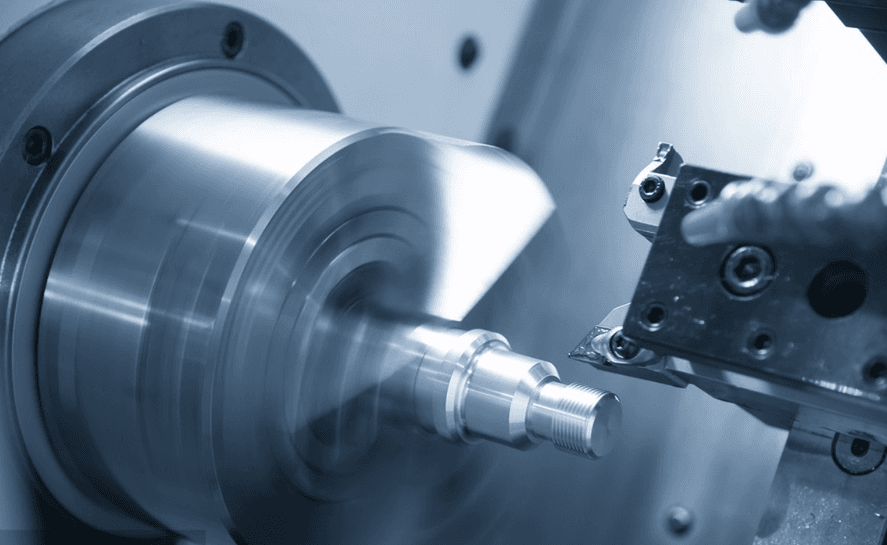

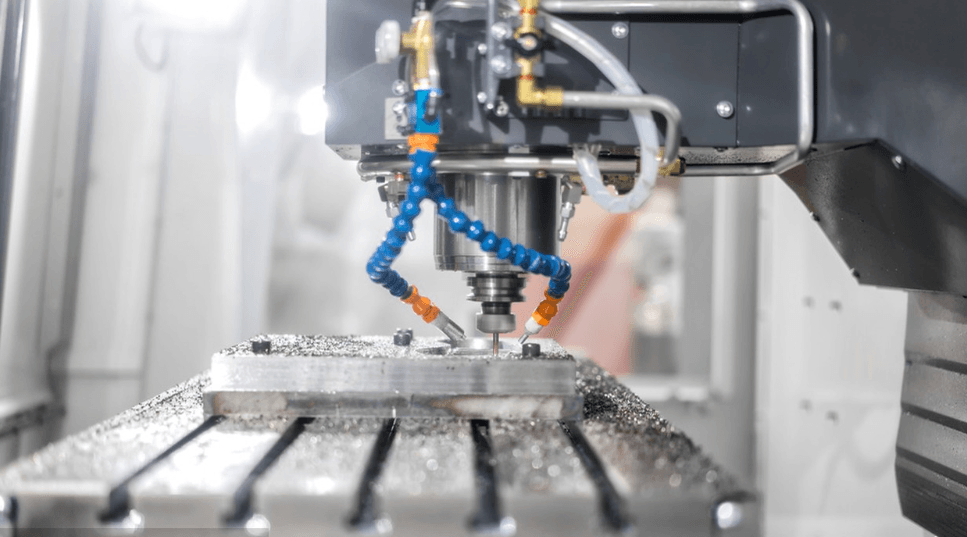

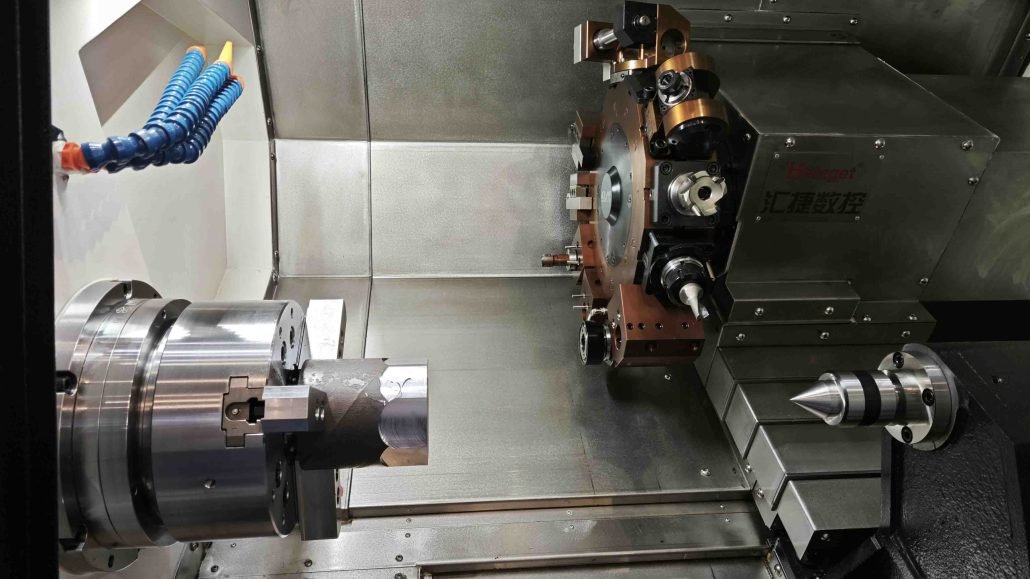

Aerospace Parts CNC Machining Manufacturing Russia

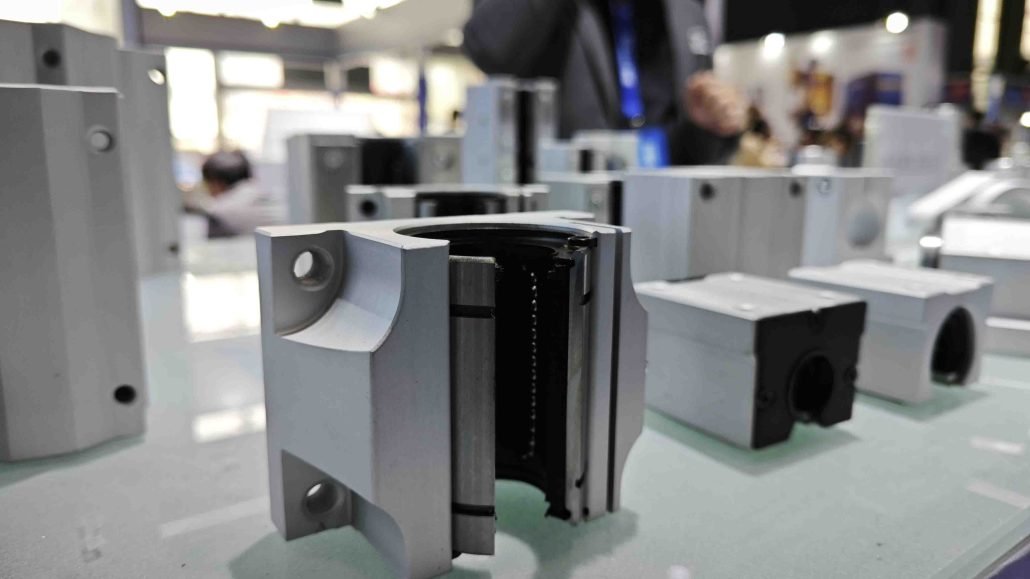

Are you in need of high-quality aerospace parts that require precision machining? Look no further than our manufacturing company in Russia! We have the latest CNC machining technology and a team of highly skilled engineers and technicians who have years of experience in the aerospace industry.

Aerospace Parts CNC Machining Manufacturing Russia Read More »