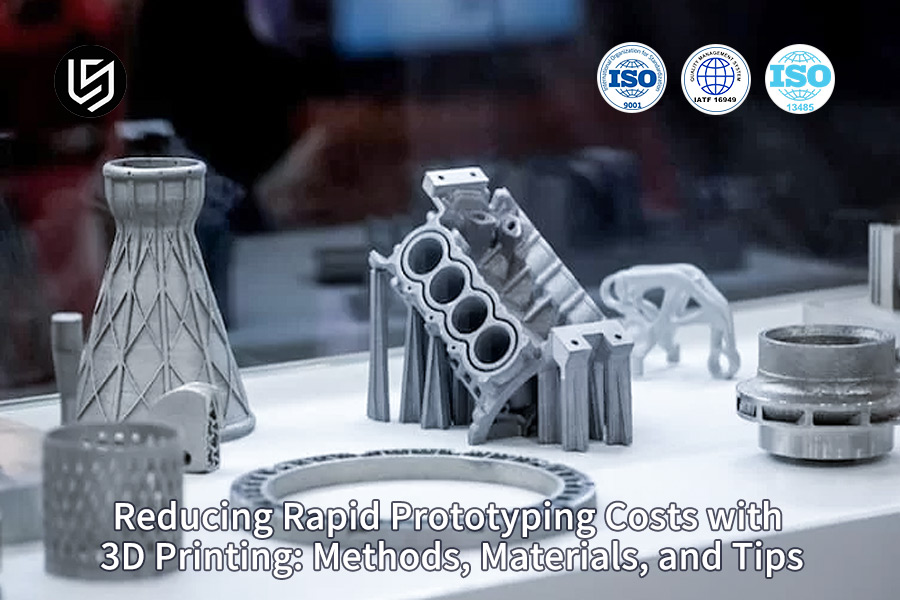

Rapid prototyping is an indispensable stage in product development for design validation and developing a competitive advantage, yet often it is the very point of bottlenecking innovation-long cycle times, high costs, and difficulties in iteration. The root cause lies in that the traditional manufacturing process (such as CNC subtractive machining) is intrinsically wasting materials, time-consuming, and inflexible in design; thus, it is difficult to optimize the R&D cost structure.

LS Manufacturing proposes a systematic approach to reduce the total cost of prototyping by strategically applying industrial-grade 3D printing technologies, encompassing technology selection, materials science, and design optimization. This paper will analyze in detail how technological innovation can lead to breakthroughs in cost and efficiency.

Rapid Prototyping Quick Reference Table

| Module Classification | Core Content | Technical Highlights | Application Value |

| Basic Concepts | Manufacturing product prototypes with the help of rapid prototyping technology. | The digital model, with the use of technologies like 3D printing, is rapidly transformed into a physical sample. | Rapid prototyping dramatically shortens product development cycles and saves trial-and-error costs. |

| Main processes | Encompasses the major mainstream technologies such as SLA, SLS, and FDM. | With different requirements, the processes may involve photopolymerization, powder sintering, or fused deposition modeling. | Applications would range from proof-of-concept to functional testing. |

| Material Selection | Engineering plastics, photosensitive resins, metal powders, etc. | According to the different requirements of tension, corrosion, and high temperature, select the 3D printing material | Ensure that it will be able to work in real conditions. |

| Key Design | Features optimizes the support structure, wall thickness, and other parameters. | Lightweight design and topology optimization methods are employed | Improve prototype quality while reducing material consumption |

| Quality Control | Precision inspection and performance testing. | Dimensional verification is performed using equipment such as a coordinate measuring machine. | Ensure consistency between prototype and design specifications. |

| Cost Control | Optimize printing parameters and layout schemes | Reduce support materials and printing time through intelligent algorithms. | Maximize cost-effectiveness while ensuring quality. |

| Development Trend | Development of hybrid manufacturing using multiple materials. | A combination of traditional processes is realizing composite manufacturing. | Expanding the application areas and effects of rapid prototyping. |

Through systemic process selection, material matching, and design optimization, enterprises can rapidly validate design solutions at the early stage of product development, thereby greatly shortening the R&D cycle. Along with further development, 3D printing technology is tending toward high precision, high performance, and low cost in rapid prototyping, which provides tremendous support for innovation within the manufacturing industry.

Why Trust This Guide? Practical Experience from LS Manufacturing Experts

LS Manufacturing has 15 years of rapid prototyping expertise. Our aerospace turbine blade prototypes ensure aerodynamic accuracy for flight testing, while medical surgical guides meet biocompatibility standards for clinical success. These projects have enabled us to master material properties and process optimization technologies.

We integrate the latest additive manufacturing technologies while rigorously adhering to safety and technical standards recognized by industry authorities such as Occupational Safety and Health Administration (OSHA) and 3D Systems. This dual commitment to innovation and compliance ensures that every prototyping project is executed reliably, with consistent quality and safe operational practices.

Based on more than 50,000 prototype cases, a comprehensive knowledge base involving all processes from metals to polymers was set up. For example, optimization of printing parameters in nickel-based alloys reduces the support structures by 40%, while it enables precise control of anisotropy in carbon fiber composites. This handbook synthesizes these industrial experiences and offers the engineers a complete solution-from concept to product.

Why are traditional methods of rapid prototyping so often costly and inefficient?

When it comes to the rapid prototyping costs, the disadvantages of traditional prototyping are where budget overruns and delays occur because of the intrinsic limitations of CNC machining and silicone molding. We can better understand the need for manufacturing innovation with a closer look at these drawbacks in traditional prototyping.

- Low material utilization results in high direct costs: Most of the subtractive manufacturing techniques using CNC shape by cutting blanks, often at material waste rates of 60%-80%. Silicone molding requires the making of a master mold first; hence, the per-piece material costs can be very high for small batches. This process of “subtraction” inherently raises the rapid prototyping costs.

- Tooling and mold preparation extend the initial development cycle: In traditional approaches, fixtures and mold design and fabrication encompass 30%-40% of the entire project cycle. These kinds of special tooling fixtures are also not reusable across different projects, further increasing the sunk cost problem inherent with traditional prototyping.

- Multiple connections between processes and manual interference reduce overall efficiency: It involves many changes of equipment from programming and clamping right through to machining and post-processing, including manual operations. Each stage may potentially generate errors that will accumulate, leading to fluctuations in the pass rate and indicating a system efficiency bottleneck inherent in traditional prototyping.

These disadvantages of traditional prototyping make it difficult to optimize the rapid prototyping costs. The modern 3D printing technology drives production directly through digital files, eliminates the intermediate link, and can fundamentally avoid the problems mentioned above. Thus, this is a new way of reducing costs and improving efficiency in rapid prototyping.

How does 3D printing fundamentally reduce prototype development costs?

In the realm of rapid prototyping, 3D printing reached a fundamental breakthrough in traditional processing methods because of the paradigm shift from “subtractive” to “additive” manufacturing. The change brings about multi-dimensional 3D printing cost advantages and systematically reduces the rapid prototyping costs. Precisely, it manifests in the following respects:

Near-zero mold costs

Traditional machining relies on large investment in mold making, while 3D printing drives the manufacturing of equipment with digital files directly and doesn’t have to go through any mold design, manufacturing, and debugging. The result is that it cuts the unit cost for a small lot prototype drastically. It is especially suitable for the early stage in product development where several iterations may be needed to verify the designs.

Extreme material usage

Additive manufacturing uses only the materials required to build the product and keeps waste rates below 5%, far lower than the potentially up-to-80% material removal rate of CNC machining. That “use only what you need” characteristic largely reduces the cost of expensive engineering materials.

Unparalleled design freedom

Accordingly, 3D printing can make complex internal structures in one piece with integrated functions that conventionally depend on several parts. This saves connector costs and time spent assembling but also enhances part performance by structural optimization to gain dual benefits of “weight reduction and efficiency improvement.”

Rapid Iteration Capability

Since direct printing depends only on changes in the data of the 3D model, no reprogramming or adjustment in tooling is needed when any design change takes place. This digital attribute decreases the iteration cycle from weeks to days, along with a considerable reduction in the time and economic cost of modification.

In a nutshell, 3D printing cost advantages are reflected not only in the direct saving of materials but also, more importantly, in the holistic optimization of rapid prototyping costs due to the application of methods for reducing rapid prototyping costs such as abolition of mold investments, maximization of material utilization, reduction of assembly steps, and speeding up the iteration process.

How to choose the most cost-effective 3D printing technology to match my project?

Precise selection of 3D printing technology is very important for cost-effective rapid prototyping. Different processes have different emphases in terms of precision, strength, cost, and efficiency; they must be matched according to project needs. The following is a brief comparison of mainstream technologies that can be used for selection.

| Type of Technology | Core Features | Applicable Scenarios | Economic Analysis |

| SLA Stereolithography | Ultra-high precision, smooth surface | Appearance verification, precision assembly inspection | Low cost per unit in small batches, moderate material strength. |

| SLS Stereolithography | Good strength with no support required | Functional testing, complex internal cavity parts | Highly cost-effective in medium batches, slightly rough surface |

| FDM (Fused Deposition Modeling) | Low cost, many material choices | Proof of concept, large-size models | Lowest cost per unit, poorer precision and surface finish |

| MJF – Multi-Jet Fusion | High isotropic strength | Small batch functional part production | Fast mass production speed, excellent mechanical properties |

In short, comprehensive consideration for cost-effective rapid prototyping involves the verification stage, performance requirements and scale. As such, we provide a free 3D printing technology selection service to accurately match processes with your project goals for an appropriate configuration that will ensure every penny in your budget creates maximum value.

Which 3D printing materials give the best balance between cost and performance?

In the rapid prototyping process, cost reduction is directly related to material selection, which will influence prototype quality and total cost. Suitable low-cost 3D printing materials can satisfy basic performance requirements but also achieve the purpose of overall cost control by optimizing lifespan and reducing reprints. Here are some mainstream materials that achieve an excellent balance in cost and performance:

| Material Category | Performance Characteristics | Cost-Benefit Analysis | Typical Applications |

| Photosensitive Resin | High surface precision, strong detail representation | Lowest unit cost, suitable for appearance verification | Demonstration models, assembly inspection |

| PA12 Nylon | Excellent mechanical strength with no major deformation | Best value-for-money in balancing strength and cost | Test pieces of functional nature, movable structures |

| Polypropylene PP | Chemical resistance is excellent; toughness is good | Performance close to injection molded PP, confirming the feasibility of mass production. | Usage: Container packaging, hinges |

| PETG Material | Balanced strength and hardness, high printing success rate | Low loss rate, economical overall usage cost | Concept models, shell parts |

The key to reducing rapid prototyping costs lies in selecting materials for rapid prototyping cost reduction that minimize redundant prototyping and maximize verification efficiency (low-cost 3D printing materials). We will recommend the most suitable solution based on your specific application scenario to help you truly achieve your goal of reducing rapid prototyping costs.

What main DFAM techniques can be applied to further optimize the cost?

The core factor in maximizing economic benefits in 3D printing is the optimization of the design in DFAM (DFAM design optimization). By applying professional tips for reducing rapid prototyping costs, it is possible to drastically reduce material consumption; printing efficiency will be improved, and post-processing costs reduced while ensuring product performance. Some of the proven key techniques include:

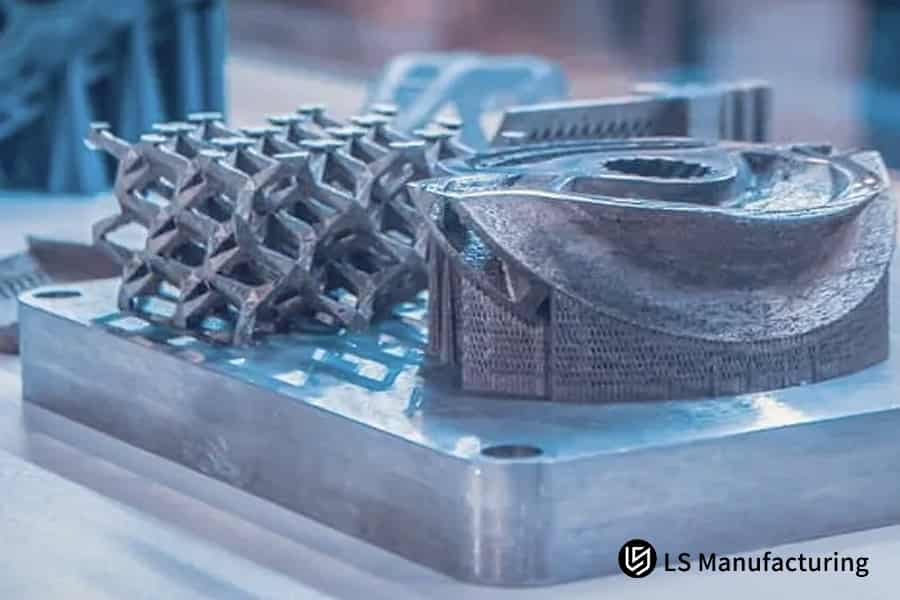

Structural lightweighting and topology optimization

The method identifies the non-load-bearing areas with finite element analysis and generates optimal force transmission paths automatically through generative design, which can achieve 20%-50% weight reduction while maintaining mechanical performance, thus directly saving material consumption and shortening printing time. This is one of the most effective ways to lower the rapid prototyping cost.

Hollow Design and Lattice Structure Application

Creating hollow structures or filling non-critical load-bearing areas with lightweight lattices contributes to material consumption reduction by 30-70%, while at the same time, it brings about better thermal insulation and cushioning performance due to the closed structure, which is the very essence of DFAM design optimization: to reduce material while increasing efficiency.

Intelligent Printing Orientation Optimization

In software, the print orientation with the least support area is determined through the analysis of geometric features. A proper orientation can reduce the amount of support material by over 30 percent while keeping all key surfaces at an optimal forming angle, reducing post-processing difficulty. This is one of the easiest techniques to implement for reducing the cost of rapid prototyping.

These RP cost-reduction techniques using rapid prototyping with 3D printing address not only the direct cost of the printing process but also achieve dual optimization in product performance and manufacturing efficiency through structural innovation. We help customers reduce prototyping costs by 15%-40% while guaranteeing quality.

How can LS Manufacturing help manufacturers of automotive parts verify their prototypes both quickly and inexpensively?

Competition in the automotive industry is continuously getting fiercer, and rapid and low-cost prototype verification is an important enabler for a company to fully exploit its market opportunities. The following LS Manufacturing prototyping case study indicates how our innovative solution helped a client overcome the specific bottlenecks in the automotive components prototyping:

Client Challenge

A leading automotive component supplier was tasked to make a lightweight prototype of a new generation intake manifold. The target was to reduce the weight by 30% without any sacrifice on airflow performance. Traditional CNC machining solutions, costing as high as 120,000 RMB, had a lead time of up to 4 weeks and could not achieve complex internal airflow optimization structures. That seriously impacted the new product development schedule.

LS Manufacturing Solution

Our engineering team applied SLS nylon 3D printing technology in combination with topology optimization design to integrate the original 12 components into one part. Internal lattice structure analysis allowed for weight reduction, while CFD analysis was performed to optimize the intake manifold shape in a way that would ensure airflow performance meets the requirements.

Results and Value

The final prototype was 35% lighter, with a cost reduction of 65% to 42,000 RMB and a reduced development cycle from 4 weeks to 5 days. Automotive component prototyping in this case helped our customer complete bench testing ahead of schedule and capture an extremely valuable market window for the project.

This case exemplifies how LS Manufacturing 3D printing solutions create exceptional value in automotive component prototyping. By innovatively integrating materials, structures, and processes, we help customers achieve significant cost reduction and efficiency gains, while providing unprecedented design freedom beyond traditional manufacturing limitations.

Is your project facing similar challenges? Get a free cost estimate from our application engineers today!

From Prototype to Small-Batch Production, Is 3D Printing Still Economical?

In the process of transitioning from rapid prototyping for small batches to production, solutions for the economics of manufacturing should be considered in a comprehensive manner in terms of mold cost allocation, iteration needs, and supply chain agility. This is especially true with the added value of 3D printing for small-batch production: when traditional mold costs cannot be reasonably allocated to small batches, additive manufacturing is showing unique advantages. Its economics are mainly reflected in three dimensions:

Effectiveness of Zeroing Mold Costs

Among the cost factors, the investment in mold is the most formidable obstacle to small-batch production. For example, a set of molds in injection molding generally costs tens of thousands to hundreds of thousands of yuan. Relatively speaking, the 3D printing method for producing small batches dispenses with this cost altogether; thus, the per-unit cost structure is much more straightforward and controllable.

Premium Value of Iteration Flexibility

The small-batch stage usually requires revision of design based on market feedback. Traditional mold modification is costly and time-consuming, but in 3D printing, small-batch production allows for digital mold modification, so product optimization can be continued throughout the whole production cycle with much-reduced improvement costs.

Hidden Benefits of Supply Chain Agility

3D printing can shorten production preparation cycles to 1-3 days and avoid many weeks of lead times with traditional manufacturing. For an enterprise, this kind of agile response will reduce inventory pressure, accelerate capital turnover, and bring about many hidden management benefits.

In a word, small-batch rapid prototyping and 3D printing small-batch production are in natural continuity. LS Manufacturing’s end-to-end service solutions are aimed at helping customers maximize economic benefits in the manufacturing paradigm.

What other hidden costs besides unit cost must be considered?

Probably the most common misjudgment concerning the question of the total cost of prototyping is the focus on unit prices. True cost control concerns the systematic identification of those easily overlooked factors in hidden cost control, and it is these potential risks that sometimes may raise the total project cost by more than 30%. Some of the key dimensions of controlling the hidden costs include:

- Costs of post-processing and secondary processing: These can include surface treatment, support removal, and other post-processing steps that may account for a significant portion of the overall cost. 20-40% of the cost. Inexperienced service providers will always underestimate the difficulty of post-processing, leading to excessive time commitments. Cost control is ensured through standardized post-processing procedures and specialized tooling.

- Quality Risks and Rework Costs: Dimensional deviation and material defect are some of the frequent problems that may cause reworks, even a restart of batches/projects. To support this, a four-level quality control system will be established to ensure a more-than-98% first-piece pass rate and reduce rework loss from its source.

- Chain Reaction of Time Delays: Delayed delivery may postpone product launching and therefore affect the capturing of certain market opportunities. With precise production scheduling and an early warning mechanism in material preparation, we can ensure timely project delivery to avoid losses in terms of opportunity cost.

Scientific total cost assessment for prototyping means coverage of control over hidden costs from very beginning to very end. If you choose us, that means you are having not only a transparent quote but also a systematic guarantee of the control of the hidden costs to ensure every penny of your budget creates maximum value.

FAQs

1. Will using 3D printing to lower prototype costs sacrifice prototype quality?

With the adoption of aerospace-certified materials such as ULTEM 1010, the industrial-grade 3D printing follows ISO 9001 quality management, ensuring that the work meets functional testing requirements at an accuracy of ±0.1mm. Layer by layer, we optimize the process and monitor it online to ensure the prototype fully meets the engineering standards of key indicators like strength and temperature resistance.

2. My prototype product requires several materials or colors; is this achievable through 3D printing?

We support single-pass molding through multi-material jetting, such as the Stratasys J850, for complex prototypes that include combinations of hard and soft adhesives, transparent areas, and colored areas. Examples include medical device handles that integrate rigid frames with a flexible grip in one go, which will eliminate any possibility of errors due to assembly.

3. From design submittal to quote, how long does LS Manufacturing take?

The inquiry system automatically parses STEP/IGES files. With the recommendation of DFM, the quotation can be presented online in detail within 2 hours. Meanwhile, urgent projects may pass through expedited channels to reply in as fast as 30 minutes, ensuring zero delay in R&D progress.

4. What is MOQ? Is producing one prototype possible?

We provide “one-piece minimum order” services for the R&D phase specifically, with no MOQ restrictions. A modular printing platform uses standardized quality control processes, even in the making of a single piece, to avoid fluctuations in quality in small orders.

5. Are my design files secure? How do you protect IP?

We deploy bank-grade AES-256 encrypted transmission. Design files are stored on local servers, and all operators sign lifetime confidentiality agreements. On request from the client, data can be physically destroyed once the project is completed; rest assured, there is zero IP risk.

6. Apart from plastics, does LS Manufacturing offer 3D printing prototyping in metal?

We are equipped with SLM metal printers supporting functional prototype manufacture using stainless steel, titanium alloys, and aluminum alloys. Examples include aerospace turbine blade prototypes that support high-temperature testing at 800℃ and achieve forging-level mechanical properties.

7. Will you be able to handle post processing, such as coloring or electroplating on the prototype?

Our post-processing center has more than 20 processes, including but not limited to sandblasting (Ra0.8μm), vacuum coating (chrome/titanium plating available), and medical-grade polishing. For example, prototypes of an automotive intake manifold can be finished with high-gloss metallic textures for direct use at trade shows.

8. How do I start my first collaboration project?

After submitting your 3D model through the official website, a project manager will contact you and give you material selection advice and arrange trial production. A CMM report is dispatched together with the first prototype to guarantee data traceability.

Conclusion

Systematic use of 3D printing technology can help lower the total cost and timeline in RP of products through the precise selection of technology, matching with materials, and DFAM design optimization. This has been proved by successful cases of LS Manufacturing in many industries such as automotive, medical, and consumer electronics. This represents not only a technological but also a strategic upgrade in R&D efficiency and cost control.

Your next product innovation shouldn’t be constrained by high prototyping costs. Upload your 3D files today and get a free, confidential Design for Manufacturability (DFM) analysis and cost estimate from the experts at LS Manufacturing. Contact our experts, let our expertise accelerate your ideas and cut your costs.

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.