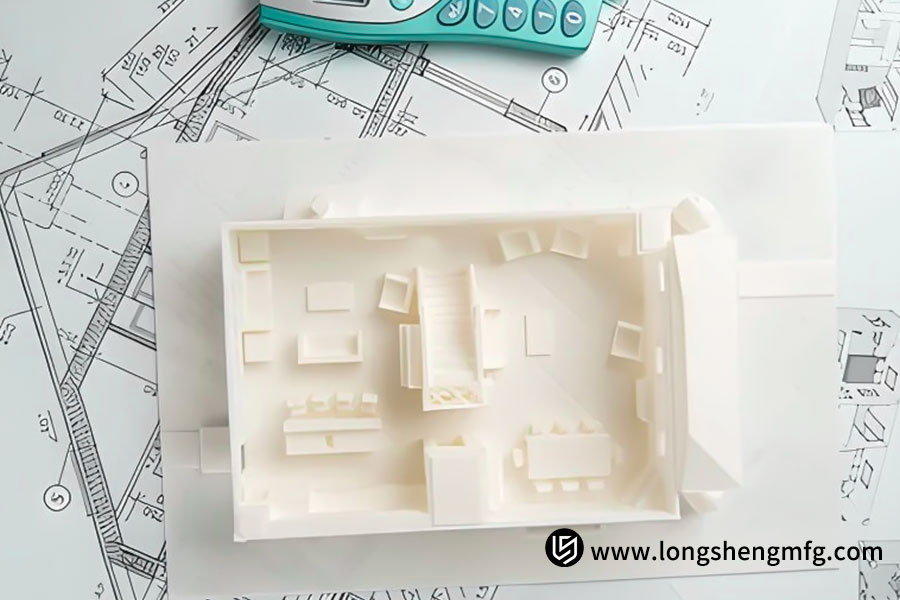

3D printing technology, with its unparalleled flexibility and efficiency, is rapidly penetrating all areas of product prototyping and functional component manufacturing. However, accurately estimating costs remains a primary challenge for customers. A wide variety of materials, diverse process options, and varying post-processing requirements—these intertwined variables lead to significant price variations, creating a complex quoting process. This process is not only time-consuming but also highly susceptible to budgetary risks due to a lack of transparency.

To address this industry pain point, a clear understanding of the core components and key influencing factors of 3D printing pricing is crucial. This is precisely where the LS Intelligent Online Quoting System comes in. Using advanced algorithms, it transforms complex cost variables into clear and transparent figures, allowing you to obtain accurate quotes with no hidden fees in just minutes. Eliminate hassles and uncertainties, plan your projects efficiently, and achieve true cost control—experience it now and start your 3D printing project journey.

Core Dimensions And Influencing Factors of 3D Printing Service Pricing

| Pricing Dimensions | Key Influencing Factors |

|---|---|

| Core Cost Drivers | Material consumption (model volume + support structure amount), material unit price, and equipment man-hour rate (printing time). |

| Process Selection | Costs vary significantly between different technologies: SLA/DLP (photosensitive resin), SLS (nylon powder), FDM (filament), MJF (nylon), various metal printing methods (such as SLM and DMLS), etc. |

| Model Design Factors | Model size (directly affects volume), geometric complexity (significantly affects support structure amount), wall thickness, whether hollow structures are used, and the orientation of the model on the build platform (affecting supports, labor time, and success rate). |

| Post-Processing Requirements | Basic post-processing (support removal and cleaning) is typically included, with added costs for value-added services: grinding, sandblasting, dyeing, painting, electroplating, assembly, and special packaging. |

| Quantity and Delivery | Discounts are often offered for mass production; expedited orders (shortening standard delivery times) typically incur a surcharge. |

| Quote Process | 1. Upload a 3D model file (STL/STEP, etc.) 2. Automatic system analysis + manual selection of material/process/post-processing options 3. Instantly generate a detailed quote. |

Why Trust This Guide? The Deep Logic Of The LS Quoting Engine

LS quotes go far beyond a simple “per-gram” price. We wouldn’t survive if we were to price solely based on material weight. Our intelligent quote engine is a practical value calculator, comprehensively analyzing:

- Material Properties: The cost and control of medical resins far exceed those of ordinary plastics.

- Equipment Investment: Printing time (complex parts take significantly longer than solid blocks) and wear and tear on high-precision equipment (such as printheads and lasers).

- Labor and Labor Hours: The specialized skills and time required for model preparation, precision monitoring, and complex post-processing (such as support removal, polishing, and specialized cleaning).

- Risk Tolerance: Based on model complexity and material, we intelligently assess failure rates and factor them into the cost of ensuring success.

Trust Built on Deployment:

The confidence in this guide stems from the data accumulated from LS’s successful delivery of tens of thousands of real parts. From concept models to final parts under demanding conditions, the process parameters, time consumption, resource consumption, and risks of each print are systematically analyzed and integrated into our algorithms. For example, a 50-gram medical microfluidic chip, while low in material cost, requires 12 hours of precision printing at constant temperature and humidity, along with specialized post-processing. Its value far exceeds its weight.

Professional, transparent, and accountable:

The engine is powered by expertise in materials science, engineering, and production management, leveraging a vast amount of manufacturing data. It accurately measures each part’s unique process challenges and true manufacturing costs, providing transparent, reliable estimates to help you plan accurately.

Get an instant, accurate quote based on deep manufacturing logic.

Why Do You Need A Clear And Immediate 3D Printing Quote?

3D printing has become an indispensable tool in the fast-paced world of product development, prototyping, and low-volume production. However, many users often encounter numerous obstacles in obtaining printing services—the first step, the quote request. This consumes valuable time and effort, and can even impact project progress. Traditional quote processing is becoming a bottleneck to improving efficiency and controlling costs. So, why is a clear and timely 3D printing quote so important? Because it directly addresses several long-standing pain points in the industry:

Pain Point 1: The traditional quote request process is cumbersome, time-consuming, and inefficient.

Email/Phone Wars? Have you ever experienced sending an STL file and then being caught up in lengthy email battles or endless customer service calls, repeatedly negotiating model details (e.g., wall thickness, minimum feature size, support requirements), material selection (PLA, ABS, nylon, resin?), surface finish requirements (sanding, painting, dyeing?), and specific quantities?

Long Waiting? After submitting your request, you passively wait for customer service or engineers to process your request. Quote turnarounds can take hours, or even days, ruthlessly delaying project progress.

Is this information black hole causing quotes to “flip”? Initial quotes from service providers are often inaccurate due to incomplete information or misunderstandings during initial communication. When you think your budget is on track, you’re later told you’ll need to pay extra for “extras” like model repairs, special supports, and complex post-processing. This throws your budget out of control and your trust plummets.

A solution for clear, instant quotes: Our online automated quote tool allows you to directly upload your model file, select materials, processes, post-processing options, and quantities in real time, and generate an accurate quote in seconds. This eliminates all intermediate communication steps and lengthy wait times, ensuring complete information input and preventing “surprise” price increases later in the process.

Pain Point 2: Pricing Structure Like a “Black Box,” Leaving You Suspicious?

Is your money being spent unclearly? The quotes you receive often contain only a cold, lump-sum price. What percentage of the cost is material? How is machine run time calculated? How are the costs of complex post-processing steps (such as grinding, sandblasting, and painting) allocated? You’re left in the dark, feeling like you’re dealing with an opaque “black box.”

Concerns about “pricing” and hidden fees? The lack of transparent pricing standards makes you wonder: Are regular customers being “price-gouged”? Are there hidden fees (such as startup fees or document review fees) hidden in the quote that you haven’t noticed? Prices vary significantly between service providers, making it difficult to discern whether they reflect true costs or are simply inflated.

Have comparisons become blind guesses? Want to choose the most cost-effective service provider? However, varying quotes based on different criteria and vague inclusions leave you in a fog of uncertainty, making it difficult to make a truly cost-effective choice.

A clear, detailed instant quote solution: A clear, detailed instant quote dissects the cost structure like a scalpel: material costs (unit price * quantity used), machine labor (calculated by hour or layer), post-processing costs (such as sanding and painting), and management fees (if any) are all clearly visible. Price transparency eliminates the “black box” mentality, allowing you to clearly understand the value of every penny. It also provides a reliable basis for fair and honest comparisons of quotes from different service providers, eliminating the possibility of “price gouging.”

Pain Point 3: Ambiguous Estimates Hinder Decision-Making and Missing Opportunities?

Budget feasibility remains a mystery? In the early stages of a project or during the design phase, you urgently need a rough cost range to determine whether the solution is within budget. However, vague estimates (“maybe a few hundred to a few thousand”) leave you feeling lost and unable to provide strong financial support.

Is your project stuck? Time waiting for a quote is time the project is stalled. R&D progress, production schedules, and marketing plans could all be pushed back due to this last-minute delay, leading to missed market opportunities.

Is cost accounting accuracy difficult to guarantee? For scenarios requiring precise project cost accounting (such as bidding and internal cost control), a vague, delayed, and potentially volatile estimate simply cannot meet these requirements, creating risks for financial management and pricing strategies.

A solution for clear and instant quotes: Immediacy is key. During the design iteration process, you can upload the latest model at any time and instantly obtain an accurate quote close to the final cost, quickly verifying the budget feasibility of the design. This greatly accelerates the decision-making process—should we continue to optimize the design, adjust materials, or immediately start production? With a clear understanding of the numbers, we can act decisively. Furthermore, accurate quotes provide a solid and reliable data foundation for project cost accounting, enabling more rational financial planning and pricing strategies.

Intelligent Online Quotation VS Traditional Quotation Method

In a highly competitive business environment, obtaining quick and accurate product or service quotes is a crucial step in business decision-making. However, relying on traditional email or phone inquiries often results in lengthy wait times, ambiguous information, and back-and-forth communication, significantly slowing down business processes. Today, we introduce you to the intelligent online quotation system, which is more than just a “faster” tool; it represents a comprehensive upgrade in quotation efficiency, information transparency, and decision-making support! Let’s take a visual comparison to reveal its unparalleled advantages:

Traditional Mail/Phone Inquiry vs. Smart Online Quote System Quick Reference

| Comparison | Traditional email/phone inquiries | LS’s intelligent online quotation system | Core advantages |

|---|---|---|---|

| Speed | A few hours to a few days (waiting for manual processing and response) | Seconds/minutes (system automatically responds immediately) | Significant efficiency gains, eliminating waiting times. |

| Transparency | Quotations are often simple, with unclear cost structures. | Detailed cost breakdowns provide clarity and transparency at a glance. | Information symmetry enhances trust. |

| Convenience | Requires repeated communication to confirm details and relies on manual response. | 24/7 self-service: Quotes can be submitted anytime, anywhere. | Highly autonomous, with no time constraints. |

| Flexibility | Adjusting parameters requires renegotiation, which is extremely inefficient. | Adjust parameters in real time, with immediate price visibility. | Dynamic optimization enables agile decision-making. |

| Accuracy | Errors can easily be caused by information miscommunication or misunderstandings. | Based on real-time models and data, algorithms provide precise calculations. | A reliable foundation reduces risk. |

| Basis for preliminary decisions | Long waiting times make it difficult to conduct a quick budget assessment. | Instant access to reliable budget references supports preliminary decisions. | Seize opportunities and accelerate the process. |

Choosing Smart Online Quotation means choosing a more efficient, transparent, agile, and reliable way of working. It’s not only a tool for reducing costs and increasing efficiency, but also a strategic solution that enhances customer experience, strengthens market competitiveness, and drives rapid business growth.

Experience the revolutionary changes brought by Smart Online Quotation now, enabling you to make faster business decisions and win from the start!

What Are The Transparent Factors That Influence 3D Printing Prices?

Want to know how 3D printing service providers quote you? What’s the tangible evidence behind price differences? LS will clearly reveal the key transparent factors that are publicly available, quantifiable, and directly impact your final cost, helping you accurately estimate costs and make informed choices!

| Factor | Description |

|---|---|

| 1. Model | Size (filaments), Geometric Complexity (supports, printing time), Accuracy Requirements (layer height, equipment level) |

| 2. Printing Materials | Material types (PLA, ABS, resin, etc.) vary significantly in cost; Material grade (common vs. engineering/medical grade) |

| 3. Printing Technology | FDM, SLA, SLS, SLM/Metal: Cost structures vary significantly |

| 4. Print Quantity | Single piece vs. small batch vs. large batch (to share preparation costs) |

| 5. Post-Processing | Requirements: Additional processes (sanding, painting, dyeing, plating, assembly) and their complexity |

| 6. Additional Services | Design optimization, model repair, expedited service fees |

1. Model Itself: The Cost Factor of the Design

Volume = Consumables: The larger the model, the more printing material is consumed, and the cost naturally increases. This is the most intuitive basis for cost calculation.

Geometric Complexity: Overhanging structures and complex hollow designs require additional support structures, which not only increases material consumption but also significantly prolongs printing time (longer equipment usage), doubly driving up the price.

Precision and Surface Requirements: Require ultra-fine details (such as miniature models) or mirror-like smoothness? This typically requires a smaller build layer height and higher-precision industrial equipment (rather than desktop equipment), resulting in higher investment costs and a correspondingly higher price.

2. Printing Materials: The Core Cost Variable

Material Types Vary Vastly:

Base Materials (PLA, PETG): Economical and Affordable.

Engineering Materials (ABS, Nylon, PC): Better Strength and Temperature Resistance, but Higher Price.

Specialty Resins (for SLA/DLP): Available in a wide variety (standard, tough, high-temperature resistant, casting, etc.), generally priced higher than FDM filament.

Metal powders (SLS, SLM/DMLS): Materials such as titanium alloys, aluminum alloys, and stainless steel have extremely high material costs, several times or even dozens of times higher than plastic printing.

Material Grade: Within the same material type, there is a significant price difference between “general grade” and “engineering grade” (higher strength/heat resistance/flame retardant) or “medical grade” (biocompatibility certified).

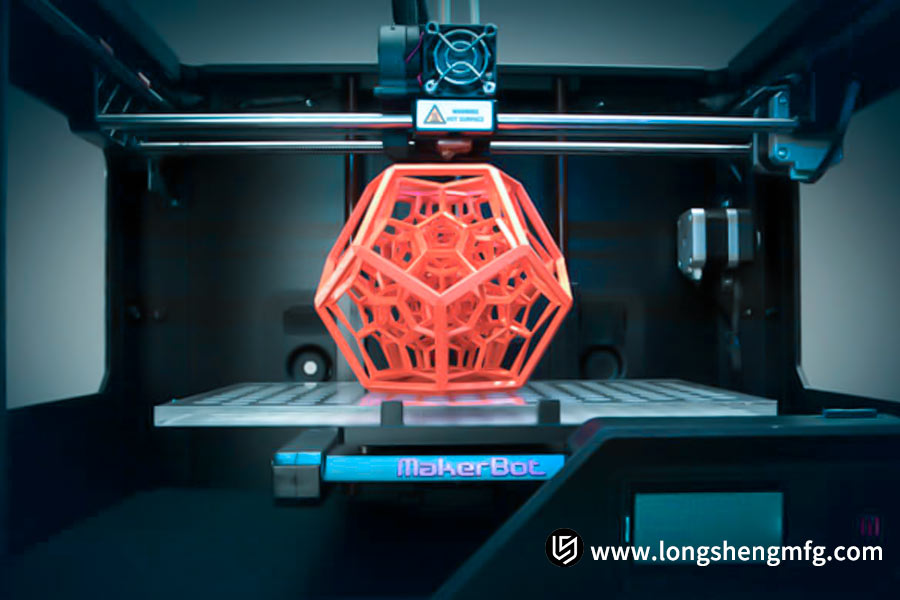

3. Printing Technology: Different processes have different cost structures.

FDM (Fused Deposition Modeling): Equipment and material costs are relatively low, making it suitable for prototypes and functional parts.

SLA/DLP (Stereolithography): Achieve extremely high precision and smoothness, but equipment and resin costs are higher than FDM. Suitable for detailed models, jewelry prototypes, and other applications.

SLS (Powder Sintering): Using powders such as nylon, it eliminates the need for supports and can create complex structures, but equipment and material costs are high.

SLM/DMLS (Metal Printing): Using lasers to melt metal powder, equipment is extremely expensive (in the millions), material costs are high, and the processing environment (inert gas) is demanding, making it the most expensive 3D printing technology.

4. Print Quantity: Scale Empowers

Single-Part Production: Fixed startup costs, such as equipment setup, calibration, and model slicing, are incurred, resulting in the highest unit price.

Small-Batch Production: Fixed startup costs can be spread over multiple parts, significantly reducing the cost per part.

High-Batch Production: Scale efficiencies are maximized, further reducing unit costs. However, 3D printing generally lacks a cost advantage over traditional processes (such as injection molding) in large-scale production.

5. Post-Processing Requirements: Finishing, an Additional Cost

Necessary Processing: Services such as support removal (SLA/FDM), powder removal (SLS), and cleaning/curing (resin printing) are typically included in the basic service.

Enhanced Processing = Additional Cost:

Surface Treatment: Sanding, polishing, and sandblasting (to improve the finish).

Surface Decoration: Painting, dyeing, and plating (to enhance the appearance).

Functional Processing: Heat treatment (to improve the performance of metal parts), assembly, and sealing.

The higher the complexity and the longer the labor time, the greater the cost markup!

6. Additional Services: Professional Value-Added Items

Design Optimization (DFAM): Engineers optimize the model to reduce printing difficulty, cost, and failure rate (e.g., reducing supports, optimizing wall thickness, and splitting large parts). This service is charged by the hour, but often results in significant savings in printing costs.

Model Repair: Repairs problematic STL files (broken surfaces, non-manifolds, incorrect normals) to ensure printability. This service is charged based on the level of difficulty.

Expedited Service Fee: Prioritizing insert orders and using faster printing parameters or equipment incurs an additional fee.

When choosing a 3D printing service provider, proactively inquire about the detailed pricing logic for these factors! Clear model requirements (format, size, accuracy, quantity, and post-processing) are essential for obtaining an accurate quote. Understanding these “transparent” factors will eliminate ambiguous quotes and help you manage your 3D printing costs!

Does transparent pricing equal the lowest price? LS takes you to find out.

When looking for 3D printing services, does “lowest price” truly equate to “best choice”? The answer is often no. We firmly believe in and practice transparent pricing, providing quotes that accurately reflect the true value of our services, rather than simply pursuing the lowest price in the market. The underlying principle is a profound balance between value and cost.

The core of transparent pricing: value-driven, not price-competitive.

High-quality equipment and consumables = lower hidden costs: We insist on using industrial-grade printers and professionally certified materials. This ensures superior print quality and ultra-high stability, significantly reducing print failures and scrap rates. You save on hidden costs such as reprints, delays, and material waste caused by substandard quality.

Strict process control = guaranteed results: From professional model slicing optimization and full print monitoring to standardized post-processing procedures, we strive for excellence in every step. This ensures that the finished product meets your expectations, works right the first time, and eliminates the time and cost of repeated revisions and communication.

Professional technical support = risk mitigation: We provide more than just printing services; we also provide professional model inspections, print orientation recommendations, and post-processing consultation. These value-added services help you avoid potential issues at the source of your design, significantly reducing the risk and cost of project errors.

Improved quality assurance and service = a worry-free collaboration experience: A clear quality issue handling process and customer service commitment ensure transparency and peace of mind throughout the entire collaboration process. You avoid the extra communication costs and effort associated with after-sales issues.

A Smart Choice: Focus on Total Cost of Ownership (TCO)

When choosing a 3D printing service provider, don’t just focus on the “print price.” True cost-effectiveness is reflected in the total cost of ownership (TCO), which includes the quality costs of the printed part itself, project delays, the cost of repeated communication and collaboration, and the potential losses caused by quality risks.

One point of transparency equals ten points of value. We provide real value and guaranteed assurance that can withstand scrutiny. In today’s pursuit of efficiency and quality, let transparent pricing reveal the true value for money and make a wise choice that truly saves you time, effort, and money. Every hidden cost you save is a testament to our professional value!

Get your accurate quote instantly? Three steps!

Still struggling with the complex 3D printing inquiry process? Want a clear, fast, and transparent quote? Get our precise 3D printing service quote instantly in just three easy steps!

Step 1: Upload Your 3D Model File

This is the foundation of your quote! Simply upload your design file (supports common formats like STL and OBJ) directly to our online platform. This step clearly outlines your core printing requirements.

Step 2: Select Key Parameters Online

Flexibly set parameters based on your project needs:

Select Material Type and Grade: Choose from a variety of engineering plastics, resins, or metals.

Select Print Technology: Manually select (e.g., FDM, SLA, SLS) or let the system intelligently recommend the best technology based on your material and model requirements.

Enter Print Quantity: Specify the exact number of pieces you require.

Select post-processing options: such as sanding, painting, staining, assembly, etc.

(Optional) Specify special requirements: such as accuracy level, specific color, etc.

Step 3: Click “Get Quote” / “Calculate Now”

Witness intelligence and speed! After clicking the button:

Instant feedback: Based on advanced intelligent algorithms and real-time cost data, the system generates a detailed quote in seconds.

Completely transparent costs: The quote clearly lists every cost component, including basic printing fees, materials, post-processing fees, taxes, and more. The total price is clear at a glance, with no hidden fees.

Get a clear quote now! After completing these three steps, you’ll receive an accurate and transparent quote.

How To Optimize Your 3D Printing Costs With Instant Quotes?

3D printing costs aren’t static! With advanced online instant quote systems, you can adjust parameters in real time to make the most economical printing decisions. The table below summarizes five core optimization techniques to significantly reduce costs:

| Optimization Technique | Core Action | Cost Savings |

|---|---|---|

| 1. Flexible Material Selection | Switch between different material types (PLA, ABS, PETG, etc.) in real time. | Compare price differences and choose the most economical one that meets your requirements. |

| 2. Smart Batch Optimization | Enter different quantities (1, 5, 10, etc.) | Leverage economies of scale to find the lowest unit price batch point |

| 3. Streamlining Post-Processing | Clearly distinguish between required and optional post-processing steps. | Only select those that are truly necessary to avoid redundancy. |

| 4. Model Lightweighting | Evaluate the volume/complexity indicated by the system and consider topology optimization. | Reducing weight directly reduces material and printing costs. |

| 5. Reasonable Accuracy | Select the minimum required accuracy level based on actual usage requirements. | Lowering accuracy significantly reduces printing time and cost. |

1. Flexible Material Selection:

Operation and Savings: Compare prices of different materials (PLA/ABS/PETG, etc.) in real time to select the most economical material that meets your core requirements.

2. Quantity Adjustment Testing (Batch Optimization):

Operation and Savings: Test different quantities (1, 5, 10 pieces, etc.) to leverage economies of scale to spread costs and find the optimal batch size for unit price.

3. Required Post-Processing:

Operation and Savings: Clearly distinguish between required post-processing (such as base sanding) and optional options (such as painting), selecting only what is necessary to avoid overlapping costs.

4. Model Lightweighting Exploration:

Operation and Savings: Evaluate the volume and complexity indicated by the system. While ensuring functionality is met, consider topology optimization or hollowing out to reduce weight and material and time costs (modify the model and re-inquire for pricing).

5. Reasonable Accuracy Setting:

Operation and Savings: Select the minimum required accuracy based on the actual application (e.g., 0.2mm layer height instead of 0.1mm) to significantly reduce printing time and cost.

Leverage the real-time quote system to adjust these five dimensions in real time, easily complete cost analysis, and make more economical 3D printing decisions! Let real-time quotes become your key tool for cost control!

Choose LS, And Getting A Quote Is Not Only Fast, But Also Reliable And Advantageous!

Still struggling with time-consuming and opaque 3D printing quotes? LS Precision Manufacturing’s industrial-grade online quote system offers 24/7 instant response, intelligent parameter calculation, clear pricing, and secure file security! Get accurate quotes now and optimize your costs!

Advantage 1: Extreme Speed – Say goodbye to waiting, quotes have never been faster!

24/7 Online Instant Response: Upload your 3D file anytime, anywhere, and our intelligent system will instantly analyze it.

Generate Accurate Quotes in Seconds: Eliminate the hours or even days of waiting in traditional systems, doubling project planning efficiency.

Accelerate Inspiration: Quickly access cost information for faster decision-making and significantly shorten product iteration cycles.

Advantage 2: Accurate and Transparent – Every penny is clearly spent!

Intelligent Model-Driven Calculation: Intelligent calculations based on complex parameters such as material properties, printing process (such as SLA, SLS, FDM, metal printing), equipment costs, and labor hours ensure scientific and reasonable quotes.

Clear Price Structure: Quotes provide a detailed breakdown of material costs, printing labor, post-processing fees (such as sanding, painting, and dyeing), and management fees. There are no hidden fees, ensuring transparent and worry-free consumption.

Easy Budget Control: A clear understanding of cost structures facilitates precise control of project budgets and avoids unexpected overruns.

Advantage 3: Professional and Reliable – Industrial-Grade Quality, What You See Is What You Get!

Advanced Industrial-Grade Equipment: We invest in [specify specific equipment type or brand, such as industrial-grade stereolithography, nylon sintering, metal 3D printers, etc.] to ensure a solid printing hardware foundation.

Strict Quality Control System: From file review and parameter setting to print process monitoring and post-processing, we implement standardized processes to ensure the final product quality closely matches the quoted expectations.

Predictable Results, Greater Confidence: Quotes based on professional equipment and rigorous processes give you confidence in the final print results, reducing communication costs and the risk of rework.

Advantage 4: Flexibility and Efficiency – Real-Time Optimization keeps costs under control!

Online Dynamic Parameter Adjustment: Experiment with different materials (e.g., PLA, ABS, nylon, resin, metal powder), modify quantities, and add or remove post-processing options (e.g., support removal, surface polishing, painting) directly on the platform.

View price changes in real time: Quotes update instantly as you adjust parameters, allowing you to intuitively compare cost differences between different options.

Intelligently optimize cost structures: Through flexible trial and error, we find the optimal, cost-effective printing solution that meets your needs.

Advantage 5: Data Security – Your designs are strictly confidential!

Strict Confidentiality Agreement: We understand the intellectual property value of design files and adhere to a strict confidentiality policy for all 3D model files uploaded by our customers.

Secure Storage and Transfer: We utilize secure encryption technology to protect the confidentiality of files during transfer and storage.

Confidentiality of Creativity: You can entrust your core design files to us without worry, allowing you to focus on innovation.

Experience LS’s exceptional quoting service now!

Choosing us means more than just speed; we deliver reliability, transparency, professionalism, and peace of mind from start to finish. This isn’t just a quote; it’s the foundation of efficiency and trust for your project’s success!

FAQs

1. Is the online quote truly accurate? Does it require manual review?

Our intelligent system, powered by massive data and sophisticated algorithms, provides highly accurate quotes for standard requirements. Complex or special requirements will be clearly marked as requiring manual review, and we will contact you immediately to confirm the details and ensure the accuracy of your quote.

2. Is the uploaded file secure? Will my design be leaked?

Your files are absolutely secure! We use bank-grade encryption for transmission and storage, and strictly enforce non-disclosure agreements (NDAs) to fully protect your intellectual property. Uploaded files are only used to provide you with accurate quotes and production services, with absolutely no risk of leaks.

3. Will the price change after the quote is issued?

The price of a formal quote generated based on your submitted parameters is fixed within its validity period. If your requirements change during the validity period, please request a new quote online to ensure accuracy.

4. What file formats are supported? What if there are issues with the model?

We support major 3D file formats such as STL, OBJ, STEP, and 3MF. After uploading, the system will perform a basic model check. If serious problems are found (such as surface cracks or non-manifolds), you will be prompted to repair the model yourself or choose our paid professional repair service.

Conclusion

In summary, 3D printing pricing is no longer a murky maze. Understanding its core drivers—material consumption, print time, post-processing complexity, equipment and labor—is key to mastering costs. Traditional pricing models are often time-consuming and fraught with uncertainty, hindering innovation.

Now, technological advances have brought a revolutionary solution: instant online quoting tools. Simply upload your 3D model file, and intelligent algorithms analyze all cost-influencing variables within seconds, providing you with a transparent, accurate, and instant quote. This eliminates lengthy wait times and back-and-forth communication, transforming the pricing process from a hindrance to a benefit.

Embracing this efficiency and transparency means you can plan projects, assess budgets, and iterate on decisions with greater confidence. No more hesitation, no more waiting—upload your design files now and experience the convenience of instant, accurate quotes. Let accurate pricing be the first step toward realizing your creative ideas and optimizing your production processes, embarking on an efficient and predictable 3D printing journey.

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

Expert service perfection, expert-level attention to detail. Competent team selected. Expert recognition.

Reliable weekly service, perfect for our hectic schedule. This is the best investment. Keep it up.