In today’s manufacturing industry, whether it is auto parts, aerospace devices, or medical devices, it is inseparable from the exquisite technology of CNC machining. In the field of CNC machining, there are three unique terms: 3-axis, 4-axis and 5-axis. They represent different dimensions of machining ability, just like a trio in music, each playing a unique advantage.

In this article, we will delve into the differences and advantages of 3-axis, 4-axis and 5-axis CNC machining. Through the analysis of this article, you will have a deeper understanding of CNC machining technology, and can make a more informed choice for your machining needs.

Introduction to 3-axis CNC machining

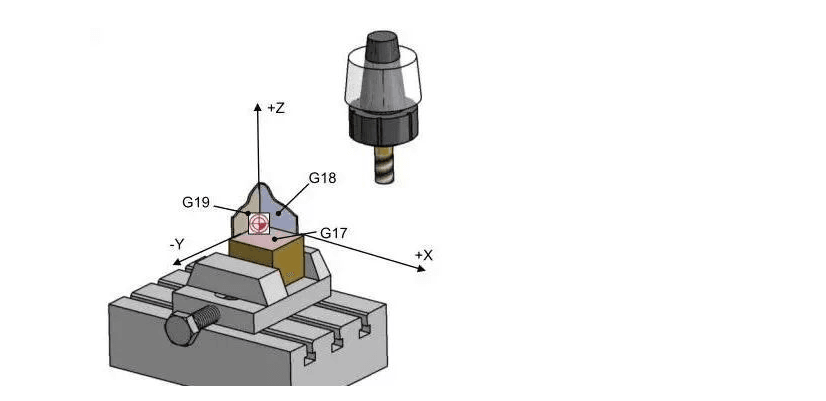

3-axis cnc machining is one of the most popular and widely used machining processes. In 3-axis machining, the workpiece remains fixed and the rotary tool cuts along the x, y, and z axes. This is a relatively simple form of CNC machining, suitable for the machining of flat and simple surfaces, such as sheet metal parts and simple three-dimensional parts.

Since cutting can only be done on three axes, the machining speed may also be slower than a four – or five-axis CNC, as the workpiece may need to be manually repositioned to obtain the desired shape.

Introduction to 4-axis CNC machining

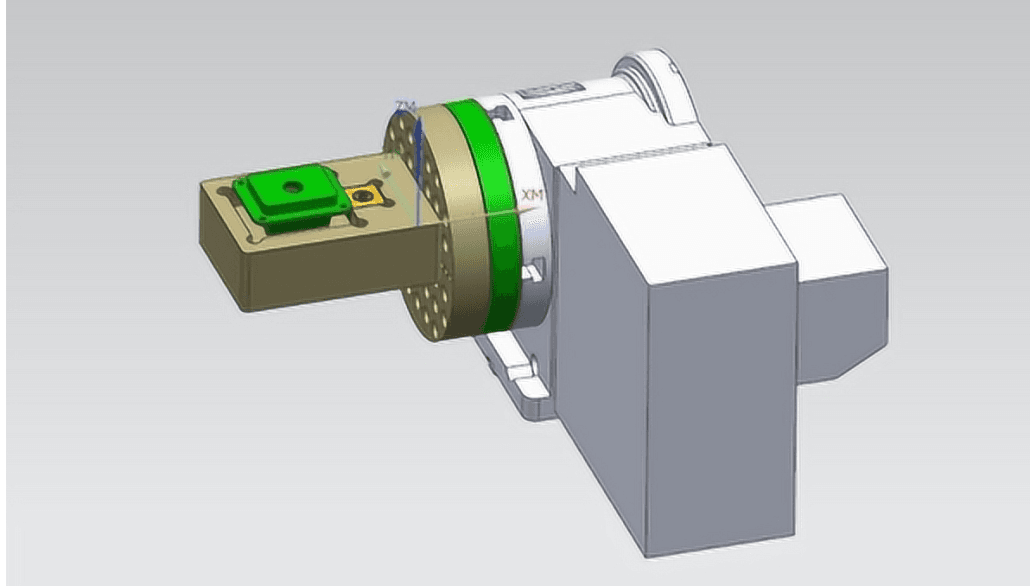

In 4-axis CNC milling, a fourth axis is added to the motion of the cutting tool, allowing rotation around the X-axis. There are now four axes – the x axis, the y axis, the z axis and the a axis (rotating about the x axis). Most 4-axis CNC machines also allow the workpiece to rotate, which is called the B-axis, so that the machine can act as both a milling machine and a lathe.

If you need to drill into the side of a part or the curved surface of a cylinder, especially those parts that need to be machined at different angles, 4-axis CNC machining is the way to go. It is more flexible than 3-axis CNC machining and can handle some more complex curved surface structures.

Introduction to 5-axis CNC machining

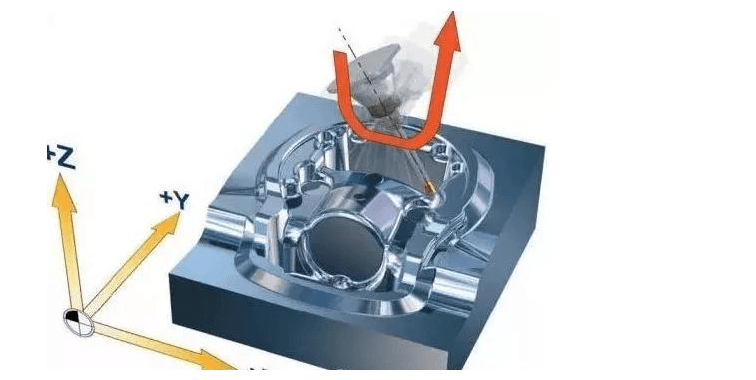

5-axis CNC machining has an additional rotating axis compared to 4-axis CNC. The fifth axis is rotation around the Y-axis, also known as the B-axis.

5-axis machining by the feed axis X, Y, Z and about X, Y, Z rotation axis A, B, C in any of the linear interpolation motion. The Siemens motion conversion instruction TRAORI supports 5-axis conversion well.

There are two kinds of 5-axis CNC machining on the market. 3+2 axis machining and continuous 5 axis machining. Both operate on all planes, but the former has the same limitations and operating principles as the indexing 4-axis machine.

The method of 3+2 axis machining is that the cutting tool is fixed at an inclined position by two rotating axes, and then processed by the feed axes X, Y and Z. The machine, also known as a positioning five-axis machine, can be programmed using Siemens’ CYCLE800 function.

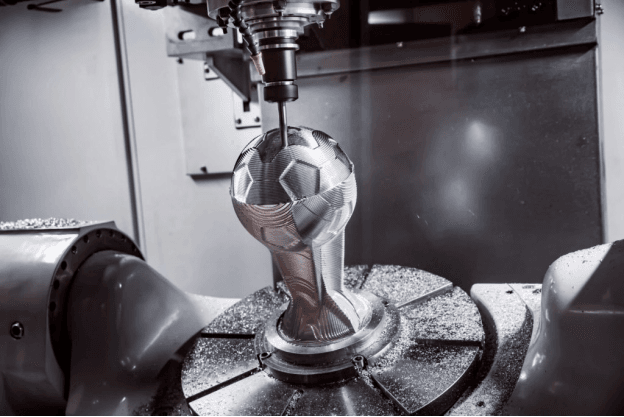

5-axis CNC machining is widely used in aerospace, automotive, mold and other industries, can process very complex curved structures, with high precision and high efficiency advantages.

3 Axis, 4 Axis, 5 Axis CNC Machining Difference

It is important to understand the main differences between 3-axis, 4-axis and 5-axis machining. Doing so ensures that the best machine is selected for any particular project without any impact on the basic quality parameters. Here are the 3 main differences between various CNC machining.

1.Precision and complexity

Precision and tolerance are very important in CNC machining. Although 3-axis CNC is already very accurate, because it can only move in X, Y, and Z three directions, it performs well for some simple plane or simple surface machining tasks, so the possibility of random errors is greater. For most applications, the machining accuracy can usually meet the requirements of general industrial manufacturing. However, for sensitive applications related to aerospace and automotive applications, even the smallest deviation can cause problems.

4-axis and 5-axis CNC machining adds a rotating axis compared to 3-axis machining, enabling more complex and precise curved structures to be machined, which allow cutting on multiple planes on a single fixture. In addition, it is worth noting that this is also the only source of quality differences in 3-axis machining. Other than that, the overall quality in terms of precision and accuracy remains the same.

2.Production efficiency

All CNC machining works on the same principle. Use M code or G code to interpret the motion of the tool with respect to the workpiece.

However, with the increase of the number of axes, the production efficiency of CNC machining has been improved. For simple parts, 3-axis CNC machining may be sufficient to meet the requirements, but when dealing with complex parts, 4-axis and 5-axis CNC machining can significantly improve production efficiency.

3.machining cost

The development cost and operation programming of cnc machine tools are different, while the cost of 4-axis and 5-axis CNC machining increases correspondingly due to the addition of more complex machining capabilities and technical requirements.

For asymmetric complex parts, or parts requiring high precision and high efficiency, 5-axis CNC machining is a better choice.

How to choose 3-axis, 4-axis and 5-axis CNC machining

In manufacturing, there is no absolute better way or one-size-fits-all solution. The right process selection depends on the complexity of the project, overall budget, time and quality requirements.

3 axis, 4 axis, 5 axis, each has advantages and disadvantages. Of course, if it is a relatively simple flat or shallow surface machining, 3-axis CNC machining may be enough. For complex parts that need to be machined in multiple directions, 4-axis or 5-axis CNC machining will be more suitable.

To sum up, there is no answer to the question which is the better choice. With the continuous advancement of digitalization and intelligence in the manufacturing industry, CNC machining technology will also continue to develop. In the future, CNC machining equipment will be more intelligent and able to automatically adjust parameters and tools to achieve a more efficient machining process.

conclusion

3-axis, 4-axis and 5-axis CNC machining methods have their unique application advantages in the machining field. According to the specific workpiece requirements and machining complexity, choosing the right CNC machining method will help to improve production efficiency and product quality.