China CNC Turning Stainless Steel Parts

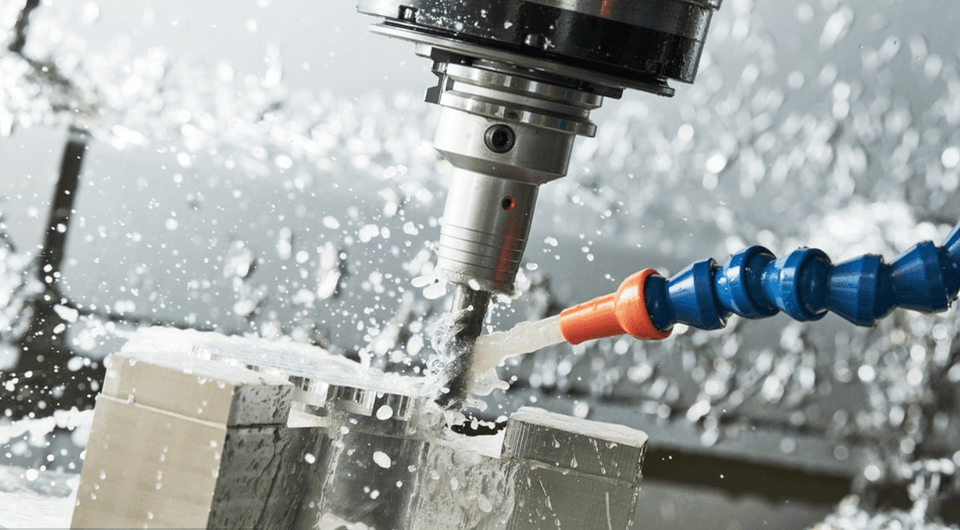

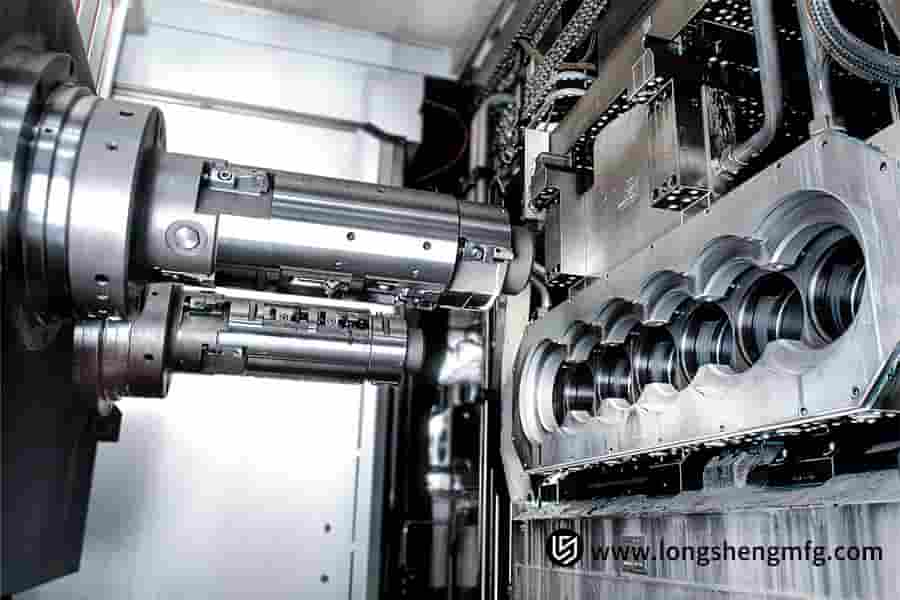

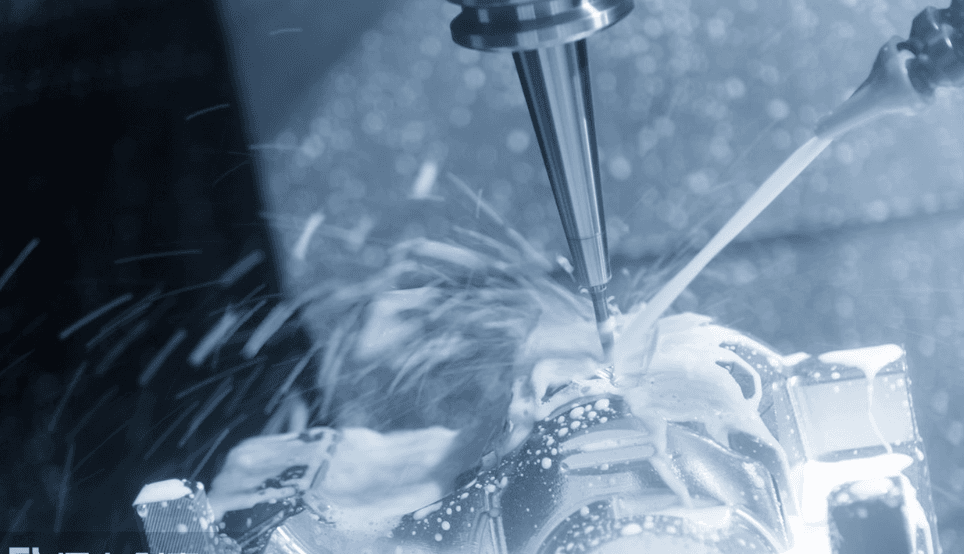

At Longsheng, we provide CNC turning services for a variety of industries, including aerospace, medical, automotive, and more. These services are crucial in creating high-quality precision parts that meet the strictest standards and specifications. But let’s focus on one area in particular: stainless steel parts.

China CNC Turning Stainless Steel Parts Read More »