Vapor Polishing Services

Steam polishing gives your plastic parts a smoother, optically clearer surface and high transparency.

Vapor Polishing Specifications

| Project | Info |

|---|---|

| Applicable materials | Polycarbonate (PC), Acrylic, ABS, Nylon |

| Colors | Clear |

| Texture | Smooth and glossy |

| Thickness | 10μm to 80μm |

| Surface finish | Ra < 0.2 |

| Pressure range | 0.5 - 2.0 bar |

| Temperature range | 40-60°C |

| Surface bubble | No bubbles, no blemishes |

| Process time | 30 minutes |

| Applications | Remove small scratches, enhance transparency, and reduce surface friction |

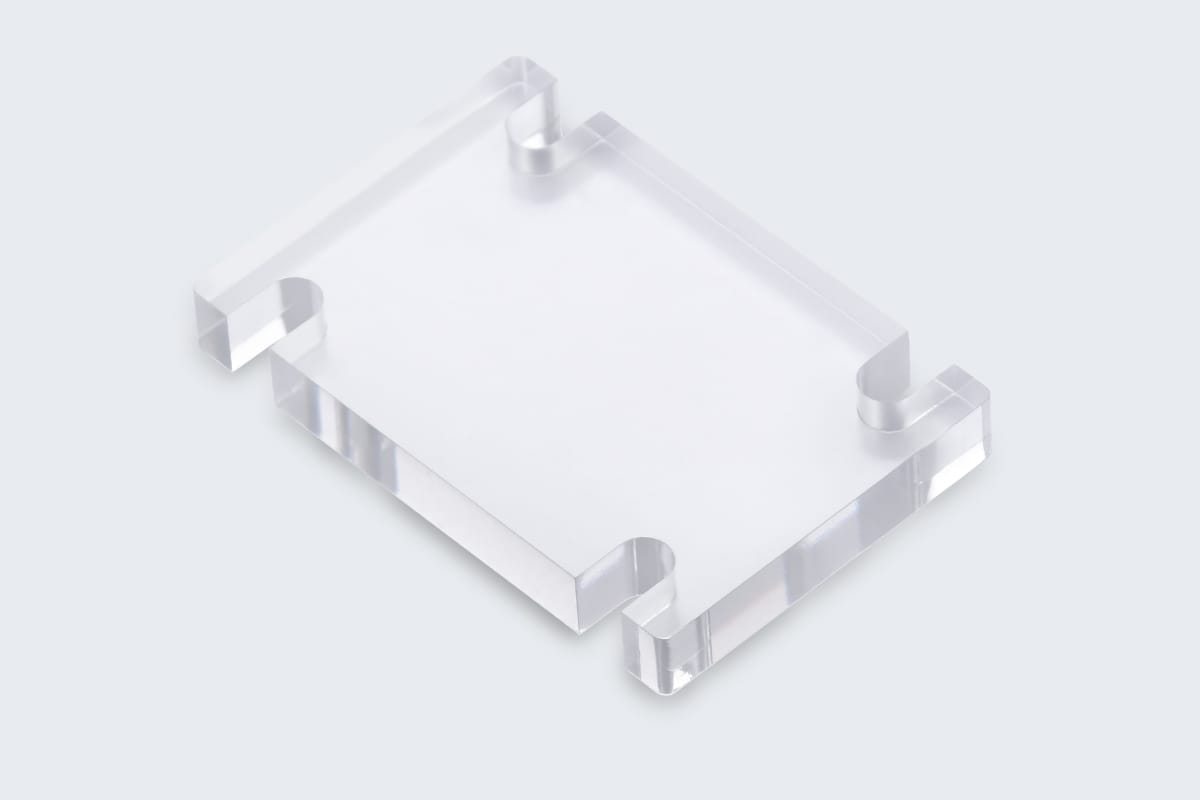

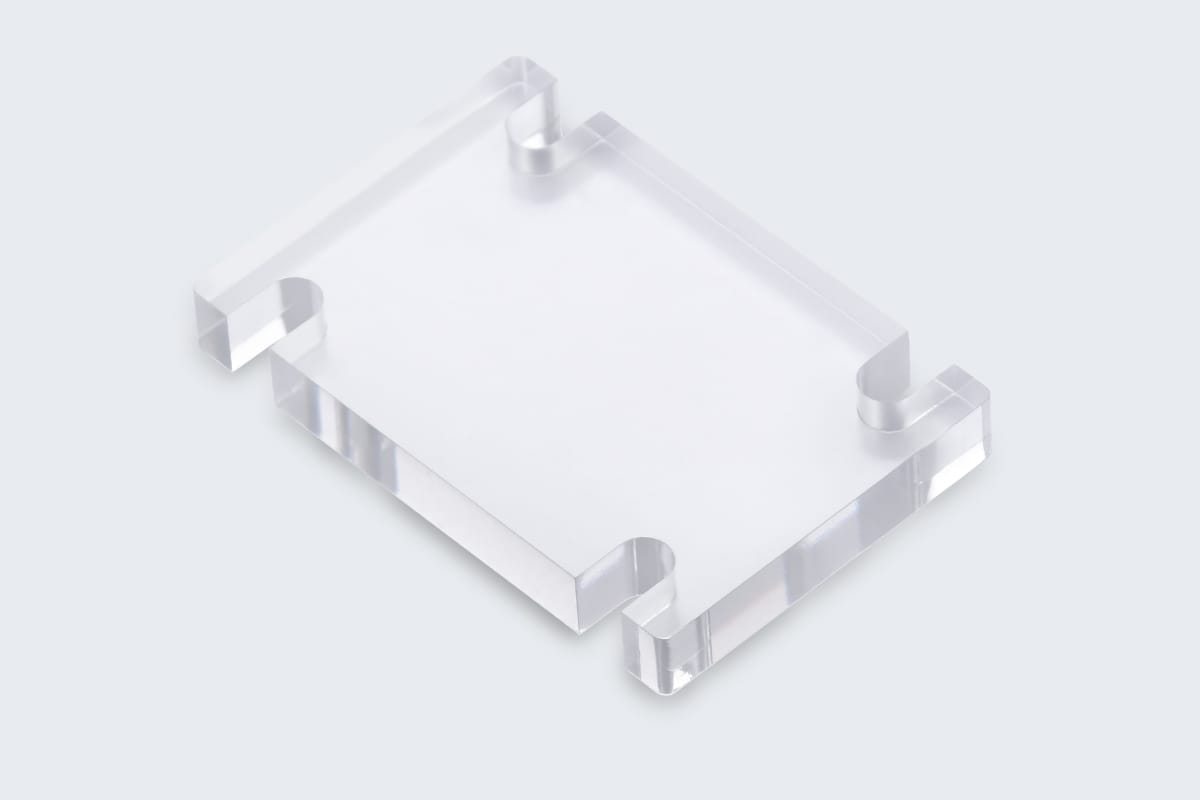

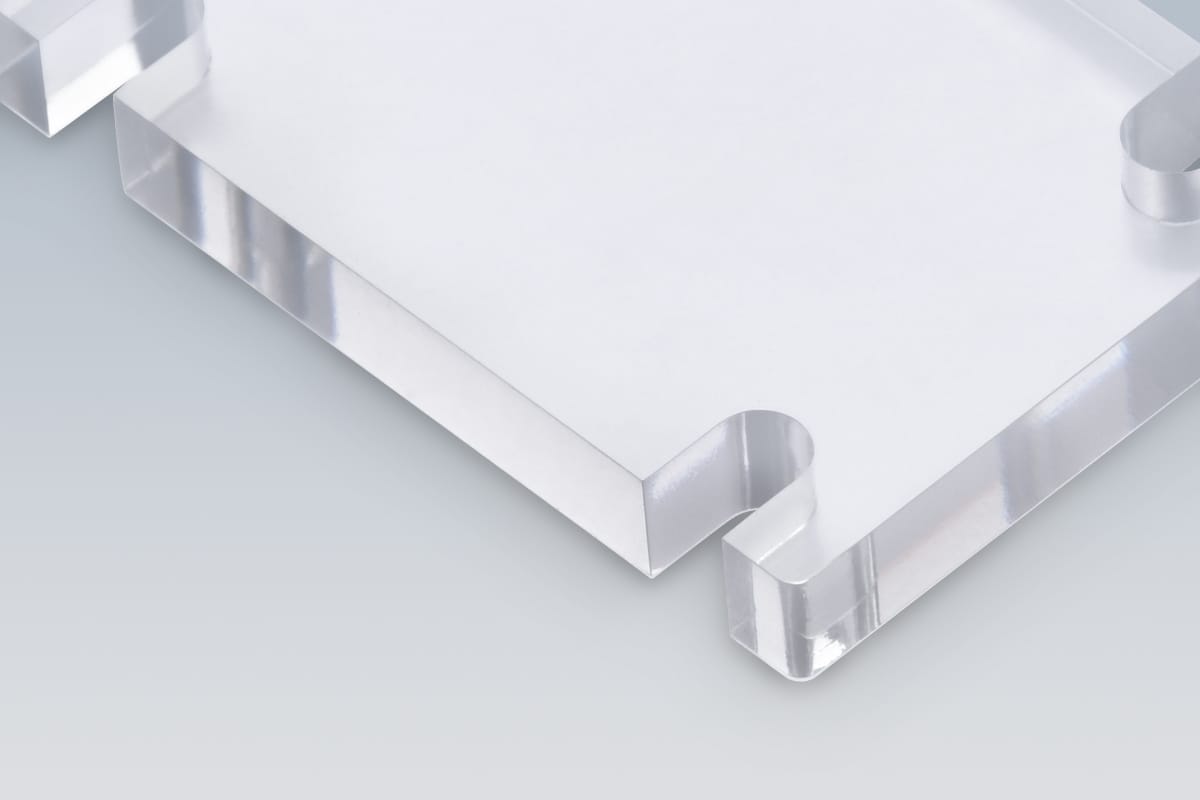

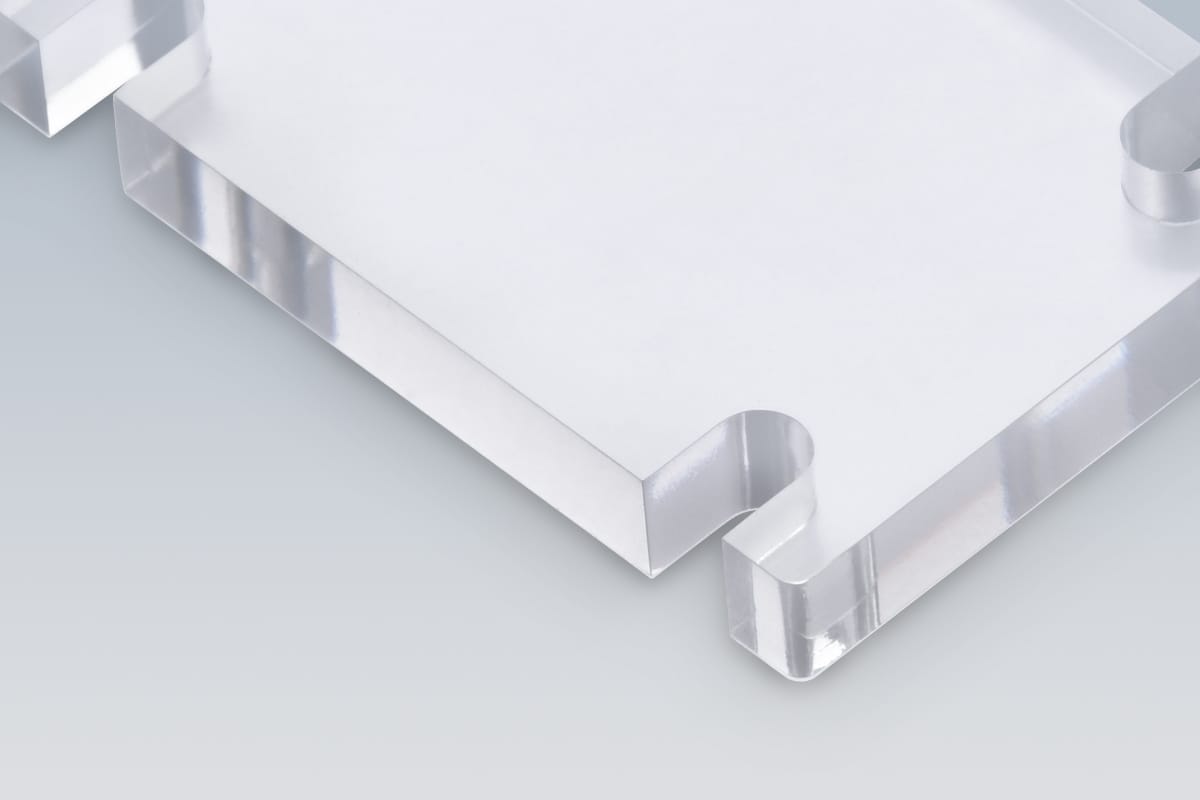

Example Of A Vapor Polishing Parts

About Vapor Polishing

Vapor polishing is a surface finishing technique used primarily with thermoplastic materials, such as acrylics (PMMA), to achieve a smooth and glossy finish on their surfaces. It is a chemical process that involves exposing the plastic part to vaporized solvent or a specific chemical mixture, allowing the surface to become slightly molten. As the plastic re-solidifies, it forms a smooth and clear surface.

Vapor polishing is often used in applications where a highly polished and transparent surface is desired, such as in the production of optical components, displays, signage, and various acrylic-based products. It is an effective way to improve the visual appeal of plastic parts and can be particularly useful for removing the “frosty” appearance that may occur during machining or laser cutting of acrylics.

Latest Blog Posts

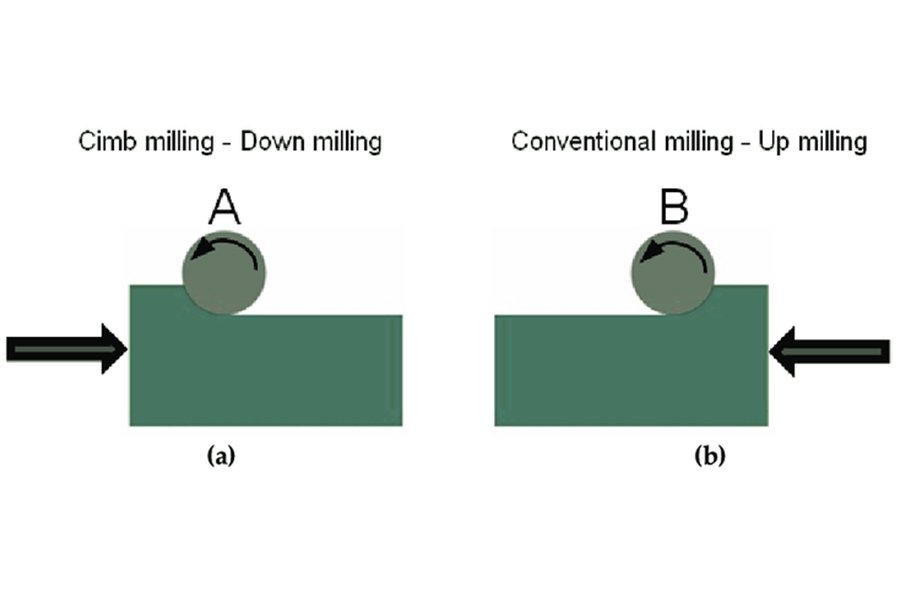

Climb Milling vs. Conventional Milling: A Battle for Manufacturing Precision

Resin Vs. Plastic: Understanding The Core Differences For Better Material Selection

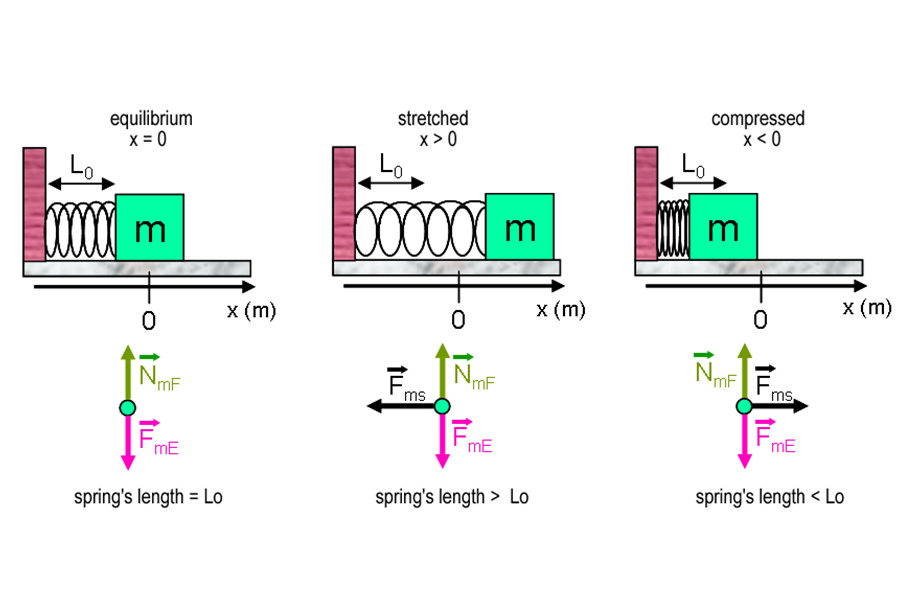

How Do Mechanical Springs Store Energy?

Put your parts into production today

- All information and uploads are secure and confidential.