Copper CNC Machining

Copper CNC machining services, whether you need simple copper parts or complex multi-part copper parts, we have the experience and expertise to help you put your ideas into practice.

- Manufacturing on demand

- Tolerances down to +/- 0.005mm

- Delivery in as little as 3 days

- Get your custom copper parts at low prices

- All uploads are secure and confidential

Copper CNC Machining Manufacturer

Our services cover the entire process of copper CNC machining, including various stages from design to manufacturing. Taking the design stage as an example, we have a professional design team who can customize designs according to customer needs. In the manufacturing phase, we have advanced production equipment and technology that can meet processing needs of different complexity levels.

We welcome all customers with copper CNC machining needs to contact us to learn more about our business and services

Our Manufacturing Capabilities

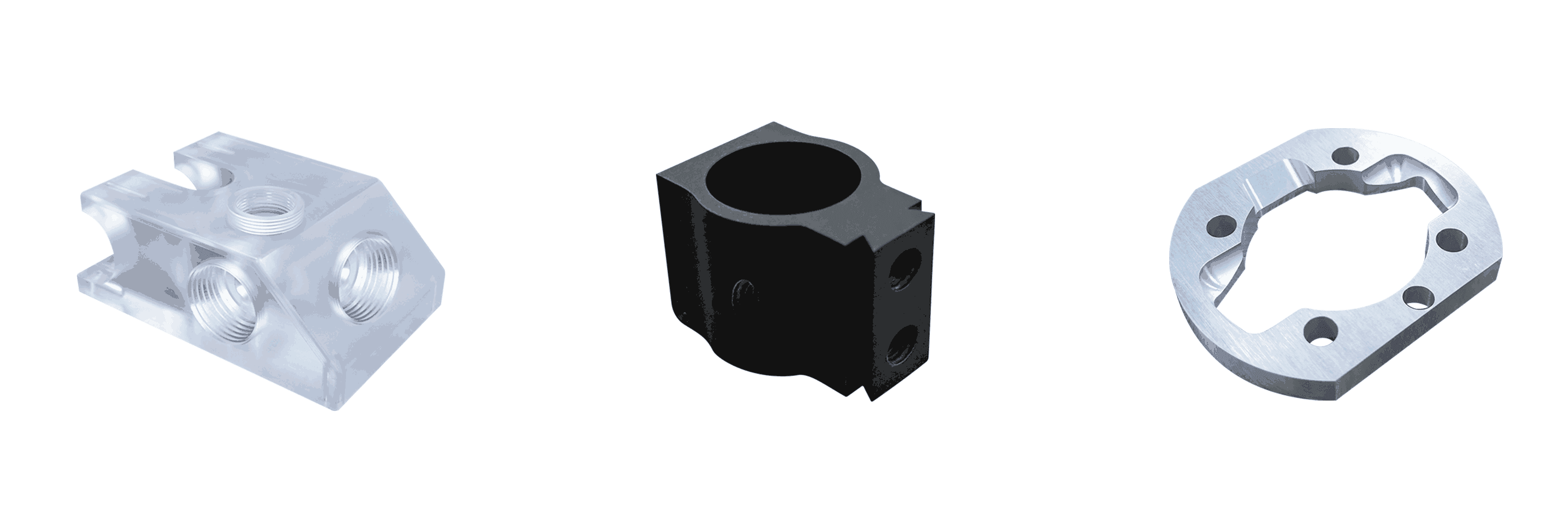

If you need custom copper parts with complex geometry, or get end-use products in the shortest possible time, at Longsheng Technology we have multiple cnc milling machines and cnc lathes that guarantee quick turnaround and quality of disposable prototypes and production parts.

CNC milling machining

CNC milling is the process of using a CNC milling machine to process copper materials. In this process, the copper workpiece is fixed on the CNC milling machine, and the copper material is gradually cut away to form the desired shape and outline by rotating the tool at high speed and moving in different directions. CNC milling is suitable for the manufacture of flat, curved and complex shapes of copper parts, such as connectors, radiators, electronic device housings, etc.

CNC turning machining

CNC turning is the process of using CNC lathes to process copper materials. In this process, the copper workpiece is fixed on the CNC lathe, and rotary cutting is carried out on the workpiece by the tool, removing the unwanted material to get the desired shape and size. CNC turning is often used to make rotationally symmetrical copper parts, such as shafts, gears, threads and bolts.

Copper CNC machining material

LS supplies most of the industry standard materials. If you do not find the materials you want in the list, please contact us

| Copper Grade | Density (g/cm³) | Melting Point (°C) | Electrical Conductivity (% IACS) | Thermal Conductivity (W/m·K) | Linear Expansion Coefficient (10^-6/°C) | Tensile Strength (MPa) | Hardness (HB) |

|---|---|---|---|---|---|---|---|

| C10100 | 8.96 | 1083 | 101 | 398 | 16.5 | 205-245 | 40-60 |

| C11000 | 8.94 | 1084 | 100 | 393 | 16.5 | 245-345 | 50-90 |

| C12200 | 8.92 | 1083 | 100 | 385 | 17.0 | 205-275 | 45-70 |

| C26000 | 8.44 | 890-955 | 29-31 | 123-149 | 19.0 | 250-350 | 60-90 |

| C36000 | 8.50 | 890-910 | 27-30 | 121-144 | 19.1 | 300-450 | 75-120 |

Finishing and Post-processing Option

Here is a table of CNC machining surface finishing and post-processing options for copper materials

| option | Texture | Description | Applications |

|---|---|---|---|

| Polishing | Smooth, glossy | Using abrasives to achieve a polished surface | Copper jewelry, electronic devices, decorations |

| Brushing | Linear texture, semi-glossy | Creating a brushed texture on the surface | Furniture, door handles, decorative panels |

| Anodizing | Ceramic-like colors, corrosion-resistant coating | Forming an oxide layer on the surface for enhanced protection | Electronic components, aerospace parts, decorations |

| Plating | Metallic appearance, anti-oxidation coating | Depositing a thin layer of another metal on the surface | Jewelry, cutlery, timepieces |

| Painting | Rich colors, protective coating | Applying paint or lacquer to add color and protection | Interior decoration, art pieces |

| Powder Coating | Smooth, wear-resistant, corrosion-resistant | Applying dry powder and curing to create a durable finish | Mechanical parts, automotive components, industrial equipment |

| Sandblasting | Rough surface texture | Using abrasive particles to create a uniform matte finish | Sculptures, art pieces, decorative elements |

| Patina | Antique bronze or greenish rust effects | Accelerating natural oxidation for desired aged appearance | Antique restoration, art pieces, architectural decoration |

Precision Manufacturing Capabilities

Download Our Brochure to Get a Full

Overview of Our Manufacturing Capabilities

Access our technical documentation, covering all core processes, tolerance standards, material options, and industry case studies, to help you quickly evaluate project feasibility.

What's in the manual?

·High-definition product images and 3D cross-sections.

·Detailed process capabilities and tolerance standards, e.g., 5-axis CNC accuracy, injection mold lifespan.

·Comprehensive material options and surface finishes, e.g., titanium, PEEK, anodizing, sandblasting.

·Quality system certifications (ISO 9001) and industry case studies.

·A complete guide to our process from rapid prototyping to mass production.

Lead Capture Form

Simply enter your email to get the download link instantly

![]() We respect your privacy and will not use your information for other purposes.

We respect your privacy and will not use your information for other purposes.

copper Parts Manufacturing FAQ

We provide new product developers with engine processing parts suitable for functional testing or final use of engineering -level materials. Get your required online CNC machining services support by reading FAQ.

How to ensure the quality of copper CNC machining?

We have professional copper CNC processing equipment and technical team, which can provide you with high-quality copper CNC machining services. We always strictly follow international standards for quality control to ensure that every product meets the needs of our customers.

What machining methods can we choose?

Copper CNC machining is usually divided into four methods: milling, turning, drilling, and turning milling composite. According to your needs, we can provide you with corresponding copper CNC processing services.

What is the cost of copper CNC machining?

The cost of copper CNC machining mainly depends on factors such as the complexity, specifications, and processing time of the parts. If you need a specific quotation, you can provide design drawings or relevant parameters, and we will reply to your reasonable quotation as soon as possible.

How long does the production cycle for copper CNC machining take?

The production cycle of copper CNC machining is closely related to the complexity and specifications of the parts. Generally, we can complete production within 3-7 working days and also provide expedited services.

What are the types of materials used for copper CNC machining?

Our copper CNC machining covers a variety of copper materials, including C11000, C12200, C26000, and so on. At the same time, we also provide CNC machining services for other metals such as steel and aluminum.

News & Blog

Deep understanding of industry knowledge and real-time updates at any time.