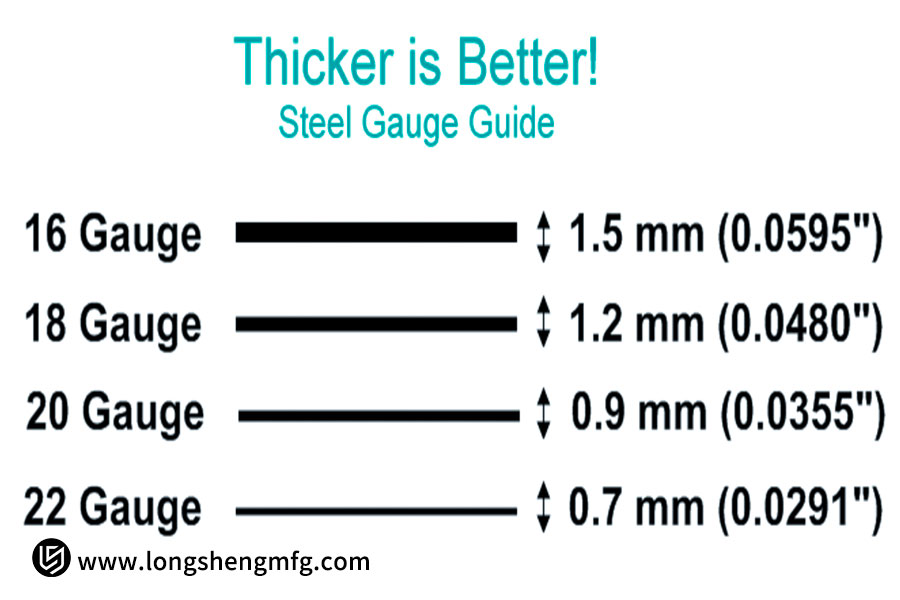

Which Is Thicker, 18 Or 22 Gauge Sheet Metal?

18-gauge metal sheet is thicker than 22-gauge metal sheet. The “gauge” number for metal sheet is a commonly used thickness designation system in North America (such as Birmingham Wire Gauge (BWG) or American Wire Gauge (AWG).

Which Is Thicker, 18 Or 22 Gauge Sheet Metal? Read More »