Colored Zinc Plating Service

We can choose different colors and effects according to needs, making the product have good aesthetics and adapt to different designs and uses.

- All uploads are secure and confidential

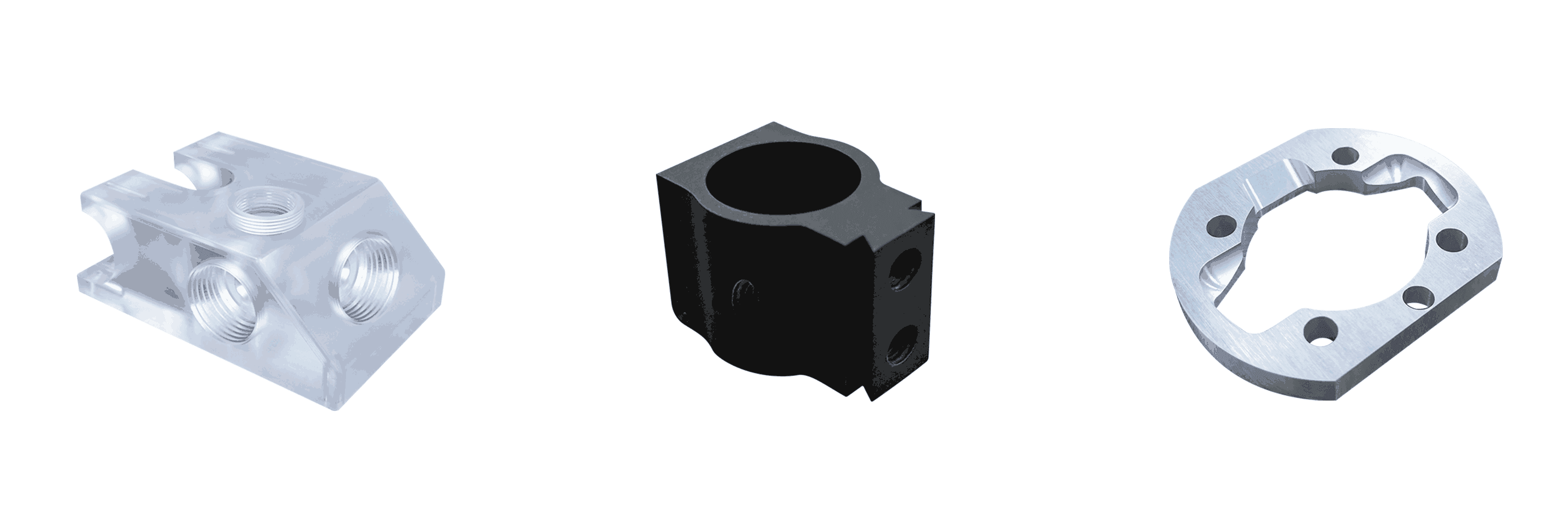

Colored Zinc Plating Specifications

| Project | Info |

|---|---|

| Applied materials | Cold rolled steel, hot rolled steel, iron plate |

| Color coating type | Polyester, Polyurethane, PVDF |

| Colors | Yellow, gold, clear, blue, black, green, RAL color card or custom colors |

| Galvanized layer thickness | 20-50µm |

| Coating thickness | 5-15µm |

| Texture | Bright, matte |

| Corrosion resistance | Comply with ASTM, ISO, or customer specifications |

| Application industry | Buildings, automotive parts, household appliances, billboards, etc |

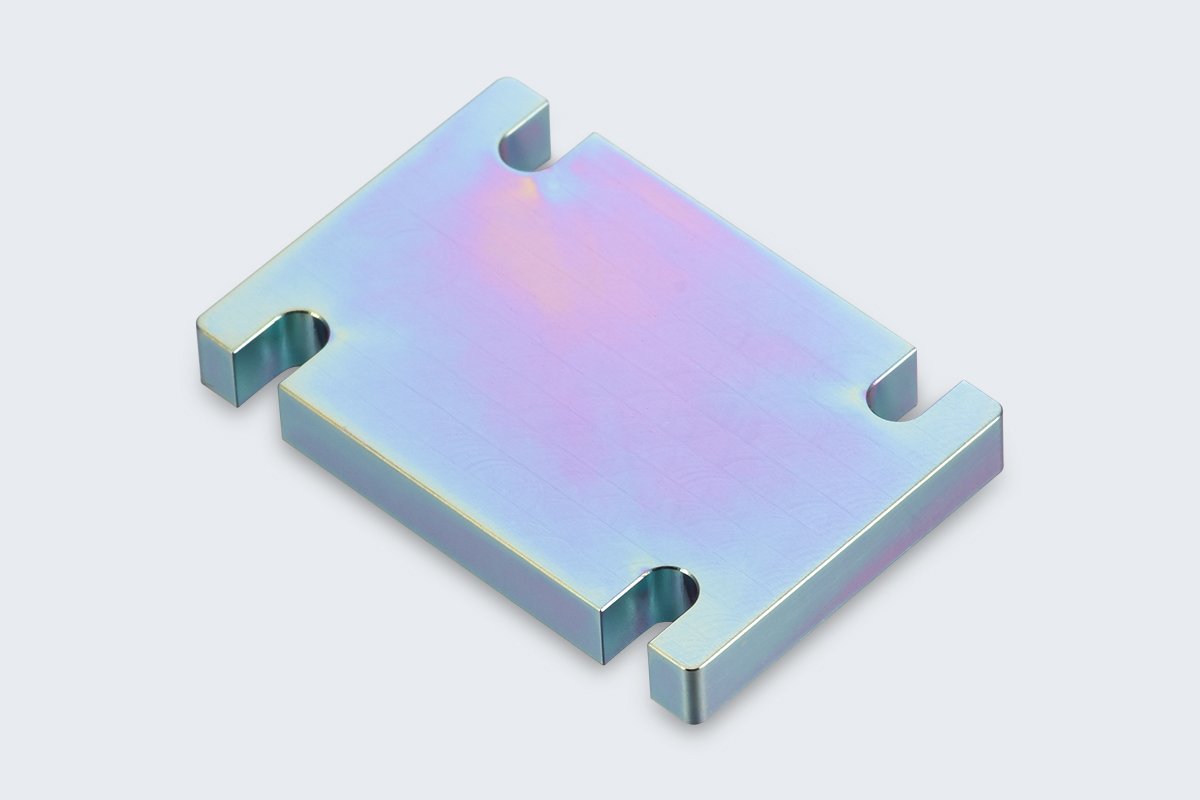

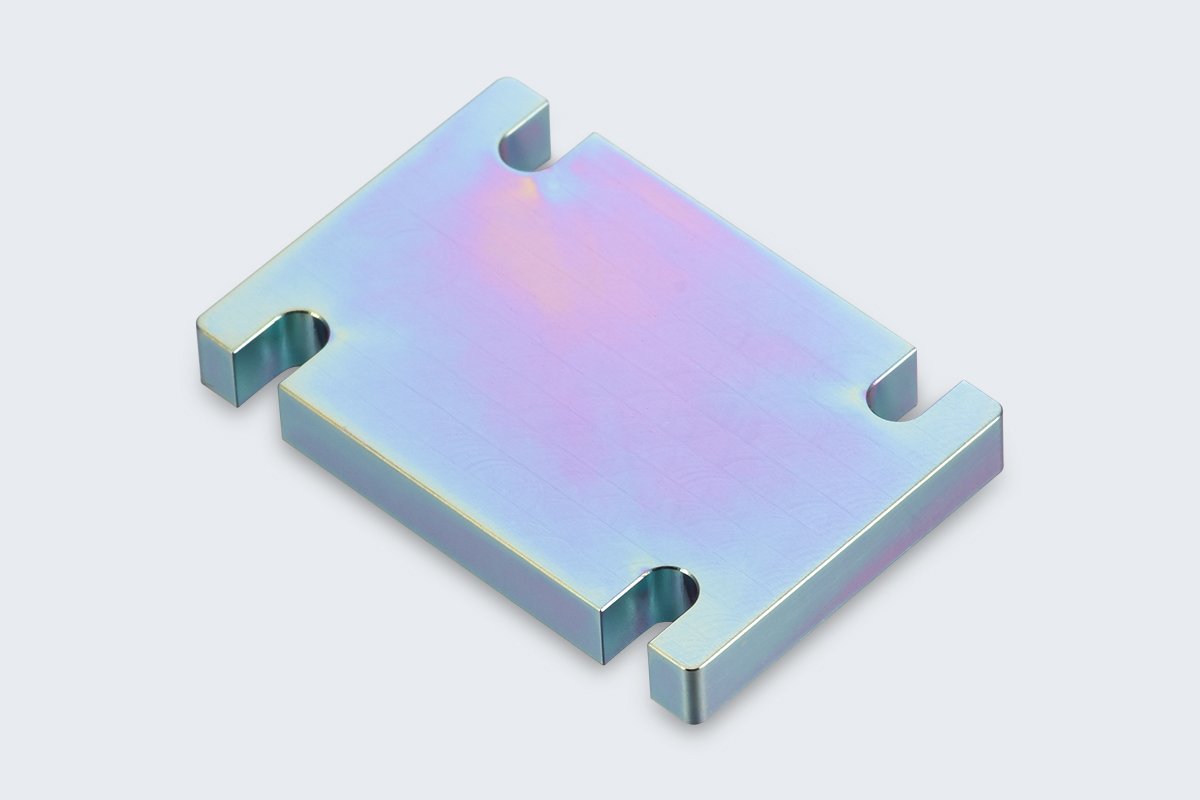

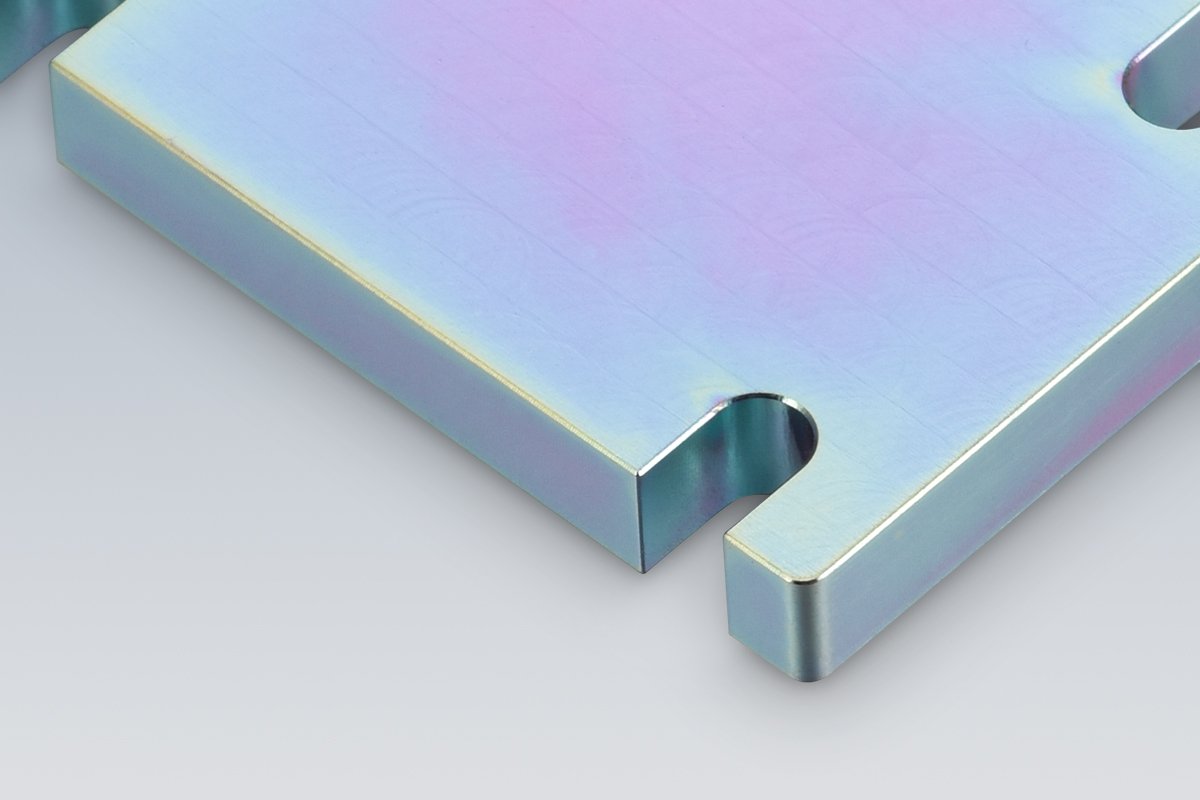

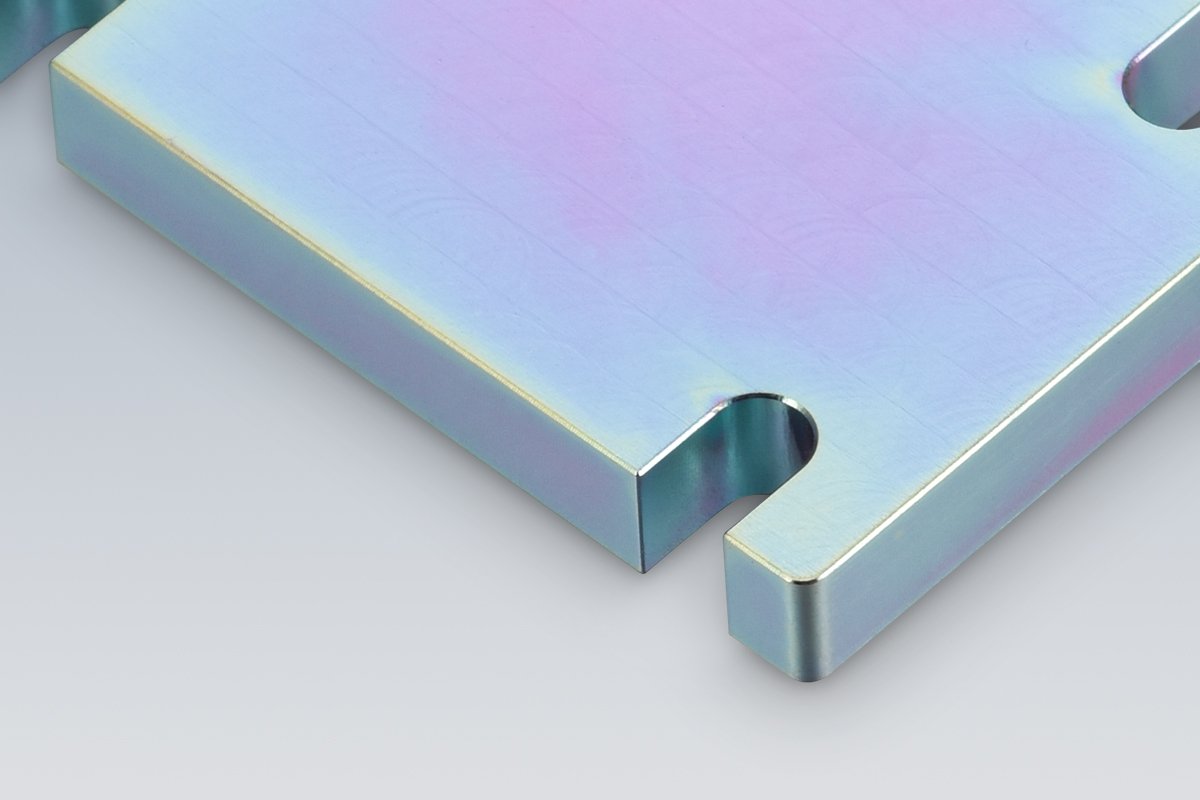

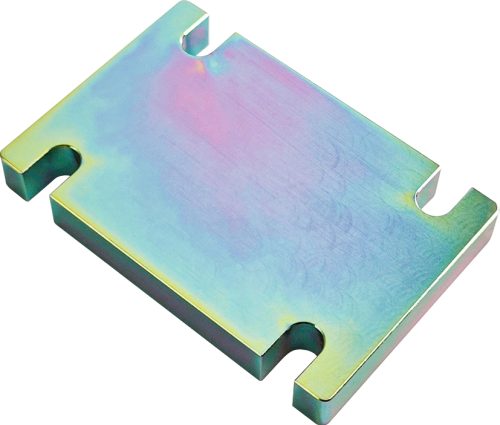

Example Of A Colored Zinc Plating Parts

About Colored Zinc Plating

Color zinc plating , which is also known as color galvanization, color zinc plating is a process of zinc plating metal parts and covering them with a layer of color coating. This process combines zinc plating and color coating, with dual functions of corrosion prevention and decoration.

Usually, color zinc plating adopts the process of hot dip galvanizing, which is a method of immersing metal parts into molten zinc to form a uniform zinc coating. Then, different colors can be achieved by applying different coatings or pigments to the zinc coating. These pigments can be powder coatings, liquid coatings, or other types of pigments.

Precision Manufacturing Capabilities

Download Our Brochure to Get a Full

Overview of Our Manufacturing Capabilities

Access our technical documentation, covering all core processes, tolerance standards, material options, and industry case studies, to help you quickly evaluate project feasibility.

What's in the manual?

·High-definition product images and 3D cross-sections.

·Detailed process capabilities and tolerance standards, e.g., 5-axis CNC accuracy, injection mold lifespan.

·Comprehensive material options and surface finishes, e.g., titanium, PEEK, anodizing, sandblasting.

·Quality system certifications (ISO 9001) and industry case studies.

·A complete guide to our process from rapid prototyping to mass production.

Lead Capture Form

Simply enter your email to get the download link instantly

![]() We respect your privacy and will not use your information for other purposes.

We respect your privacy and will not use your information for other purposes.

News & Blog

Deep understanding of industry knowledge and real-time updates at any time.