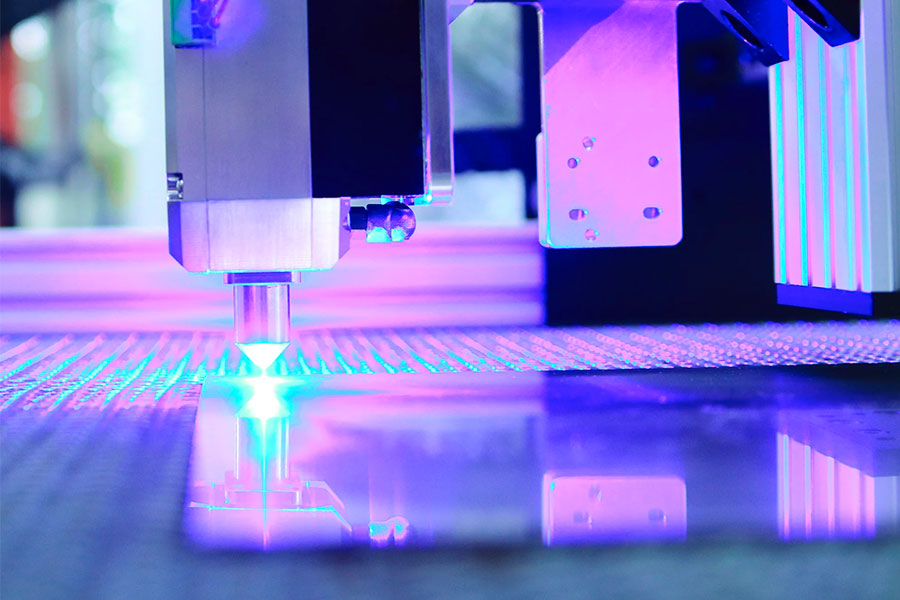

Acrylic is widely used in advertising, handicrafts and industrial fields due to its high light transmittance and easy processing. Laser cutting is the core technology of its precision processing, and the selection of laser power needs to find a balance between material thickness and processing efficiency.

CO2 lasers with a wavelength of 10.6μm have good adaptability to acrylic and are the first choice for cutting. 40W can cut 3mm thin plates, and 100W and above are required for thick plates above 10mm. However, the effect of laser cutting is affected by many factors. The type of material (casting or extrusion), cutting speed, focus position and the use of auxiliary gas will significantly affect the cutting edge quality and efficiency.

Based on scientific parameters and practical experience, this article will analyze how to accurately match laser power to achieve the best balance between efficient production and high-quality cutting.

Can a 10W Diode Laser Actually Cut 3mm Acrylic?

10W blue light module diode lasers are popular among DIY enthusiasts because of their low price, but the “easy cutting of acrylic” claimed by merchants is inconsistent with the actual effect, and problems such as poor cutting and edge carbonization often occur.

1. Physical Limitations

(1)The contradiction between wavelength and material absorption rate

10W diode lasers emit 455nm blue light. According to ASTM E2544 standard, acrylic only absorbs 7%, and 93% of the energy is reflected or transmitted. CO₂ lasers emit 10.6μm infrared light, and the acrylic absorption rate exceeds 95%. The energy utilization rate differs by 13 times, and the cutting efficiency is higher.

(2)Carbonization problem caused by thermal effect

ISO 11553 standard experiments show that when 10W blue light is focused on 3mm acrylic, the surface exceeds 300℃, a 0.8mm carbonization layer is generated, and the deepest slit is 1.2mm, which cannot be penetrated. Because the energy density is less than 20J/cm², it can only be ablated and carbonized, and cannot be gasified and cut.

2. The boundary between cutting and engraving in industry practice

(1)Engraving is feasible, but cutting has limitations

A 10W diode laser can engrave patterns <0.2mm on the acrylic surface. However, to cut 3mm transparent acrylic, the German Trotec white paper points out that a CO₂ laser of more than 40W is required with auxiliary gas cooling.

(2)The truth behind the merchants’ propaganda

The merchants’ statements such as “repeated cutting” and “low-speed cutting” will aggravate carbonization, cause edge cracking, reduce material strength, and the methyl methacrylate gas released by carbonization violates OSHA safety standards.

In summary, the 10W diode laser is limited by wavelength and power and cannot cleanly cut 3mm acrylic. It is recommended to use a CO₂ laser of ≥40W for acrylic processing.

Why Do 30W CO2 Lasers Dominate Acrylic Fabrication?

In the field of acrylic manufacturing, 30W CO₂ lasers have become the industry’s first choice due to their many advantages. Their dominance is determined by the following factors.

1. Naturally adapted wavelength characteristics

The far-infrared wavelength of CO₂ lasers is highly compatible with the molecular structure of acrylic, and the light energy is almost completely absorbed and converted into heat energy, achieving efficient cutting. In contrast, due to wavelength mismatch, blue light and fiber lasers have low cutting efficiency and are prone to carbonization of edges due to energy reflection or penetration.

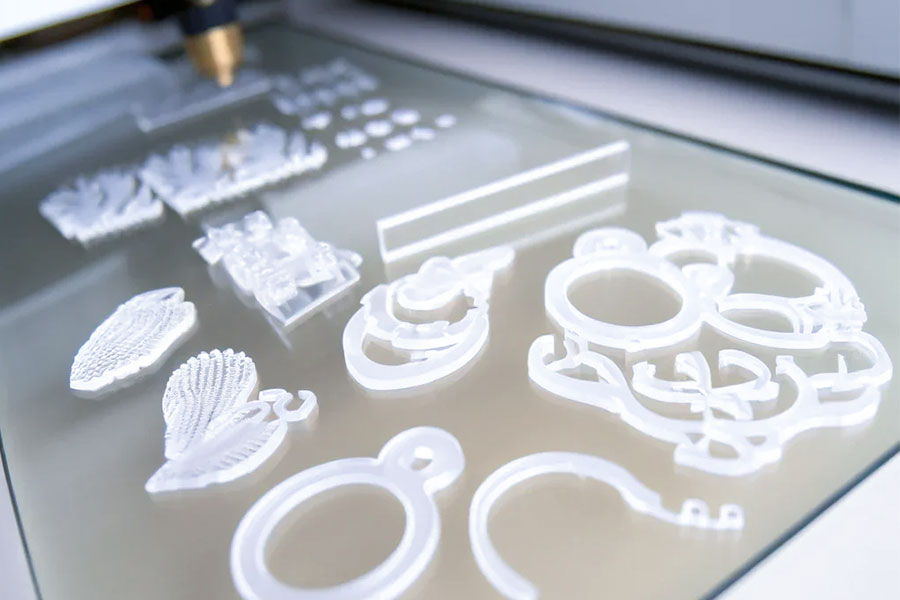

2. Excellent cutting quality

CO₂ lasers cut in a “vaporization” manner, making the acrylic surface as smooth as a mirror without the need for secondary polishing. Mechanical cutting is prone to burrs, and low-power lasers leave residual slag and cause yellowing, while CO₂ laser cutting can retain the transparent texture of transparent acrylic.

3. Balance between economy and practicality

(1)Power adaptation requirements

30W power can meet the thickness processing of most acrylic products such as signs and light boxes, taking into account efficiency and cost.

(2) Controllable operating costs

The technology is mature, and maintenance only requires cleaning the lens and replacing the gas, with low consumables costs; fiber laser has a low input-output ratio in acrylic processing.

(3)Multifunctional utilization

One device can complete cutting, engraving, punching and other processes, improving equipment utilization.

4. Mature industry ecological support

CO₂ lasers have been used in the field of acrylic processing for decades, forming a complete industrial chain. There are abundant equipment models and stable supply of accessories; the industry has accumulated a large number of operation parameter templates to reduce the cost of trial and error; manufacturers and user communities provide timely technical support.

5. Safety and environmental protection advantages

By adjusting the power and auxiliary gas, cutting smoke and harmful gases can be effectively controlled to meet environmental protection standards. Low-power laser cutting of thick plates is prone to produce more toxic volatiles and increase ventilation costs.

6. Advantages compared to other technologies

Fiber laser cutting acrylic has low absorption rate and is easy to carbonize; diode laser is only suitable for shallow engraving and has rough cutting edges; mechanical cutting is difficult to process complex shapes and may also cause material cracking.

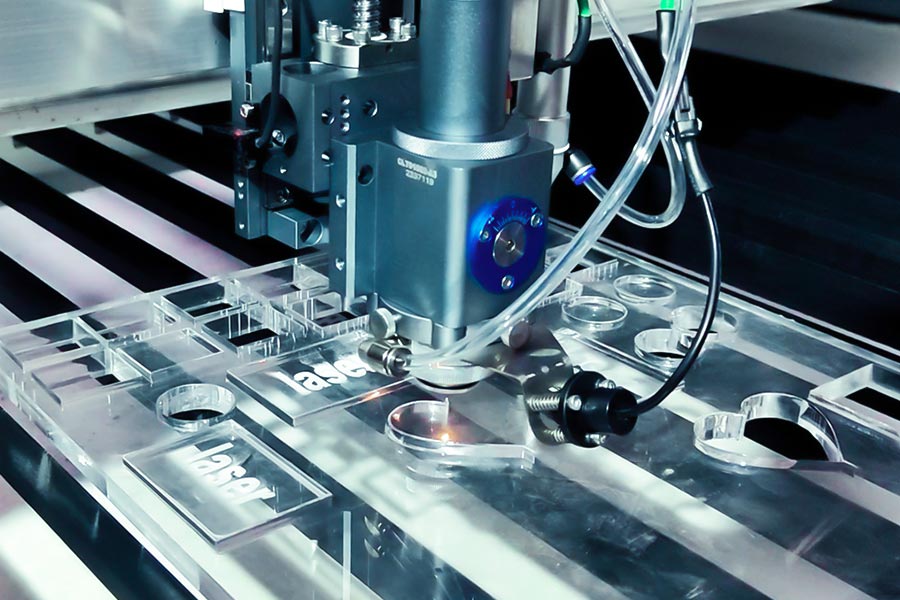

Can Fiber Lasers Replace CO2 Systems for Clear Acrylic?

Fiber lasers are rapidly replacing CO₂ lasers in the field of metal processing due to their high efficiency and maintenance-free advantages. However, when faced with transparent acrylic, this “replacement revolution” has come to a standstill – the inherent defect of the 1μm wavelength causes the fiber laser energy to be “ruthlessly filtered” by the material.

With giants such as TRUMPF launching 3μm mid-infrared fiber lasers, will the situation be reversed? LS will penetrate the technical fog and analyze the possibility of replacement and the turning point of the industry.

1. The “transparent wall” dilemma of 1μm fiber laser

(1)Wavelength mismatch: How energy is “swallowed”

- Physical essence: Transparent acrylic absorbs less than 5% of 1μm near-infrared light, just like glass is “transparent” to visible light.

Actual measured data:

- After 1μm laser penetrates a 5mm thick transparent acrylic plate, the energy attenuates by 83%, leaving only 17% for cutting.

- At the same power, the cutting speed is less than 1/5 of that of CO₂ laser, and the edge is severely carbonized.

(2)The cost of brute force cracking

Power compensation trap:

If you force 1000W fiber laser cutting (CO₂ usually only requires 80W), although it can penetrate the material, it:

- Heat accumulation explosion: Excess energy causes acrylic to decompose and release toxic gases (methyl methacrylate).

- Damage to the optical system: The energy reflected back to the laser burns the lens, and the maintenance cost soars.

2. Game-breaker: Technological breakthrough of 3μm mid-infrared fiber laser

(1)Wavelength transition: from “transparent” to “absorption”

The magic of 3μm:

- This wavelength is close to the molecular vibration absorption peak of acrylic acid, and the material absorption rate jumps to 85%, almost comparable to the 92% of CO2 laser.

TRUMPF experimental data:

- When cutting 5mm transparent acrylic, the efficiency reaches 92% of CO2 laser, and the edge roughness (Ra) is ≤2μm.

- With the annular spot technology, the heat affected zone (HAZ) is reduced to 0.1mm, which is better than traditional CO2 laser.

(2) Hidden advantages: unlimited possibilities of flexible processing

Multi-material compatibility:

The same 3μm fiber laser can switch between cutting metals (stainless steel, aluminum) and non-metals (acrylic, PET) without changing equipment.

Intelligent potential:

Real-time adjustment of wavelength (2.8-3.2μm fine-tuning) through software, adaptive to different colors/thicknesses of acrylic, and reduction of manual adjustment.

3. The moat of CO₂ laser: Why has it not been completely replaced?

(1) Cost barrier: the “noble threshold” of new technology

Equipment price:

The unit price of 3μm fiber laser is about 3 times that of CO₂ system (2 million yuan vs. 700,000 yuan), which is difficult for small and medium-sized manufacturers to afford.

Cost of use:

Mid-infrared fiber has high loss, and the cost of consumables increases by 15% per hour of cutting.

(2) Constraints of process inertia

Parameter database vacancy:

The power-speed-focal length parameters of CO₂ laser have been accumulated for 30 years, while the optimal process for 3μm fiber is still in the experimental stage.

Industry certification lags:

Medical/optical-grade acrylic component processing standards (such as ISO 13485) have not yet been incorporated into fiber laser processes, limiting their high-end applications.

(3) The ultimate showdown of energy density

Peak power limitation:

The pulse energy of 3μm fiber laser is still lower than that of CO2 laser. When cutting ultra-thick acrylic over 10mm, the speed drops by 40%.

Mirror cutting challenge:

For mirror polishing cutting of transparent acrylic (Ra<0.8μm), CO2 laser remains irreplaceable.

3μm mid-infrared fiber lasers have torn open the iron curtain of CO₂ laser dominance, but full replacement still requires overcoming the three barriers of cost, process, and standard. For transparent acrylic processing, the next three years will be a transition period of coexistence of dual technologies; and in the field of color/composite acrylic, fiber lasers may be the first to achieve subversion

Why Must Medical-Grade Acrylic Use Water-Cooled Lasers?

In the manufacturing of high-end medical devices such as heart stents and artificial joints, medical-grade acrylic acid has become a core material due to its biocompatibility. However, a small mistake – a processing temperature exceeding the standard by 1°C may cause the material to release toxic monomers, directly threatening the patient’s life.

Traditional air-cooled lasers have been “blacklisted” by the medical industry due to insufficient temperature control accuracy. LS will deeply analyze how water-cooled lasers can maintain the safety red line of medical materials with “operating room-level” temperature control technology.

1. Medical-grade acrylic acid: a heat-sensitive restricted area that matters life and death

(1) “Sterile corridor” from materials to organs

Medical-grade acrylic acid must meet the following requirements:

- Zero toxic release: Any residual monomer (such as MMA) will cause rejection (mandatory requirement for FDA Class III devices).

- Micron-level precision: The slit error of devices such as vascular stents must be less than 10μm, and thermal deformation will directly block the blood flow channel.

(2)The fatal critical point of thermal degradation

120℃ = death switch:

When the cutting temperature exceeds 120℃, the acrylic acid molecular chain breaks and releases methyl methacrylate (MMA). If the concentration exceeds 5ppm, it will violate the ISO 10993 biosafety standard.

Hidden risks:

Even if the material looks normal after cutting, the internal microcracks will continue to release toxins after sterilization (high temperature and high pressure) or implantation.

2. Water-cooled laser: How to achieve “cell-level” temperature control?

(1)Precision control of dual-circulation water cooling system

Primary cooling:

The cooling circuit inside the laser stabilizes the temperature of the resonant cavity within ±0.5℃ fluctuation, ensuring the consistency of output power (fluctuation <1%).

Secondary cooling:

The cutting head has built-in micro-water channels to directly cool the focusing mirror and nozzle, suppressing the temperature of the processing area to the safe zone of 80±5℃.

(2)Dynamic temperature control algorithm: AI prediction of thermal risks

Real-time feedback system:

The infrared thermal imager monitors the cutting temperature at a speed of 1000 frames per second and automatically adjusts the laser power and cutting speed.

Case comparison:

| Cooling method | Temperature fluctuation range | MMA release |

|---|---|---|

| Air cooling | ±25℃ | Exceeding the standard by 8 times (test failure) |

| Water cooling | ±5℃ | <0.1ppm (compliant) |

3. Compliance code: How does the water cooling system pass medical certification?

(1) “Triple verification” of FDA 21 CFR 820

Design control:

The water cooling circuit must pass 100,000 pressure cycle tests to ensure zero leakage (refer to ASME BPE standard).

Process verification:

The temperature data during the cutting process must be recorded throughout the process and can be traced back to the serial number of each medical device.

Environmental control:

The cooling water must reach pharmaceutical grade purity (conductivity <1μS/cm) to prevent microbial contamination.

(2) ISO 13485 “Thermal Management” Clause

Risk Control Documentation:

A microscopic map of the heat affected zone (HAZ) must be submitted to prove that there is no lattice structure damage.

Sterilization Compatibility:

Parts cut by water cooling process must pass gamma ray sterilization test to ensure no performance degradation.

4. Water cooling vs. air cooling: The truth of the game between cost and safety

(1) The “pseudo energy saving” trap of air cooling system

Low initial cost:

The price of air cooling equipment is usually 60% of that of water cooling system, but:

- The yield rate loss: The scrap rate caused by temperature out of control is as high as 15%, far exceeding the price difference of equipment.

- Certification risk: If the product fails to pass the medical review, it will directly lose the qualification to be listed.

(2) Long-term benefits of water cooling system

Maintenance cost:

Deionized water only needs to be replaced once a year (cost is about 500 yuan), while the optical devices of air-cooled lasers are damaged due to overheating, and the annual maintenance cost exceeds 20,000 yuan.

Premium ability:

The terminal selling price of medical parts processed by water-cooled lasers can be increased by 30% (compliance premium).

In the field of medical-grade acrylic processing, water-cooled lasers are not an “option” but a “must” for survival. With millimeter-level temperature control accuracy, they build a firewall for patient safety and medical compliance. Choosing water-cooling technology is essentially choosing to respect life.

How to Prevent Micro-Cracks in Automotive LED Light Guides?

Once micro cracks appear in automotive LED light guides, they will directly affect the life and appearance of the headlights. To solve this problem efficiently, it is necessary to start from multiple key links such as material selection, stress control, process optimization, installation and use.

1. Material selection: Lay a solid foundation for crack resistance

In terms of material selection, modified PMMA (acrylic) or PC materials are preferred, and their excellent impact resistance can effectively resist external impact. For example, the light guide of the Mercedes-Benz EQC is made of UV-resistant PMMA material, which significantly improves weather resistance and allows the light guide to be used stably in complex environments. In addition, adding nano-silicon dioxide (SiO₂) and antioxidants to the material can delay material embrittlement and reduce the risk of micro cracks from the source.

2. Stress control: reducing internal hidden dangers

Before injection molding, refer to the process of the BMW i8 headlight supplier and preheat the PMMA particles to 60°C, which can greatly reduce the internal stress of the material. In the laser cutting process, the nitrogen protection process is used to significantly reduce the generation of microcracks. After the injection molding is completed, the annealing treatment at 80°C for 4 hours can effectively eliminate the residual stress and make the internal structure of the light guide plate more stable.

3. Manufacturing process optimization: control production details

During the injection molding process, the parameters need to be precisely controlled, the PMMA melt temperature is maintained at 220-250℃, and the pressing pressure is reduced in stages to reduce shrinkage stress. When cutting, diamond tools or CO₂ lasers are used to ensure smooth cutting edges with a roughness of less than 0.1μm. To further improve the surface strength of the light guide plate, a SiO₂ hardening layer can be applied to increase the surface hardness from 2H of ordinary materials to 6H.

4. Installation and use: Take protective measures

During installation, use EPDM rubber gaskets as elastic fixing structures to buffer vibration impact. Reserve a gap of 0.5-1mm between the light guide plate and the bracket to adapt to temperature changes from -40℃ to 85℃. At the same time, install a silicone sheath at the contact harness to prevent long-term friction from damaging the surface of the light guide plate.

To prevent micro-cracks in automotive LED light guide plates, it is necessary to work together in the entire process of design, production, assembly, and testing. Through the above-mentioned preheating stress reduction, nitrogen protection cutting, elastic installation and other technologies and measures, it can effectively improve product reliability, reduce after-sales costs, and help create high-quality automotive lighting systems.

What Makes 100W Lasers Overkill for Thin Acrylic?

Many users mistakenly believe that the higher the power, the stronger the cutting ability. In fact, when cutting acrylic resin below 3mm, a 100W laser not only causes thermal damage, but also brings high costs.

1. Thermal cutting: Overkill of 100W laser

(1)The heat-affected zone (HAZ) is significantly enlarged

Acctual measurements show that the heat-affected zone of 40W laser cutting 3mm acrylic is only 0.3mm, and the cut is smooth; the heat-affected zone of 100W laser reaches 1.2mm, the edge is carbonized, and it cannot meet the precision standard, and the scrap rate is higher.

(2)Energy overload causes chain problems

The high temperature of 100W laser exceeding 400℃ destroys the material structure and reduces the impact strength. The micro cracks caused by cutting will expand in subsequent processing, shortening the product life.

2. Economic failure: the “triple cost curse” of 100W lasers

(1)Procurement cost premium of 210%

Equipment price comparison:

| Laser power | Average price (10,000 yuan) | Applicable material thickness |

|---|---|---|

| 40W CO₂ | 8-12 | 1-8mm |

| 100W CO₂ | 25-35 | 10-20mm |

Waste of investment:

Thin acrylic processing only requires 40W, and the 70% power redundancy of the 100W model is actually an ineffective investment.

(2) Energy efficiency plummeted by 58%

Electricity cost model calculation (based on 8 hours of work per day):

- 40W laser: power consumption 1.2kW, annual electricity cost ≈1.2×8×300×1.2=3456 yuan.

- 100W laser: power consumption 3.5kW, annual electricity cost ≈3.5×8×300×1.2=10080 yuan.

Energy efficiency ratio:

Cutting 1㎡ thin acrylic, the power consumption of 100W model is 2.9 times that of 40W.

(3)Soaring maintenance costs

Optical device loss:

The reflectors and lenses of high-power lasers are more susceptible to contamination and ablation, and the annual maintenance cost increases by 8,000-12,000 yuan.

Cooling system pressure:

A 100W laser needs to be equipped with an industrial chiller, while a 40W model can be cooled with air, saving 20,000 yuan in equipment investment.

3. Golden power for thin plate cutting: 40W laser’s dimensionality reduction advantage

(1)Precise energy control to meet diverse needs

When cutting 3mm acrylic, the 40W laser operates at a speed of 15mm/s, and the heat-affected zone can be accurately controlled within 0.3mm, and one-time forming does not require secondary processing. Its power can be flexibly adjusted from 30% to 70%. Whether it is an ultra-thin plate of 0.5mm or 8mm thick acrylic, one device can easily cover a variety of processing scenarios.

(2) Small and flexible, convenient and efficient deployment

The 40W laser device is small in size and occupies 40% less space than the 100W model. It is very friendly to small and medium-sized workshops or maker spaces, and can effectively save site rental costs. The device supports 220V household voltage, and there is no need to modify the circuit. It can be used by plugging in the power supply, and the deployment cost is almost zero.

(3) Green and safe, reducing hidden expenses

The smoke generated by low-power 40W laser cutting is greatly reduced, saving 5,000 yuan in filtration system maintenance costs each year. Its operating noise does not exceed 65dB, and no additional sound insulation facilities are required; while the noise of 100W models often exceeds 80dB, and sound insulation costs are required when using it.

In the field of thin acrylic cutting, 100W lasers are like “cannons hitting mosquitoes”, which wastes resources and makes it difficult to ensure quality. Choosing a 40W laser is not only a guarantee of processing quality, but also a wise move for lean production and cost control. Only by selecting a reasonable model according to actual needs can we avoid falling into the misunderstanding of using high-power equipment.

Conclusion

When cutting acrylic, the laser power needs to be flexibly selected according to the material thickness and processing accuracy: CO2 laser (wavelength 10.6μm) is the mainstream choice in the industry, usually requiring a power range of 40W-150W – 3-5mm thin plates are suitable for 40-80W (cutting speed 0.5-2m/min), and thick plates above 10mm require 100-150W and nitrogen-assisted purge to reduce edge melting and microcracks. The key point is to balance power, speed and gas protection. For example, using 80W laser + nitrogen protection can achieve a smooth cut surface with a finish Ra < 5μm, while avoiding hidden damage caused by thermal stress. In practical applications, parameters need to be optimized through preliminary experiments to ensure a win-win situation of efficient cutting and material integrity.

📞 Phone: +86 185 6675 9667

📧 Email: info@longshengmfg.com

🌐 Website: https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

FAQs

What is the power of laser cutting acrylic?

It is recommended to use CO₂ laser (wavelength 10.6μm) for cutting acrylic, with a power range of 40W-150W. 3-5mm thin plates are suitable for 40-80W (speed 0.5-2m/min), and thick plates above 10mm require 100-150W and nitrogen assist (to reduce edge melting and microcracks). Industrial-grade cutting often uses equipment above 80W, such as Epilog or Trotec brand models, and combined with a gas pressure control system to improve the surface finish to Ra < 5μm.

Can a 30W laser cut acrylic?

A 30W laser can barely cut 1-2mm ultra-thin acrylic, but the efficiency is extremely low (speed < 0.3m/min), and the cut surface is easy to carbonize and yellow, requiring multiple trimming. This power is suitable for DIY enthusiasts or small-batch prototype production, and is not recommended for industrial mass production. Long-term use may also damage the life of the laser tube due to overheating.

Can a 10W laser cut acrylic?

A 10W laser cannot effectively cut acrylic and can only be used for surface marking or engraving of thin sheets below 0.5mm. Forcibly cutting materials above 1mm will cause local burning, release of toxic fumes (such as methyl methacrylate), and uneven cutting depth. It is recommended to use equipment above 40W or CNC engraving machines to balance safety and precision.

Can a 20W laser cut acrylic?

A 20W laser can cut 1-2mm acrylic at a low speed (<0.5m/min), but the cut surface is rough and the edges are yellowed, requiring subsequent polishing. If used temporarily, try to reduce the power to 15W and increase the number of cuts, or install an air-assisted nozzle to blow away the slag. For long-term needs, it is recommended to upgrade to a laser above 40W, or use water jet cutting technology instead.

I do believe all the ideas you have introduced for your post. They are very convincing and can definitely work. Still, the posts are very brief for starters. Could you please lengthen them a little from next time? Thanks for the post.

Thank you so much for your trust and support! We also appreciate your excellent suggestion; you’re absolutely right, more detailed explanations would be much more helpful for beginners. I’ve already added “increasing content length and depth” to my content improvement plan. Do you have any specific subtopics you’re particularly interested in that you’d like me to prioritize for further development?

Thanks , I have just been looking for info about this topic for ages and yours is the greatest I’ve discovered till now. But, what about the conclusion? Are you sure about the source?

Very interesting info !Perfect just what I was searching for! “If you want to test your memory, try to recall what you were worrying about one year ago today.” by Rotarian.