Springs are a vital, hidden component in the operation of mechanical components. They hide and deliver energy in the form of elastic deformation and thus create the fundamental components for applications such as cushioning, motion control, energy storage, and load measurement.

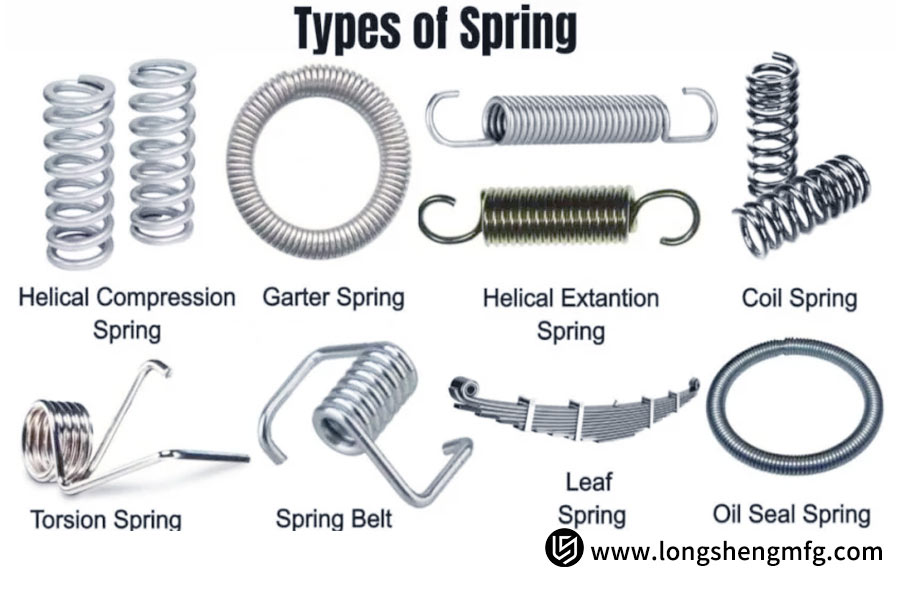

Faced with a variety of and diversified work requirements—pressure shock, bearing tension, rotational requirement of torque, or heavy working under limited space—a single spring cannot do. Four predominant types have therefore been developed, each for a separate function: compression springs can best be used to resist compression, extension springs can best endure tension, torsion springs provide rotational torque, and disc springs provide stiff support under limited space.

A clear understanding of the four types of spring’s structural characteristics, inherent functions, and environments of use is the initial critical step towards rational decision-making in mechanical design. This report provides a comprehensive overview of their operating mechanisms, conventional applications, and most critical selection factors to enable you to correctly pair them with your project needs.

Spring Type Core Function And Application Selection Table

| Spring Type | Core Function | Typical Application Scenarios | Key Selection Parameters |

| Compression Spring | Resists axial compression, stores energy, and releases it when unloaded, providing thrust or support. | Automotive suspension, valves (e.g., safety valves, regulating valves), shock absorbers, mechanical buffers, electronic device buttons | Free length, outer/inner diameter, wire diameter, stiffness (spring constant), material, end form (ground/unground), maximum working stroke, ultimate load |

| Extension Spring | Resists axial tension, stores energy, and provides rebound force when unloaded, maintaining connections or tension between components. | Door locks (e.g., garage door locks), fitness equipment (e.g., tensioners), mechanical hooks, balancing systems, textile machinery | Initial tension, hook and loop type (e.g., full hook, half hook, English hook, German hook), free length, wire diameter, outer diameter, stiffness (spring constant), maximum tensile length (or elongation) , Materials |

| Torsion Springs | Suppresses torsional loads about the axis, generating rotational torque for resetting angles, applying rotational force, or storing rotational energy. | Clothespins, car seats (angle adjustment reset), electrical switches (push-button reset), clamps, mouse buttons, garage door hinges | Torque value (usually refers to working torque), spring center diameter, wire diameter, swing arm length, rotation angle (working angle/limit angle), material, swing arm type (straight arm, curved arm, etc.) |

| Disc Springs | Provide high stiffness and high load resistance within a very small axial space. Features nonlinear load-deformation characteristics, and are resistant to heavy loads and relaxation. | Bolt preload (flange connections), heavy machinery (presses, clutches), safety valves (overload protection), pipe supports, and buffering/energy storage in confined spaces. | Number of discs, stacking method (aligned, stacked, combined stacking), individual disc taper (height/thickness ratio), outer/inner diameter, thickness, material, and load-deformation curve (stiffness characteristics) |

Here’s What You’ll Learn:

- A 60-second selection process: A decision framework for quickly matching pressure/tension/torque/impact loads with spring types.

- The physical secrets of four types of springs: How the structural differences between compression, tension, torsion, and disc springs determine their mechanical behavior and operating limits.

- Professional strategies for overcoming extreme environments: Material and process solutions for high temperature, corrosion, and millions of cycles.

- LS Spring Case Histories: Suspension on cars to valve application in nuclear power, creating drivers of performance in mission-critical application.

- Engineering FAQs: Engineers’ Myths About Selection (e.g., “ultimate fatigue resistance” and “ultra-high pressure options for small spaces”).

Finally, let us be a master of the basics of spring technology by scientific categorization and engineering practice.

Compression Springs: The Simple, Effective Solution To Pressure-Sensitive Applications

Compression springs, in their plain and outstanding appearance, are the undisputed global solution for pressure-sensitive designs wherein shock absorption, energy storage, or a uniform return force is essential. The coiled cylinder of wire of tremendous strength can apparently be present in a plain state, but possesses boundless capability to offer the solution to complex engineering challenges.

1. Core Structure: Simple Design, Powerful Functionality

- Basic Form: Spiral cylinder made of wire of high-strength metal (spring steel or stainless steel).

- Geometric Characteristics: Maintains a constant outer, inner, or pitch diameter (as per design specification) and an initially defined free length.

- Initial Form: Made typically of no initial tension (the coils are free in the free state), the springs use external compression to generate force.

- Key Design Parameters: Cover wire diameter, pitch diameter, number of active coils, number of total coils, free length, and hand (right-hand or left-hand).

- Working Space: The intercoils provide space for compression at the very center of its operation. Compression reduces the intercoils space to a level where they are practically next to one another (compressed state).

2. Working principle: An energy conversion model

When an axial load is applied to a compression spring:

- Energy storage: The spring elastically deforms (is axially shortened) upon compression and places stress on the material so that it can withstand the deformation and hence stores potential energy (mechanical energy).

- Release of energy: During de-loading (external force is reduced or eliminated), stored potential energy is released and the spring, with the assistance of material elastic recovery force, tries to come back to its original form (free length), thereby developing and generating axial thrust (rebound force).

- Mechanical basis: As per Hooke’s law (in the elastic regime, force is proportional to deformation), its force-displacement response (spring stiffness) is a function of structural parameters (wire diameter, median diameter, effective number of turns, material modulus).

3. Ubiquitous key applications

Due to its commonality, compression springs are found in widespread use across many industries:

(1) Automobiles:

- Suspension system: Dampens road shock, sustains vehicle body weight, and provides driving comfort and stability in handling (generally in conjunction with shock absorbers).

- Clutch pressure plate: Provides clamping force to keep clutch plate and flywheel together always and power transmitted; allows pressure plate to rebound to normal condition upon release.

(2) Industry

- Mechanical valve: Supplies closing force or opening force (depending on type) to put the valve into a safe position (usually closed or usually open) whenever it perceives no control signal.

- Punch/press buffer: Reduces impact energy, safeguards molds and equipment, and dampens vibration and noise.

- Clamp and positioning mechanism: Supplies uninterrupted clamping force or reset force.

(3) Daily necessities

- Ballpoint pen: The foremost component of the press mechanism, enabling extension (compression energy storage) and retraction (energy release) of the pen core.

- Home appliance buttons (remote controls, keyboards): Provides a damping feel upon depression and reset force on release, enabling a definite and accurate touch.

From precision equipment to heavy machinery, from pocket pens to racing cars, compression springs have provided reliable, universal and economical solutions to pressure working situations with their inbuilt ability of converting pressure into reset thrust sufficiently. Its simple looks but robust performance, combined with dominant processes such as variable pitch and end grinding, allow it to continuously transform to more challenging and sophisticated applications, a flat-out superior starting point in modern engineering. The correct compression spring choice is the dual choice of selecting a surefire bulwark against stress for your mechanical system.

Extension Springs: Axial Tension Supplied Directly

Extension springs play an essential role in much mechanical assembly and precision machinery. With the specific intent to reverse axial tension, extension springs’ structure and operation are essential to a vast number of applications requiring precision and repeatable return forces. LS Precision Manufacturing will explain the principal characteristics, operating modes, and most important applications of extension springs in numerous prominent industries.

I.Structural Features: For Tension

Extension spring design is mainly concerned with its principal function of providing axial tension:

- Tightly Wound Helical Coil: The tightly wound helical coil configuration of hard metal wire (e.g., stainless steel or music wire) constitutes the spring body composition. The configuration is suitable for high load-carrying capacity and elasticity along the direction of tension.

- End Connection Design: Springs are typically supplied with specially formed ends (half-round hooks, cross hooks, and English hooks) or threaded holes/screws.

The end members are point contacts for direct rigid connection to outside mechanisms and tension transfer, in which tension is able to be imparted deep along the axis of the spring.

II. Working Principle: Energy Storage and Release

Working principle of tension spring is simple and efficient:

- Tension Energy Storage: When an axial tension is developed at the end of a spring, the spring becomes extended with increased gap between coils. In doing so, the material of the spring becomes elastically deformed and stores the provided mechanical energy in the form of elastic potential energy within the spring.

- Compression Energy Release: The moment the external force applied is decreased or eliminated, elastic potential energy in the shape of the spring is released. With its material elastic restoring force, the spring produces a gigantic recoil force as it attempts to revert to its initial free length. The recoil force is the natural response of the tension spring.

III. Main Application: Effective Tension-Driven Core Function

Thanks to their accurate axial tension and strong rebound, tension springs are being used extensively in high-priority applications of different kinds:

1. Rail Transit: Safety in Emergency Release

Scenario Requirement: Inside doors of subway or train, in case of an emergency situation (e.g., power loss or disconnection), a manual door-opening facility shall be available for evacuation of passengers.

Spring Function: Extension springs are typically employed in emergency release designs. In service conditions, the spring remains pre-tensed and held. In the case of emergency release of the lock (e.g., through operation of a switch or handle), the lock shall be swung open and the high return force of the spring used to operate the unlocking mechanism or link to release the door lock automatically and rapidly and establish an essential safety for safe egress of the passengers. Safety is based entirely on emergency response speed.

2. Medical Devices: Precise Repositioning Mechanism of Surgical Forceps

Motivation for Scenario: The surgical forceps and needle holders need to be picked up by the surgeon to snap together (working state) and reset automatically when released to open (ready state) for the next procedure.

Spring Function: Small, precise tension springs are installed at regular intervals in instrument joints or handles. When the surgeon closes the jaws by tightening the handle (places handle in spring tension), the jaws close. As the spring unwinds on release, potential energy generates a precise return pressure that travels back to move the handle or joint so the jaws snap rapidly and uniformly back to the open position. Smooth, precise, efficient surgical technique is generated.

3. Farm Implements: Constantly Available Opening Power for Planter Lifting

Requirement Scenario: The opener, in the process of operating the planter, should have the ability to lift as rapidly as possible from the ground to any predefined height at any given time (e.g., head setting of field head, towing lifting).

Use of Springs: Extension springs would be used as the prime or secondary power source for opening up the opener device. In running position (engaged into the ground), the spring would be stressed and has stored energy. Upon receiving the lift command (hydraulic cylinder or mechanical release actuation), spring stored energy is unleashed and a good return force is provided to help or even pull on the lift linkage such that the opener lifts freely and efficiently from the ground and into position. This enhances planter strength and performance, especially in prolonged lifting and lowering cycles.

Due to tightness (closely wound wires/threaded hole/shackle) and energy storage-release system, extension springs possess precise axial tension and even rebound. They are an emergency door opening safety device, the secret key to successful repositioning of surgery instruments, and the force behind some farm equipment lifting openers. They are a must in transport, medical, and agricultural industries.

Torsion Springs: Efficient Rotational Torque Transmitters

Torsion springs are accurate components that can withstand rotational torsional forces (torsion). They are the hearts of mechanical systems that require angular reset or sustained rotational force. They have a unique structure and mechanism that make them become good master energy transmitters and motion controllers.

1. Structural Features

Tight Coil: Body is made up of tightly coiled turns of rigid metal wire (no space between turns), having torsional stiffness.

Extended Lever: Primary lever arms (straight, hinged, or linear) are extended from both spring ends to transmit or withstand torque and connect the load to the drive member.

2. Working Principle:

Rotational Energy Storage: When the spring is twisted (torsions) around the axis, the material is elastically distorted and torsional potential energy (angular energy) is stored.

Release Torque: At on withdrawal or removal of the applied external force, released energy is obtained and the spring gives a high return torque that enables the drive mechanism to precisely restore to the identical angle or maintain a specified rotational force.

3. Main application fields

(1) Principal automobile components:

Wiper reset: Delivers controlled torque to enable the wiper arm reset to its original parking position securely and reliably after every wipe.

Seatbelt retractor: Generates preload torque, thus allowing the seatbelt to be automatically and smoothly retracted with slack taken up and improved convenience and comfort.

(2) Home convenience source

Folding table and chair/hinge system: Incorporated into the hinge, applying constant torque. Stored energy when opening; torque released when folding, assisting in completing folding motion smoothly and effortlessly and maintaining folded state, improving user experience.

(3) Industrial automation and robotics

Robot joint buffer/limiter: Placed in the joint travel range of motion, providing controlled resistance torque. As joint travel approaches the limit position, the spring is rotated to absorb impact energy, creating a reset torque, offering smooth and soft mechanical limit and buffering, and protecting precision components.

Torsion springs, by their tightly wound and long lever arms and their inherent concept of exchanging rotational energy for restoring torque, are perfectly suited to transfer and control rotational torque. It is they which make possible the accurate reset of windshield wipers and silky retraction of seat belts. They are a leading enabler of effortless mobility of folding furniture and a capable guardian of safe and accurate mobility of industrial robot joints. They are a unavoidable element in a wide range of applications where angle control, restore, or retained torque is required.

Disc Springs: The Compact Solution To Ultra-High Pressure Applications

In design engineering, especially under ultra-high pressure conditions and considerably restricted axial installation space, the search is on for a spring component that can endure gigantic loads yet have an extremely small footprint. Disc springs are the perfect answer to this need. Their unique construction and high performance have made them the space-efficient solution to numerous demanding industrial applications.

1. Competitively Equivalent Design: Conical Discs, Stacked for Economy of Space

The conical disc design is the basic is of the disc spring. Discs are stacked in series, in parallel, or in a combination. Stacking, while maintaining the axial space as minimum, has very high load density (load per unit volume), and hence it should be employed in those applications where space is not plentiful.

2. Basic Principle: Elastic Deformation, Lifting the Weight

Disc springs operate by controlled elastic flattening of their conical discs. The axial loading flattens the discs to create high elastic stresses in the material to enable them to carry extremely heavy loads with minimal flattening. Stacking permits controlled design of desired load, stiffness, and travel.

3. Principal Applications: A Pillar in Harsh Environments

Energy (Valves for Nuclear Power): Provides long-term stable ultra-high preload for safety bolts, accommodates thermal expansion and contraction, resists stress relaxation, and assures safe sealing under high pressure and high temperature with excellent space advantages.

Aerospace (Landing Gear): As a structural cushion, it efficiently dissipates the massive landing impact energy with low weight and volume needs, offering high reliability and satisfactory fatigue life, with very stringent requirements for lightweighting and space minimization.

Mold (Injection Molding Machine Clamping): Stored compression energy is utilized as part of the clamping system in order to generate enormous stable clamping force (up to 10,000 tons). It makes significant energy saving in contrast with all-hydraulic systems, reduces leakage, provides faster response, and saves space.

Disc springs are a high-precision product that transcends the paradox between ultra-high pressure and restricted axial space. Its disc-shaped layer tapered structure and economical elastic deformation principle make it a certainty of space saving and loading capacity in harsh applications such as nuclear power safety, aviation landing, and 10,000-ton mold clamping.

How To Select Different Types Of Springs?

Your basic requirements determine which spring you choose. There are specialized features and areas of expertise for each of the four spring categories. A summary of spring selection for each category is outlined below:

| Characteristics/Requirements | Compression Springs | Extension Springs | Torsion Springs | Disc Springs |

| Main Force Direction | Axial Compression | Axial Extension | Rotation/Torsion | Axial Compression |

| Core Functions | Energy Storage, Thrust, Cushioning | Energy Storage, Tension, Restoration | Energy Storage, Torque, Angular Restoration | Ultra-High Load, Extremely Small Space, Precise Load Control |

| Space Advantages | Large Stroke | – | – | Extremely Small Axial Space |

| Load Capacity | Medium-High | Medium-High |

Medium (Torque)

|

Extremely High |

| Typical Applications | Suspension, Cushioning, Valves, Buttons | Reset Mechanisms, Tensioning Devices, Doors | Reset Torque, Angle Positioning | Heavy Machinery, Safety Valves, Bolt Preload |

| Choose When… | Requires pressure bearing, cushioning, or axial thrust | Requires continuous tension and reliable reset | Requires rotational reset or torque application | Requires extremely tight spaces, extremely large loads, or precise/nonlinear load characteristics |

| Key Advantages (LS Example) | Anti-separation (variable pitch), stability (ground end faces) | High reliability (integrated shackle), precise pretension | Precise torque (±5%), optimized stress | High load density, long life, and combinable to achieve complex characteristics |

| Avoid When… |

Requires tension or torque

|

Requires pressure or torque | Requires pure axial force | Requires large travel, low-cost, and simple application |

- Need to take pressure or pass axial thrust?-> Compression springs are the workhorse of the world.

- Need to pass tension or return repetitively?-> Extension springs are the standard choice.

- Need to generate rotational torque or angular return?-> Torsion springs are specialists.

- Need to support high pressures in very limited space, or require special or unique load behavior?-> Disc springs are the monarch.

There is no “best” spring; only the spring best for you based on your needs for your specific applications. Clearly defining your needs is the first of effective selection’s two basic principles.

How Do We Ensure Performance In LS Spring Manufacturing?

To better describe how we ensure each spring to perform at the high level we promise, let me detail the most important aspects of our LS spring manufacturing process:

1. Source Control – Highest Quality Material: We exclusively use high quality wire rod conforming to German (DIN) or American (ASTM/SAE) standards only. Material is traceable to its source. Its tensile strength is guaranteed to be ≥1900 MPa, so the spring will have a good foundation for the high strength, long life, and resistance to permanent deformation to military standards.

2. High Precision Shaping – Elimination of Residual Stress: We utilize high-precision CNC spring coiling machines with precision up to ±0.02mm. Besides our high dimensional consistency, what’s more importantly, our own exclusive forming process efficiently eliminates the internal residual stress, reducing the risk of premature failure.

3. Performance Optimization – Double Warranty

Intensive Shot Peening: All the principal spring surfaces are treated with intense shot peening. It increases the surface fatigue strength of the spring by over 30% and its dynamic load life significantly.

Cryogenic Stabilization: Certain springs of high usage are exposed to aggressive cryogenic treatment (cryogenic freezing). This stabilizes and case-hardens the core structure of the material, in effect improving dimensional stability, load-bearing capacity, and anti-relaxation characteristics, to deliver long-term dependability.

4. 100% Full Inspection – The Iron Rule of Quality:

Accurate Dimensional Control: Highly technologically advanced optic measurement equipment is utilized to check every single significant dimension of every spring with accurate tolerance up to ±0.05mm in order to fit perfectly and run smoothly.

Performance Testing: Every spring is strictly tested in the spring every year using a high-precision load testing tool to maintain a spring modulus (spring constant) deviation of not more than ±3%. This gives very consistent force behavior for each spring, meeting design requirements.

From testable, high-grade material, to precise molding for stress reduction, to advanced processes for fatigue and stability, and finally, 100% full-dimension and full-performance testing, LS is governing at every step of the manufacturing process. This bold closed-loop system of processes, materials, and test is the key to the promise of delivering highly reliable, long-lasting, and consistent performing springs. You are guaranteed of LS springs quality and performance.

FAQs

1. Which spring has the greatest fatigue resistance?

Compression springs are the leaders in fatigue resistance by virtue of largely ideal end design (stress concentration minimization) and shot peening (surface toughness and hardness maximization), which significantly enhances cycle life. For example, LS brand compression springs, due to precision processing and strengthening, can achieve 50 million cycles and are extensively applied in heavy load conditions such as automobile suspension and industrial machinery. Shot peening creates compressive stress on the surface, actually compressing microcracks and showing steady performance when subjected to repeated compression and release, and is therefore best suited for use with long life requirement.

2. What material is to be utilized in high-temperature applications (>200°C)?

High-temperature stainless steel 17-7PH or Inconel 718 alloy needs to be utilized in applications at temperatures above 200°C. These two alloys possess enhanced high-temperature strength, thermal stability, oxidation resistance, and are capable of preventing creep and deformation effectively. LS offers full-temperature solutions ranging from -200°C to 550°C, which are useful in extreme working conditions such as aerospace engines and energy equipment. The materials are heat treated through a patented heat treatment process to make them stronger, elastic, and resilient with long-duration and high-temperature operation. LS solutions also include design support on customer requirement to meet reliability requirements for different temperatures.

3. How to prevent spring corrosion failure?

The key to preventing corrosion failure at spring failure is surface treatment and material selection: Type 316L austenitic stainless steel (highly corrosion-resistant) is employed, or the zinc-nickel electroplating coating processes and Dacromet coating processes are utilized to apply a protective coating against chemical attack and atmospheric exposure. LS products undergo extreme salt spray testing and possess corrosion resistance up to 2,000 hours and are therefore absolutely suitable for applications in marine, chemical, or wet environments. These treatments provide a combination of material natural resistance and protective coatings for successful spring life extension. LS also offers bespoke treatment solutions to deliver functional integrity in corrosive environments.

4. What is small-volume customization lead time?

For small runs of custom orders, LS offers quick and efficient delivery services: 3-day rapid prototyping (for proof), and mass production orders up to 500 pieces can be shipped within 7 days. Furthermore, LS offers free DFM (Design for Manufacturing) optimization services to help customers optimize spring designs for enhanced manufacturability, cost savings, and reduced development times. This configuration is extremely well-suited to test R&D production or small batch needs. Combined with a versatile line, it allows for quick shipping of quality custom springs to meet strict project time schedules.

Conclusion

The four basic spring types—compression, tension, torsion, and disc springs—each offer unique shapes to battle pressure, tension, torque, and ultra-high loads. Proper spring choice requires complete attention to load parameters, area constraints, environmental, and lifespan requirements, and material science and manufacturing methods determine the performance.

Whether vibration and shock, high temperature corrosion, or billions of cycles, LS Springs redrafts reliability with aerospace-grade materials, micron levels, and lifecycle planning! Contact an LS engineer today and get a free selection guide and instant price quote to try a “zero-failure” spring solution!

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.