The CNC milling machine is one of the most versatile and precise tools used in today’s manufacturing industry. They are able to cut and shape various materials with high accuracy and accuracy, making them an indispensable tool in the manufacturing process. However, in order to effectively operate the CNC milling machine, we must thoroughly understand the basic knowledge of CNC milling machine processing, let us walk into the ocean of knowledge about CNC milling machine processing.

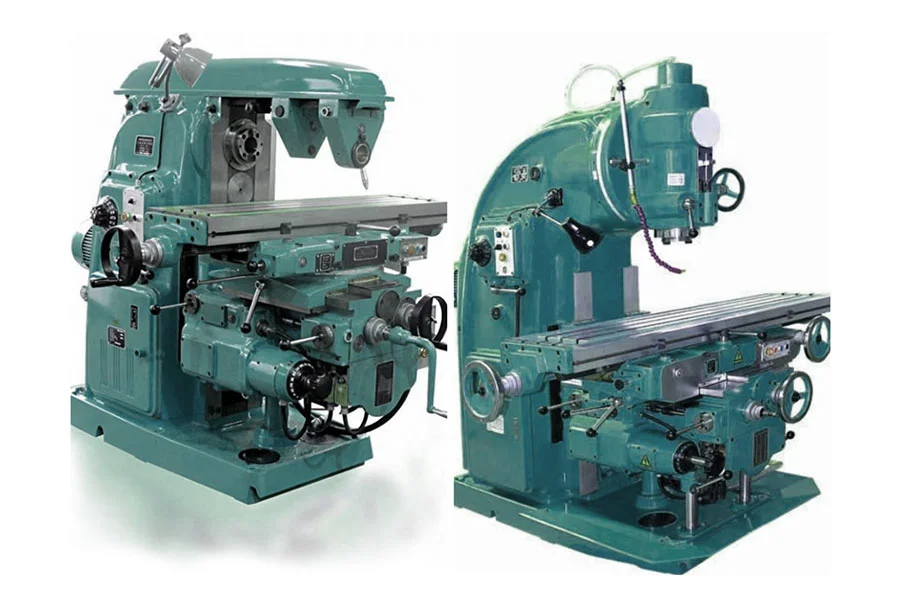

What is a CNC milling machine?

CNC milling machine, also known as CNC (Computer Numerical Control) milling machine, is a milling machine controlled by the digital signal of an electronic meter.Numerical control milling machine is a digital controller implemented on an ordinary computer controlled platform, which can make precision milling under the limit of program code.The machining range of CNC milling machine is very wide, which can produce a variety of complex surface, seams, grooves, etc.but also can achieve multi-axis processing, such as five-axis joint processing, in order to produce more complex parts required for the car.

How done CNC milling machine ?

Remove material from the work by a high-speed rotary cutting tool while the parts to be processed remain still. Cutting tools are controlled by a computer program that determines the tool path and cutting parameters, such as speed, feed rate, and cutting depth. CNC milling machine is widely used in machinery manufacturing, precision parts processing, aerospace, automotive, electronics, medical and other industrie.

The difference between the CNC milling machine and the machining center

| Option | CNC milling machine | Machining center |

| Different processing methods | Different modes of exercise | The spindle drives the rotating movement of the work |

| Different functions | Only has the milling function | With drilling, tapping, boring and other functions |

| The scope of application varies | Suitable for the plane and surface processing of the work | A variety of processing operations for complex work |

| The control axis is different | There are only two axes | Four axis, five axis linkage |

| Different modes of exercise | The spindle drives the rotating movement of the work | The spindle drives the rotating movement of the cutting tool |

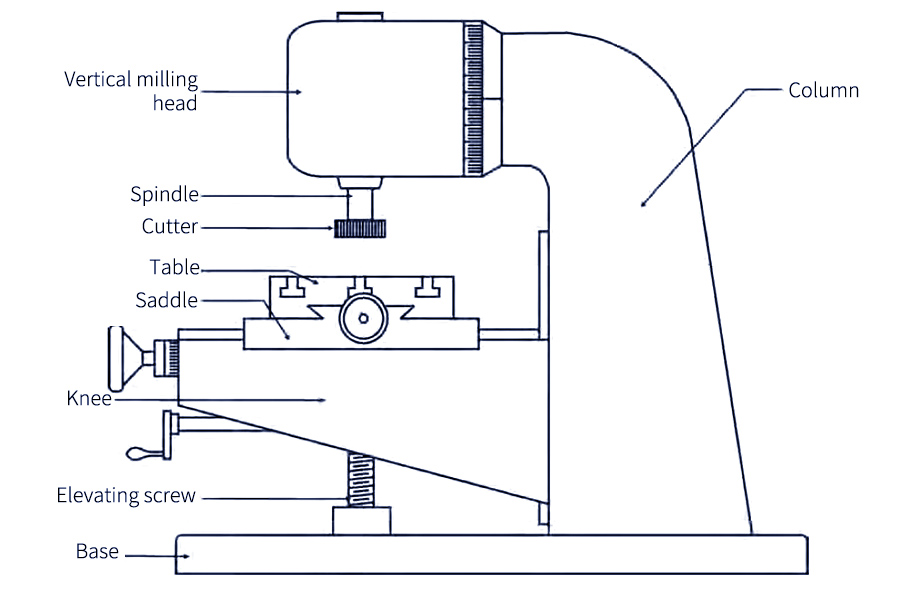

Difference between the vertical and horizontal milling machines

The main difference between vertical milling machine and horizontal milling machine is the direction of the spindle. On the vertical milling machine, the main shaft is vertically oriented to the work table, while on the horizontal milling machine, the main shaft is oriented parallel to the work table. Each milling machine has its advantages and specific environment, and the choice will depend on the specific requirements of the processed parts processed.

CNC Milling Machine Machining Pros

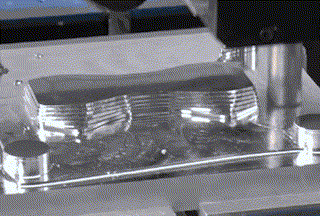

- High-precision:One of the main advantages of CNC milling machines is their very high accuracy. These machines are designed to run at high speeds and to produce parts with complex details and strict tolerances. This accuracy and precision makes them well suited for industries where quality and reliability are critical. The CNC machine tool can achieve tolerances as low as 0.0001 inches, making it ideal for producing high-precision complex parts.

- High efficiency:The CNC milling machines are also very efficient. They can work continuously without rest or rest, and can produce parts at much faster speeds than manual machines. This makes them an excellent choice for mass production. They are also able to produce parts with minimal waste, thereby reducing production costs and improving profitability. Nc machines can also operate 24 hours a day, meaning they can produce parts at any time, increasing the efficiency of the manufacturing process.

- Flexibility:CNC milling machines are widely used and can be used to process a variety of materials, including metal, plastic and composite materials. They can also be programmed to produce complex shapes and designs that are difficult or impossible to produce manually. This flexibility makes them an excellent choice for manufacturers who need to produce a variety of components.

- High cost performance:Although CNC milling machines can be expensive to buy, they are cost-effective in the long run. They require minimal maintenance and can produce high-precision parts, thus reducing the expensive rework requirements. Moreover, they last longer than manual machines, meaning means in the long run they offer better value for money. CNC machines can also reduce labor costs because they require fewer operators to run, thereby reducing overhead and improving profitability.

CNC Milling Machine Machining Cons

1.The initial cost is high:One of the main disadvantages of CNC milling machine is the high initial investment cost. They require a lot of upfront investment, which can be a problem for small businesses or startups. However, if you plan to use the machine for mass production or for producing complex parts, the investment will pay off in the long run.

2.Need programming:The CNC milling machine requires programming to control the machining process, so a special programming personnel is needed to write and modify the machining program.

3.Maintain:Although CNC milling machines require minimal maintenance, they still require regular maintenance to ensure that they operate at the highest efficiency. This may include tasks such as lubrication, cleaning, and calibration. Regular maintenance can be very time-consuming and may affect production planning. However, regular maintenance must be performed to ensure the service life and efficiency of the machine.

4.The outdated risk:As with any technology, CNC milling machines always carry the risk of obsolwith the advent of new technologies. This could be a problem for businesses that have invested heavily in these machines. However, with regular upgrades and maintenance, you can extend the service life of the machine and keep it synchronized with the latest technology.

If I were you, how I would make a choice

If it is with a variety of processing operation, extremely complex processing process, the priority machining center, if only simple plane, surface machining choose CNC machining, for the need of multiple axis linkage machining center, machining parts just need milling choose CNC milling machine, and drilling, tapping, boring and other complex functions choose machining center, in general, what is choose CNC milling machine or machining center, according to your need processing model to make the optimal choice.

Longsheng will always be your CNC milling car partner

In using CNC milling machines, the basic DFM (manufacturing design) skills must be followed to ensure that the parts can be truly processed. Choosing longsheng will bring you unexpected harvest! To take advantage of our CNC milling service, you will immediately get free quotes and free preliminary DFM advice. At Longsheng, our team of professionals will help you refine your design and ensure that you get the standard precision milling parts you want.

Conclusion

CNC milling machines offer many advantages over manual machine tools, including accuracy, efficiency, flexibility, and cost-effectiveness. However, they have some disadvantages, such as high initial investment costs, the need for programming technology, maintenance conditions and the risk of obsol. Overall, the CNC milling machine is an excellent choice for enterprises seeking to improve the manufacturing process. But the pros and cons must be carefully considered before making a major investment. With proper planning, training, and maintenance, you can maximize the advantages of CNC milling machines and take your manufacturing process to a new level.

FAQs

How to do with the error of machining accuracy?

Optimize the processing procedure, set reasonable processing parameters and cutting conditions; use high precision machine tools and cutting tools; ensure the overall consistency of the materials; regularly check and maintain the machine tools to ensure its high precision and strong stability.

What about the scratches on the processing surface?

Optimize the cutting parameters and cutting conditions; select appropriate cutting tools and cutting fluid; and use appropriate polishing and grinding techniques.

How to do the short tool life of CNC milling machine processing?

Select tools with good quality and adopt proper maintenance methods; set reasonable cutting parameters and coolant usage; avoid passivation and replace new tools with wear.

What if there are program errors and improper operation during programming and debugging?

Provide professional training for programming and operation personnel to improve their skills and level in programming and debugging; adopt advanced programming software and debugging tools; strengthen program review and testing to ensure that correct procedures exist.