Gloria.

Expert in Rapid Prototyping & Rapid Manufacturing, LS TECH.

Gloria.

Over a decade of deep expertise in precision manufacturing, with encyclopedic industry knowledge.

Gloria is a seasoned expert in the field of rapid prototyping and rapid manufacturing, with mastery across key processes including CNC machining, 3D printing, polyurethane casting, rapid tooling, injection molding, metal casting, sheet metal fabrication, and extrusion. With a wealth of experience serving over a thousand clients, she is capable of handling the entire production chain—from prototyping to small- and large-batch manufacturing—consistently delivering professional services and valuable knowledge sharing.

Integrating Processes, Driving Growth

Tailored cross-process manufacturing solutions that ensure speed, cost-efficiency, and quality.

- From 2010 to 2014, Gloria collaborated with Foxconn Technology Group. She pioneered the integration of 3D printing and CNC technologies for a flagship smartphone project with an annual production volume exceeding 20 million units. Her innovative approach established a new hybrid validation process, which successfully shortened the prototyping iteration cycle by 40%.

- In 2015, Gloria provided technical support for Chery’s new energy vehicle division. The solution she led raised the mass production pass rate of high-voltage connector housings to 99.2%, ensuring the on-schedule launch of three electric vehicle models.

- From 2016 to 2018, Gloria worked with leading domestic laser equipment companies and a global top-tier medical device manufacturer. She led complex component development projects in the laser equipment sector, significantly reducing design iteration times for aerospace-grade nickel alloy parts. Later, she provided rapid prototyping and trial production management services for the medical device manufacturer, successfully solving the dual challenge of optimizing both surface finish and biocompatibility of orthopedic implants.

- In 2019, Gloria joined LS Hardware Technology as a prototyping and manufacturing expert. She has since driven business growth and addressed critical challenges in the automotive, medical, consumer electronics, aerospace, automation, and smart home sectors—especially in the areas of lightweighting, rapid delivery, and cost control.

- Currently, Gloria oversees a wide range of manufacturing capabilities at LS, including CNC machining, sheet metal, rapid tooling, injection molding, and 3D printing. Her strength lies in multi-process integration and resource coordination, enabling her to deliver comprehensive, cross-process manufacturing solutions tailored to client needs.

Latest Posts:

Ceramic CNC Machining: Key Processes, Parameter Optimization & Practical Techniques

LS

September 30, 2025

Successful CNC machining of ceramics is a highly specialized technology that combines professional knowledge, practical experience and special equipment.

Metal Casting Shrinkage: A Comparison of Iron, Steel, And Aluminum

LS

September 29, 2025

The degree of control over metal casting shrinkage behavior directly determines the success or failure of the project. The fundamental difference between iron, steel, and ...

Top 10 Local Powder Coating Services Near Me | Free Quotes

LS

September 27, 2025

Choosing powder coating services is far more than just comparing prices. It is also about choosing a long-term partner who can ensure product quality and ...

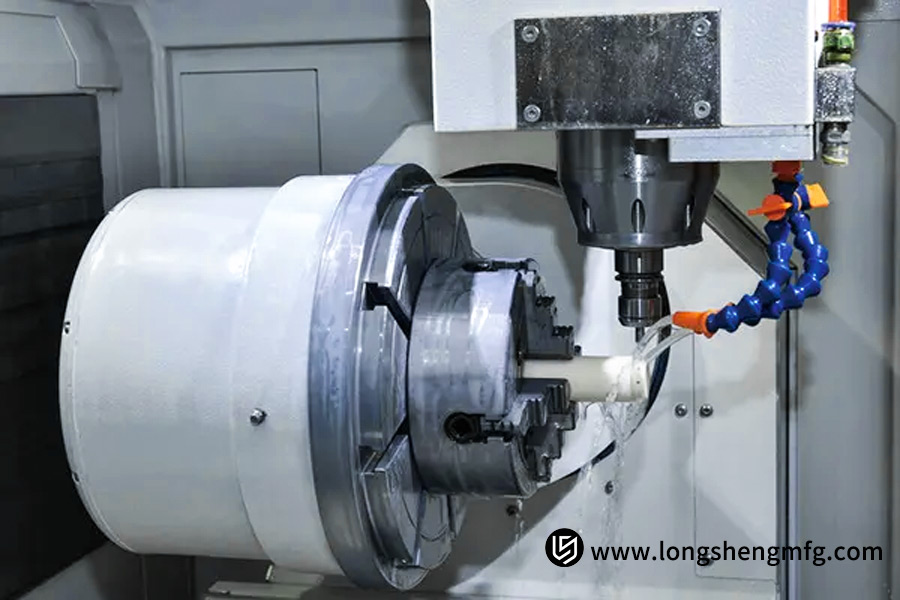

How To Achieve ±0.01mm Tolerance Consistently: A Guide To High-Precision CNC Lathes

LS

September 26, 2025

Achieving and stably maintaining an extreme tolerance of ±0.01mm is a project that combines high-precision CNC lathes, rigorous craftsmanship, quality control, and engineering experience.

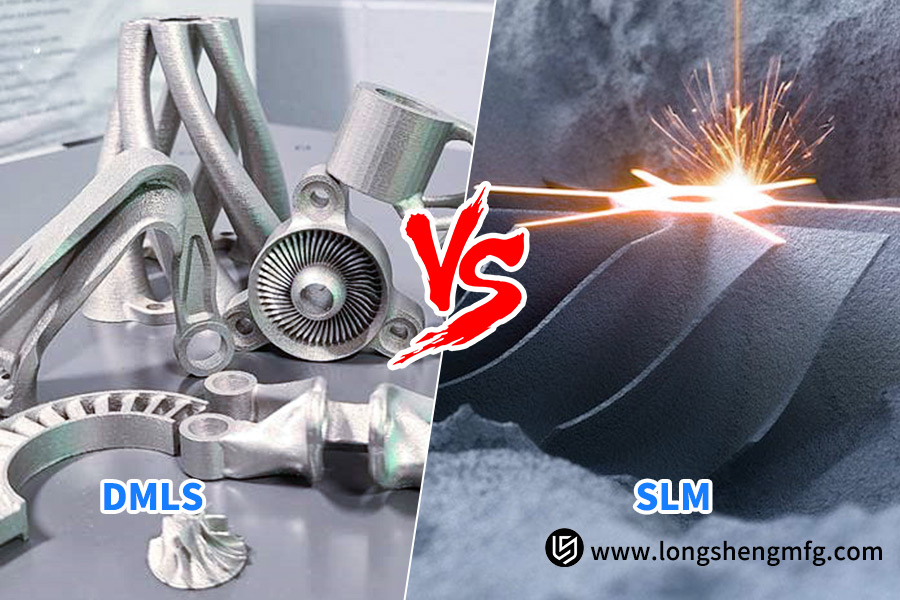

SLM vs. DMLS: Which Metal 3D Printing Technology Is Right For Your Needs?

LS

September 25, 2025

Choosing between SLM and DMLS is a professional decision that requires a comprehensive consideration of materials, performance, cost, and the end application scenario.

How To Choose Vacuum Casting Resin: Save Up To 30% On Production Costs

LS

September 23, 2025

Vacuum casting project success and cost control begin with a proper balance and intelligent choice of material characteristics, defined requirements, and manufacturing goals.

Medical Injection Molding: Process, Advantages, And Applications

LS

September 22, 2025

Medical injection molding is a highly technical process, requiring precision engineering, material science, and rigorous regulatory standards for product.

Brass vs. Stainless Steel vs. Aluminum Alloy: The Ultimate Comparison For Rapid Prototyping

LS

September 19, 2025

In the choice of rapid prototyping materials between brass, stainless steel, and aluminum, success lies in precisely matching material properties to your functional testing, environmental ...

Low Volume Production Cost Hacks: 7 Strategies To Save Money & Boost ROI Now

LS

September 18, 2025

Effectively reducing low-volume production costs is a systematic optimization process that spans design, process, materials, supply chain, and partner selection.