In mechanical joints, threads are a fundamental construction feature—they are spiral, continuous ribs (thread profiles) precisely machined on the surface of a cylinder or cone, enabling secure engagement and force transmission. To create such internal threads in a hole, special cutting tools—taps—must be used. However, in practice, “tap” and “thread” are confused, like mistakenly referring to “thread tapping” or referring to tap as simply “internal thread.” Not serious but incorrect use of the terms might lead to wrong process selection, confusion, and thus influence assembly accuracy and efficiency.

The basic difference between them is their final purpose: threads are the “result,” the functional form on a part that allows a connection (e.g., the external thread of a bolt or the internal thread of a nut); taps are the “means,” the manufacturing tool that “cuts” the thread form into a predrilled hole by rotary cutting. In brief:

Thread = Functional Structure: The helical projection on the surface of an assembled part.

Tap = Manufacturing Tool: The cutting tool that creates internal threads.

Proper understanding of the fundamental difference between functional structure and manufacturing tooling is essential for the correct selection of machining process, prevention of terminology confusion, and efficient and reliable assembly. The structure, principles, and applications of both will be outlined in the subsequent article.

What Is The Difference Between Tap And Thread?

| Comparison Dimensions | Thread | Tap |

|---|---|---|

| Essential Properties | Mechanical structure characteristics | Threading tools |

| Physical Form | Continuous spiral projections (external threads)/grooves (internal threads) | Cylindrical (hand/machine) or tapered (pipe threads) tools with cutting edges |

| Core Function | Transmitting force/motion, fastening connections, sealing | Cutting internal threads in prefabricated holes (bottom holes) |

| Existing Form | Appears on the workpiece surface (internal or external threads) | Standalone consumable tools |

| Classification | Thread profile (triangular/trapezoidal/rectangular, etc.), pitch, direction of rotation (left/right), tolerance grade, thread count | Structure (straight/spiral/point), shank type (straight/curved), coating, and processing material |

| Manufacturing Methods | Turning, milling, rolling, grinding, die threading, tapping, etc. | Precision grinding on specialized tool grinders (materials typically high-speed steel (HSS) or carbide) |

| Applications | Bolts, nuts, pipe connections, transmission mechanisms (screws), measuring instruments, etc. | Manual tapping, drilling machine tapping, CNC machine threading |

| Lifecycle | As part of the workpiece/product, it is typically a permanent structure (unless damaged). | After a certain number of threads are machined, they fail due to wear and require replacement. |

| Key Parameters | Major diameter, minor diameter, pitch diameter, thread pitch, thread angle, lead, number of threads | Cutting taper angle, number of chip flutes/flute type, core thickness, material (hardness), coating type (TiN, etc.), precision grade |

| Failure Indications | Slippage (thread damage), deformation (stretching/extrusion), fatigue fracture, corrosion | Chipping, twisting, excessive wear (out-of-tolerance dimensions/poor surface roughness), blockage/breakage caused by poor chip removal |

Why Believe This Guide? Real-World Know-How From LS Experts

As a maintenance engineer on the production line, I know firsthand the pain of a broken tap—a non-productive shutdown, busted plans, and unquantifiable losses. Having a truly trustworthy tap solution was one of those high-priority headaches for a long time. That was before LS’s cobalt-based high-speed steel taps came along and turned everything around.

Our proven track record in the field says it all:

- Extended lifespan: The nano-TiAlN coating on LS taps lives up to its promise. Under our continuous, high-load machining, its lifespan is over three times that of conventional taps, conserving significant downtime for tool changes.

- Smooth chip removal: Chip clogging is the most common problem in machining blind stainless steel holes, leading to rotten threads and even tap breakage. LS’s unique spiral flute design allows for smooth and self-flushing chip removal, completely eliminating this inconvenience.

- Intelligent protection: Our “guard of safety” is LS’s intelligent tap chuck. It disengages the screws precisely at the time of torque abnormality. In the past two years, we’ve been successful in eradicating our workpiece scrap rate due to tap issues to zero—an absolute pillar for the untainted and efficient operation of our production lines.

The situations in our customers’ cases demonstrate its applicability in all walks of life.

A major auto parts manufacturer was combating thread rot in M8×1.25 deep blind holes in transmission housings (with a rot rate of up to 15%). LS engineers conducted on-site inspection, carefully studying material properties and ultimately offering a full solution including an internally coolant spiral-fluted tap, precision collet, and special cutting fluid parameters. The result was compelling: tapping speed increased by 40%, thread rot rates dropped to 0.3%, and the customer saved over 500,000 yuan in a month’s worth of scrap losses!

This is the confidence that stems from direct experience of LS experts with customers, with real results. Choosing it means choosing a proven, reliable productivity guarantee.

Important Definition: Structural Properties VS. Manufacturing Tools

In the mechanical manufacturing field, threads, as a necessary connecting and transmission component, cannot be distinguished from taps, specialized processing tools. The two have fundamentally different intrinsic definitions: the former is a standard structural component, whereas the latter is a precision processing method to acquire this component.

| Comparison Dimensions | Thread | Tap |

|---|---|---|

| Category | Standardized helical geometry (structural feature) | Multi-edge cutting tool (processing tool) |

| Functional Positioning | Functional element: Fastening or transmission through meshing | Manufacturing tool: Used to cut internal threads in holes |

| Core Features | Helical profile (e.g., metric 60° triangular thread, imperial 55° Whitworth thread) | Cutting edge structure: Tapered guide, calibrated teeth, clamping shank |

| Typical Examples | External threads on bolts, internal threads in nuts | Hand taps, machine taps, spiral-fluted taps, etc. |

A thread is a continuous helical projection or groove of definite cross-sectional form (e.g., triangle, trapezoid, or sawtooth), subject to strict standards (e.g., metric and imperial). A thread is a permanent structural feature on a part, its inherent value being its meshing with the thread of a mating part, creating a secure connection or transmitting power or motion. Its function relies on geometric parameters such as thread profile, pitch, and diameter.

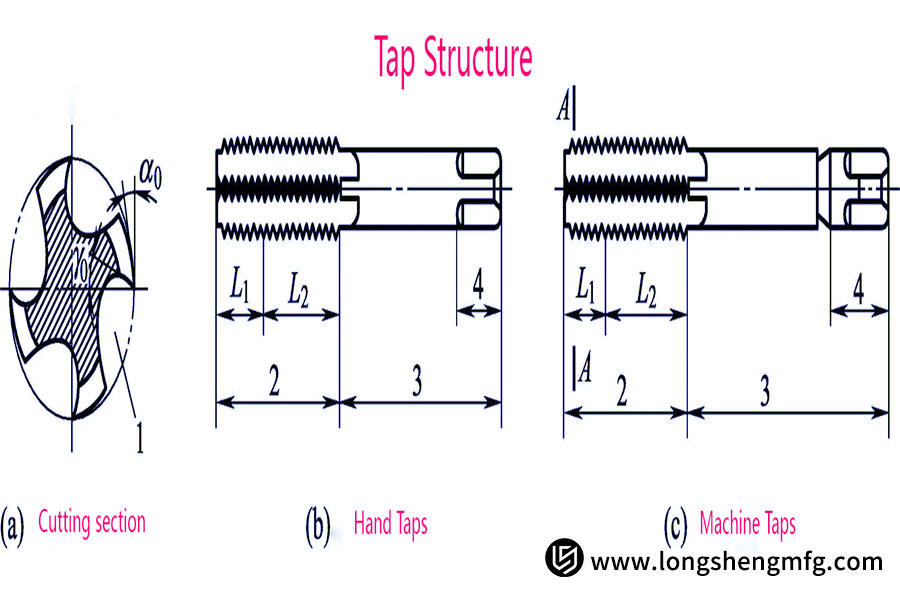

A tap is essentially a metal-cutting tool. Its working portion generally has three or four straight or spiral grooves that form the cutting edge. The guide portion, which is tapered, penetrates the work and indicates the direction; the calibrating teeth, which have the full tooth profile, complete the threads and direct the tap; and the clamping shank is used to connect to a wrench or machine tool. The function of a tap is to machine an internal thread in a pre-drilled hole. It is a machining operation for creating this structural feature, threaded holes.

In short, a thread is a geometric feature for carrying out some certain function, and a tap is a cutting tool specially designed for creating that internal thread in a workpiece.

Manufacturing process: How Are Threads Created?

As a very significant aspect of mechanical joining, threads are manufactured using several methods, each with some unique characteristics. The major methods can be summarized as:

Overview of Thread Manufacturing Processes

| Thread Type | Manufacturing Method | Processing Principle | Main Features | Typical Applications |

|---|---|---|---|---|

| External Threads | Turning | Cutting (rotating workpiece) | High precision and flexibility | Single piece, small batch, various specifications |

| Die Threading | Cutting | Easy operation and low tooling costs | Manual or small machine processing | |

| Rolling | Chipless plastic forming | Extremely high efficiency, good strength, and high material utilization | High-volume production of standard fasteners | |

| Internal Threads | Tapping | Cutting | The most widely used, with moderate tooling costs | Most small and medium-sized internal threads |

| Thread Milling | Cutting | Suitable for large sizes and hard materials, with good flexibility | Machining large-diameter threads and carbide |

External Thread Production:

- Turning: The job is fixed on a lathe and carbide or high-speed steel turning tool is advanced axially to closely cut the thread shape. This operation is preferred for single-piece, small lots, and external thread production of different specifications and accuracies.

- Die Threading: A rotating or fixed cylindrical blank is used with a motorized threading machine or manual die holder to produce threads. The process is simple to perform and is extensively used for small-scale or manual machined work.

- Rolling: A threaded profile roller (or plate) presses high pressure at room temperature onto the cylindrical blank, inducing plastic deformation of the surface metal in order to create the threads. The process provides chipless operation, high efficiency, high thread strength, and a high surface finish, and it is thus the method of choice for bulk production (e.g., bolts and screws).

Internal Thread Manufacturing:

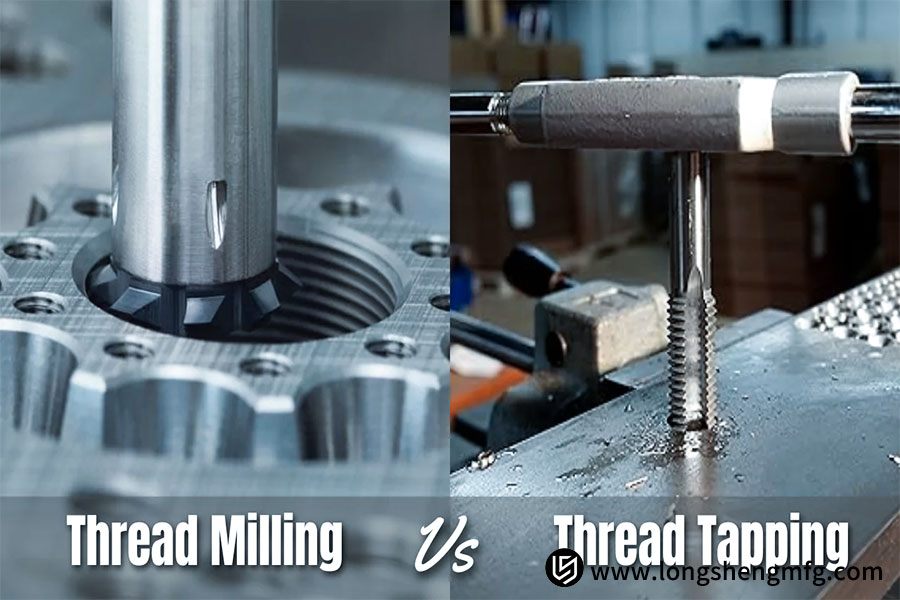

- Tapping: A multi-edged tool (tap) is used in the creation of internal threads by rotating inside a pre-drilled hole. It is the most frequently used process, accounting for more than 90% of the manufacture of internal threads and for the majority of small to medium internal threads. It can be performed by hand (using a tap wrench) or mechanically (with a drill press or tapping machine).

- Thread milling: This process is performed by a thread milling cutter specially designed on a CNC mill or machining center. The cutter rotates and moves in a helix path, removing the inner thread point-by-point or layer-by-layer. Thread milling is particularly well suited for large threads, deep-hole threads, hard material (such as hardened steel), and high-flexibility applications (such as multi-pitch threads and multi-diameter threads).

The choice of the thread manufacturing method entails a careful consideration of factors such as thread type, size, accuracy, material, batch size, and cost. There is no one-size-fits-all approach.

The Cost of Confusion: Four Core Pain Points Eroding Your Profits!

Confusing “tap” with “thread” is no minor matter. It’s an insidious trap on the shop floor, which instantly translates into four core pain points:

Procurement Errors and Wasted Costs:

- Scenario: A warehouse foreman yells in frustration, “Out of threads!” Purchasing places a rapid delivery order for “threads,” and a mountain of taps arrives instead, leaving the production line stalled.

- Loss: Increased emergency buying expenses + down-time losses + wasteful inventory = disappearing profits!

- LS Solution: Implement a straightforward material coding system (to distinguish between tools and parts), provide purchasing personnel basic training, and LS provides precise product selection guides.

Technical Communication Barriers and Inefficiency:

- Scenario: A drawing with “Processing M8 threads” leaves the shop floor confused: Is it rotating? Milling? Tapping? Time-wasting repeated assurances.

- Loss: Project delays + communication inefficiency between engineers and operators = lost production capacity!

- LS Solution: Formalize drawing markings (make process methods explicit, e.g., “tapping M8 internal threads”), and the LS technical team provides complimentary process consultation to eliminate communication uncertainties.

Process Selection Errors and Quality Risks

- Scenario: Blindly tapping a thin-walled aluminum component with a general-purpose tap results in broken threads, deformed workpieces, and scrap.

- Loss: Scrap material + rework cost + customer quality claims = brand damage!

- LS Solution: Precisely match LS high-performance taps (e.g., spiral-flute aluminum taps) by material, hole diameter, depth, and accuracy requirement, and provide detailed processing parameter recommendations.

Most Common Quality Problems and Difficulty in Locating the Root Cause

- Scenario: Thread go-gauges fail specifications and tend to strip. Is it a worn tap? A misplaced core hole? Or a material problem? Troubleshooting consumes much time and effort.

- Loss: Risk of defective product outflow + analysis and debugging cost + loss of customer confidence = market slump!

- LS Solutions: Our advanced tap wear inspection and failure analysis capability allows us to quickly determine root cause of problems (tool, process, material?), and pair them with LS high-stability taps to reduce variations.

LS Precision’s Commitment: We are not merely a tap supplier, we are the answer to your threading woes! From precise selection to process optimization, from failure to inefficiency minimization, we are here to help you along the way.

LS Precision: 5 Pernicious Pitfalls In Tap Selection And How To Escape Them!

One miscalcured tap choice can lead to damaged threads and rework on the job at best, or equipment destruction and worst-case tap breakage! The cost of overestimating threading is higher than you’d ever imagine. Avoid these five decision blunders and end threading loss forever:

⚠️Trap 1: Single-mindedly thinking about cost and not material compatibility

- Painful Lesson: Drilling stainless steel with a common high-speed steel tap for low-budget leads to chipping and seizure, resulting in bulk workpiece failure.

- LS Precision Solutions: LS offers powder metallurgy high-speed steel (PM-HSS) and cobalt alloy taps, which are tailored for use in stainless steel as well as heat-resistant alloys. They offer high toughness and wear resistance, completely eliminating chipping.

⚠️Trap 2: Blind and through hole misidentification, resulting in poor chip evacuation

- Painful Lesson: Misuse of straight-flute tap for blind hole machining results in chip clogging and lack of evacuation, ultimately resulting in tap breakage and inadmissible damage to the hole bottom.

- LS Precision Solution: LS Precision Spiral Fluted Taps (blind holes) or Spiral Point Taps (through holes) offer aggressive, directional chip evacuation, resulting in a clean hole and absolutely no possibility of tap breakage.

⚠️Trap 3: Poor Coating Selection Causes Significantly Shortened Tap Life

- Painful Lesson: Tapping hot-working alloys with a coating that is not high-temperature resistant can lead to high tap wear, which equates to a life of less than a third of a typical scenario. Continuous changing of taps also hinders efficiency.

- LS Precision Solution: LS TiAlN (titanium aluminum nitrogen) super-hard tapped taps have excellent heat resistance and oxidative wear resistance. Designed particularly for hard-to-machine high-temperature alloys and hardened steel, they significantly extend tap life.

⚠️Trap 4: Mismeasured Borehole Diameter, Leading to Loss of Thread Quality

- Painful Lesson: Oversized borehole creates incomplete thread profile and poor strength; undersized borehole substantially increases tapping torque, with the tap being susceptible to breakage or thread rot.

- LS Precision Solutions: LS provides precise bottom hole calculation equipment and recommendation tables, encompassing a wide range of materials and thread specifications, providing precise bottom hole measurement and flawlessly controlled thread quality.

⚠️Trap 5: Omission of Cutting Fluids Hastens Tool Destruction

- Painful Lesson: Dry cutting, either to save money or because it is inconvenient, can lead to rapid tap failure by high friction and heat, tap breakage at regular intervals, and deteriorating surface quality.

- LS Precision Solutions: LS strongly recommends and provides high-performance extreme pressure emulsions or oil-based cutting fluids for efficient cooling and lubrication, which substantially extend tap life and yield a smooth thread surface finish.

Choosing the perfect tap is choosing efficiency and profit! LS Precision not only offers taps with matching materials, structure optimized for performance, and long-wearing coatings, but also precision bottom hole calculation tools and specialist cutting fluid solutions, providing a one-stop solution to threading pain and rendering scrap losses a relic of the past! Contact an LS Precision technical engineer today to customize your efficient threading solution.

LS Taps For One-of-a-kind Working Conditions, Intelligent Manufacturing And Perfect Connection

General-purpose taps are at a loss when faced with the particular problems of tapping deep holes, challenging-to-machine materials, thin-walled parts, and robotic production lines. LS Taps employs its intelligent manufacturing to provide custom-fit solutions and perfect connections.

Challenge 1: Deep hole tapping – is chip evacuation very difficult?

Pain Points: Ineffective chip evacuation causes blockage, high vibration, loss of control of accuracy, and frequent tap edge breakage.

LS Intelligent Manufacturing Solution: Long-spindle flute taps, with huge chip volume and robust chip evacuation geometry designed to smooth chip evacuation, ensure firm chip evacuation. Internal cooling taps apply high-pressure coolant through the cutting body to effectively sweep chips away from the bottom of the hole and chill them, totally removing the long-time challenge of deep hole machining.

Challenge 2: Tapping titanium/high-temperature alloys – are tools being subjected to premature aging?

Pain Points: Strong material adherence, rapid work hardening, and very fast tool wear.

LS Intelligent Manufacturing Solution: Powder metallurgy ultra-hard matrix materials applied to tap production (e.g., high-speed steel (PM)/HSS-E PM) possess excellent toughness and wear resistance. Special wear-resistant coatings (e.g., AlCrN and TiAlN) reduce friction significantly and counteract adhesive wear. When combined with specially optimized geometric design, they minimize cutting forces very effectively, avoid work hardening, and exhibit very extended tool life.

Challenge 3: Thin-walled/deformable workpieces and thread “twisting

Pain Point: Distortion of the thread caused by machining workpiece deformation and clamping forces.

LS Intelligent Manufacturing Solution: Low-cutting-force extrusion taps thread by plastically deforming the material with extremely low cutting forces and creating virtually no chips, perfectly protecting thin-walled workpieces. High-precision spiral point taps featuring their sharp cutting cone and accurate guides ensure easy entry and accurate positioning, reduce radial forces to a minimum, and provide thread geometry accuracy and finish.

Challenge 4: High-volume automated manufacturing, causing tool failure?

Pain Points: Extremely high requirements for process stability and consistency in tool life lead to a huge amount of losses through unscheduled downtime.

LS Intelligent Manufacturing Solutions: Extremely consistent precision manufacturing of machine taps ensures that the performance parameters of every tool are strictly consistent, ensuring stable operation for auto-prodution lines. Coupled with a tool life prediction and management system, the solution utilizes big data analysis to provide precise life monitoring and tool change notification, realizing highest production efficiency and equipment utilization.

Choose LS for stress-free intelligent manufacturing! We specialize in eliminating the pain points of thread turning under specific working conditions. With our firm customization power and technical competence, we provide you with sound guarantee for your precise requirements, ensuring a perfect connection every time.

FAQs

1. Why easily break taps while tapping by hand?

Manual tapping is prone to tap breakage primarily due to stress concentration due to a non-perpendicular hole, undersized bottom hole, or excessive operating torque. Such conditions cause unsymmetrical loading on the tap, causing breakage. In order to avert this problem, we recommend LS spring-loaded tapping chucks. They release excess torque actively, providing protection and enhancing tool life, making machining safe and more uniform.

2. Can multiple taps be used to thread cut through the same specifications?

Yes, but precision grade (e.g., LS has H1-H4 precision taps), flute type (e.g., hand or machine), and tap type (e.g., skipped, spiral, or straight flutes) must be selected depending on specific needs. Different taps suit different materials and working conditions. Making proper tap choices improves thread quality and productivity, avoids machining defects, and ensures compatibility and durability.

3. How do LS taps address hard-to-machine materials?

LS taps utilize a variable pitch design and MF coating technology to machine hard-to-machine metals like titanium and high-temperature alloys with efficient cutting resonance dissipation and reduced frictional heat. The new design reduces tap wear by as much as 200% and doubles tap life, while providing high precision and stability, enabling efficient and reliable machining in adverse industrial conditions.

4. What instrumentation is needed for thread inspection?

Thread testing requires a go/no-go gauge for basic dimension checking, thread micrometer for measuring pitch diameter parameter, and an LS smart thread inspection system for fast, full-parameter scanning (within 3 seconds). The instruments address dimensional, tolerance, and surface quality inspection. LS tools, besides, provide fast digital readings, enabling thread accuracy to be in compliance and quality control to be simplified.

Conclusion

Threads are the “language” of mechanical connections, and taps are the “pen” that writes this language. Threads, as functional structures, exist on various parts, fulfilling the functions of fastening, sealing, and transmission. Taps, as precision tools, replicate standard thread cavities within holes through cutting motion. Understanding the essential differences between the two (result vs. tool), manufacturing logic, and matching rules is essential for avoiding machining failures and improving assembly quality.

Whether you need a mass tapping solution or face the challenge of threading specialized materials, LS offers comprehensive technical support, from tap selection and cutting parameter optimization to in-process testing. Receive a free LS threading manual (including a material-tap matching chart) or schedule an on-site trial tapping service to create perfect threaded connections with professional tools!

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.