Imagine that buzzing 3D printer on your desk, no longer just spitting out brightly colored plastic toys or models, but forging hard, shiny stainless steel parts – does this sound like something out of a science fiction novel, or is it a tangible reality? As 3D printing technology continues to push the boundaries of what is traditionally thought of as a “metal beast” that can only be handled by massive industrial equipment – stainless steel – it is being “tamed” by desktop-level printers. Stainless steel, traditionally thought of as a “metal beast” to be handled by bulky industrial equipment, has become the ultimate dream of many creators, designers, and even small manufacturers. However, transforming this rugged alloy from powder or wire into a precision solid that can be realized from the comfort of your desk or workbench is no easy task. It involves crossing barriers of high temperatures, special processes and complex post-processing, forcing us to ask: Can the “metal beast” of stainless steel really be tamed in a desktop environment?

Can 3D printers print stainless steel directly?

Yes! However, you must use a professional industrial-grade metal 3D printer, which is not possible with ordinary desktop equipment. Here are the key facts and technical limitations:

1. Direct metal printing: the field of specialized equipment

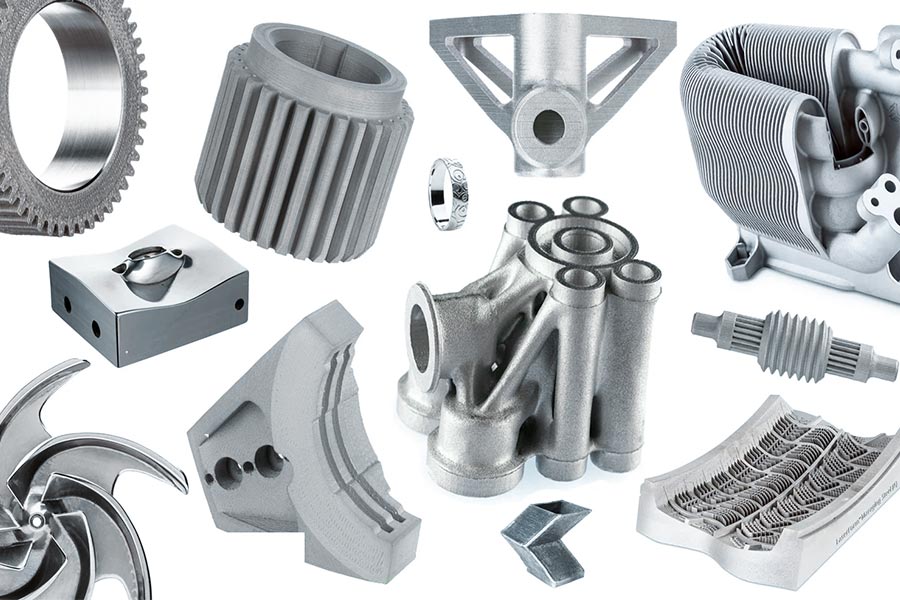

True “direct” printing of stainless steel refers to metal additive manufacturing technologies. These high-end systems use high-powered lasers or electron beams as “pens” and stainless steel powders as “inks”, which are fused and built up layer by layer. Core technologies include:

(1) (SLM / DMLS (Selective Laser Melting / Direct Metal Laser Sintering):

- Principle: High-energy laser beams precisely scan a bed of stainless steel powder, completely melting and solidifying the powder particles.

- Material: Mainly aerosolized stainless steel powders (e.g. 316L, 304L, 17-4PH, 15-5PH, 420, etc.) are used. Powder particle size, sphericity and fluidity requirements are extremely high.

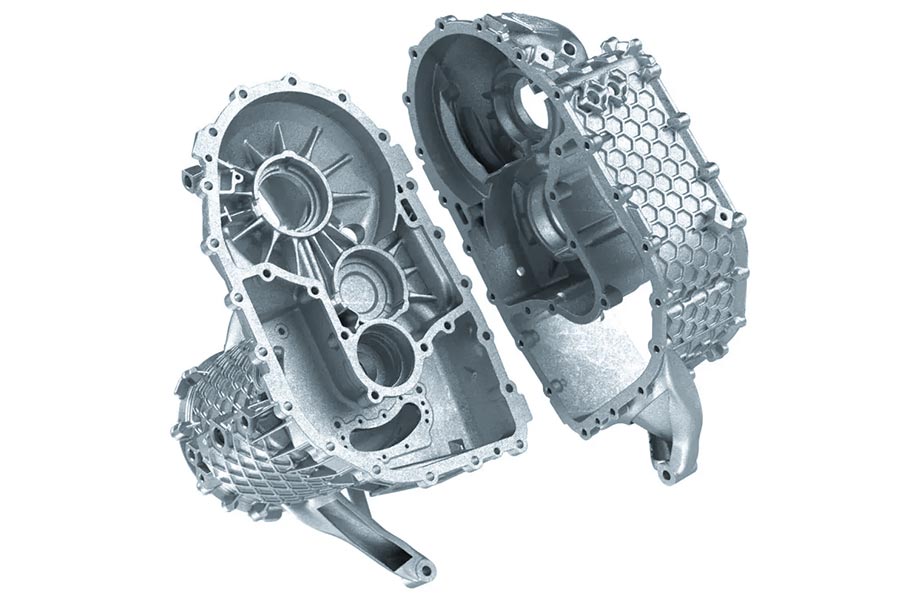

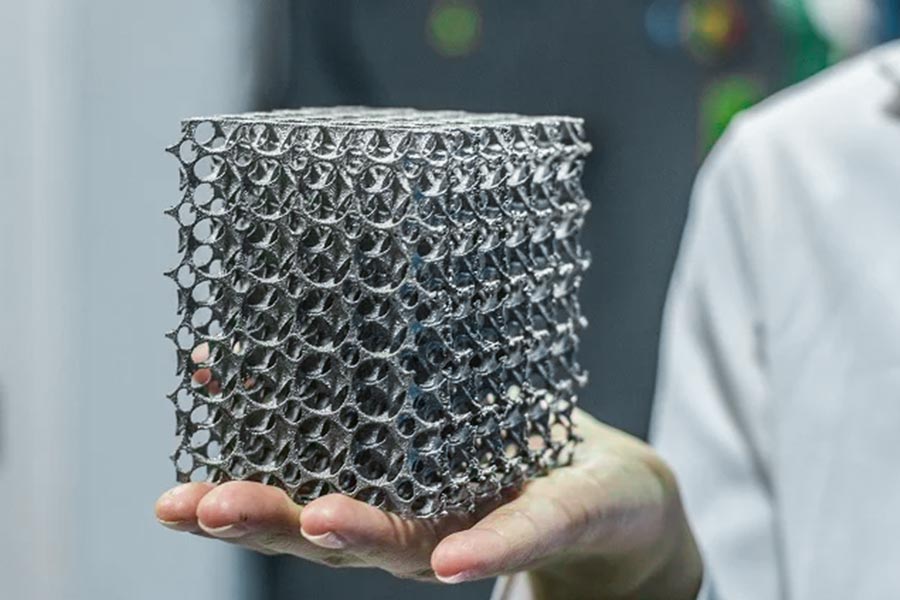

- Characteristics: High density of the finished product (close to 100%), excellent mechanical properties, can create extremely complex geometries (such as internal runners, lattice structure). It is the current mainstream technology for metal 3D printing.

- Equipment representative: EOS, SLM Solutions, 3D Systems and other brands of professional industrial-grade equipment.

(2) EBM (Electron Beam Melting):

- Principle: In a vacuum environment, the use of high-energy electron beam melting metal powder.

- Material: Stainless steel powder is also used, especially suitable for titanium alloys, chrome cobalt alloys, etc., but also for certain stainless steels.

- Characteristics: Higher melting pool temperature, printing speed is usually faster, parts with less residual stress, but the surface is relatively rough.

- Equipment representative: EBM equipment from Arcam (now GE Additive) in Sweden.

What these “direct” metal prints have in common:

- Raw material: Specialized stainless steel metal powder.

- Energy source: High-power laser or electron beam.

- Environment: Typically requires protection from inert gases (e.g., argon) or a vacuum to prevent oxidation of the metal.

- Post-Processing: Printed parts typically require removal of support structures and may be heat treated (to relieve stress and improve performance), surface treated (e.g., sandblasted, polished), and machined (to achieve final dimensional accuracy).

- Cost: Equipment and material costs are very high, and are mainly used in high value-added applications such as aerospace, medical implants, high-end molds, energy, and automotive.

2. “Indirect” metal printing: a desktop-level workaround

Stainless steel cannot be printed directly on common desktop FDM 3D printers (using plastic wires). However, there are a number of “indirect” methods where the printing process and final part properties are fundamentally different from traditional metal printing:

(1) FDM printing with metal-filled wire:

- Principle: The wire is made of a plastic (e.g. PLA, PETG) matrix mixed with a high percentage (up to 80-90%) of fine stainless steel powder.

- Printing: Using a modified FDM printer (requires wear-resistant nozzles), the wire is molded as if it were a normal plastic.

- Post-processing: The printed “raw” parts are extremely fragile and must undergo a complex degreasing and sintering process. Degreasing removes the plastic binder and sintering fuses the metal particles, causing significant shrinkage of the part (up to 15-20%), resulting in a solid metal part (often less dense than SLM prints).

- Characteristics: Relatively low equipment threshold, but complex and time-consuming post-processing, dimensional accuracy greatly affected by shrinkage, and mechanical properties usually lower than those of direct melt-printed parts. Materials such as BASF Ultrafuse 316L are representative.

(2) binder jet technology:

- Principle: The printer sprays a liquid binder onto a bed of stainless steel powder like an inkjet, selectively bonding the powder.

- Post-processing: The printed “green part” also needs to be degreased and sintered to become a dense metal part, again with shrinkage issues.

- Characteristics: Fast print speeds, large part sizes, suitable for mass production, but accuracy and surface finish are generally not as good as SLM/DMLS. e.g. Desktop Metal, HP.

Key Takeaways

- Desktop FDM plastic printers cannot directly print stainless steel.

- Industrial-grade metal 3D printers (SLM/DMLS/EBM) can directly “print” high-performance stainless steel metal parts, which is the true meaning of stainless steel additive manufacturing.

- FDM or binder jetting technologies using metal filled wires are “indirect” methods that require complex post-processing (degreasing and sintering) to obtain metal parts, with different performance, accuracy, and cost structures than direct metal printing.

- The choice of technology depends on the application needs, budget, part performance and accuracy requirements.

Can home 3D printers handle “stainless steel wire”?

It can be printed, but the finished product is not real metal! The “stainless steel wire” sold on the market is actually a metal-filled plastic (Metal-Filled Filament), which can be processed by ordinary FDM desktop printers, but its physical properties are fundamentally different from those of real stainless steel.

1. The real composition and performance of “stainless steel wire”

| Attributes | So-called “stainless steel wire” | Real stainless steel (such as 316L) |

|---|---|---|

| Material composition | 80% PLA/PETG plastic substrate + 20% stainless steel powder | 100% molten stainless steel |

| Tensile strength | Unsintered: about 110MPa After sintering: 200-300MPa | ≥520MPa (industrial forging standard) |

| Conductivity | Complete insulation | Good conductivity (resistivity 7.4×10⁻⁷Ω·m) |

| Corrosion resistance | Porous structure is easy to rust | Pass ASTM G48 corrosion test |

| Applicable standards | Metal-free certification | Meets ASTM F3184 medical grade |

2. Three truths about home printers processing this filament

(1)Printing feasibility

- Compatible devices: All desktop FDM printers (nozzle ≥ 0.4mm) can print normally.

- Printing loss: Metal powder accelerates nozzle wear (hardened steel nozzle is recommended).

(2)Sintering ≠ Metallization

Subsequent oven sintering (usually 200℃×2 hours) can only burn off the plastic substrate, and the residue is a porous stainless steel powder bond, which has two major defects:

The density is less than 60% of real stainless steel, and it is easy to break when tapped.

The microporous structure causes corrosion resistance failure, and it will rust quickly when exposed to sweat and moisture.

(3)Functional limitations

| Application scenario | Is it available? | Reason explanation |

|---|---|---|

| Decorative ornaments/props | Available (the surface can be polished and chrome-plated) | Only metal appearance texture |

| Load-bearing structural parts | Unavailable | Strength is only 20-40% of real metal |

| Electronic conductive parts | Complete failure | Insulation and no conductivity |

| Food/medical contact | Prohibited use | Powder migration poses a safety risk |

3. User Decision Guide: Rational Selection of Consumables

When choosing metal composite wires:

- Applicable scenes: non-load-bearing display models, metal texture prototypes.

- Tips to avoid the pit: do not buy for functional parts, sintering can not be upgraded to industrial metal performance.

When you need real metal:

- Alternative: outsourcing professional metal 3D printing (DMLS/SLM process) or CNC machining.

- Cost reference: small stainless steel printing about $50-500/pc (including post-processing).

Home 3D printers can process “stainless steel wire”, but the output is always a plastic part with metal fillers, which cannot obtain the strength, conductivity or corrosion resistance of real stainless steel even if sintered. If the project requires metal functionality, industrial-grade manufacturing technology must be used.

How much does stainless steel 3D printing cost?

Want to 3D print stainless steel parts? Cost is the core issue that can’t be bypassed. Don’t be confused by the vague offer, this in-depth analysis to help you see the real cost composition of stainless steel printing.

1. Core factors affecting cost

(1) technology route: This is the largest cost watershed.

(2) Part characteristics:

- Size and volume: the amount of material is directly related.

- Complexity: the impact of printing time, the amount of support, post-processing difficulty.

- Accuracy and Surface Requirements: The higher the requirements, the higher the cost of post-processing (machining, polishing).

- Mechanical Requirements: Is there a need for additional processes such as heat treatment?

(3) Materials: Specialized metal powders vs. metal-filled wires, price difference.

(4) Equipment & Operations: Industrial grade equipment is expensive in its own right, and maintenance and gas consumption are also costs.

(5) Post-processing: The cost of support removal, heat treatment, surface treatment, machining, etc. cannot be ignored.

2. The cost of different technical routes is revealed

| Technical route | Equipment cost range (RMB) | Material cost range (RMB) | Typical part cost range (example reference) | Main cost composition |

|---|---|---|---|---|

| Industrial direct melting (SLM/DMLS/EBM) | Millions – tens of millions/unit | High: 500 – 2000 yuan/kg (316L powder) | High: thousands of yuan – hundreds of thousands of yuan/piece (complex functional parts) | Equipment depreciation/rental, high-value powder, high energy consumption, protective gas, professional operators, complex post-processing, support materials |

| Metal binder jetting (BJ) | Millions – tens of millions/unit | Medium-high: 300 – 1200 yuan/kg | Medium-high: hundreds of yuan – tens of thousands of yuan/piece (especially suitable for batches) | Equipment depreciation, powder, binder, debinding sintering furnace, sintering support, post-processing, batch production has advantages in diluting costs |

| Desktop FDM + Metal Filled Wire + Sintering | Low: Thousands – Tens of Thousands of Yuan/Unit (Modified FDM) | Medium: 800 – 2500 Yuan/Roll (Contains High Proportion of Metal Powder) | Medium: Hundreds – Thousands of Yuan/Part (Small and Medium Size Parts) | Wire itself (including metal powder), debinding and sintering outsourcing service fee (key!), risk cost of scrap caused by sintering shrinkage |

Industrial grade direct melt (SLM/DMLS/EBM):

- It’s all about the starting point and the process: expensive equipment is the threshold, specialized stainless steel powders are costly (several or even ten times more than conventional bars), and the printing process consumes a lot of power and requires constant flow of protective gases (argon, nitrogen).

- Post-processing is the main event: removing supports (especially complex cavities) can take hours; heat treatment (stress relieving, solution aging) is just what’s needed; CNC finishing is often required to achieve precise dimensions and finish. Costs are extremely high for small lots or prototypes.

- Suitable Scenarios: Aerospace engine components, medical implants, extremely complex mold inserts that cannot be machined, high performance custom parts. The value is in performance, complexity, and freedom from molds.

Metal Binder Jet (BJ):

- Volume Advantage: Fast print speeds, molding cylinders can lay up a large number of parts at a time, high equipment utilization. Material utilization is relatively high (unbonded powder can be recycled).

- Sintering is a key cost: Degreasing and high-temperature sintering require specialized large furnaces, often outsourced to service providers or centralized. High sintering shrinkage (~15-20%) requires precise compensation design, and support design and removal are also cost points.

- Scenario: Mass production of small to medium sized stainless steel parts (e.g. pump and valve housings, hardware, lightweight structural parts), cost advantage over SLM, especially when the quantity goes up.

Desktop FDM + wire sintering:

- Minimal equipment threshold: ordinary FDM printers can be retrofitted with hardened steel nozzles (limited cost increase).

- Wire cost is not low: while the machine is cheap, a spool of metal-filled wire (e.g. Ultrafuse 316L) can cost 10x more than regular plastic.

- Sintering is the biggest variable and cost: Users are often unable to perform the complex degreasing and sintering process on their own and must rely on a professional service provider. Sintering service fees are calculated by volume/weight of the part, and there is a high risk of shrinkage and deformation, or even failure, which accounts for a high percentage of the cost.

- Suitable Scenarios: Education, small batch customized jewelry, prototype parts with low stress requirements, end parts with less stringent requirements for absolute performance and precision. Value lies in low equipment investment and design verification speed.

3. money-saving strategies and cost optimization

(1) Design optimization:

- Lightweight design: Topology optimization, lattice structure, significant reduction of material usage (material in direct melt = major cost).

- Reduce support: Optimize the angle of parts placement, design self-supporting structure, reduce expensive support materials and post-processing time.

- Consideration of post-processing: Design with machining allowances to avoid dead ends where it is difficult to remove supports.

(2) Technology route selection:

- Small parts/prototypes/low requirements: Prioritize metal FDM wire + outsourced sintering.

- Small to medium volume/medium requirements: Evaluate the economics of binder jetting.

- High Performance/Extreme Complexity/Small Volume High Value Parts: SLM/DMLS is the only option, accepting high unit prices.

(3) Utilize professional service providers:

- No need to purchase your own overpriced equipment, pay per piece. Service providers have experience in optimizing parameters and processes to reduce scrap rates.

- Compare prices across multiple vendors and clarify what is included in the quote (does it include reprocessing? What is included?) .

(4) Material selection:

- Choose a more economical grade (e.g. 316L vs 17-4PH) while meeting performance requirements.

- Confirm service provider’s powder recycling policy (affects cost).

In summary: The truth about the cost of stainless steel 3D printing

- “Direct” stainless steel (industrial grade): very costly. Suitable for areas with high capital or very high part values (aerospace, medical). The unit cost of the part is mainly due to the equipment, materials and specialized post-processing.

- “Indirect” Stainless Steel (Desktop FDM + Sintering): Low cost of entry level equipment, but the combined cost of the final metal part (wire + sintering service) is not cheap and performance is compromised. Suitable for scenarios with limited budgets and less demanding requirements.

- Binder jetting: has the potential to offer a more competitive cost per part than SLM when mass producing small to medium sized parts.

- Design is a key lever for cost reduction! Material and time savings from optimized design are significant.

Which industries have applied stainless steel 3D printing?

Stainless steel 3D printing technology has been deeply applied in many industrial fields due to its high strength, corrosion resistance and design freedom. The following are the specific application directions and technical characteristics of each industry:

🏥 1. Medical and Dental: Accurately Reinventing Life and Health

Customized surgical implants:

- Orthopedic revolution: Based on patients’ CT data, 3D printing of perfectly matched titanium/stainless steel bone plates, intervertebral fusion devices, and joint components. Say goodbye to traditional implants that “cut to fit” and dramatically improve surgical precision and healing speed.

- Complex structures: Create porous trabecular structures that cannot be realized by traditional processes, promoting bone growth and significantly reducing the risk of rejection (clinical data shows that the fusion rate can increase up to 20%).

High-performance surgical instruments:

- Lightweight design: Printing of hollow and skeletonized needle holders, bone drill guides, and minimally invasive surgical instruments reduces hand fatigue by up to 30%.

- Functional Integration: One-piece electrosurgical instruments with internal cooling channels to address overheating pain points.

Dental applications:

Long-lasting durability: Produces high-precision, biocompatible metal endosseous crowns/bridges and implant abutments that are much stronger than traditional cast parts.

✈️ 2. Aerospace: A weapon to conquer the blue sky and space

Engine core upgrade:

- Fuel nozzle king: GE Aviation uses 3D printed fuel nozzles to combine 20 traditional parts into one, reducing weight by 25% and increasing durability by 5 times, becoming a benchmark application in this field.

- Extreme heat exchange: Manufacturing 316L stainless steel heat exchangers with ultra-complex flow channels inside, with heat exchange efficiency soaring by 40%.

Satellite lightweight and high performance:

- Topological optimization brackets/connectors: While ensuring strength, weight reduction of up to 40%, significantly reducing launch costs.

- Customized RF components: Waveguide and antenna structures that meet special electromagnetic performance requirements.

Fast guarantee and maintenance:

- On-demand manufacturing: Rapidly produce spare parts for old or discontinued aircraft and satellites to avoid sky-high inventory and long delivery times.

⚡ 3. Energy industry: guardian of harsh environments (petroleum, chemical, nuclear)

The king of corrosion resistance:

- New standard for valves/pump bodies: Printed monolithic molded ball valves, centrifugal pump impellers and chambers, eliminating weld leakage points and extending life by 3 times in strong acid, alkali and high pressure environments.

- Flanges and Seals: Customized solutions to sealing problems in complex working conditions.

Breakthrough in nuclear power field:

- Radiation Resistant Components: Manufacture of specially shaped monitoring devices and maintenance tools in reactors, with material purity and performance far exceeding traditional processes.

Piping system innovation:

- Shape-optimized piping: Designing internal flow paths to be more hydrodynamic, reducing pressure loss by up to 15%, and improving energy efficiency.

🏭4. Industrial Equipment and Mold Production: Efficiency and Intelligence Drivers

Mold Revolution – Conformal Cooling:

- Rebellious cooling efficiency: In the injection mold inserts printed inside the cooling waterway to correspond to the product shape, 30%-50% decrease in cooling time, product deformation eliminated, improve yields.

High-performance fluid equipment:

- Integrated impeller/worm gear: Produceton impellers with maximum blade surface for 10%-20% enhanced efficiency and improved cavitation resistance.

Agile Manufacturing

- Custom jigs/fixtures: Rapidly respond to production line needs and print high-complexity lightweight fixtures at 50% cost reduction and 70% lead time savings.

🚗5. Automotive and high-performance racing: the world of speed and performance

Performance Squeeze:

- Turbocharger parts: Manufacturing high-temperature-resistant turbine housings and blades with internal cooling channels.

- Racing exhaust systems: High-temperature resistant, lightweight custom exhaust tubing, collector chambers.

Lightweighting industry pioneer:

- Topology-optimized suspension components: Applied in formula vehicles and luxury sports cars, without compromising strength but with a significant reduction in weight.

Rapid prototyping:

- Functional test components: Rapid availability of high-fidelity metal prototypes for bench testing, reducing the R&D cycle by 60%.

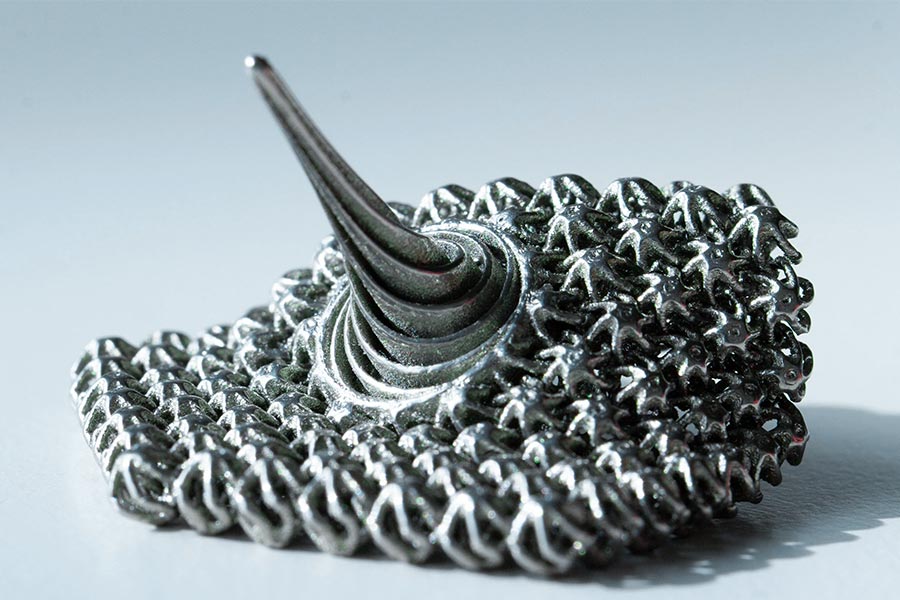

💎6. Luxury consumer products and jewelry: the convergence of art and technology

Personalization:

- Sophisticated art jewelry: 316L stainless steel printing, rings, pendants, skeleton, woven, micro-carved texture, difficult for ordinary goldsmiths to realize, with boundless design freedom.

- High-end components: Making personalized watch cases, limited edition pen components, luxury eyeglass frames with texture and design.

🔬7. Research and education: a future research lab

Personalized experimental equipment:

- Corrosion-proof reactors: Printing custom-shaped reactors, microchannel reactors for chemistry and materials research.

Teaching aids:

- Metal teaching aids: Print advanced mechanical structures, molecular models, architectural models, so abstract concepts are within reach.

The inherent value of stainless steel 3D printing drives industry applications:

- Free extreme complexity: Print hollow, porous, internal runner structures which cannot be produced by traditional processes (casting, machining, welding).

- Small batch customization king: Erase the shackles of molds to economically produce customized, small batch, high value parts.

- The height of lightweighting: Topology optimization and lattice structure to significantly reduce weight and improve performance (e.g., fuel efficiency).

- Improved Material Performance: High-density stainless steel parts such as 316L, 17-4PH, etc. with much better mechanical properties (almost as good as forgings) are possible with unique processes (e.g. SLM).

- Speed wins: Accelerated development cycle times and spare parts delivery times from concept to completed product.

Industry Application Map:

| Industry | Core application scenarios | Unique value |

|---|---|---|

| Medical dentistry | Custom implants, surgical instruments, dentistry | Precise matching, promote healing, biocompatibility |

| Aerospace | Engine parts, satellite parts, spare parts | Extreme weight reduction, performance improvement, rapid response |

| Energy industry | Corrosion-resistant valve pumps, nuclear power parts, pipelines | No welds, leak-proof, extreme environment resistance, long life |

| Industrial molds | Conformal cooling molds, fluid equipment, tooling | Efficiency soaring, yield improvement, agile manufacturing |

| Auto racing | High-performance parts, lightweight structure, prototype | Speed upgrade, weight reduction and efficiency improvement, accelerated R&D |

| High-end consumption | Art jewelry, luxury parts | Design freedom, complex aesthetics, personalized customization |

| Scientific research and education | Customized experimental equipment, teaching models | Exploration and innovation, intuitive teaching |

Conclusion

Stainless steel can be 3D printed, but not all printers can control this “metal beast”. Desktop printers (FDM) can only “indirectly print” through metal filling wires, relying on complex degreasing and sintering post-processing, and finally obtain metal parts with reduced performance. The real “tamer” is the industrial-grade metal 3D printer (SLM/DMLS/EBM) – they use lasers or electron beams as “claws” to melt stainless steel powder layer by layer into high-performance dense parts, completely unlocking cutting-edge manufacturing such as complex designs, medical implants, and aerospace engines. Which path to choose depends on whether you need not only the “metal appearance” but also the “real soul of steel”.

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email: info@longshengmfg.com

🌐 Website: https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

FAQs

1. Can ordinary desktop FDM printers directly print solid stainless steel parts?

Absolutely not. Desktop machine can only use metal composite wire (such as PLA substrate containing 80% stainless steel powder), print out the fragile “blank”, must be through the professional degreasing (dissolve plastic binder) and 1400 ℃ high-temperature sintering (so that the metal particles are fused) in order to be transformed into metal parts, the whole process takes more than 48 hours, and the shrinkage of parts The whole process takes more than 48 hours, and the shrinkage rate of the parts is as high as 15-20%, and the density is only 90%-95%, so the mechanical properties are significantly lower than those of industrial-grade products.

2.Industrial metal 3D printer how to overcome the high melting point of stainless steel manufacturing challenges?

Industrial equipment using ultra-high temperature energy source: SLM/DMLS technology to kilowatt-class laser beam (power 500W-1000W) in an argon environment, instant melting of stainless steel powder (local temperature > 2500 ℃), layer by layer build-up of density of more than 99.5% of the fully dense parts; EBM technology with an electron beam in a vacuum chamber melting powder, suitable for the manufacture of large-size, low-stress parts, both can directly achieve forging-grade mechanical properties. Both can directly achieve the mechanical properties of forging level (such as 316L tensile strength > 500MPa).

3. What are the hidden costs and risks of choosing desktop metal wire program?

Hidden costs include: ① special wire price of about 1500-2500 yuan / roll (500g), 15 times more than ordinary plastic; ② degreasing and sintering outsourcing service fee of about 300-800 yuan / piece (depending on the volume); ③ sintering shrinkage and deformation of the scrap rate of more than 30%; ④ the final part of the existence of pores and impurities, tensile strength than industrial parts is lower than the tensile strength of more than 30% (only about 300MPa), only It is only suitable for non-structural applications such as jewelry and display models.

4. What are the key application scenarios mandatory industrial-grade stainless steel printing?

Three types of rigid demand scenarios: ① life-related fields: such as medical implants (spinal fusion, dental abutments) need to be 100% dense and sterile, desktop program pores will breed bacteria; ② extreme operating conditions parts: aerospace fuel nozzles (to withstand 1,000 ° C high temperature / high-pressure fuel flushing), nuclear power valves (radiation corrosion resistance) requires material purity and fatigue strength; ③ integrated functional structure: shaped ③ integrated functional structure: the cooling mold (waterway from the surface of only 1mm), engine lightweight impeller (wall thickness of 0.3mm complex curved surface), desktop solutions can not achieve precision and functional integration.

I definitely wanted to write down a simple note to express gratitude to you for some of the pleasant hints you are posting on this website. My extended internet search has now been compensated with really good information to go over with my pals. I ‘d express that many of us website visitors actually are undeniably fortunate to dwell in a really good network with very many outstanding professionals with great strategies. I feel very happy to have come across your website and look forward to tons of more pleasurable times reading here. Thanks once again for everything.

Reading your message filled me with warmth and gratitude. The fact that you took the time to write this “short letter” means so much to me. I’m especially happy to know that my sharing has truly helped others. Thank you so much for your kind words; you are always welcome here, and we look forward to seeing you again soon!

I beloved as much as you will receive performed proper here. The cartoon is attractive, your authored subject matter stylish. nevertheless, you command get got an nervousness over that you want be handing over the following. unwell indubitably come more beforehand once more since precisely the same just about a lot frequently inside case you defend this increase.

I truly appreciate this post. I¦ve been looking everywhere for this! Thank goodness I found it on Bing. You have made my day! Thanks again

I’ve been absent for a while, but now I remember why I used to love this website. Thank you, I will try and check back more often. How frequently you update your site?

Thank you for your like, our article is updated daily

I am not sure where you’re getting your information, but great topic. I needs to spend some time learning more or understanding more. Thanks for fantastic info I was looking for this information for my mission.