Colored Zinc Plating Service

We can choose different colors and effects according to needs, making the product have good aesthetics and adapt to different designs and uses.

Colored Zinc Plating Specifications

| Project | Info |

|---|---|

| Applied materials | Cold rolled steel, hot rolled steel, iron plate |

| Color coating type | Polyester, Polyurethane, PVDF |

| Colors | Yellow, gold, clear, blue, black, green, RAL color card or custom colors |

| Galvanized layer thickness | 20-50µm |

| Coating thickness | 5-15µm |

| Texture | Bright, matte |

| Corrosion resistance | Comply with ASTM, ISO, or customer specifications |

| Application industry | Buildings, automotive parts, household appliances, billboards, etc |

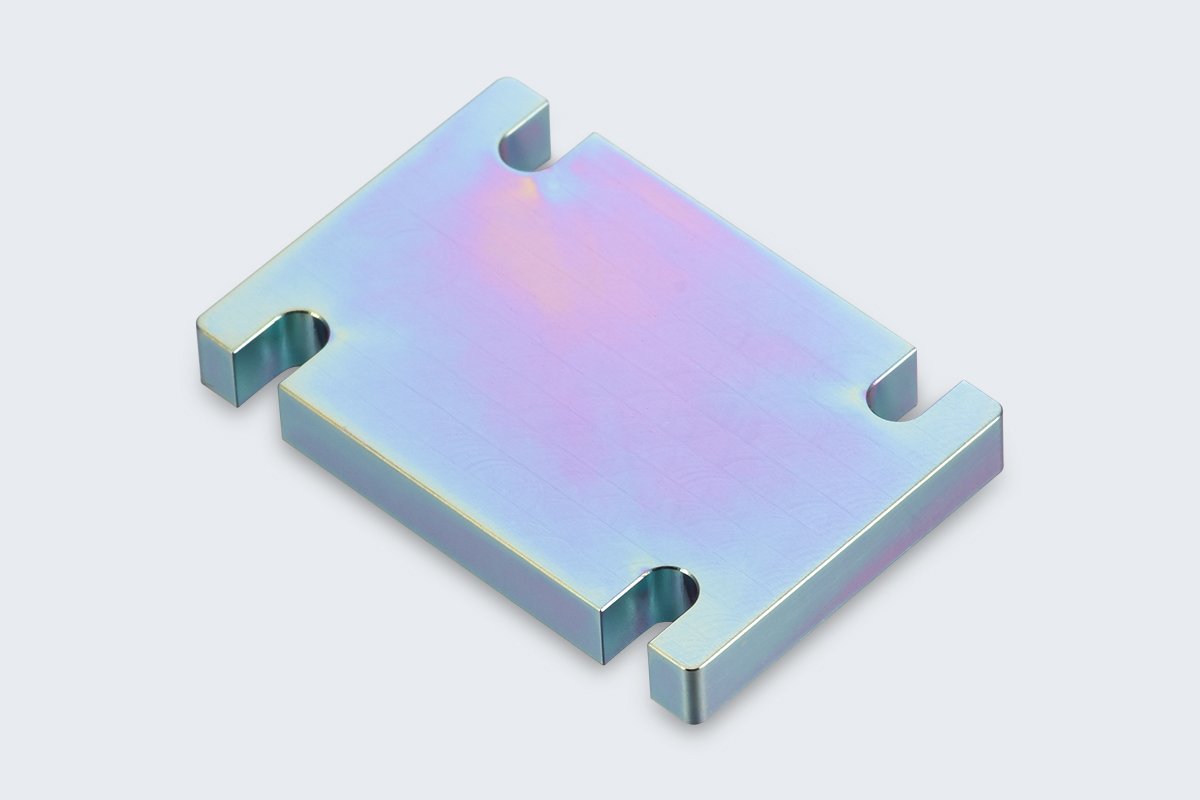

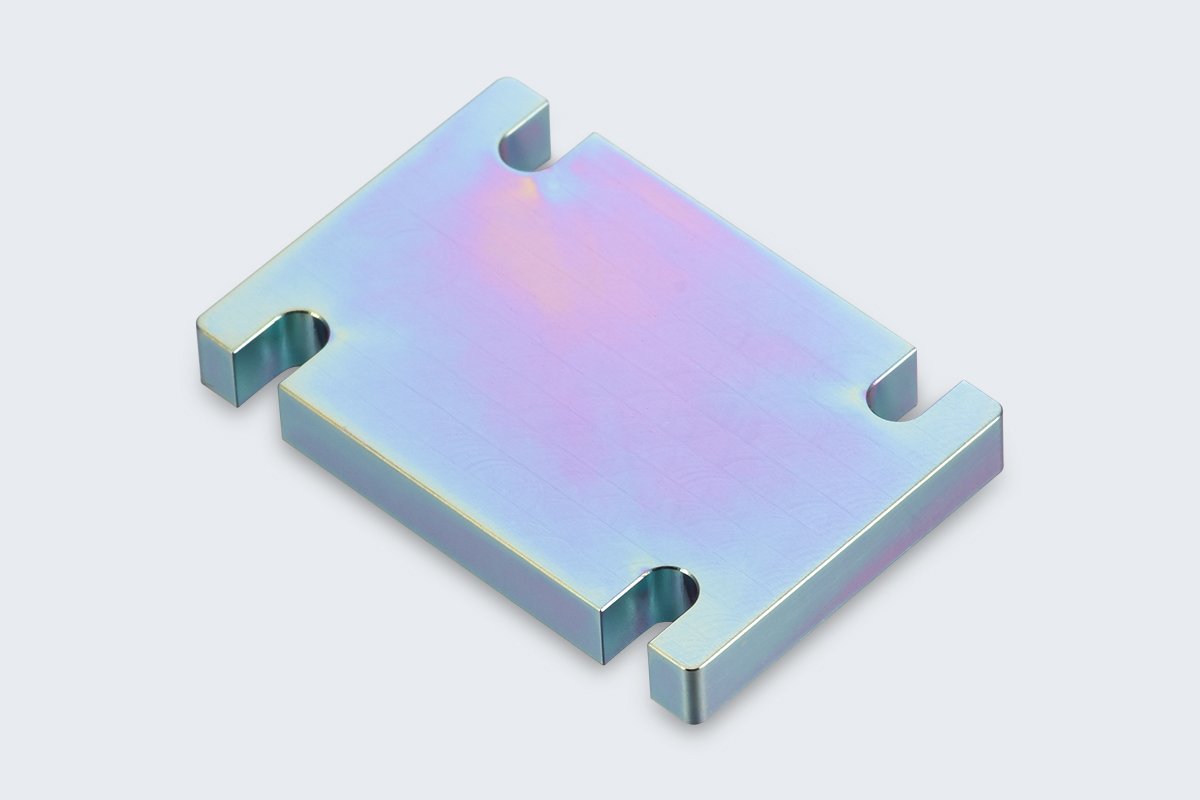

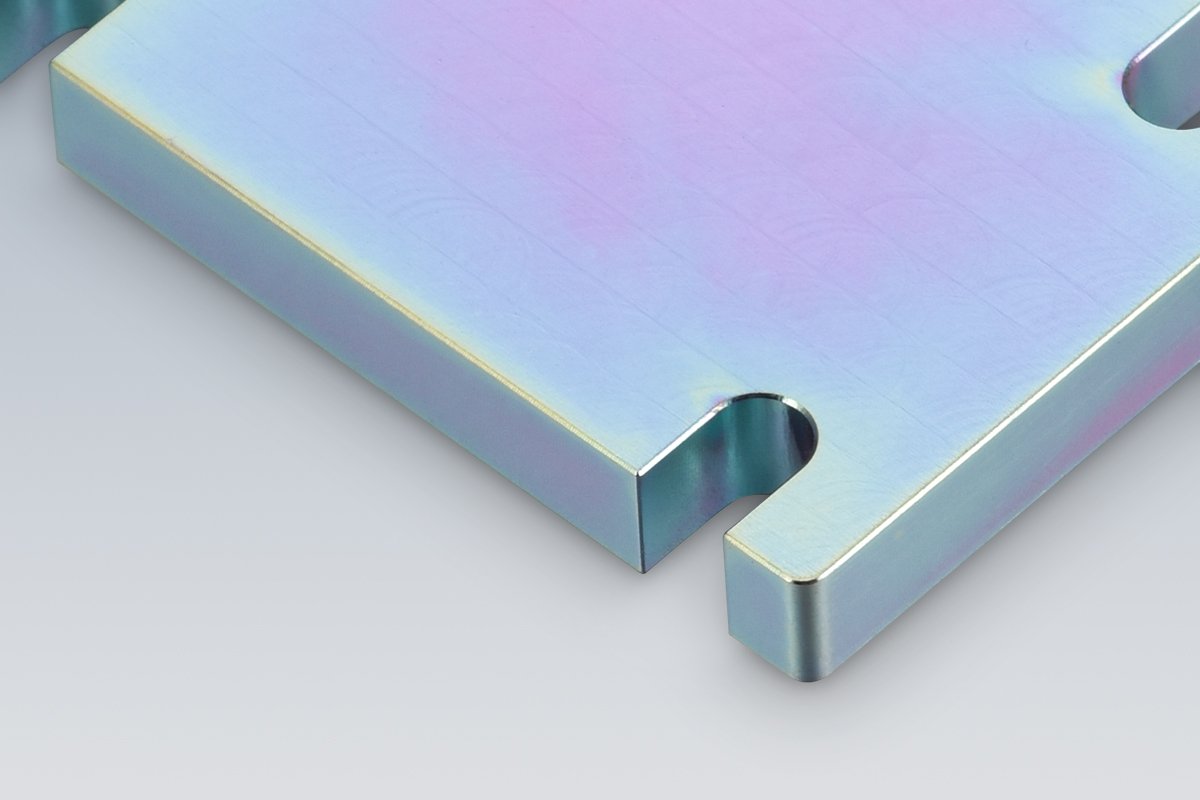

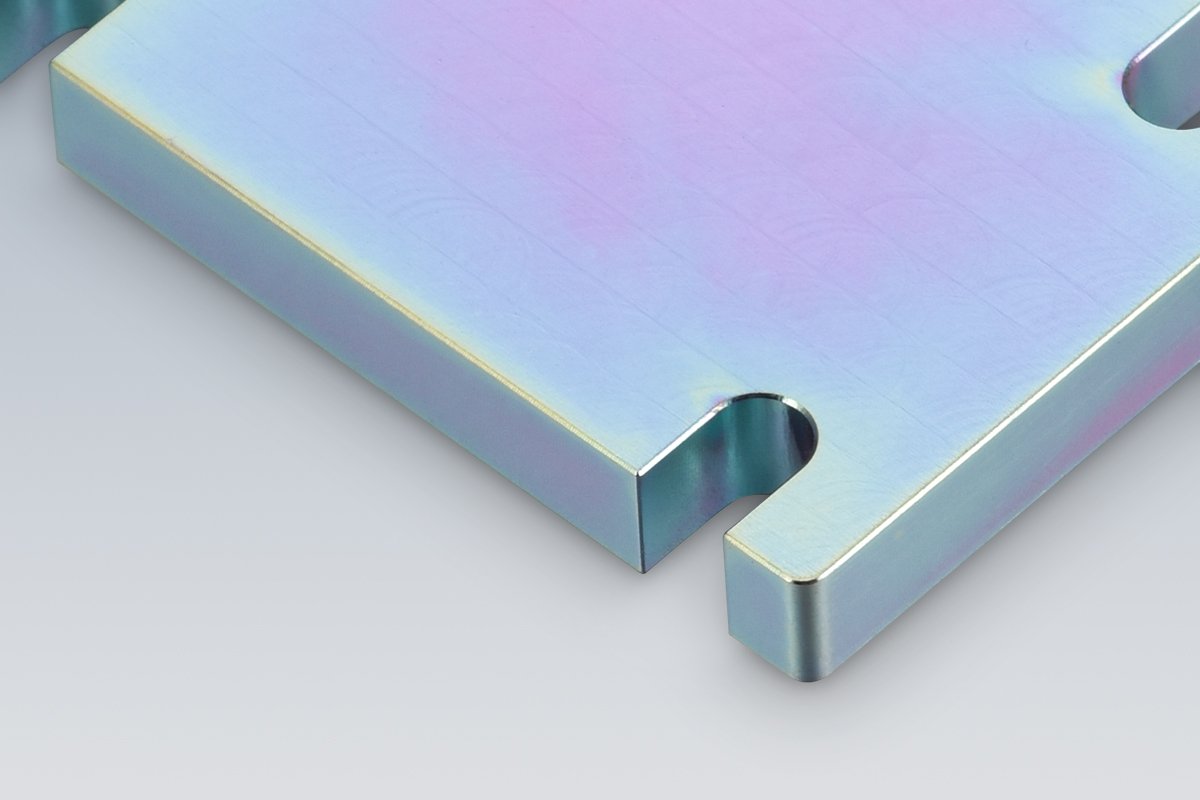

Example Of A Colored Zinc Plating Parts

About Colored Zinc Plating

Color zinc plating , which is also known as color galvanization, color zinc plating is a process of zinc plating metal parts and covering them with a layer of color coating. This process combines zinc plating and color coating, with dual functions of corrosion prevention and decoration.

Usually, color zinc plating adopts the process of hot dip galvanizing, which is a method of immersing metal parts into molten zinc to form a uniform zinc coating. Then, different colors can be achieved by applying different coatings or pigments to the zinc coating. These pigments can be powder coatings, liquid coatings, or other types of pigments.

Put your parts into production today

- All information and uploads are secure and confidential.