Aluminium CNC Machining

Reliable aluminum cnc machining services, on-demand manufacturing production, whether complex machining or special needs, can meet your requirements.

- Manufacturing on demand

- Instant CNC parts online quotes

- Tolerances down to +/- 0.005mm

- Delivery in as little as 3 days

- All uploads are secure and confidential

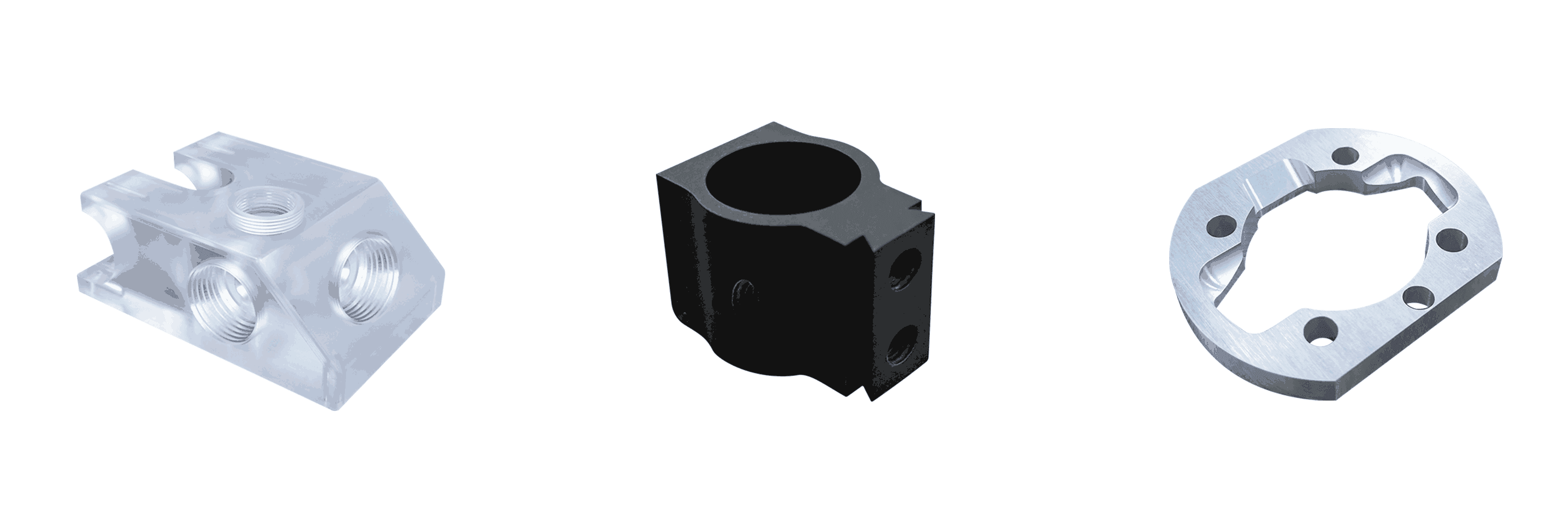

Aluminium CNC Machining Services for Custom parts

Through our comprehensive aluminum CNC machining services, you will be able to obtain high-precision, accurate, and complex customized aluminum parts with extremely complex geometric shapes. Our services extend from prototype production to the final manufacturing of aluminum parts, ensuring that you meet your needs with the highest quality products.

Our aluminum CNC machining services cover a wide range of aluminum alloy parts, aluminum automotive parts, aerospace parts, and more. Whether it is batch production or small batch production, we are able to complete projects on time and with quality.

We also provide personalized services to customize different aluminum CNC machining solutions according to customer needs and requirements, ensuring that customers can achieve the best product quality and production efficiency.

If you need high-quality aluminum CNC machining services, Longsheng is your best choice. Contact us and we will be able to provide customized aluminum CNC machining services to meet all your needs.

Our Aluminum Parts Manufacturing Capabilities

CNC Milling

With our aluminum CNC machining services, parts in a variety of shapes can be manufactured on demand in milling technology, including planes, bosses, grooves, chamferes and more. By selecting suitable milling tools and processing parameters, aluminum materials with high precision and complex shapes can be machined.

CNC Turning

In LS's aluminum cnc machining service, the turning technology can be used to process cylindrical shaped parts, such as shafts, threads and holes. By choosing the right turning tool and tool path, high precision and high efficiency aluminum material processing can be achieved.

5 Axis CNC Milling

Our 5-axis machining enables high precision machining of complex surfaces and three-dimensional shapes. In aluminum CNC machining, five-axis machining can be used to manufacture complex parts in aerospace, automotive, mold and other fields to improve processing efficiency and accuracy.

Aluminum cnc parts material grade

LS supplies most of the industry standard materials. If you do not find the materials you want in the list, please contact us.

| types | Density (g/cm ³) | Melting point (℃) | Thermal conductivity (W/(m · K)) | Coefficient of thermal expansion(10 ^ (-6)/K) | Strength (MPa) | Bending strength (MPa) | Hardness (HB) | Conductivity (% IACS) |

|---|---|---|---|---|---|---|---|---|

| Pure aluminum (Al) | 2.7 | 660 | 237 | 23.5 | 80 | 50 | 20 | 61 |

| 1050 | 2.7 | 660 | 237 | 23.5 | 55-95 | - | - | 57-63 |

| 1100 | 2.7 | 660 | 237 | 23.5 | 95 | - | - | 61 |

| 2011 | 2.8 | 535 | 152 | 22.2 | 260 | - | - | - |

| 2024 | 2.8 | 640 | 121 | 23.2 | 470 | 270 | 120 | - |

| 3003 | 2.7 | 655 | 167 | 23.6 | 130 | - | - | 40 |

| 5052 | 2.7 | 605 | 138 | 23.8 | 210 | 193 | 60 | - |

| 6061 | 2.7 | 585 | 167 | 23.6 | 240 | 228 | 95 | 40 |

| 7075 | 2.8 | 635 | 130 | 23.4 | 570 | 503 | 150 | - |

Why choose our aluminum CNC machining services

By choosing our precision CNC machining manufacturer, you will receive high-quality, customized parts, fast delivery, and competitive prices. We will cooperate with you to provide excellent CNC machining solutions for your project.

No minimum order quantity

Whether it requires a single aluminum part or thousands of aluminum parts, we manufacture and produce them

Strict tolerance standards

We ensure consistent product quality, and a comprehensive inspection can also ensure that you receive aluminum parts without any defects

Fast delivery

We have the most advanced machines to accelerate your prototype or parts production, and can receive aluminum parts within 2 days at the earliest

24/7 technical support

We provide 24/7 technical support. No matter where you are, our experienced engineers can provide the most suitable solution for your aluminum parts

Precision Manufacturing Capabilities

Download Our Brochure to Get a Full

Overview of Our Manufacturing Capabilities

Access our technical documentation, covering all core processes, tolerance standards, material options, and industry case studies, to help you quickly evaluate project feasibility.

What's in the manual?

·High-definition product images and 3D cross-sections.

·Detailed process capabilities and tolerance standards, e.g., 5-axis CNC accuracy, injection mold lifespan.

·Comprehensive material options and surface finishes, e.g., titanium, PEEK, anodizing, sandblasting.

·Quality system certifications (ISO 9001) and industry case studies.

·A complete guide to our process from rapid prototyping to mass production.

Lead Capture Form

Simply enter your email to get the download link instantly

![]() We respect your privacy and will not use your information for other purposes.

We respect your privacy and will not use your information for other purposes.

FAQ for Aluminum Parts Manufacturing

How to choose the appropriate aluminum CNC machining process?

Choosing a suitable aluminum CNC machining process requires considering factors such as material type, machining shape, machining accuracy, and production batch size, and determining the optimal machining strategy and parameters based on these factors. Please submit your specific requirements, and Longsheng Technology technicians will provide a reasonable solution for your project

What grade aluminium for CNC machining?

This requires selecting the appropriate level of aluminum alloy based on specific application requirements, mechanical performance requirements, and cost factors. Longsheng Technology can customize and manufacture aluminum parts, such as 6061/7075/5020/2024 aluminum alloys

How long will it take to receive aluminum CNC machining products?

The delivery time will vary depending on your needs and product complexity. We will make every effort to ensure that your products are delivered to you in the shortest possible time.

What aluminum CNC machining services can you provide?

We provide all aluminum CNC machining services including aluminum cutting, drilling, milling, cutting, etc. Not only that, we also provide customized services to meet your specific needs.

What is the price of aluminum CNC machining?

The price of aluminum CNC machining is influenced by various factors, including product material, size, complexity, etc. Longsheng provides high-quality machining services at reasonable and reasonable prices, which can meet the diverse needs of customers.

News & Blog

Deep understanding of industry knowledge and real-time updates at any time.