Don’t you struggle with getting custom injection molding? The antiquated quoting process is riddled with back-and-forth emails, unnecessary delays, and ambiguous pricing that discourages serious product development and manufacturing.

LS Manufacturing now offers the game-changing solution, our stand-alone online injection molding quote tool, designed to put an end to this misery. Upload your 3D model, and our intelligent system will carry out in-depth analysis automatically to give you a transparent, precise, and instant quote. It shatters the traditional model to make complex injection molding pricing more transparent and accessible than ever.

Say goodbye to lengthy waits and embrace ultimate efficiency. Upload your design today and enjoy the benefits of a new age with open, glanceable pricing for custom plastic parts! To save you time, here’s a quick overview of the core conclusions.

Injection Molding Online Instant Quote Core Quick Reference Table

| Core Dimensions | Key Content | Your Benefits |

| Applicable Files | STEP/IGES Format 3D Models | Guarantee complete geometric data for better quotes |

| Quote Speed | Produce within 1 minute of upload. | Instant quotes prevent long delays. |

| Major Drivers of Pricing | Material type, application, mold life, and manufacturing cycle. | Injection molding pricing is transparent and costs are easily clear. |

| Core Process | Post drawings → Smart Analysis → Quote and manufacturability feedback. | Fast self-service process eliminates to-and-fro communication. |

| Next Steps | After quote acceptance, one-click to mold design and manufacturing. | Seamless integration reduces project delivery cycles by a tremendous factor. |

This reference sheet merely lists the inherent value of the injection molding quote platform:

Through standardization and digitalization, this complex inquiry process, previously dependent on human experience, has been turned into an operational, open, and immediate service. Not only does it render custom injection molding manufacturing price transparent and predictable, but you also get to focus on the product itself, freeing you from tedious processes.

Upload your 3D designs to LS Manufacturing’s company website today and experience unparalleled efficiency and clarity in injection molding prices.

Why Trust This Guide? Real-World Experience From LS Manufacturing Experts

This quote and guide system upon which it is based is more than just words; it is built on over 15 years of LS Manufacturing injection molding expertise. We’ve have successfully offered enhanced injection molding solutions to more than 1,000 customers in consumer electronics, automotive, and medical devices and shipped high volumes of cases from simple housings to intricate complex parts.

This rich hands-on experience has been integrated into our online quoting web system with ease. What you see is real-time quoting driven by a cost model developed by our experienced process engineers that mirrors the actual consumables, machine time, and process concerns of production.

You’re not viewing numbers; you’re viewing the computerized work of LS Manufacturing’s years of injection molding know-how, knowledge brought to your fingertips.

How Do Traditional Injection Molding Quotes Slow Down Product Development?

With the frantic speed of product development, time is of the essence. But traditional injection molding quotation is perhaps like a heavy yoke that slows you down at every corner. It typically involves:

Step 1: Cumbersome Initial Communication

You invest hundreds of hours searching for your ideal supplier, then composing emails, making a couple of phone calls, and emailing 2D drawings, 3D models, and specs again and again, just to request an injection molding quote.

Step 2: Lengthy Waiting

Once you have sent the email, you are in a “black box” waiting period of days or weeks. You just sit idle, and have no idea of the quote status, and wait for internal review and approval of the supplier process, procurement, and other departments. Waiting is very disruptive to your project planning.

Step 3: Inefficient Repeated Confirmation

When that initial quote finally does arrive, there are usually a series of follow-up questions: Can the wall thickness be adjusted? Can the material be replaced? This creates internal squabbling with engineers and designers, followed by a few rounds of give-and-take phone calls and emails with the supplier, turning the whole injection molding quote process into a long-term, back-and-forth fight.

This slowness and inaction result in more than just lost time. It extends product introduction timetables directly, possibly through overlooking fleeting market opportunities, and introduces first-project cost and planning uncertainty.

This is precisely the subterranean source of frustration the LS Manufacturing platform aims to eliminate. One-minute instant online quoting eliminates this series of slow steps and brings back the development process to business as usual.

Upload A Drawing, Get An Instant Quote: The LS Manufacturing Speed Experience

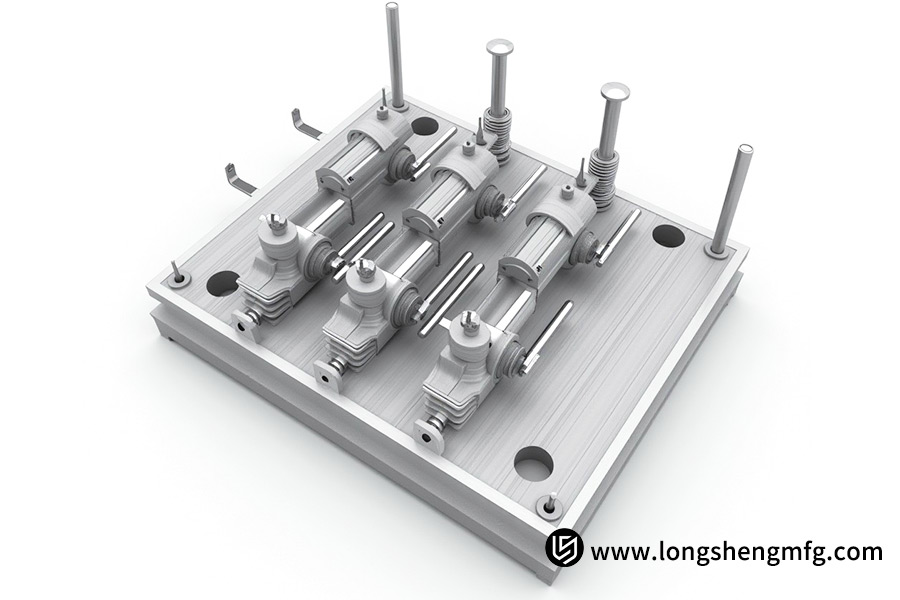

You might wonder how a cutting-edge injection molding quote is possible in a minute. The answer is LS Manufacturing, where decades of experience have been transformed into intelligent algorithms that set the standard for online injection molding services. When you upload 3D drawings, sophisticated cloud-based analysis begins immediately:

1. Intelligent geometric analysis lays the foundation for precision:

The system initially automatically and accurately determines your part’s most important physical parameters like volume, projected area, wall thickness distribution, and structural complexity. This step creates an solid foundation for all subsequent calculations in order to deliver objectivity and precision in your quote.

2. Multi-dimensional Factor Integration for Comprehensive Simulation:

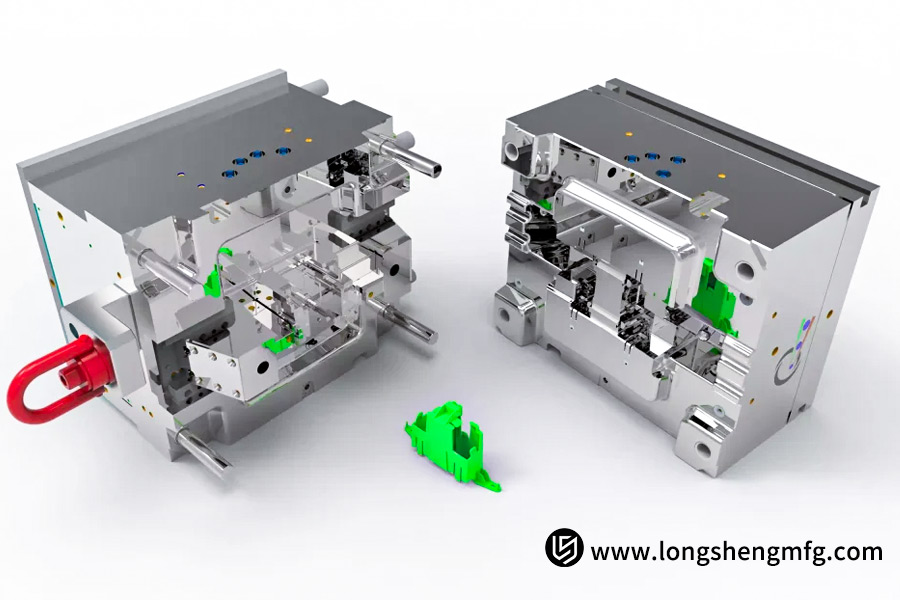

The platform then logically aggregates all pertinent online quotation drivers to complete a complete-cost simulation in the cloud. This encompasses more than material cost; it includes a holistic model with material cost (based on the resin selected and weight), mold cost (based on complexity and lifespan assessment), and process cost (approximate cycle time and power consumption).

3. Cloud-based Calculation in Seconds, Transparent Quote Output:

All the above calculations and analysis occur in real time in the cloud, ultimately presenting you with not only a cost but also an adequately decomposed and logically transparent cost split. This is to say that you can actually see where every penny is going.

The underlying philosophy of LS Manufacturing’s online injection molding service is to take extensive knowledge and know-how and make it a ridiculously simple and accessible user experience, so you can focus completely on product development and market strategy.

What Key Factors Determine The Final Price Of Your Injection Molded Part?

When you receive an injection molding quote, do you ever think about how it was created? Having an idea of what it is made up of isn’t just useful in terms of being able to redesign to meet your price, but also necessary to make a judgment regarding the professionalism and transparency of a quote. The final injection molding cost of your part is determined to a great extent by the next five basic online quote parameters, each of which is combined in the LS Manufacturing platform’s intelligent calculation model.

1. Part Design and Geometric Complexity:

This is the basis of cost. Part size, structural complexity, wall thickness uniformity, and aspects like deep cavities and undercuts have a direct bearing on mold difficulty and production costs. Good part design is the basis for controlling injection molding costs.

2. Material Selection:

Different engineering plastics (such as PP, ABS, PC, Nylon) have widely varying costs. Brand, grade, and special attributes such as flame retardant or reinforcement are among the largest injection molding price variables aside from part weight.

3. Mold Life and Number of Cavities:

This relates to mold investment allocation. Is it a simple mold that will be required to make 50,000 pieces, or a long-life hard mold that will operate in the millions? Also, the number of cavities within a mold will affect output per cycle directly and will be the determining factor for attaining the balance between unit cost and mold cost.

4. Production Batch:

Order size has a direct influence on injection molding costs. Mass production essentially distributes fixed expenses such as molds and startup, cutting unit costs dramatically. This is one of the critical parameters dynamically evaluated during the platform’s computations.

5. Post-processing and secondary operation requirements:

After being taken out from the injection molding machine, are gate trimming, painting, screen printing, ultrasonic welding, or assembly required? These secondary operations entail labor, time, and material consumption, and are included in the total cost.

To illustrate, the correlation of these variables is depicted in the table below:

| Core Factor | Major Cost Impact | Direction of Impact on Unit Price |

| Part Complexity | Mold Cost and Production Yield | Significantly Improved |

| Material Grade | Raw Material Cost | Increased Linearly |

| Mold Life/Number of Cavities | Mold Shared Cost | Originally Increased, Decreased in the Long Term |

| Production Batch | Fixed Cost Shared | Substantially Decreased |

| Post-processing Requirements | Secondary Operation Cost | Stepped-Increase |

LS Manufacturing’s real-time quoting tool has totally automated this complex evaluation process. Just upload your designs and select your needs, and the system will intelligently balance all online quote parameters to provide you with an open and professional injection mold cost, so you can make better decisions.

How Is The Accuracy Of Instant Quotes Guaranteed?

Faced with “one-minute quotes,” you will find yourself wondering: How can the rapid injection molding quote be accurate? Fear not, the instant injection molding prices presented by the LS Manufacturing platform are not guesstimates; they are precise outcomes based on a solid professional foundation.

1. Data-Driven Accurate Model:

The brain of our quotes isn’t some cold equation; instead, it’s a smart program with millions of instances of learning from our vast archive of historical manufacturing experience. This means the quotes you receive are derived from the experience and research of thousands of real, completed projects, so they track very well with actual market prices in the real world.

2. Continuous Optimization by an Expert Team:

This quote configuration is also updated by LS Manufacturing’s team of experienced injection molding engineers from time to time and is calibrated. They feed the system with up-to-date material prices, trends in processes, and production experience to keep all the online quote variables and calculation logic up to par with production conditions.

3. Transparent Pricing and Post-Production Guarantee:

We promise you clear pricing with no additional charge. To ensure your complete satisfaction, our qualified staff will undergo one final professional review of your drawings even after we’ve given you your instant quote.

In case a highly complex design results in a significant cost variation from the initial injection molding cost, we shall actively notify you to have this understanding in place prior to commencement of production so that all of your budget dollars are in your budget.

LS Success Story: How Did “Smart Home” Secure A Housing Supplier In Just 3 Days?

For a startup, one day of dawdling in the launch of a product might mean enormous losses in the market. In search of a housing supplier for its upcoming smart gateway, “Smart Home” found itself stuck in the vicious circle of traditional price queries.

1. Customer Pain Point:

“Smart Home” needed a gateway that had a complex structure and was custom-built to fit. They invited RFQs from five traditional suppliers, yet three of these did not make a response at all, and the other two responded after one week with unclear quote ranges and lack of cost transparency. This inefficiency and lack of transparency paralyzed the decision-making and project advancement of the project team.

2. LS Manufacturing Solution:

Once they became aware of LS Manufacturing’s injection molding service online, they were willing to give it a try:

- Upon submitting a 3D drawing of the gateway housing to its website, the system produced a detailed price report for the injection molding within one minute, with clear prices on major expenses such as materials and molds.

- The open quote gave them the decision-making framework the moment they saw it. They immediately finalized production specifications with the responsive LS sales engineer and successfully placed the order.

3. Results and Value:

Total process from the initial order request to the final supplier selection and order placement took just three days. This not only significantly cut time to market, but open-book injection molding pricing also provided even greater budget control for “smart homes.” Customers appreciated immensely the revolutionary efficiency and end-to-end visibility created by LS Manufacturing.

You too can make decisions as quickly as your “the Smart Home team did”! Contact LS Manufacturing today and upload your 3D drawings to get your own, transparent, instant quote.

Beyond Price, What Other Insights Can A Quote Platform Provide?

Do you think that an online quote website is merely a price calculator? At LS Manufacturing, our website does much more. Besides generating transparent injection molding prices, it also functions as a “design consultant,” providing you with important insights from the initial stage of your customized injection molding manufacturing process.

1. Early Warning of Design Risks:

With built-in DFM (Design for Manufacturability) analysis logic, the system automatically detects design risks that could influence production and costs when it analyzes your 3D designs.

- It alerts you to ensure uniform wall thickness to avoid sink marks or warpage;

- It also checks whether draft angles are appropriate in order to make demolding of parts simple and not cause mold damage.

2. Provides Optimization Directions to Control Costs at the Source:

These observations do more than just point out problems. They directly guide you towards optimizing design so you don’t fall into traps that would cause decreased yields, longer cycle times, or convoluted mold designs prior to production. This basically saves you the extra time and capital spent on downstream design changes.

LS Manufacturing Platform is your first professional reviewer of your product design, so you’re able to control cost at the source. We always provide the best injection molding quotes to our customers.

Are The Drawings Secure? How Is Your Intellectual Property Protected?

When you send core injection molding part design drawings to any website, you can worry sick about their safety. We realize that your design drawings are the beating heart of your valuable intellectual property. Security does not come as an add-on at LS Manufacturing; it comes as a matter of course. We solemnly pledge:

1. Bank-grade data encryption to prevent technical leaks:

The instant you upload your drawings, all information is being transmitted and saved using bank-grade SSL encryption technology. This makes your injection molded part design files encrypted and protected throughout the process so that third-party theft and snooping are no longer possible, thereby your technical confidentiality is completely protected.

2. Strict Non-Disclosure Agreement (NDA) and Rights Management:

We fully acknowledge and respect your the importance of intellectual property. In addition to technical warrants, we support and strongly recommend signing a legally binding Non-Disclosure Agreement (NDA). We also have stringent employee data access rights management to ensure that your design information is only allowed access by the project team and all operations are traceable.

Your designs and original concepts receive not only professional manufacturing but also utmost intellectual property security at LS Manufacturing. Share confidently and initiate our transparent and secure collaboration.

After Receiving A Quote, How Can I Proceed With My Collaboration With LS Manufacturing?

The moment we provide you with an instant quote on our website, you’ve taken your first effective step toward your bespoke injection molding project. LS Manufacturing provides a clear and flexible collaboration process to ensure a seamless transition from inquiry to production:

1. One-click ordering for a quick start:

If you are satisfied with the quote and your design is fully done, you can order straight away on our web-based injection molding service platform. The system automatically locks pricing and manufacturing time, and your project will be added to production scheduling for earliest possible start.

2. In-depth communication and dedicated support:

If you’d like to discuss quote information, material selections, or process selections in depth, select “Contact Customer Service” and a member of our dedicated sales engineers will respond promptly. They will provide expert advice and tailor the best solution for your specific injection molding production needs.

3. Professional collaboration for design optimization:

For more sophisticated projects with greater specifications, we strongly recommend advancing into the “Comprehensive Design, Function, and (DFM) Analysis” phase. You may ask our team of experienced engineers to prepare a detailed design for manufacturability report and give you professional improvement suggestions so you can further enhance your product quality as well as better optimize total cost.

A quote is our initial step of working together. We look forward to helping you from design to completion! Wherever you choose to go, LS Manufacturing is your trusted manufacturing partner.

FAQs

1. What 3D file formats are supported for upload?

Our platform is completely compatible with standard 3D formats such as STP, STEP, IGS, and X_T. These modes fully preserve your design’s geometric properties and product structure data, allowing our intelligent system to automatically and accurately identify and measure key parameters (such as volume and projected area), providing you with a reliable costing guide. Upload with confidence; accuracy and security of data are our top concern.

2. What specific costs are included in the quote?

Your first quote is transparent and open, consisting of two main components: the mold cost, scientifically segmented based on assumed quantity of production; and the total unit price for a single injection-molded item (machine time, raw materials, and basic post-processing). We strive to provide you with an open view of each injection molding cost, allowing you to accurately budget your project without any hidden charges.

3. Does the quote apply to any order quantity?

Yes, our system is very flexible. If you are just looking for a small pilot build for market testing or big runs of production, simply enter your planned quantity when you quote. Our intelligent system automatically considers economies of scale and instantly calculates the optimum injection moulding price for that run so that you are getting maximum cost-effectiveness for each order.

4. If my design needs to be modified, will this affect the quote?

Certainly. Any design change, no matter how minor, can have a direct impact on mold complexity, material use, and even production cycle time. That is the greatest advantage of our online quote system, simply re-upload your new 3D file, and the system will generate a new, accurate, instantaneous quote from the new design in one minute. This allows simultaneous cost analysis and design optimization, which is simple and efficient.

Conclusion

The LS Manufacturing web-based quoting system completely eliminates the pain points of traditional injection molding quoting in a revolutionary digital process. We deliver on our promise of “speed” with one-minute instantaneous quotes, offer “transparent” pricing with an open-book cost structure, ensure “accuracy” and reliability with data-driven smart models, and secure your design “security” with bank-grade encryption and NDA agreements.

These four core advantages collectively create a fast path from concept to product, significantly accelerating your project development and lowering injection molding costs to historic levels.

Don’t let the frustration of time-consuming RFQ processes slow you down! Contact us and upload your 3D models now and experience the digital injection molding manufacturing revolution for yourself. Trust us with your concepts and let us transform them into reality in an instant.

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.