Car Parts Manufacturer

On demand manufacturing of precision car parts, providing custom car prototypes and component manufacturing services for car product development, regardless of complexity, we can provide high-quality precision car parts.

- Manufacturing on demand

- Instant car parts quotes

- 24/7 engineering support

- ISO 9001:2015 certiified

- All uploads are secure and confidential

Our car parts Manufacturing Capabilities

We offer high quality services at different stages of the production cycle, from prototyping to mass production, and we guarantee you high quality custom car parts. In addition, our quality control processes ensure that you get precision car parts that meet your quality requirements at a low cost.

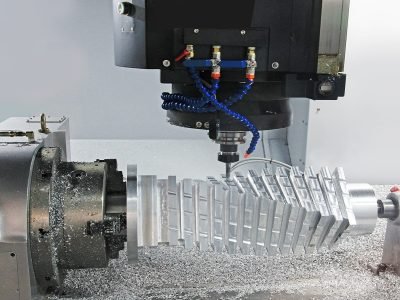

CNC machining

CNC machining is a technology that uses a pre-programmed computer control system to operate machine tools for precise machining

Sheet Metal Fabrication

Sheet metal fabrication is the process of using sheet metal material (usually metal) to make car parts or components by cutting, bending, stamping and welding

Plastic Injection Molding

Plastic injection molding is the process of injecting melted plastic material into a mold and taking it out after cooling and curing

3D Printing

3D printing is a manufacturing technique that builds objects layer by layer, by stacking materials layer by layer to create three-dimensional objects

car parts Manufacturing material

Longsheng supplies most of the industry standard materials. If you do not find the materials you want in the list, please contact us

| Aluminum alloy material | Stainless Steel | Alloy Steel | Copper alloy | Other alloy | plastic | Special materials and other |

|---|---|---|---|---|---|---|

| Aluminum alloy 6061 | Stainless steel 303 | Q235 (A3 steel) | Bronze-H59 | Electrician pure iron-DT4C | Engineering Plastic -ABS | Carbon fiber board |

| Aluminum alloy 5052 | Stainless steel 304 | 45 steel | Bronze-H62 | Electrician pure iron-DT4E | Polytetrafluoroethylene-PTFE | graphite |

| Aluminum alloy 2A12 | Stainless steel 316 | Cr12 | Copper-T2 | Titanium alloy-TC4 | Saigang-POM | - |

| Aluminum alloy 7075 | Stainless Steel 316L | 3Cr13 | Oxygen Tu2 | Magnesium alloy -AZ91D | Organic Glass-PMMA | - |

| - | Stainless steel 420 | Spring Steel-65MN | Tin Bronze-QSN-6-6-3 | - | Polyzenzene-PPS | - |

| - | Stainless Steel-17-4PH | Mold Steel-SKD11 | Beryllium copper-C17200 | - | Nylon-PA6 | - |

Reasons for Choosing Our car Parts Manufacturing

Provide reliable solutions and carefully design customized car parts to meet and exceed industry standards for durability and performance, spanning different production stages to meet production goals.

Flexible production capacity

Whether it's small batch orders or large-scale production, we have flexible production capabilities that can meet customer needs and ensure delivery time

Quality certification

We have passed international quality certification and comply with relevant industry standards to ensure that our manufacturing process and product quality meet the highest standards.

Customization capability

We are able to provide personalized car parts manufacturing services based on customers' needs and specifications, meeting their unique requirements.

Car Parts Finishes and Post-Processing

- Painting

- Plating

- Powder coating

- Anodizing

- Polishing and buffing

- Surface treatments

- Assembly and integration

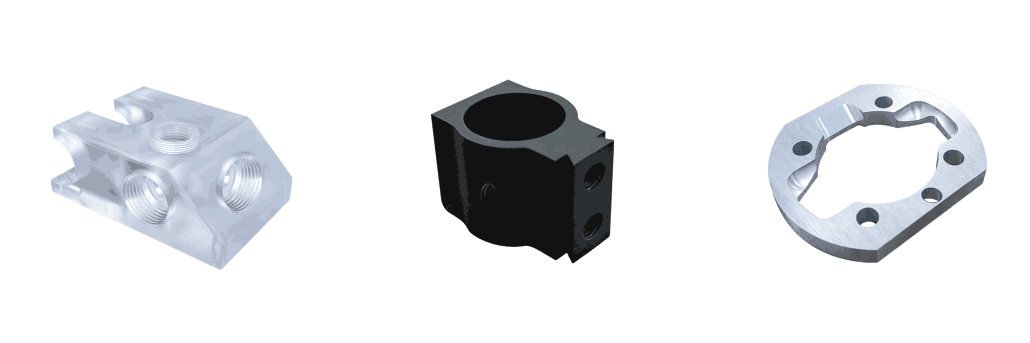

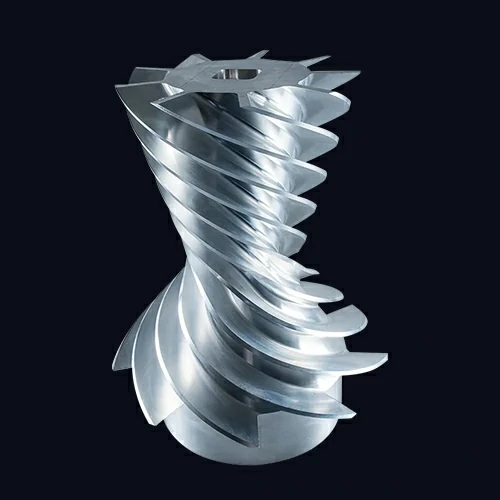

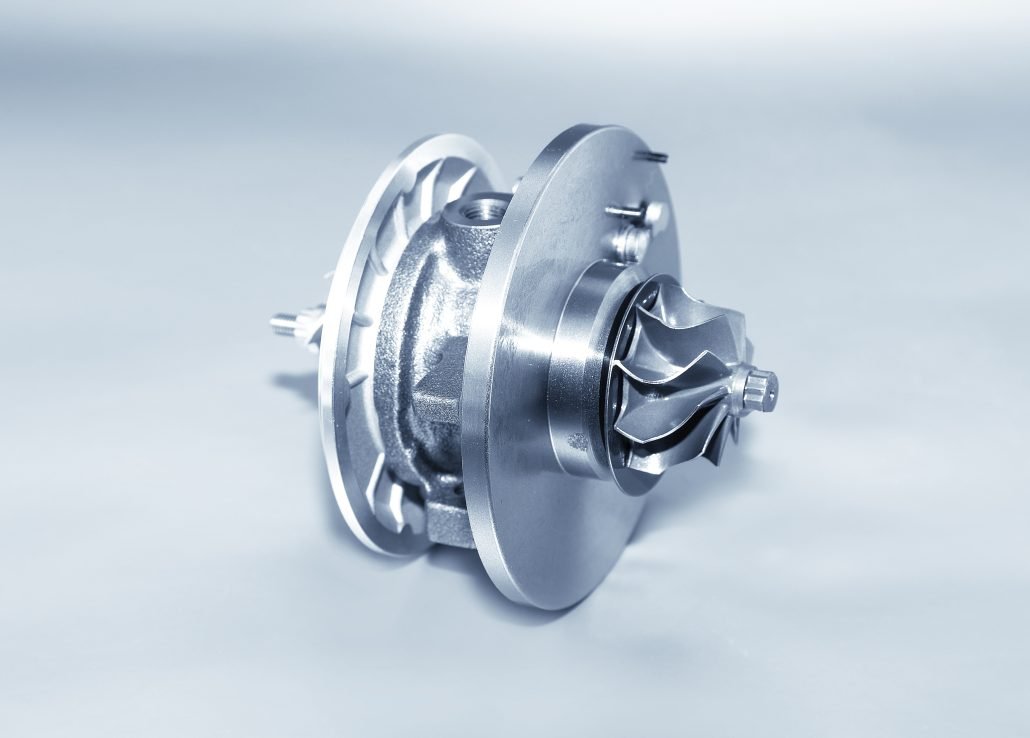

Custom Prototypes and Parts for car Companies

View the custom car parts we process for customers, from rapid prototyping, small batch production to batch production orders

Top tier car parts manufacturing applications

- Engine components

- Chassis components

- Body parts

- Transmission system parts

- Interior parts

- Electronic components

- Fuel system parts

- Air conditioning system parts

- Lighting and electrical components:

- Brake system parts

Frequently Asked Questions about car Parts Manufacturing

We provide new product developers with engine processing parts suitable for functional testing or final use of engineering -level materials. Get your required car parts manufacturing services support by reading FAQ.

Our production capacity and capacity vary depending on specific equipment and processes. We can provide appropriate production capacity based on customer needs to ensure timely delivery of orders and meet requirements.

We have the ability to manufacture various types of car parts, including engine components, chassis components, body components, electronic components, etc. Our manufacturing capabilities cover various processes such as CNC machining, sheet metal fabrication, plastic injection molding, and 3D printing.

Yes, we can provide custom parts manufacturing services according to customer requirements. We have a technical team and production equipment that can produce according to customers' design and specification requirements, and provide corresponding technical support and suggestions.

The delivery time varies depending on the type, quantity, and complexity of the car parts. We will provide accurate delivery times based on customer order requirements and production plans. We strive to ensure timely delivery and maintain communication with customers to update delivery status in a timely manner.

Yes, we can provide sample or prototype production services. If the customer needs to verify the design or conduct market testing, we can make samples or prototypes according to the requirements and ensure that they meet the customer's expectations and requirements

Yes, we can conduct international quality certification according to customer requirements. Our manufacturing process and product quality comply with ISO 9001 quality management system standards and can obtain other industry specific certifications as needed.

Yes, we have experience in handling large quantities of orders. We have advanced production equipment and management systems that can effectively organize production processes and ensure efficient and stable mass production.

We attach great importance to quality control and adopt a strict quality management system. We implement comprehensive quality inspections, including raw material inspection, production process monitoring, and final product testing, to ensure that the car parts meet customer requirements and international standards.