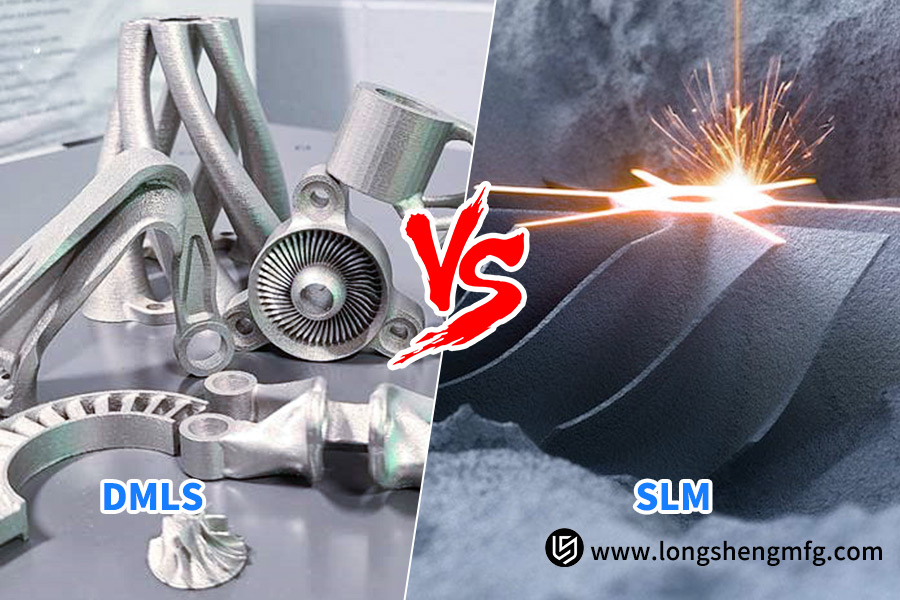

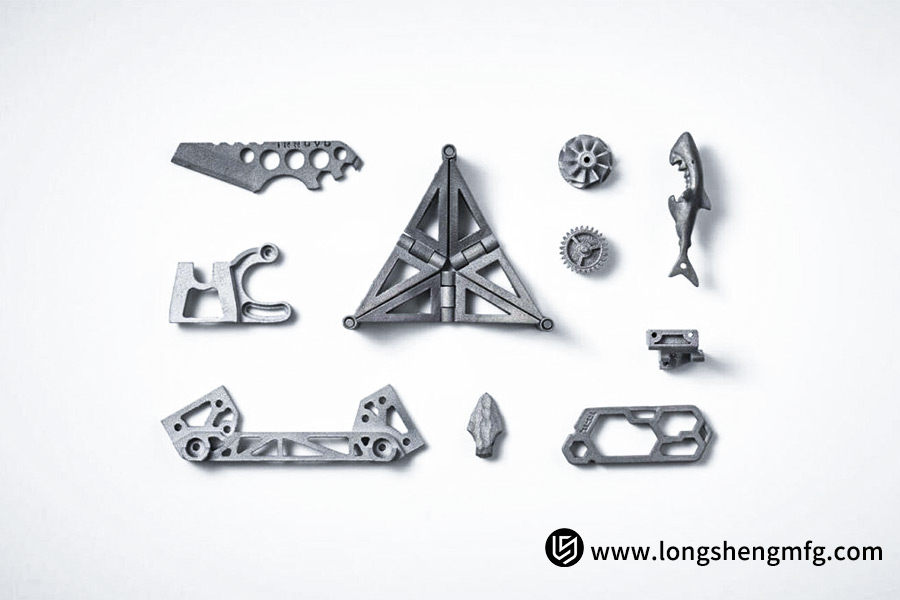

Within metal 3D printing, when faced with technology choice, SLM (Selective Laser Melting) and DMLS (Direct Metal Laser Sintering) are the two most frequently compared mainstream technologies. Your choice will have a direct impact on the end product’s mechanical properties, manufacturing accuracy, and the overall project cost.

While they use different terminologies, the underlying difference is in the mechanism for processing the material: SLM aims to completely melt metal powder to produce a uniform part, whereas DMLS metallurgically bonds the powder particles together with sintering. Appreciating the difference is crucial for preserving the success of your application.

At LS Precision Manufacturing, we understand that no technology is suitable for every situation. Therefore, not only do we provide improved metal 3D printing but technical consulting in total. To save you time, here’s a quick overview of the core conclusions.

SLM vs. DMLS Core Quick Reference Comparison Table

| Comparison Dimensions | SLM (Selective Laser Melting) | DMLS (Direct Metal Laser Sintering) |

| Working Principle | Metal powder is completely melted by a high-energy laser to achieve metallurgical bonding and a dense and uniform metal structure. | The laser sinters the powder particles together in a solid structure by bonding high-melting-point metal particles to the low-melting-point metal. |

| Strength and Accuracy | Improved mechanical properties and density with almost forging strength of the part. Fine surface finish. | High and dense mechanical properties. However, the surface roughness of the part is relatively higher and generally more post-processing is required. |

| Cost Consideration | Very expensive machinery (tens to hundreds of millions of dollars). Post-processing also has the potential to incur cost by requirement for support structures. | High equipment investment cost. Material cost can be very variable depending on application since it may consist of several pieces and more complex process control. |

| Applicable Materials | Pre-alloy metal powders are applied most often, i.e., titanium alloys, aluminum alloys, stainless steel, and nickel-base superalloys. | Other materials can be applied, i.e., single-component metals, multi-component mixtures of metals, or pre-alloy powders, i.e., some hard-to-melt carbides. |

How to Select:

- For maximum performance, apply SLM: If your application demands highest part strength, density, and surface finish (e.g., critical aerospace components or medical implants), SLM technology is the best option.

- For demanding materials or specialty application, apply DMLS: When you need to work with specialty composites or gradient materials, or with metals of high melting points, DMLS technology gives you greater material freedom.

Why Trust This Guide? Practical Experience from LS Experts

The information presented in this guide does not stem from theory but from actual practice of LS Precision Manufacturing in day-to-day production. We are aware that technical abilities and SLM and DMLS limitations are no theoretical abstract. Rather, they are characterized by having very close familiarity of scores of hundreds of material and process parameters, wise application of technology choice in successful printing of ultra-light aerospace structures with ultra-high mechanical properties for aerospace clients, and successful tailoring of implants with complex internal flow channels for medical clients.

For example, LS Precision advised one client to rethink their project. They had initially wanted DMLS, but we guided their material experts through their extremely high fatigue strength requirements, and we were able to produce a part with the SLM process at 99.9% density, much better than they had expected. This shared experience through hands-on use is the foundation of our conservative recommendations.

LS Precision Manufacturing supposes real knowledge to be the capability to translate technical know-how into effective client projects.

Under The Hood: What Is The Fundamental Difference Between SLM And DMLS?

In choosing a metal 3D printing technology, understanding the distinction between SLM and DMLS is the basis of choosing the right one. Both depend on lasers for building parts layer-wise, but both technologies operate on principles that are fundamentally different, and those distinctions have a direct influence on the end part properties. Briefly put, the major distinction between the two is in the manner the laser acts upon the metal powder:

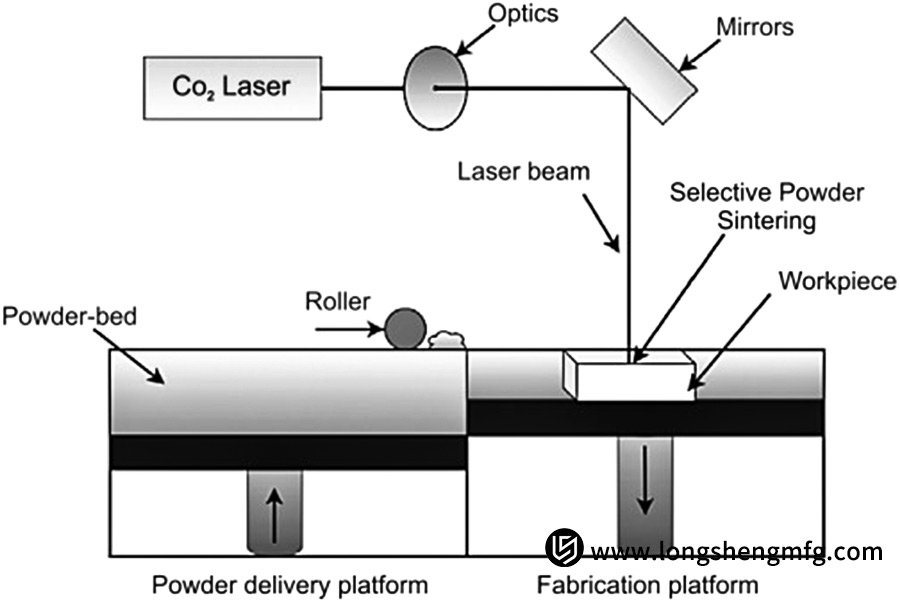

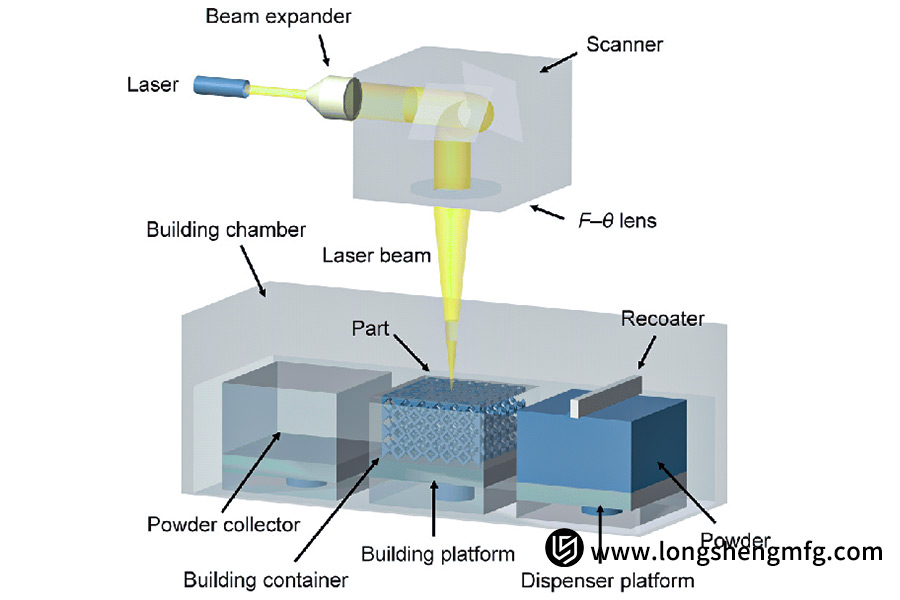

1. SLM (Selective Laser Melting):

SLM uses a laser beam as a tiny “furnace,” that melts the metal powder to the extent of being completely liquid, forming a very small molten pool. The molten pool quenches quickly and solidifies to form a fully dense, chemically homogeneous solid metal layer. This is similar to heating an entire ice cube to its melting point and then freezing it again into a solid ice block. As such, parts manufactured by SLM have extremely high mechanical properties and density similar to those produced through traditional forging.

2. DMLS (Direct Metal Laser Sintering):

The DMLS process itself is more of a “sintering” process. A controlled laser melts the metal powder below its complete melting point. The powder particle surface will melt first and will weld and fuse at a molecular level while the interior of the particles remains solid. It is like partially melting the surface of a pile of aggregate sand particles to high temperatures, and thus, they become very stiffly attached to each other.

3. What does this fundamental difference lead to?

This basic distinction between “complete melting” and “sintering bonding” gives rise to a series of chain reactions:

- SLM, due to its complete melting character, is more suitable for the production of homogenous high-performance components with a single alloy;

- DMLS benefits from greater flexibility in handling multi-component materials, e.g., metal matrix composites.

Acquiring information regarding the principle is the basis for reasonable selection of the metal 3D printing mode.

Strength vs. Precision: DMLS vs. SLM: Which Wins?

Strength and precision of DMLS and SLM are the key parameters determining technology to be employed in 3D printing of metals. Both technologies are different in their fundamental principles: SLM melts metal powder completely to form a solid of uniform composition, while DMLS binds powder particles at the molecular level through the sintering process. This directly determines their performance in terms of density, mechanical properties, and surface accuracy. A comparison of key dimensions follows below:

| Comparison Indicators | SLM Technology | DMLS Technology |

| Density | Up to 99.8% (nearly as high as forging standards) | Approximately 99% (lower than SLM but still extremely close) |

| Mechanical Properties | Significantly enhanced tensile strength (e.g., AlSi10Mg which can have 550 MPa after heat treatment) and hardness. | At 90%-95% of the maximum strength of the same metal grade. |

| Accuracy and Surface Finish | The surface roughness can be optimized to Ra <5μm but high residual stress and deformation are probable. | Relatively large surface roughness typically requires additional post-processing. |

| Process Control Flexibility | The melt pool can be accurately controlled by parameters such as laser power and scanning strategy. | Variable material pairs and sintering parameters can be utilized to accommodate complex structures. |

LS Precision Manufacturing sacrifices between strength and precision by optimizing process parameters dynamically (e.g., laser power, scanning speed, and layer thickness). For example:

- For SLM technology, checkerboard scanning strategy is used to reduce residual stress by 40%, preventing deformation.

- For DMLS technology, multi-material gradient sintering and post-processing are utilized to optimize surface quality to meet requirements of personalized medical parts.

At LS Precision, we maximize every technology using digital parameter simulation and real-time monitoring to bring you maximum value for every technology, so you enjoy the ideal combination of the strength and precision of DMLS and SLM.

The Truth About Costs: What Exactly Are The Cost Differences Between SLM And DMLS?

In order to truly understand the cost difference between SLM and DMLS, we must look beyond the surface price and inspect the cost structure across their lifetime. This choice has a direct impact on the total cost of ownership (TCO) of your project.

1. Equipment and Depreciation Costs:

SLM equipment, as a requirement of complete metal melting, requires very high levels of the laser and control system. Initial capital expense will usually be higher than DMLS equipment, impacting long-term depreciation charges proportionally.

2. Material Cost and Utilization:

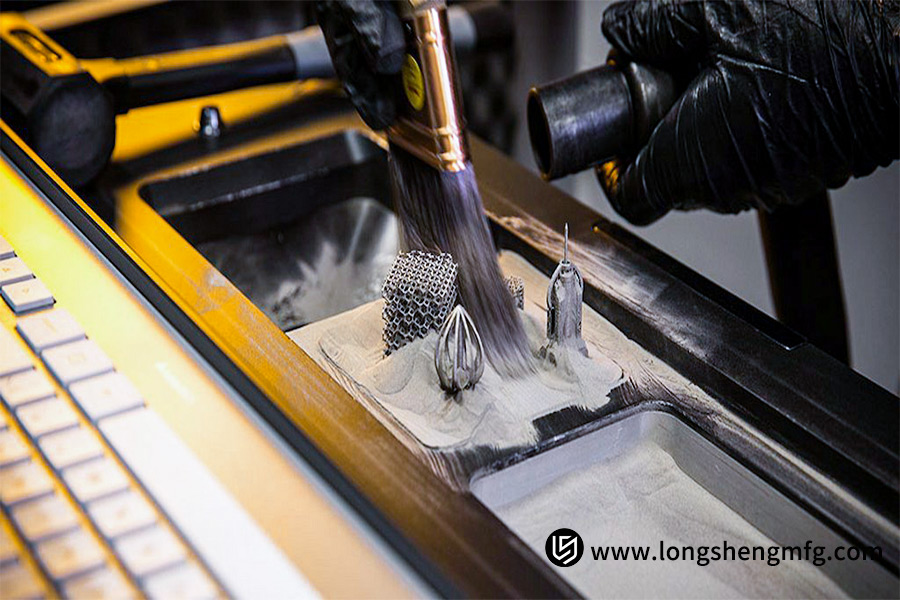

SLM is made from pre-alloyed high-purity powders with a greater unit cost. DMLS offers greater material selection freedom. LS’s new powder handling system brought powder recovery for both techniques above 95%, albeit reducing the unit cost significantly.

3. Post-processing Costs:

That is the key to cost differentiation. SLM generates more internal stress, which requires greater strength and greater numbers of support structures to resist deformation. This not only contributes to additional support material usage but also significantly contributes to the effort and time of subsequent support removal (e.g., wire EDM) and surface finishing, resulting in significant hidden expenses. DMLS is comparatively low in thermal stress and simpler to support but can have higher initial surface roughness. Having a high finish contributes additional cost for follow-up machining.

4. Energy Consumption and Operational Efficiency:

The entire melting process of SLM is energy intensive. LS Precision employs smart scheduling and process optimization to drive energy usage per print time down while maximizing overall equipment usage.

We optimize supports at LS Precision by simulating early process and incorporate automated post-processing lines to enable you to realize optimal total cost of ownership while fulfilling technical specifications.

Which TechnologyCan Print The Metal You Need?

Material compatibility is a key factor in determining the most suitable type of metal 3D printing. Not all metals are processed equally. SLM and DMLS, through their distinct principles, excel at two distinct areas. Your project requirements will dictate your technology choice. The following are the main material applications of the two technologies:

1. SLM: Expert in High-Performance Homogeneous Materials

The SLM process, where the powder is completely melted, is best suitable for post-processing pre-alloyed powders with a uniform composition. It produces parts of uniform microstructure and excellent mechanical properties, particularly in the following materials:

- Lightweight, high-strength alloys, such as titanium alloys (Ti6Al4V) and aluminum alloys (AlSi10Mg/AlSi7Mg) are the material of preference for lightweighting in aerospace and automotive applications.

- Superalloys at high temperature, such as nickel-based superalloys (Inconel 718/625), are used in high-temperature resistant components such as engine blades.

- Strong and corrosion-resistant industrial parts, such as 316L and 1.2709 (die steel), are used.

2. DMLS: A Flexible Solution for Multi-Material and Specialty Alloys

The sintering principle of DMLS provides a superior flexibility of material combinations, allowing it to be perfectly suited for the processing of high-melting metals or metal-matrix composites:

- Tool and die steels: H13 and Maraging Steel are used to create complex molds with built-in cooling channels.

- Cobalt-chromium alloys: They are ideal for medical and dental implants due to their better biocompatibility and wear resistance.

- Copper alloys: Better heat input control by DMLS enables it to print copper components with better thermal and electrical conductivity efficiently.

At LS Precision Manufacturing, our material engineers use their experience to test, refine, and recommend the ideal material-process combination so that not only will your parts be printed, but they’ll perform at optimal level.

Seeking record-breaking material properties or designing a custom metal 3D printing application? LS Precision has it covered with superior technical support and complete material solutions.

How Do I Choose Between SLM And DMLS?

The key to choosing between SLM and DMLS is to get very clear on your primary requirements. There is no universally “better” technology, but the best one for your specific application. You can instantly identify the right technology by answering the following most crucial questions:

| Decision Dimension | Key Questions | Preferred Technology Choice | Core Reasons |

| Strength and Density | Does the part have to resist very high loads, fatigue strength, or severe environments? | Prefer SLM. | By melting metal powder completely, SLM can produce parts with high density (99.8%) and mechanical properties comparable to forgings, resulting in increased strength and other properties. |

| Geometric Complexity | Does the print feature extremely thin walls, fine internal flow channels, or difficult-to-support overhangs? | Prefer DMLS. | DMLS typically generates less residual stress than SLM, which helps in managing deformation and maintaining dimensions constant when printing complex and detailed structures. |

| Material Requirements | Is the project based on the use of specific composite materials or alloys alone? | DMLS: Greater flexibility. | DMLS is more material flexible and has the capability to accept some specialty composite materials. SLM, on the other hand, primarily uses pre-alloyed powder. |

| Comprehensive Cost | While meeting basic requirements, is it necessary to strictly control the total cost of ownership (including post-processing)? | A comprehensive assessment is required. | SLM equipment investment is generally higher, and due to its process characteristics, it often requires more support structures, which may increase post-processing costs. DMLS parts may also require post-processing to improve surface quality. Cost comparisons require a specific project analysis. |

LS Precision do not just provide printing; we also provide intensive technical consulting. Our engineers will conduct a data-driven decision making and a design for manufacturability analysis and then recommend the solution with the best balance of cost, cycle time, and performance when faced with a difficult decision.

It is your specific application case that will drive the decision between SLM and DMLS. We encourage you to call us and discuss your part requirements and performance requirements, and LS Precision will provide you with an experienced technical road map.

LS Success Story: How Did DMLS Technology Help Reduce The Weight Of An Aerospace Bracket By 40%?

In aerospace, lightening each component translates to substantial performance gain and lower operating expenses. This article will reveal how LS Precision Manufacturing employed DMLS technology to overcome the lightweighting dilemma of a core bracket component for a world-leading aerospace manufacturer.

1. Client’s Dilemma:

The company needed to develop a critical titanium alloy bracket for a new aircraft. The design required radical weight reduction with complex internal topology optimization, yet traditional casting and machining processes could not replicate the complex hollow structure. SLM technology met the performance requirements in the initial review, but with the depreciation cost of the equipment at a high level and the post-processing cost for the extensive supports that the complex structure necessitated, the project budget was far exceeded.

2. LS Precision Solution:

Faced with this challenge, the LS Precision Engineering team went beyond the usual solutions. After careful analysis, we discovered that even though the component required high strength, the mechanical properties were lower than what was required for SLM. We therefore creatively proposed DMLS technology and advised the following precise solution:

- Material and Process Match: We selected Ti6Al4V (TC4) titanium alloy powder, capitalizing on the excellent formability of the DMLS process for printing this material.

- Parameter Optimization: Using a specially designed laser scanning plan and layer thickness control parameters, we were able to successfully reduce residual stress during printing, minimize use of support structures, and optimize post-processing.

- Integrated Post-Processing: We provided an entire post-processing solution, including heat treatment, wire EDM support elimination, and surface finishing, to produce a part that was dimensionally precise and also performed as required.

3. Results:

The finished shipped bracket part exceeded customer expectations:

- Extreme Weight Reduction: We successfully realized a 40% weight reduction, thereby making an effective contribution towards the overall lightweighting goals of the aircraft.

- Meeting Performance Standards: Third-party testing confirmed that the part’s strength, stiffness, and fatigue characteristics were all in full compliance with all rigorous mechanical specifications.

- Cost Optimization: By the selection to utilize the DMLS technology path and by optimizing the process, we effectively kept overall costs within the client’s budget.

The bracket has been successfully implemented in this model of aircraft and now is a completed product. This case establishes that proper choice of technology and solid process understanding are the key to achieving the optimal balance between performance and cost.

What Else Should An Excellent Metal 3D Printing Service Manufacturer Provide?

Choosing a good metal 3D printing service provider is not so much about having advanced machines. The actual core value is providing value-added technical services at all stages of the product development process, so that you deliver not just a “print,” but a high-quality, ready-for-use final product. At LS Precision Manufacturing, we aim to be your one-stop production partner.

1. Design for Manufacturability and Process Optimization in Early Stages:

LS Precision’s process begins even prior to your uploading of drawings. Our engineers, with their extensive experience in metal 3D printing, conduct professional Design for Manufacturability analysis. This includes build orientation optimization to minimize supports, wall thickness adjustment to avoid warping, and topology optimization to reduce weight and increase toughness, ensuring success in design and cost savings from the outset.

2. Precise Control and Real-Time Monitoring of the Printing Process:

In the printing process, LS Precision utilizes an advanced real-time melt pool monitoring system to track the build quality of each layer. This not only detects and documents potential defects in a timely fashion, thus guaranteeing the stability of the process, but also provides data support for subsequent quality traceability, providing invaluable quality assurance for the manufacture of safety-critical components such as aerospace and medical implants.

3. Comprehensive One-Stop Post-Processing and Quality Inspection:

Printing is only half of the fight. LS Precision also offer a full line of post-processing, including heat treatment (stress relieving, solution aging), wire EDM, support removal, CNC finishing, and surface treatment (sandblasting, polishing). Further, with measuring tools like coordinate measuring machines and CT scanners, we see to it that each shipped part meets the accuracy and performance indicated on the drawings.

At LS Precision, we believe outstanding metal 3D printing services as one-stop solution from design to end product, providing peace of mind.

FAQs

1. Do SLM and DMLS printed parts require post-processing?

Yes, it does. The “printed part” taken out of the machine is only a blank and must pass through a series of post-processing steps before it can be an accredited part. This typically includes: base processing (wire cutting to detach the base plate from the support members and to cut away support members), inherent performance enhancement (stress relief or solution failure heat treatment; for high-performance parts, hot isostatic pressing is typically utilized to close microscopic internal porosity and improve fatigue strength), and finishing (sandblasting, CNC machining, and others for final dimensional tolerance and surface finish).

2. Can LS Precision certify the performance of printed parts?

Yes. LS Precision not only makes parts, but also authoritative information certifying their quality. LS’s laboratory is outfitted with state-of-the-art equipment, having the capability to perform mechanical testing (tensile, impact, and fatigue) to verify strength, metallographic analysis to observe microstructures, and industrial CT scanning for non-destructive internal flaw detection. We are able to create test reports to high industry standards such as aerospace (AMS) and medical (ISO 13485), providing critical quality certification and traceability for your mission-critical applications.

3. Is metal 3D printing also an option for low-volume prototyping?

This is precisely the advantage of metal 3D printing. It is ideally suited for low-volume, complex prototypes and indeed direct production. Without the cost of tooling, you can quickly turn your design into a physical product, significantly minimizing your R&D time and enabling you to make many, inexpensive iterations within the design phase. From a proof-of-concept part for functional verification to a small-batch final product, LS Precision’s flexible metal 3D printing solutions help you achieve innovation sooner and at lower cost.

4. How do I start my first metal 3D printing project?

The start of a partnership is simple and quick. You simply need to send your 3D model file (STP/STL file) and minimum orders (e.g., material and quantity) via our website or by mail. After receiving the file, LS Precision’s application engineers will directly initiate a free manufacturability analysis to assess the print feasibility, optimize the building plan, and provide you with a comprehensive, full-scale technical proposal and quote within 24 hours. The entire process is clear and efficient, and it is easy for you to take your first steps in metal 3D printing.

Conclusion

Choosing between SLM and DMLS is an expert decision that requires careful evaluation of materials, performance, cost, and the ultimate application context. There is no “one size fits all” solution; the trick is discovering the best process for your specific needs.

LS Precision Manufacturing strives to be your trusted partner. Leveraging our extensive technical expertise and diverse suite of services, not only do we provide you with precise technology selection guidance, but we also offer end-to-end metal 3D printing services, including manufacturability analysis and process parameter tuning, through post-processing and quality certification, to deliver you with the finished part that fulfills your genuine requirements.

Contact LS Precision and upload your 3D model today, and LS Precision’s experts will provide you with a free manufacturability analysis and a customized SLM/DMLS technology comparison quote!

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.