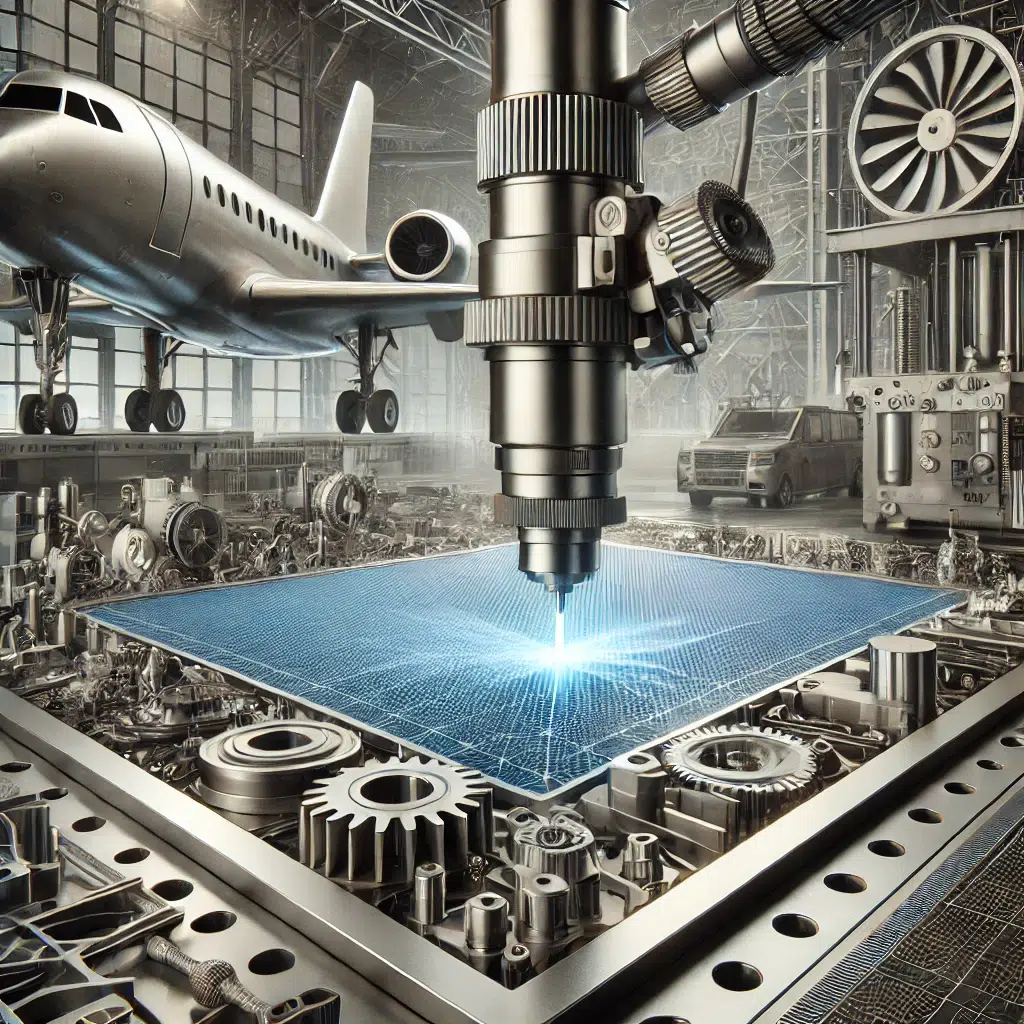

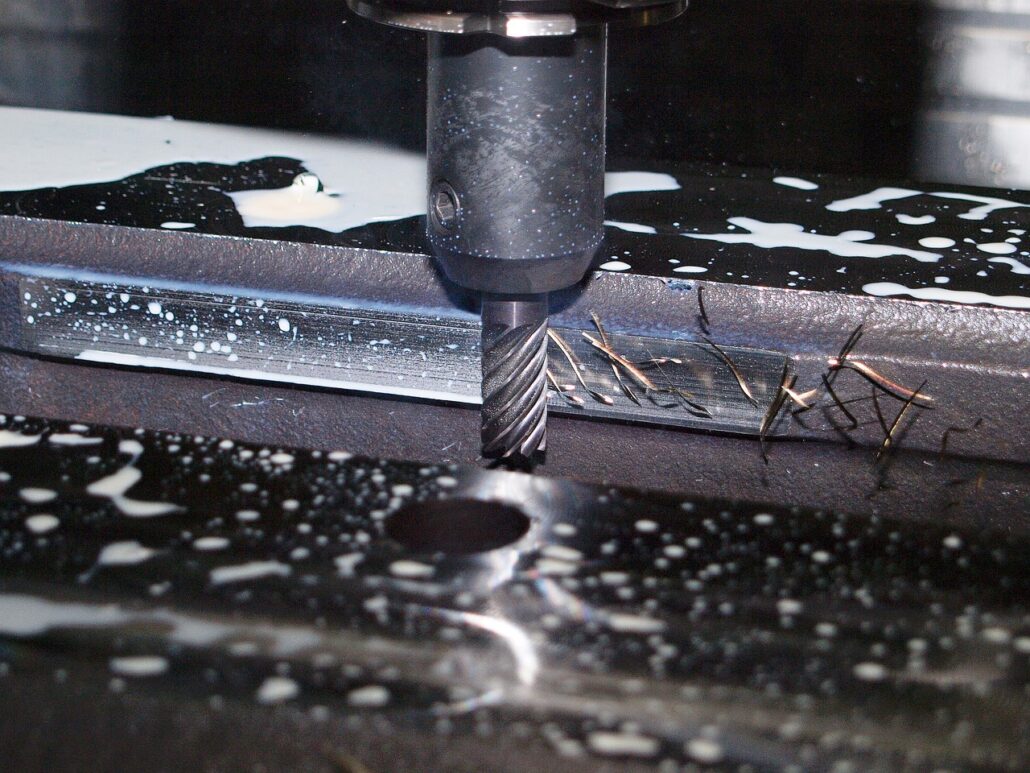

Precision Waterjet Cutting: Achieving Accuracy Manufacturing

Waterjet Cutting: Precision […]

Precision Waterjet Cutting: Achieving Accuracy Manufacturing Read More »

Machined parts ship in 3 days, order your metal & plastic parts today. Contact us now

Machined parts ship in 3 days, order your metal & plastic parts today. Contact us now

Waterjet Cutting: Precision […]

Precision Waterjet Cutting: Achieving Accuracy Manufacturing Read More »

Dongguan City Longsheng Hardware Technology Co., Ltd (东莞市隆胜五金科技有限公司)

Don’t miss our future updates! Get Subscribed Today!

Copyright © 2023 Dongguan City Longsheng Hardware Technology Co., Ltd. All rights reserved.