Among the extensive array of metal materials, low-carbon steel is basic and pivotal and is the framework of modern industrial production. Its name teaches us something: it contains a carbon content generally below 0.25%, a little bit of alloying element giving it an unique set of properties. Primarily among them is its excellent ductility and plasticity, and hence it is also called “mild steel” in engineering. This makes it proof against brittle fracture and goes through a great deal of plastic deformation without fracture so that it becomes very versatile to a large number of hot as well as cold forming operations like rolling, bending, stamping, and drawing. This native ductility not only reduces the energy usage and production cost to a huge extent but also allows it to be rolled into an enormous range of complex shapes, from enormous automobile bodies to delicate nail wires. Precisely due to these unmatched forming advantages and superior weldability, low-carbon steel has long been the material of choice for structural construction, automotive body sheet metal, household appliances, and numerous deep-drawn parts, unobtrusively supporting the physical structure of human civilization. To save your time, here we give a concise overview of the key findings.

Quick Reference: Choose Your Tap at a Glance

| Characteristics | Mild Steel | Medium-High Carbon Steel | Advantages of Mild Steel |

| Cost | Low | Medium to High | Excellent economic efficiency, with the lowest raw material and production costs. |

| Weldability | Excellent | Poor to Fair | Simple welding process, low cracking after welding, and the highest versatility. |

| Strength | Low | Medium to High | Low strength and hardness, but can be moderately increased through cold working (work hardening). |

| Hardness | Low | High | Poor wear resistance, but easy to machine. |

| Toughness/Ductility | Very High | Low | Excellent formability, capable of extensive cold bending, stamping, and deep drawing without breaking. |

- The inherent strengths of mild steel lie in its unrivalled economic efficiency, excellent weldability, and satisfactory formability. It sacrifices some strength and hardness to achieve exemplary toughness and ductility and is therefore the most ubiquitous and fundamental engineering material used in contemporary manufacture.

- It is no “low-end” material but, quite the opposite, its immense flexibility and low price have made it the first choice for building everything from giant buildings to the “skeleton” of consumer items. Medium and high-carbon steels are, however, complementary, being used in specific applications requiring improved strength, hardness, and wear resistance.

Why Trust This Guide? Practical Experience From LS Experts

Mild steel in LS Precision Manufacturing is not a textbook term but our everyday companion. We have ourselves processed hundreds of thousands of tons of mild steel sheet and wire, experimenting with it and testing temper and limits by hand at each operation—stamping through bending, welding, and deep drawing. All that is recommended and concluded here is derived from information gathered in our own production facilities, problems encountered, and solutions arrived at. We not only possess theoretical information but also basic practical know-how as it relates to cost, efficiency, and quality. We’ve worked in many different industries, so we’re quite familiar with the nuanced material requirements of various applications.

We know how to transform a soft sheet of mild steel into a hard energy-absorbing component for an automotive chassis by varying processes. We’ve precisely calculated the heat input in every weld point of a building truss to ensure total structural strength. We’ve even conceived the cheapest and most cost-efficient stamping process for a home appliance enclosure, giving aesthetics without wrinkling and cracking. This hands-on learning throughout the automobile, construction, and consumer goods manufacturing industries enables us to provide an all-encompassing, impartial, and useful guide for you to fully grasp this fundamental and all-purpose material. By thorough research on the customer’s demands, LS Precision Manufacturing designed a new method: First, under material selection, they applied high-strength, light low-carbon steel (i.e., HC220YD+Z). Through microalloying and precision-controlled rolling and cooling technology, they significantly improved the strength of the material with superior stamping properties.

What Is Mild Steel? And Why Do We Call It “Mild Steel”?

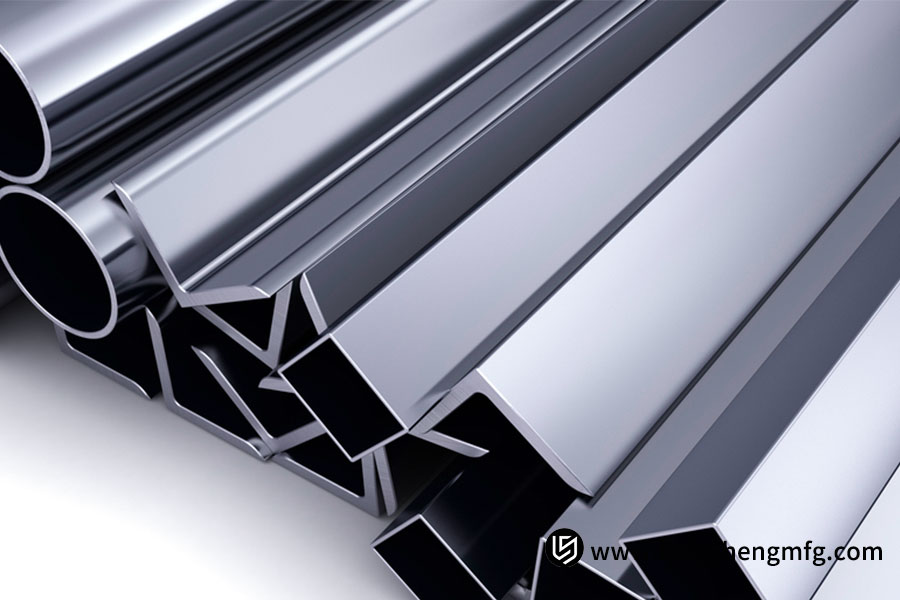

What is mild steel? Essentially, it is an iron-carbon alloy that has a very low carbon content, typically less than 0.25% by weight. This implies that it is primarily iron and very low amounts of carbon as well as other elements such as manganese, phosphorus, and sulfur. Its low alloy content imparts a unique and useful set of properties to it and makes it one of the simplest and most widely used steels in the industrial world, with typical forms being angle steel, plate, and wire.

It is because of its extremely low carbon content that it has earned the common nickname of “mild steel.” The “soft” here does not imply brittle, but graphically describes its mechanical property of low hardness and softness. Carbon is a key element that strengthens steel and hardens it, but significantly lowers its ductility and toughness. Due to the low carbon content, the internal crystal structure of mild steel (ferrite) is soft and ductile and thus low in hardness and easy to scratch. This, however, allows it to exhibit very high plasticity, with the capability to withstand large and permanent deformations without fracturing.

This “soft” quality is precisely its greatest asset. It gives mild steel unmatched workability, allowing it to be readily formed by such procedures as cold bending, stamping, forging, and drawing, as well as being highly weldable.

Thus, from construction steel bars to automobile bodies, from hardware to everyday tanks, “mild steel” has been the preferred material for building the modern world with its economy and high formability.

What Are The Significant Material Properties Of Low-Carbon Steel?

For the significant material properties of low-carbon steel, it have four aspects such as unequalled toughness and ductility, good weldability, good cold-forming ability and machanical properties. Next, I will intruduce these properties in detail for you and hope it will assist you.

1. Unequalled toughness and ductility:

The most significant property of low-carbon steel is its unequalled toughness and ductility. Due to its low carbon content (<0.25%), its microstructure is predominantly soft ferrite, and hence it can undergo extensive plastic deformation without breaking under tensile stress. This enables it to absorb high impact energy and makes it an ideal choice for structural components under deformation, e.g., automobile bumper beams.

2. Good weldability:

Good weldability is the key to the performance of low-carbon steel. The low carbon content ensures that in the welding thermal cycle, the tendency to generate high-hardness, brittle structures (e.g., martensite) in the weld seam and heat-affected zone is extremely low. This makes welding simpler and joint performance more stable, with no need for complicated preheating and post-heat treatment, greatly lowering production costs and technical difficulties. This is one of the reasons it finds widespread application in building construction, bridge construction, shipbuilding, and pipeline laying.

3. Good cold-forming ability:

Its good cold-forming ability directly affects its ductility. Mild steel can be easily fabricated through cold bending, stamping, deep drawing, and spinning with large changes in shape without intermediate annealing. It is this characteristic which renders mild steel the preferred material for the production of auto sheet metal, appliance cases, metal containers, and hardware products, making economic mass production of complex shapes possible.

4. Mechanical properties:

Mechanically, mild steel is relatively soft and weak, but this gives a useful “design window.” It can be significantly hardened and strengthened by cold work hardening (for example, cold rolling and cold drawing) at some cost in ductility, to meet the requirements of increased strength. It is also highly machinable and easily available for machining processes such as turning, milling, and drilling.

- In brief, the properties of mild steel are a synergistic combination of advantages. Its ductility, toughness, and weldability are very good at the cost of a low carbon content, resulting in unprecedented advantage in processing and forming.

- While its absolute strength and hardness are less than those of medium- and high-carbon steels, its performance can be effectively enhanced through processes such as cold work hardening.

- It’s this perfect balance between machinability, affordability, and versatility which has rendered mild steel such an unshakeable foundation material in the modern industrial world.

- It’s not necessarily the highest performing material, perhaps, but undoubtedly the most widely applicable and fundamental foundation material.

What Are The Particular Advantages Of Mild Steel Over Other Steels?

No wonder that mild steel is the most widely used base material of many types of steel. Its competitiveness by nature is due to a sequence of advantages, particularly when compared to medium- and high-carbon steels, as well as stainless steel. For the sake of simplicity, we have taken advantage of a comparison table for a quick visual display of their basic differences:

| Characteristics | Low Carbon Steel | Medium-High Carbon Steel | Stainless Steel |

| Cost | Very Low | Medium | Very High |

| Processing Difficulty | Very Easy (Good formability and weldability) | Relatively Difficult (Welding preheating is required, cracking tendency) | Difficult (Excessive work hardening, special process required)

|

| Core Properties | High ductility, High toughness | High hardness, High wear resistance | High corrosion resistance |

| Applications | Structural frames, automotive sheet metal, deep drawing parts | Springs, cutting tools, rails | Medical devices, kitchenware, chemical equipment |

1. Unparalleled cost-effectiveness

As can be seen from the table above, the biggest advantage of low carbon steel is its unparalleled cost-effectiveness. It enjoys significantly lower raw material and process costs than stainless steel, which requires high levels of alloying elements (such as chromium and nickel). It is also cheaper than medium-high carbon steel, which requires more advanced heat treatment. This is the reason why it is the preferred material for mass-produced consumer goods and major structural applications.

2. Excellent machinability:

Then there is its excellent machinability. As opposed to medium- and high-carbon steels, which are hard, brittle, and require complex welding techniques to resist cracking, low-carbon steel can be readily formed, cut, and welded, both hot and cold. Compared to stainless steel, for which work hardening requires special processing techniques, low-carbon steel is simpler and more effective to process, significantly reducing production energy and equipment wear. It is this formability that explains its indispensability in the manufacturing industry.

3. Wide application:

Its wide application lies in its successful balance between performance, price, and ease of processing. Although it is not as corrosion-resistant as stainless steel or as hard and wear-resistant as high-carbon steel, its satisfactory strength, excellent toughness, and good weldability meet the demands of most industrial applications, from load-bearing building structures to automobile body panels.

- In brief, the strengths of low-carbon steel lie in balance and economy. It is not a “specialized” performer in terms of performance but a “universal player” with the highest overall strength.

- It trades extreme hardness or corrosion resistance for extremely low cost, easy processing, and good-enough performance for most uses. This particular cost-effectiveness and process-friendliness have made it an imovable foundation in the world of engineering materials.

What Are The Main Applications Of Mild Steel In Automobile Manufacturing?

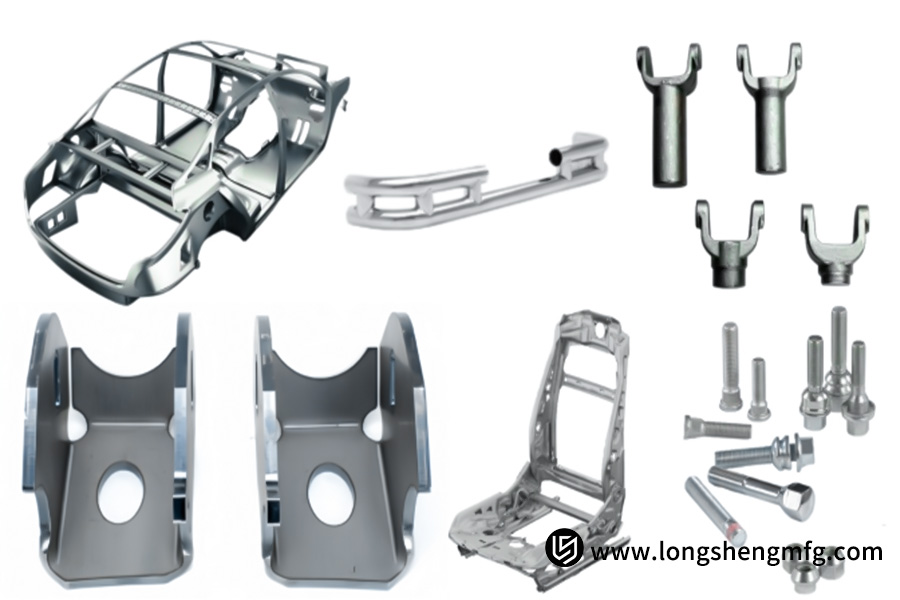

Mild steel, with its excellent all-around performance, has become an indispensable fundamental material in the manufacturing of automobiles. Its applications are concentrated in the following three areas.

1. Body panels and sheet metal:

Mild steel has wide usage in body panels and sheet metal, i.e., fenders, hoods, doors, and roofs. These components entail complex stamping and stretch forming processes, and the extremely high ductility of mild steel and its excellent cold forming characteristics enable it to be readily formed into smooth and complex shapes without risks of cracking and wrinkling.

2. Chassis systems and associated structural members:

It is also used in chassis systems and associated structural members, including subframes, control arms, and wheel arches. The secret to the use of mild steel is its outstanding balance of toughness and strength. It has enough structural stiffness for these safety structures, while its high toughness efficiently absorbs impact energy and adds safety.

3. Body structural components:

Most importantly, mild steel is a crucial material for the manufacture of body structural components, i.e., A/B-pillar reinforcements and longitudinal beams. This part forms the safety cage structure of the passenger cell. Mild steel’s high weldability ensures that these critical components can be safely joined into a high-strength structure through processes such as spot welding. Furthermore, in the event of a collision, these components effectively absorb and redistribute impact forces through controlled deformation, maximizing passenger safety.

The basis for this choice is evident: Mild steel, at low cost, perfectly meets the basic automotive manufacturing requirements of high-volume producibility, high-strength formability, uniform weldability, and acceptable energy absorption. It is the key to achieving a balance between vehicle safety, affordability, and manufacturability.

How Can The Construction Industry Fully Utilize Mild Steel?

The construction industry is a basic consumer of mild steel, and fully utilizing it is reflected in maximizing the use of material properties with focus on three aspects.

1. Steel structures

In steel structures, mild steel, rolled in the form of H-beams, I-beams, angles, and other shapes, forms the skeleton of modern factories, stadiums, and skyscrapers. Its superior strength, toughness, and weldability enable these members to be made in factories as prefabricated components and then joined and welded together quickly in the field, significantly improving construction efficiency. Its superior ductility also provides the structure with excellent seismic resistance, as earthquake energy is absorbed by deformation, ensuring building safety.

2. The backbone of reinforced concrete

As the backbone of reinforced concrete, mild steel is utilized thoroughly in the form of threaded rebar. It has a nearly ideal synergy with concrete: steel provides excellent tensile strength, compensating for concrete’s own vulnerability; Besides, their similar coefficients of thermal expansion allow them to work together and not induce devastating stresses. The synergy creates a structural system that has very good load-carrying capacity at a very low cost.

3. Bridge construction

Aside from this, in bridge construction, from main trusses to the steel framework, mild steel is the primary material. Not only does it meet the stringent structural strength and stability requirements of bridges, its high weldability facilitates the fabrication and joining of big members with ease, and it has the ability to withstand complex loads and dynamic loading.

The origin of the choice of mild steel is its unmatched economy and reliable structural behavior. It possesses sufficient strength, satisfactory workability, and ease of construction at minimum expense, with an optimum balance between structural safety and economic effectiveness, and constitutes a basis of the development of the modern construction industry.

The Commonness Of Mild Steel In Daily Appliances

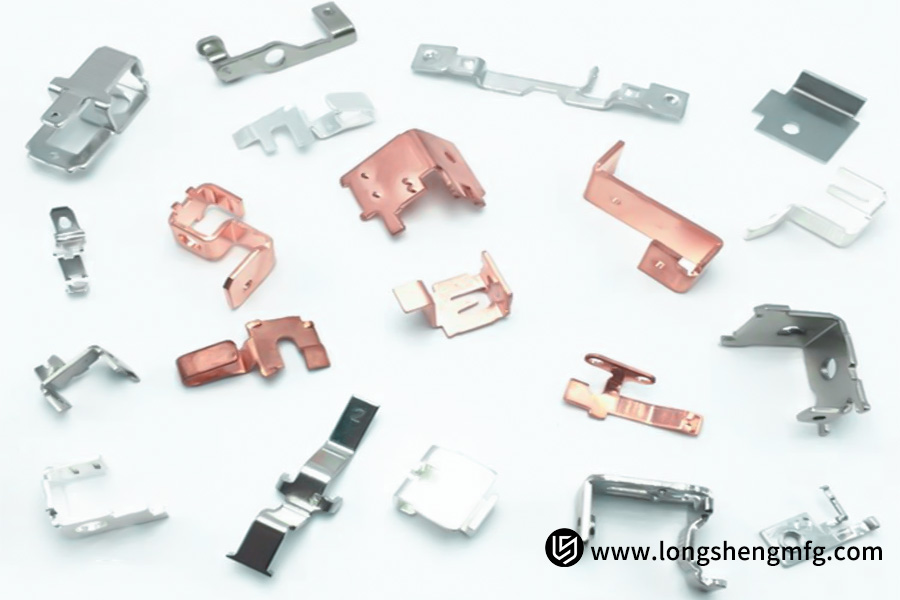

A closer look discovers mild steel, with its unbeatable formability and affordability, to be deeply implicated in every aspect of our life, silently supporting the operations of modern living.

Home appliances industry

In the home appliances industry, it is a veritable workhorse. Outer coverings and inner structural supports of such everyday products as refrigerators, washing machines, and microwave ovens are made largely of mild steel sheets obtained by stamping and bending. This material is easily formed into complex curved shapes, providing home appliances with efficient protection along with being the foundation for their stylish designs.

Fixtures and furniture

Mild steel is also ubiquitous in fixtures and furniture. From simple, modern metal bookshelves, table and chair legs, and filing cabinets to security grilles for windows, balcony, and even the common fasteners like screws, all are made from this material. By going through processes such as welding and bending, it forms strong and affordable dwellings.

A great many tools and devices

More importantly, it’s also used in a great many tools and devices we utilize on a daily basis. From garden shovels and hoes, to kitchen pots (base material) and knives (blade base materials), to staplers, scissors, and pen holders in the office, mild steel, with its excellent comprehensive properties, finds an ideal balance between strength, cost, and processing difficulty, meeting the mass production needs of a vast variety of everyday items.

One can say that despite its modest appearance, mild steel, with its “ordinary” characteristics, underpins all aspects of modern life and therefore constitutes a truly essential foundation material.

LS Case Study: How To Optimize Low-Carbon Stamping Part Production For Home Appliance Manufacturers?

1. Challenges encountered by customers:

A major producer of home appliances wished to enhance the manufacture of stamped parts for air conditioner top covers to achieve lightweight components without any loss of structural strength, at reduced costs. The major concerns they had were: conventional low-carbon steel lacked strength, and the use of high-strength special steels would imply forming difficulties and prohibitive costs. Furthermore, the then-existing production processes were not quite efficient, and it was difficult to meet the demands of high-volume and high-quality production.

2. Limitations of traditional solutions:

Property improvement of low-carbon steel used to rely on the addition of expensive alloying elements (such as Ti and Nb) or energy-consuming bell annealing processes. This not only increased the raw material cost but also decreased the production cycle speed, resulting in inadequate weight reduction, which made it difficult to meet the energy conservation and environment protection requirements of modern home appliances.

3. LS Precision Manufacturing’s innovative approach:

In addition, LS Precision Manufacturing optimized the stamping die design and annealing process (through continuous annealing technology). By accurately controlling annealing temperature and cooling rate parameters, LS obtained stable coiling performance and good surface quality, significantly improving stamping yields. Besides, in a “one steel, many grades” production pattern (a single raw material to make parts of varied strength), LS Precision Manufacturing streamlined production planning, reduced raw material costs, and relieved pressure on inventory.

4. Final results and value realization:

Last but not least, the home appliance company achieved a 16% weight reduction on air conditioner top cover parts, significantly reduced stamping cracking rate, and boosted production. Not only did this lower the unit cost and enhance the competitiveness of the product, but also the light structure realized energy saving and environmental protection in the end product, which showed the wide application opportunities of low-carbon steel in green manufacturing. LS Precision Manufacturing provides customers with high-value solutions via systematic innovation in the material, process, and cost control.

How To Choose And Treat Low-Carbon Steel Properly?

The choose of low-carbon steel must be deliberated from a comprehensive perspective based on the actual application circumstance. The following are key steps on how to properly select and process mild steel.

Grade selection

Grade selection is an important initial step:

- For deep-drawn parts that require high formability (e.g., automotive body panels), high-grade cold-rolled low-carbon steels such as SPCE and DC01 are preferred.

- For general structure and welded parts, general carbon structural steels such as Q195 and Q235 can meet these requirements, both of which have economic efficiency and reliability.

- When selecting a material, take heed to ensure that the parameters of yield strength and elongation are in accordance with design requirements.

Appropriate heat treatment

Having selected a material, its properties can frequently be enhanced further by appropriate heat treatment. Recrystallization annealing (heating in the range 600-700°C) can be used to eliminate work hardening from cold working and restore plasticity for further forming. Normalizing can be used for forgings or castings that require more uniform microstructure and overall mechanical properties. Quenching is not usually used for low-carbon steel, as the hardening effect is small and deformation is more likely to occur.

Surface treatment

Surface treatment is required for better durability. The most widely used economical solution is electrogalvanizing or hot-dip galvanizing, which can effectively resist corrosion in atmospheric conditions. For those products that need aesthetics, such as home appliances, a combined process of phosphating and then spraying (painting or powder coating) can be used, achieving both rust resistance and aesthetics. Those parts with specific requirements for wear resistance can be carburized, which increases the carbon content of the surface and, on heat treatment, creates a wear-resistant surface that is hard with good toughness in the core.

The reasonable selection of grades, along with appropriate heat treatment and surface protection, can maximize the inherent advantages of low-cost and easy forming of low-carbon steel and meet diverse engineering requirements.

What Are The Trends Of Future Low-Carbon Steel Development?

The future of low-carbon steel development will have three major trends: high performance, composite material, and green development. The following is a detailed analysis of these three major trends by us at LS Precision Manufacturing.

1. High performance

The first trend is the research and application of high-strength low-carbon steel. Advanced microalloying practice (addition of small amounts of elements such as niobium, vanadium, and titanium) and exact heat treatment processes such as controlled rolling and controlled cooling (TMCP) can significantly improve the material’s strength without sacrificing formability and weldability. This type of high-strength low-carbon steel (such as DP steel in AHSS) will better meet the combined demands of automotive and machinery lightweighting, high safety, energy conservation, and environmental protection, and is an important future development prospect.

2. Composite material

Composite materials are another key direction. Low-carbon steel is combined with aluminum alloys, stainless steel, or polymers by processes such as rolling and explosive lamination to make “metal composite plates.” These materials combine the low cost and high rigidity of low-carbon steel with the particular characteristics of other materials (e.g., corrosion resistance and lightness), and will penetrate new fields such as new energy and marine engineering.

3. Green development

Green production processes will be industry standards. This includes bringing in a fully continuous annealing process to replace the energy-intensive bell-type annealing process, as well as promoting green technologies such as acid-free pickling (such as green mechanical dephosphorization technology) and low-temperature rolling. These technologies aim to significantly reduce energy consumption and carbon emissions in the production process, achieving sustainable development throughout its entire lifecycle.

- The future of mild steel lies not in substitution but in being developed by technological innovation. Its basic trend is to maintain economic and versatility advantages and continue to push the boundaries of strength and performance through developments in composition and process.

- It will also embrace lightweighting, composite material, and green manufacturing technologies heavily, thereby further entrenching itself as a fundamental engineering material of importance.

FAQs

1. Does mild steel rust? How can it be prevented?

Yes, due to its iron-based composition, mild steel is susceptible to electrochemical corrosion from environmental influences. Prevention of rust includes selecting the proper surface treatment based on the end-use environment. Outdoor structures can utilize hot-dip galvanizing to achieve long-term sacrificial anodic protection. Indoor equipment can achieve both rust prevention and appearance by phosphating followed by painting (powder coating). For temporary corrosion prevention, oil or corrosion inhibitors can be used, which is convenient and economical for subsequent processing. In special environments (such as high humidity), compound protection methods such as electrophoretic coating can be used.

2. Will the strength of low-carbon steel meet the demands of structural components?

Low-carbon steel may be work-strengthened (for example, cold rolling, cold drawing) to increase the strength by 30%-50%, or normalized to refine grain size and improve comprehensive performance. For example, Q235 steel can be increased to over 350 MPa yield strength through cold bending, which is sufficient to meet the structural requirements of the majority of building trusses, warehouse shelves, and other structures. In critical load-carrying areas, micro-alloyed high-strength low-carbon steel (e.g., Q355) can be used to balance formability and strength.

3. What are the precautions to be taken when welding low-carbon steel?

Although mild steel is highly weldable, three significant factors should be considered: First, use low-hydrogen electrodes to avert hydrogen-induced cracking; second, control the interpass temperature (ideally <200°C) to prevent excessive grain growth; and third, preheat thick plates (80-150°C) to reduce the cooling rate and stress and distortion. For thin plates, use low-current, high-speed welding to help restrict softening in the heat-affected zone. Post-weld stress relief annealing will add dimensional stability.

4. How do I know mild steel will work for my project?

It is recommended to take the following four points into consideration: first, the load requirements (whether it requires high strength >400 MPa); second, forming (whether it requires complex processes such as deep drawing and cold bending); third, corrosion resistance (whether it requires acid and alkali corrosion resistance over extended periods of time); and fourth, cost budget (whether the unit price of the material has any constraints). For example, mild steel delivers dramatic advantages in end uses such as appliance housings and specialty equipment mounts. LS Precision Manufacturing offers free material selection and trial production to help determine the optimum solution.

Conclusion

Despite the introduction of new materials, low carbon steel is a staple of modern industry because of its unbeatable economy, excellent formability, and predictable weldability. Its utility lies in its “perfect balance”—it delivers sufficient performance for most applications at very low cost, while being readily shaped into an excellent variety of forms by known methods. Skyscraper structures to automobile bodies, household appliances to common hardware, mild steel, with its unmatched versatility and availability, unobtrusively underpins the operation and prosperity of modern society. It is the epitome of industrial-sized production and is equated with the highest cost-effectiveness.

If your project requires an economical, cost-effective, and easily processed material solution, mild steel is likely your best choice. LS Precision Manufacturing’s materials expert team is always available to provide technical support, from material selection and process optimization to cost control, to custom-make the most valuable mild steel processing solution for your application. Contact our experts today for a free technical consultation and a quick quote, and let this traditional material bring efficiency and reliability into your products.

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

You should participate in a contest for among the best blogs on the web. I will suggest this site!

Wow, that’s the highest compliment! Thank you so much for the recommendation. Having readers like you support us is the greatest reward we can receive. Thank you!