cnc machining of metals is a highly automated method for the production of metal parts of various shapes and sizes. After years of development and practice, metal cnc machining technology has gradually formed its own variety of processes, in different production environments, there are different applications.

This article will introduce 8 common metal CNC machining processes to help you understand the process and technology of metal CNC machining, and choose your own processing method

Metal CNC machining: overview

CNC machines in metal processing have a variety of functions, such as gearboxes, to make metal cutting more precise, accurate and efficient. With CNC technology, you can digitize your designs and upload them to your computer. The computer can read your digital design data and control the machining tools to achieve high-precision cutting and engraving of metal.

Compared with traditional machining methods, this method has higher precision and efficiency, and reduces the influence of human factors on machining quality. The use of CNC machining to produce complex parts in industrial production can greatly reduce labor and time costs. precision CNC machining of metal has higher accuracy than manual operation, because it can quickly determine the path and depth of the tool, and guarantee the high precision and high quality of the product.

8 common metal cNC machining process

一、Laser machining

二、Turning machining

三、Milling machining

四、Electric discharge machining

五、Wire-cut machining

六、Stamping machining

七、Drilling machining

八、Grinding machining

1.Laser machining

Laser machining is a technology that uses laser cutting tools to process materials into the desired shape. In general, laser processing is often used in the cutting of thin metal sheets. In addition, laser processing can also be used to create patterns, text and logos on the surface of objects. Laser processing has extremely high accuracy and speed, but also has excellent accuracy and repeatability.

2.turning machining

Turning is the process of using a tool on a rotating workpiece. This method is often used to make shaft and cylindrical materials. Turning is considered one of the best techniques for manufacturing high-precision parts and is often used to manufacture machine parts that require high precision.

3.milling machining

Milling is a process widely used in CNC machining of metals. It works by firmly fixing the workpiece to the workbench and removing the material by rotating the milling cutter, so that the workpiece gets the desired shape. Milling can be applied to materials of different shapes, from flat simple shapes to workpieces with complex geometries.

4.Electric discharge machining

Electrical discharge machining (EDM) is a process of cutting by means of discharge generated by high frequency voltage. This method is often used to manufacture high-precision, complex workpieces. It can cut materials of various shapes and can change the shape or size of the material without damaging the surface of the material.

5.wire-cut machining

Wire cutting is a method of material cutting using a process of electric spark discharge. Unlike EDM, wire cutting uses live metal wires for cutting. It is generally used for cutting metal plates or thicker metal parts.

6.stamping machining

The stamping process is a method used to cut metal materials to the desired shape. During the stamping process, the metal plate is sandwiched between two rubber pads and machined using a stamping die suitable for the desired shape. This technique is often used to mass produce parts of the same shape.

7.drilling machining

Drilling is a process of making holes by moving a bit or drill over a workpiece along a predetermined path. This method is suitable for cutting holes of all shapes and depths, including through holes, blind holes and local holes.

8.grinding machining

Grinding is a process of cutting the surface of a workpiece by using abrasive tools. A very fine, smooth surface can be produced using this method. Grinding is often used to manufacture parts that require high precision and higher surface quality requirements.

conclusion

The following are 8 common processes in metal CNC machining. Different processing methods are suitable for different types of metal processing, and you can choose according to your needs. You can learn more about these processing methods in detail. At Longsheng Technology, we offer a variety of metal CNC machining technology. Please upload your design file and let us provide efficient, accurate and reliable processing services for your products.

Mobile:+86 185 6675 9667(Gloria Wu)

E-Mail:gloria.wu@longshengmfg.com

Characteristics of metal cnc machining materials

| material | density (g/cm³) | strength (MPa) | hardness (HRC) | melting point (°C) | Thermal expansion coefficient (10^-6/°C) |

|---|---|---|---|---|---|

| aluminium alloy | 2.7 – 2.9 | 100 – 500 | 20 – 70 | 580 – 660 | 23 – 24 |

| stainless steel | 7.7 – 8.0 | 500 – 2000 | 20 – 50 | 1400 – 1500 | 16 – 17 |

| carbon steel | 7.8 – 7.9 | 400 – 1000 | 20 – 50 | 1420 – 1510 | 12 – 14 |

| copper alloy | 8.4 – 9.0 | 200 – 600 | 40 – 90 | 1080 – 1100 | 16 – 18 |

| ferroalloy | 6.9 – 7.9 | 200 – 1000 | 20 – 60 | 1370 – 1530 | 10 – 14 |

| nickel alloy | 8.2 – 8.9 | 400 – 900 | 20 – 40 | 1310 – 1390 | 12 – 14 |

| titanium alloy | 4.4 – 4.5 | 800 – 1000 | 30 – 40 | 1660 | 8.6 – 9.4 |

| Lead alloy | 11.3 | 5 – 20 | 5 – 20 | 327 | 28 – 30 |

Application of metal CNC machining

Metal CNC machining is widely used in various industries and fields. The following are some common metal CNC machining application cases:

Manufacturing: Metal CNC machining is used to manufacture a variety of parts and components, including machinery parts, molds, tools and equipment components.

Aerospace industry :uses metal CNC machining to manufacture aircraft engine parts, aircraft structural parts and spacecraft parts, which need to have high precision, high strength and high temperature resistance.

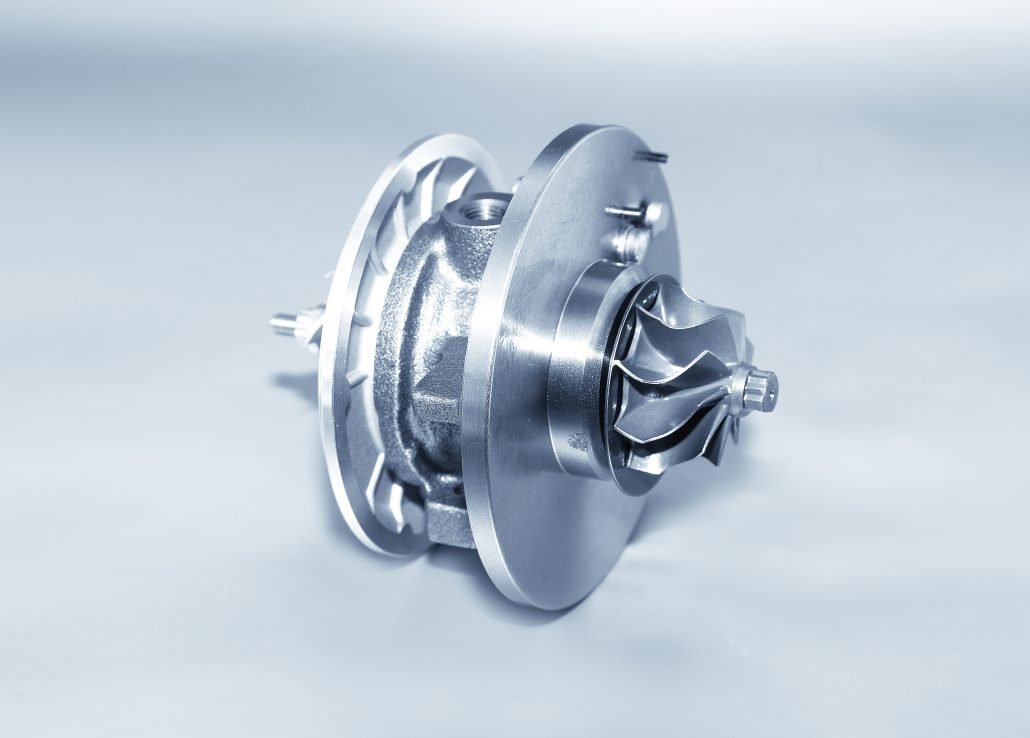

Automotive industry:metal CNC machining is widely used in the manufacture of vehicle engine parts, transmission systems, chassis components and body structures, the purpose of which is to improve the performance, accuracy and durability of the vehicle.

Medical equipment:Metal CNC machining is widely used in the manufacture of medical devices, such as artificial joints, bone plates and implants. These devices require high accuracy, surface smoothness and biocompatibility.

Energy industry:metal CNC machining is widely used to manufacture energy equipment and components, such as gas turbine blades, generator parts and oil drilling equipment.

Electronics industry: Metal CNC machining is used to manufacture electronic equipment shells, radiators, connectors and connectors, as well as metal parts on high-precision circuit boards.

Metal cnc machining surface finishing options

| Surface Finishing Option | Texture | Characteristics | Color | Suitable Materials |

|---|---|---|---|---|

| Polishing | Smooth, glossy | Improves surface smoothness, removes scratches and defects | Natural | Various metal materials (e.g., aluminum, stainless steel, copper) |

| Sandblasting | Uniform sand grain or matte | Creates a uniform sand grain pattern on the metal surface, adds visual texture and slip resistance | Natural | Various metal materials (e.g., aluminum, stainless steel, titanium) |

| Anodizing | Uniform oxide layer | Increases surface hardness and corrosion resistance, provides wear resistance, heat resistance, and insulation | Multiple colors | Aluminum alloy |

| Plating | Bright, coating | Provides corrosion resistance, wear resistance, and decorative effects | Multiple colors | Copper, nickel, chromium, gold, and other metals |

| Painting | Smooth, colored coating | Provides decorative effects, enhances corrosion resistance and wear resistance | Multiple colors | Various metal materials (e.g., steel, aluminum) |

| Oxidizing | Uniform oxide layer | Provides a natural, rustic appearance, increases corrosion resistance | Dark brown | Copper, copper alloys |

| Bead Blasting | Uniform matte | Increases surface roughness, improves adhesion and decorative effects | Natural | Various metal materials (e.g., aluminum, stainless steel, titanium) |

| Chemical Etching | Textured surface | Forms patterned or textured areas on the metal surface through chemical corrosion | Natural | Stainless steel, copper, aluminum, and other metals |

Metal parts quote online

Longsheng Technology can provide a variety of metal CNC machining materials, in addition to other materials not listed above can also be provided. If you have any material needs, please contact us immediately and we will discuss and start your project together. Please upload your design file, we will arrange the metal CNC machining quotation today, and our team will reply you within 24 hours.

Mobile:+86 185 6675 9667(Gloria Wu)

E-Mail:gloria.wu@longshengmfg.com