When it comes to CNC machining, there are two main types of machines: 3-axis and 5-axis. While both types of machines are capable of producing high-quality parts and components, there are some key differences between them that may impact which type of machine is best suited to your needs.

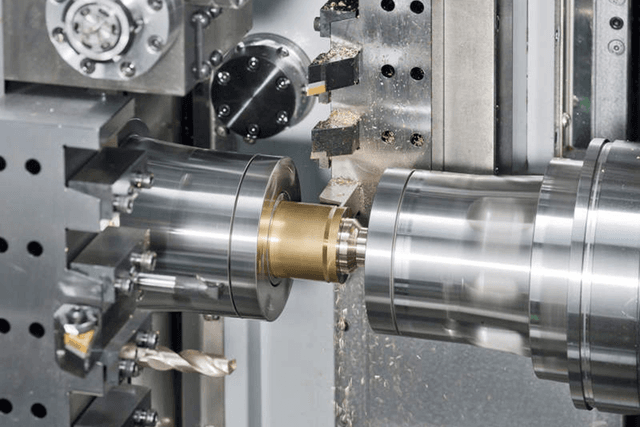

What is 3-Axis CNC Machining?

3-axis CNC machining is the most common type of CNC machining. It uses a computer program to control the movement of a machine tool along three axes: X, Y, and Z. This means that the machine tool can move back and forth, left and right, and up and down. 3-axis CNC machines are typically less expensive than 5-axis machines and are ideal for producing simple parts and components.

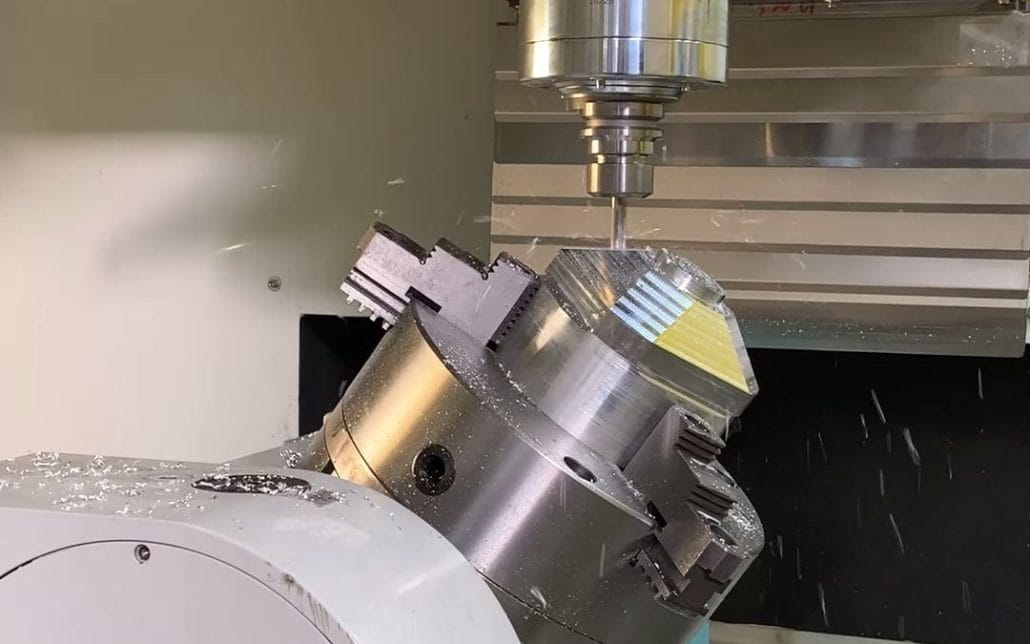

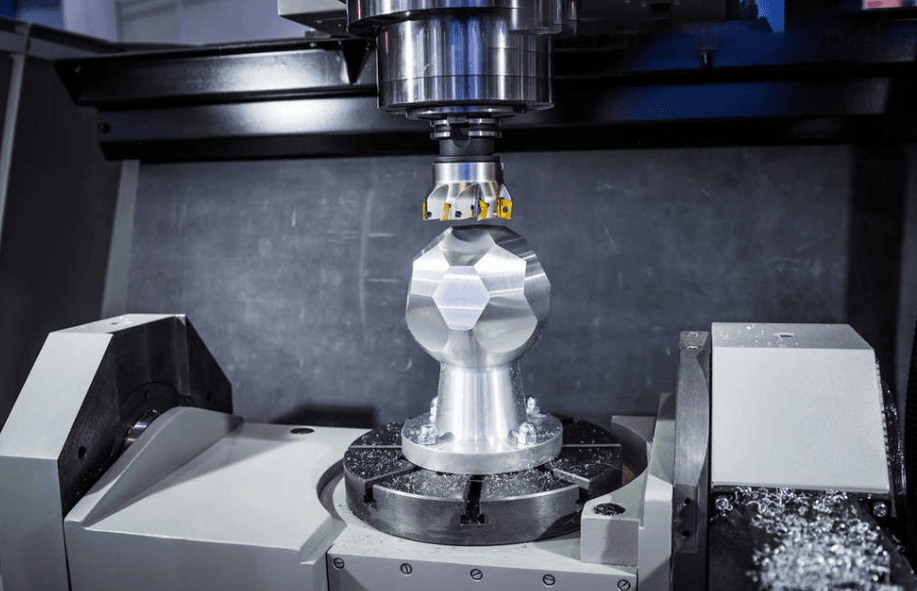

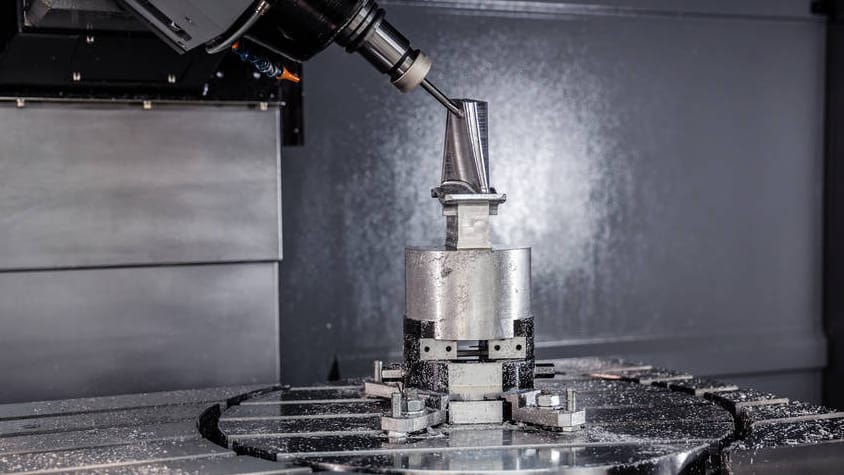

What is 5-Axis CNC Machining?

5-axis CNC machining is a more advanced type of CNC machining. It uses a computer program to control the movement of a machine tool along five axes: X, Y, Z, A, and B. This means that the machine tool can move in multiple directions, including rotating around the X and Y axes. 5-axis CNC machines are typically more expensive than 3-axis machines and are ideal for producing complex parts and components.

Key Differences Between 3-Axis and 5-Axis CNC Machining

- Complexity: 5-axis CNC machines are able to produce more complex parts and components than 3-axis machines.

- Precision: 5-axis CNC machines are generally more precise than 3-axis machines, thanks to their ability to move along multiple axes.

- Speed: 3-axis CNC machines are typically faster than 5-axis machines, which can be advantageous when producing large quantities of simple parts.

- Cost: 3-axis CNC machines are generally less expensive than 5-axis machines, making them a more cost-effective choice for simple parts.

Which Type of CNC Machine is Right for You?

When deciding whether to use a 3-axis or 5-axis CNC machine, it is important to consider your specific needs. If you are producing simple parts in large quantities, a 3-axis machine may be the best choice for you. If you are producing complex parts or components that require a high degree of precision, a 5-axis machine may be the better option.

Conclusion

3-axis and 5-axis CNC machining are two different methods of producing high-quality parts and components. While there are some key differences between the two, both types of machines have their own unique advantages and disadvantages. When deciding which type of machine to use, it is important to consider your specific needs and the requirements of your project.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC Milling Parts Machining Service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items