used to clean, finish, or texture a surface by forcibly propelling small, spherical abrasive materials, called "beads" or "media," at high speeds onto the surface being treated. | Aluminum, copper, stainless steel, steel | N/A | Grainy, slightly matte texture |

As machining

As machining

|

Machining is a subtractive manufacturing process in which a machine tool, typically a cutting tool, removes material from a workpiece to achieve the desired shape, dimensions, and surface finish. | Metals | N/A | Smooth, glossy finish |

Why Choose Us for Online 3D Printing Services

Multi material machining

We have the ability to handle multiple materials, and we can provide professional solutions no matter what material of cnc parts you need to process.

Customized Services

Provide customized solutions based on customer design requirements and specifications to ensure that CNC parts meet their unique needs.

Competitive pricing

We provide competitive prices and cost-effective solutions to ensure that customers gain the greatest advantage in cost control.

Rapid delivery

We have efficient production processes and flexible production plans, which enable us to timely deliver customer orders and meet urgent project needs.

Our 3D Printing Services for Various Industrial Applications

Crossing numerous industries, LS Manufacturing uses highly advanced technology, from prototype production to on-demand manufacturing, and then to large-scale production, to ensure the excellent quality and reliable performance of parts, ensuring the success of your project.

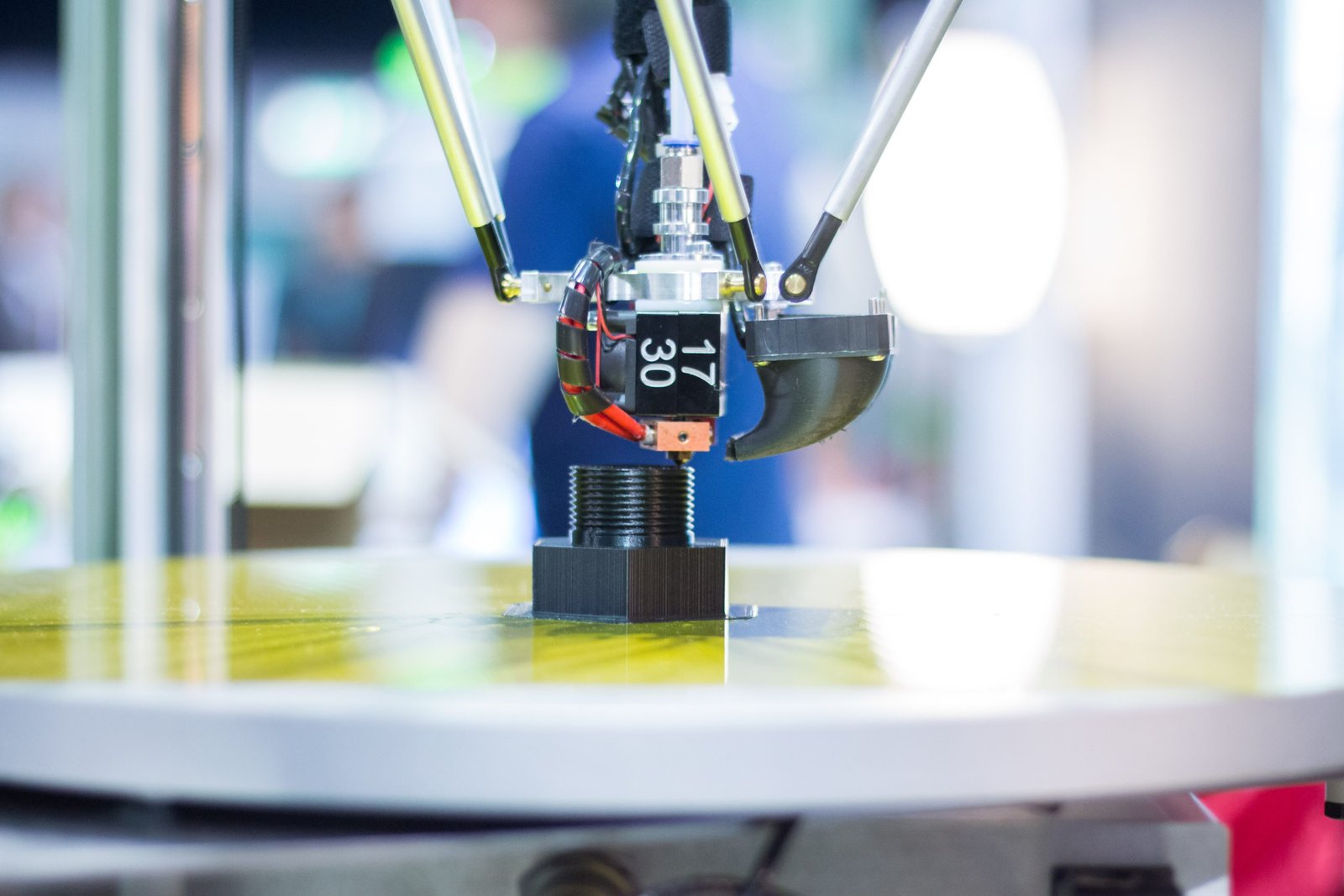

3D Printing Overview

What is 3D Printing?

3D printing, also called additive manufacturing, is a process of creating physical objects from digital models by adding material layer by layer. It’s used for rapid prototyping, customization, and making complex shapes in various industries.

What are the advantages of 3D printing?

This revolutionary technology, in stark contrast to traditional subtractive manufacturing methods like machining and casting, builds objects layer by layer from digital designs, unlocking a treasure trove of advantages that have reshaped the way we think about manufacturing.

– Iterative design and prototyping

– Cost-effective for low volume production

– No upfront tooling costs

– Complex Geometries

How 3D printing works step by step?

It starts with designing a 3D model on a computer, which serves as a blueprint for what you want to create. This model is divided into very thin horizontal layers using special software.

Next, a 3D printer prepares for action. It’s loaded with the material you want to use, which could be plastic, metal, resin, or even food. The printer reads the digital design and starts building the object layer by layer.

Each layer is like a super-thin slice of the final object. These layers are carefully placed on top of each other, and they stick together, eventually forming the complete 3D object.

Depending on the type of 3D printer, some layers may cool down and harden while others are being added. This process continues until the entire object is finished.

Once printing is complete, you may need to do some post-processing, like sanding or painting, to get the desired look and feel. Then, you’ve got your 3D-printed object, ready to be used for whatever purpose you had in mind!

Client's Reviews

Listen to our customers’ voices! We have received praise and satisfactory evaluations from many customers.

Put Your parts Into production Today

All information and uploads are secure and confidential.

Gallery Of CNC Turning Parts

Check out our custom turning parts for valued customers, from rapid prototyping, to low-volume production, to mass production orders.

Precision Manufacturing Capabilities

Download Our Brochure to Get a Full

Overview of Our Manufacturing Capabilities

Access our technical documentation, covering all core processes, tolerance standards, material options, and industry case studies, to help you quickly evaluate project feasibility.

What's in the manual?

·High-definition product images and 3D cross-sections.

·Detailed process capabilities and tolerance standards, e.g., 5-axis CNC accuracy, injection mold lifespan.

·Comprehensive material options and surface finishes, e.g., titanium, PEEK, anodizing, sandblasting.

·Quality system certifications (ISO 9001) and industry case studies.

·A complete guide to our process from rapid prototyping to mass production.

Lead Capture Form

Simply enter your email to get the download link instantly

![]() We respect your privacy and will not use your information for other purposes.

We respect your privacy and will not use your information for other purposes.

Applications for 3D Printing

Here are some common 3D printing applications in various industries and examples of typical parts produced:

- - Prototyping of new aircraft designs

- - Home decor items and artistic creations

- - Prototyping of electronic enclosures and components

- - Rapid prototyping of vehicle components and designs

- - Dental implants and surgical guides

- - Rapid production of small-batch and customized parts

3D Printing FAQs

We provide new product developers with engine processing parts suitable for functional testing or final use of engineering -level materials. Get your required 3D printing service support by reading FAQ.

What is 3D printing?

3D printing is a manufacturing process that involves creating three-dimensional objects from a digital design. The process involves building up layers of material, such as plastic or metal, until the final object is complete.

What materials can be used in 3D printing?

A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, and resins. The choice of material will depend on the specific requirements of your project, such as strength, durability, and flexibility.If you have any questions or would like to learn more about our 3D printing capabilities, please don’t hesitate to contact us. We are always happy to help and look forward to working with you.

What is your quality control process?

We have a rigorous quality control process that involves multiple inspections and tests throughout the manufacturing process. We use advanced inspection and testing equipment to ensure that all parts meet or exceed industry standards.

What is your lead time for manufacturing metal parts?

Our lead time varies depending on the complexity and quantity of the parts being manufactured. We will provide you with an estimated lead time when you submit your order, and we will keep you informed throughout the manufacturing process.

What types of 3D printing technologies do you offer?

We provide various 3D printing methods including SLA, SLS, FDM, and PolyJet to accommodate different material needs and production scales.

What materials are available for 3D printing?

Our 3D printing materials range from standard plastics like ABS and PLA to engineering-grade resins, nylon powders, and flexible or durable polymers.

How do you determine the best 3D printing technology for my project?

Our engineers evaluate your design requirements, including complexity, mechanical properties, surface finish, and budget to recommend the most suitable 3D printing process.

What is the typical surface finish quality of 3D printed parts?

Surface finish depends on the technology: SLA parts usually have smooth finishes, while SLS parts have a slightly grainy texture. Post-processing options are available to improve appearance.

Can you print functional prototypes or end-use parts?

Yes, depending on the material and technology, we can produce both functional prototypes and some end-use components suitable for limited production runs.

What is the maximum build size for your 3D printers?

Build sizes vary by machine, but generally range up to 3000 x 3000 x 3000 mm. For larger parts, we can print in sections and assemble them.

News & Blog

Deep understanding of industry knowledge and real-time updates at any time.

What is 3D Printing?

From Free 3D Printing Models to Reality: LS Manufacturing’s Full Service

Save 50%: LS Manufacturing On-Demand 3D Printing For Small-Batch Development

SLM vs. DMLS: Which Metal 3D Printing Technology Is Right For Your Needs?

TPU vs. PLA: The Ultimate 3D Printing Filament Guide

Is Resin Plastic? 5 Fundamental Differences

Online Rapid Manufacturing 3D Printing Services–Get a Fast Quote & Order Today

Selective Laser Sintering Cost: Is SLS 3D Printing Cost-Effective?

Put your parts into production today

- All information and uploads are secure and confidential.