Bead blasting services

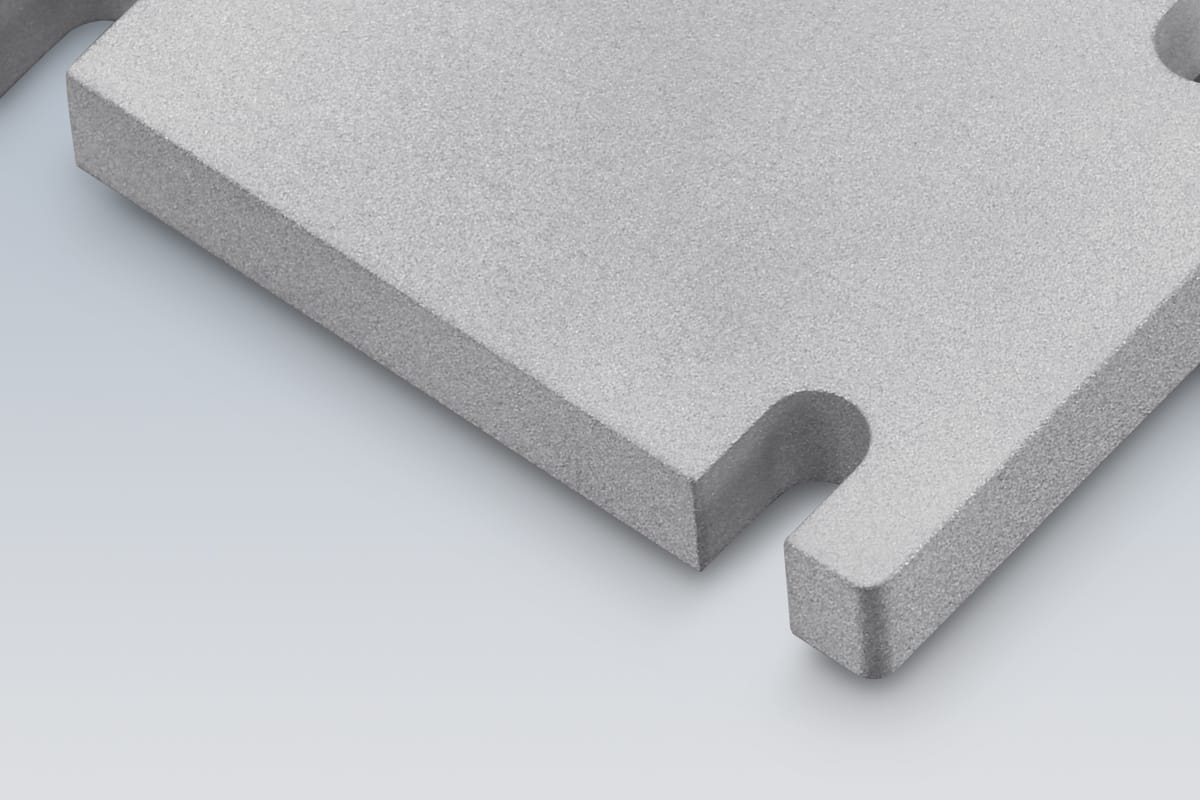

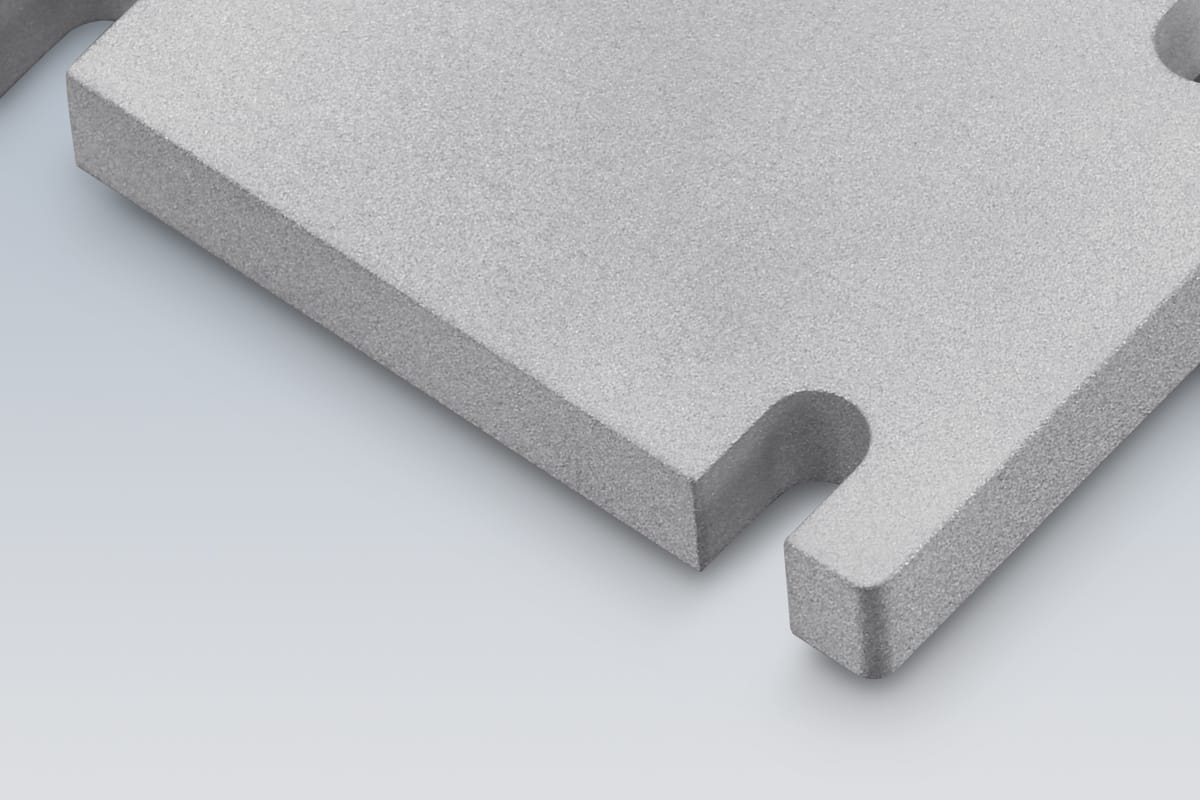

Our bead blasting service can leave a uniform matte or satin texture on machined parts. Customizable appearance options according to requirements.

Bead blasting specifications

| Materials | Colors | Applications | Thickness | Texture |

|---|---|---|---|---|

| Aluminum, Steel, Stainless steel, Brass, Copper, Tool steel | N/A | Cosmetic parts | N/A | Grainy, slightly matte texture |

* Bead blasting involves forcefully propelling a stream of blast media against a surface, typically using high pressure. This process is aimed at removing unwanted coating layers and surface impurities.

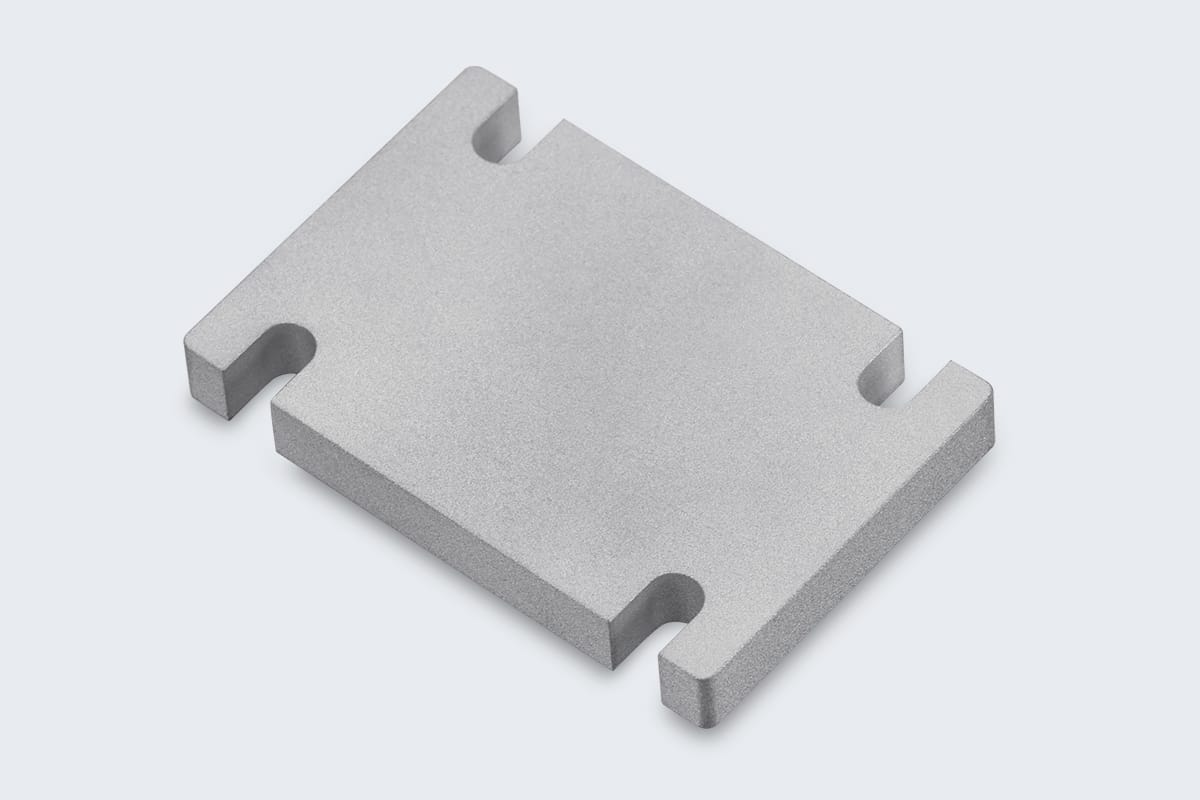

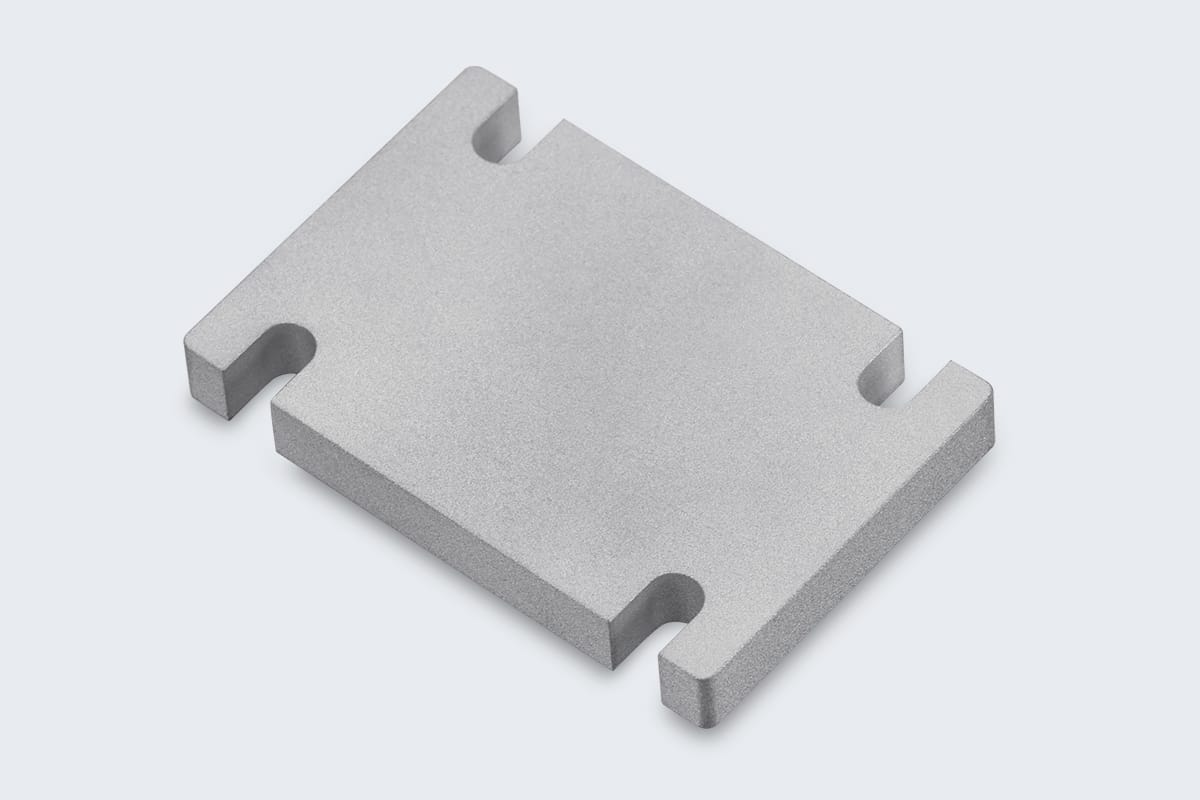

Example Of A Bead Blasting Parts

Bead blasting Process

Media blasting is a surface finishing technique that employs a pressurized jet of abrasive media to achieve a consistent matte finish on the surface of parts. The abrasive media typically used includes varying sizes of glass beads or sand, although for different levels of abrasion, materials like plastic beads can also be employed.

This process serves the purpose of not only creating a uniform matte finish on parts but also concealing machine marks or eliminating minor flaws in parts before subsequent processes such as anodizing or other plating methods. It is a versatile method commonly employed in industries where precise surface finishes and quality are crucial.

Latest Blog Posts

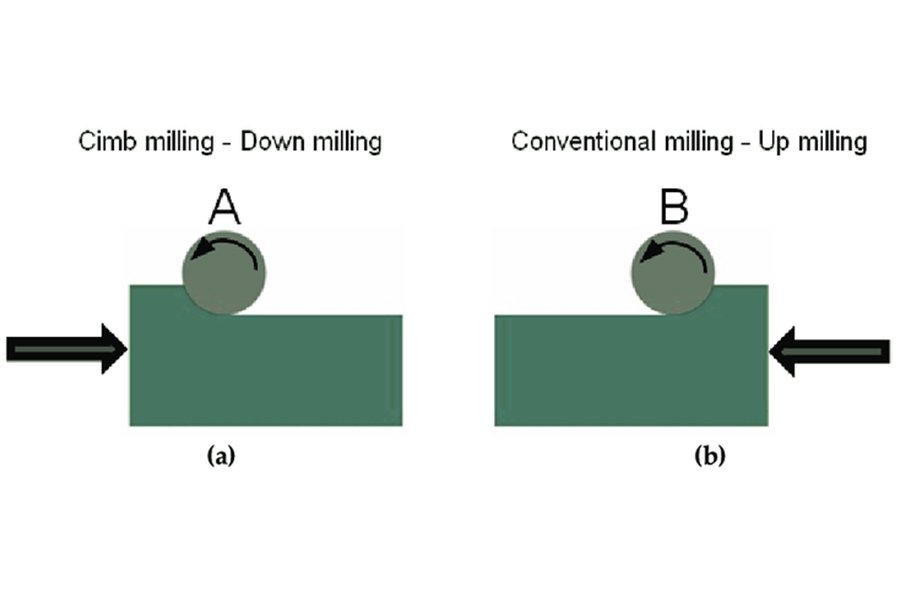

Climb Milling vs. Conventional Milling: A Battle for Manufacturing Precision

Resin Vs. Plastic: Understanding The Core Differences For Better Material Selection

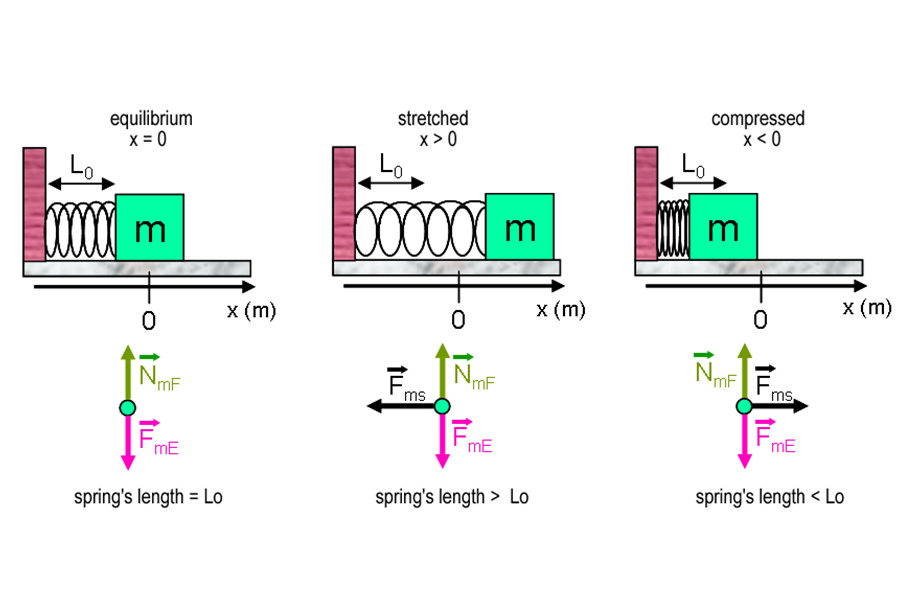

How Do Mechanical Springs Store Energy?

Put your parts into production today

- All information and uploads are secure and confidential.