A flawless sheet metal hem is the acme of a product’s strength, safety, and looks; a rough, unfinished hem can undermine the integrity of the entire assembly and even be a safety hazard. Such subtle differences in workmanship are usually the determining factor between greatness and adequacy.

Whether you are an engineer seeking to master your trade or a purchaser seeking a reliable manufacturer for a project, a deep familiarity and mastery of systematic core sheet metal hemming technologies are the key. This paper is not only the authoritative technical manual to your journey from beginner to expert, but also evidence of LS Manufacturing’s commitment to systematizing and standardizing the hemming process.

We’ll describe the seven basic technologies that ensure zero defects—from precise material prediction to micro-matching of molds, from precise control of pressure parameters to end-closed-loop quality validation. To save you time, here’s a quick overview of the core conclusions.

Sheet Metal Hemming Core Technologies Quick Reference

| Core Areas | Main Aims | Core Methods and Equipment |

| Cognitive Foundation | Learn the basic function of hems in strength, safety, and appearance. | Define the functions of hemming: Enhance edges, eliminate sharp edges, and enhance stiffness. |

| Type Selection | Utilize the best hem shape for specific products and applications. | Comparative Analysis: Flat hemming, open hemming, and teardrop hemming. |

| Process Design | Obtain quality from the origin and ensure precise manufacturing. | Calculate hemming allowances properly; scientifically determine bending order; and use expert upper and lower dies. |

| Operation | Master equipment and tools to continually achieve high-quality hemming. | Master speed and pressure controls of modern hemming machines; and be adept at using professional tools such as hemming knives and rulers. |

| Problem Solving | Quick identification and fixing of hands-on manufacturing issues. | Build a defects database (e.g., loose hemming, indentation too deep); and learn from successful case studies (e.g., LS Manufacturing’s resolution of the wire cutting problem in telecommunication cabinets). |

| Quality Closed Loop | Carefully examining and fine-tuning on a continuous basis to achieve a bottom line of quality. | Perform initial, regular, and final inspections; check dimensions and tightness with standard measuring instruments; record data and provide feedback to the design group. |

This guide chart in sequential form summarizes the entire process from theory to quality control. World-class hemming technology is not the product of a single step, but the product of closely coupled and systematic process of understanding, design, implementation, and verification. This implies that engineers need to be competent at machine operation, as well as design, materials, and inspection.

Mastery of the whole technology of sheet metal hemming, from knowledgeable individuals to experts capable of solving genuine issues creatively in a proper manner, ultimately achieves zero-defect manufacturing with high reliability.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

The information presented in this handbook isn’t textbook theory; it’s the result of LS Manufacturing’s trial and error refinement cycle for thousands of precision sheet metal parts. We understand that an effective hemming process must be adaptable to changing material and design specifications.

For example, in fixing the issue of cable cutting near the edge of a top-of-the-line telecom enclosure, conventional hemming solutions did not work since there wasn’t much room. Our engineers applied an innovative “micro-slit pre-pressing process” and micro-molds adapted to their needs and were able to produce a secure hem on one fold within millimeter-scale working space. This completely eliminated rough edges and provided 30% increased strength. This example shows how we apply our core technologies to provide value to customers.

We believe that real expertise is founded on the ability to solve for specific problems in complex applications. LS Manufacturing is committed to turning this experience, earned with each flawless hem, into reliable productivity for you.

What Is Sheet Metal Hemming? Why Is It A “Must-Have” For High-Quality Parts?

In sheet metal production, hemming of sheet metal—a traditional process—is all about the edge of the sheet metal, creating a smooth, continuous, rounded edge. Such a seemingly simple operation is the starting point which delineates average parts from good-quality ones. LS Manufacturing strongly believes that product excellence starts with the relentless pursuit of basic processes such as hemming.

A qualified hemming product must at the same time meet the following four basic values:

- Safety First, Removing Hidden Hazards: Trimming all the sharp edges created due to cutting to avoid injury during installation, use, and maintenance is very important for the safety of the product.

- Strength and Rigidity Enhanced: Hemming significantly enhances the strength and rigidity of the edge and thereby the impact and deformation resistance and the functional life of the entire sheet metal part.

- Better Appearance, Higher Durability, and Improved Quality: Radius edges that are smooth provide a better appearance and result in a cleaner finish with a more consistent adhesion surface for additional painting or plating, thus improving coating durability and overall product quality.

- Functional Extension and Easy Joining: Some hemming processes (such as tubular hemming) can also be applied for articulation among parts or to fasten wiring harnesses, enabling more functional part design.

Precisely because of the above four main values, the new hemming technology is today a must-have tool for quality sheet metal products and the cornerstone of LS Manufacturing’s commitment to precision in all manufacturing processes.

How To Choose The Most Suitable Hemming Type For Your Product?

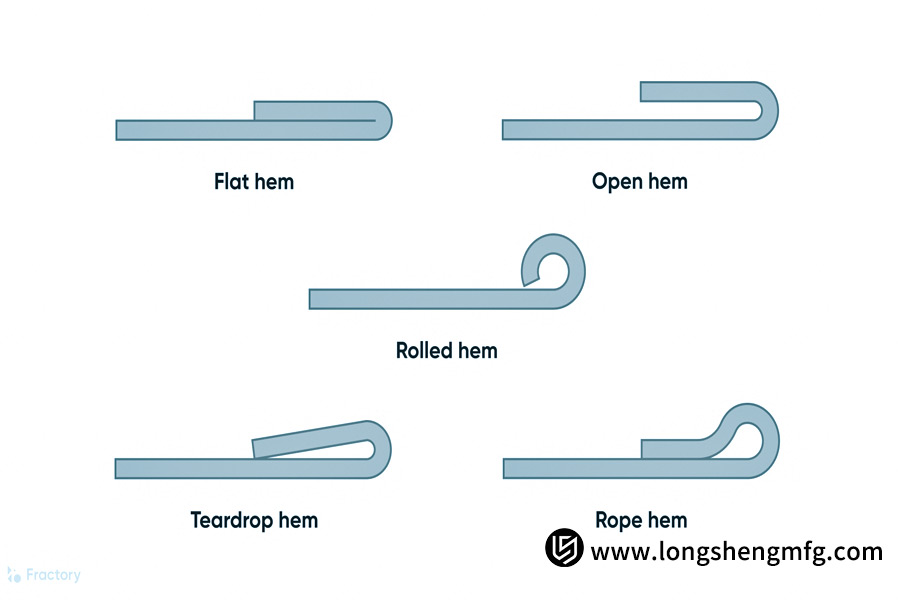

After deciding on hemming necessity, the second important decision is how to choose the most suitable sheet metal hemming type. Different hemming structures vary significantly in strength, appearance, and performance, and the right choice has a direct impact on the performance of the final product. LS Manufacturing knows this and excels at offering specialized selection advice according to the real application conditions of customers’ products. Now, the popular sheet metal hemming types are as follows, each with an ideal range of applications:

1. Flat Hem:

The edge is rolled under and made flat to form a flush, even hem. It is the most popular and least expensive type, which is used for computer boxes, door panels, partitions, etc. Its primary purpose is to eliminate sharp edges, ensure safety, and achieve a tidy appearance.

2. Single-Layer Closed Hem:

The edge is rolled into a tube shape without being flattened. It is stronger than flat hems and is used where the edge must be somewhat stronger, e.g., bracket edges that support loads and metal edges of certain furniture. It also provides for wiring harnesses to pass through.

3. Teardrop Hem:

The curl is teardrop-shaped with a small hole at the end. This not only provides enhanced strength and appearance, but the hole is also a workaday design feature that serves as a wiring, hanging, or connection point. It seems to turn up quite often on upper-end cabinetry, security doors, and sheet metal parts that require additional functionality.

The designers at LS Manufacturing will carefully study your product’s application, stress requirements, appearance requirements, and budget to recommend the optimal solution, and all hem will be utilized to best advantage.

Hemming Die Selection and Design: The Key to Consistency

Precise sheet metal hemming dies are the secret to very consistent hemming results and productive manufacturing. Die geometry and material directly influence the smoothness, tightness, and manufacturability efficiency of the hem. LS Manufacturing’s extensive die inventory and custom design capability make sure that all hems are exactly per the design intent. To achieve an ideal hem, die selection and die design must prioritize the following three elements:

1. Precise Geometry Matching:

The upper die arc radius and lower die V-groove opening have to exactly match the sheet thickness, hem type, and allowance. Any difference, even small, will result in an excessively loose or tight hem, or unsightly indentations and warping. This is the first basic requirement for consistent hem shape.

2. Material and Heat Treatment Reliability:

Based on the raw material (e.g., common cold-rolled sheet, stainless steel, and aluminum alloy) and batch size, different mold materials (e.g., tool steel and alloy steel) and corresponding heat treatment processes are required. By this means, sheet metal hemming molds can be highly accurate and long-lasting with wear and deformation resistance even under high-frequency stamping for a long time.

3. Customized Design Capabilities:

Standard molds generally don’t work well for non-standard or space-constrained designs. LS Manufacturing can easily convert sheet metal hemming molds to fit by product features such as longer elbows and special-shape molds, to avoid interference issues and provide best hemming quality for any complex design.

Without a high-technology mold, the greatest design of the process is all words. LS Manufacturing provides stable hemming quality and manufacturing efficiency through lean management of the mold, which is an important piece of machinery.

How Can We Accurately Calculate Hemming Allowances To Prevent Scrap At The Source?

Accurate calculation of sheet metal hemming allowance is the keystone of successful hemming and directly affects production success. Excessive allowance produces an ugly, unsightly hem, while inadequate allowance produces a loose, unclosed hem, both of which can have direct effects on scrapped workpieces.

The key to accurate sheet metal hemming allowance calculation is proper comprehension of sheet thickness and hem type relationship. The following is a table of allowance calculation for standard hem types, which can be referred to:

| Hem Type | Sheet Thickness (t) | Recommended Allowance (W) | Calculation Formula |

| Flat Hem | 1.0 mm | 2.5 – 3.0 mm | W ≈ (2.5 – 3.0) × t |

| Hollow Hem | 1.0 mm | Around 5.5 mm | W ≈ π × (D – t) / 2 |

| Teardrop Hem | 1.0 mm | Approximately 7.0 mm | Adjustable according to shape of individual |

*D is the desired hem outer diameter and t is the material thickness. This is a theoretical formula; in actual practice, springback and material characteristics will have to be considered.

In actual production, our engineers witnessed a typical example: a customer’s design of a 1.5mm-thick stainless steel component was given a hollow hem in the drawing, but there remained allowance of only 4mm. During inspection, our process engineers, having a rich experience, noticed that this sheet metal hem’s allowance was grossly underestimated. They immediately informed the customer and revised it to 6.5mm, and thereby they avoided the risk of scrapping the entire batch of the components.

This is a demonstration of how LS Manufacturing, through performing aggressive process audits, saves cost and material for the buyer.

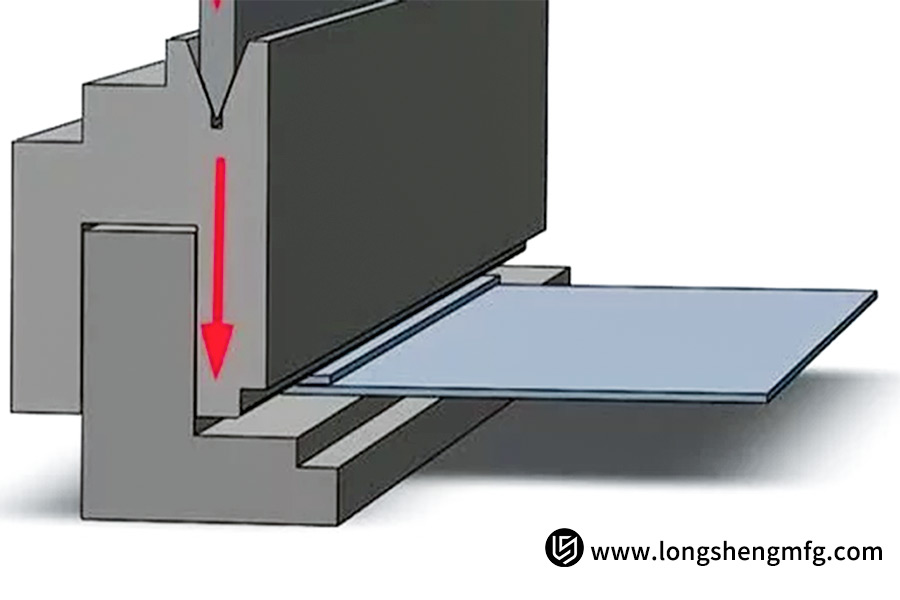

Key Tips For Hemming Machine Operation: The Core of A Modern Sheet Metal Workshop

Precision sheet metal hemming machines are the pinnacle of impeccable hemming. Especially on most recent CNC machines, precision in parameter settings will precisely determine the quality level of the finished product. A state-of-the-art sheet metal hemming machine is not an exercise in strength but an art of precision control as well.

LS Manufacturing’s state-of-the-art range of CNC bending and hemming centers, combined with the top-notch skill of the operators, guarantees that every product exactly follows standards of craftsmanship. To effectively operate a modern sheet metal hemming machine, the following key parameter settings are significant:

1. Pressure Control:

Pressure must be carefully adjusted based on material type, thickness, and hem diameter. Too little pressure will result in a loose, sloppy hem; excessive pressure will cause the material to stretch too far or even rupture. Our operators use our process database to perform initial settings and adjust the optimal pressure point.

2. Speed Coordination:

The lower speed and press speed must be synchronized. There is every possibility of getting scratches or displaced by forceful blows between the sheet and the die using higher speeds. There should be some optimal speed that leaves a smooth and fast hemming process with a uniform and even hem shape.

3. Tool and Program Coordination:

Even the newest machines require good tooling. LS Manufacturing operators run pre-programmed process programs per operation and rigorously inspect the die model to ensure that equipment capability is precisely coordinated with the workpiece and hence yields efficient and damage-free hemming.

Proper Use Of Professional Hemming Tools

In machining big workpieces, on-site maintenance, or made-to-measure structures, professional sheet metal hemming machines with flexibility and high efficiency are generally the point of success and failure. The machines not only serve to reinforce big sheet metal hemming machines perfectly but also provide engineers with precious assistance in conquering one-case process challenging issues.

LS Manufacturing, having many years of real experience, has abundant experience in pneumatic and hand tools and therefore outstanding hemming with high quality under any complex conditions. In order to select and apply professional sheet metal hemming tools properly, you need to understand the following three general situations:

1. Manual Crimping Tools:

These are ideal for small production batch sizes, repair, and limited space applications. As repeated, incremental crimping cycles are executed, the operator subconsciously senses the cycle of material deformation and applies precise control. In an in-situ repair of a communications base station, a hand-held crimp tool designed specifically for that purpose was employed to precisely duplicate a defective cabinet edge to save the cost of replacement.

2. Pneumatic Crimping Tools:

For larger workpieces or large production runs, pneumatic tools are preferable. They deliver consistent output force to provide repeat crimping. LS Manufacturing operators made use of dedicated pneumatic crimp tools designed to their own specifications to crimp a series of reinforced edges on a run of control cabinet liner panel panels with 60% time savings per unit without sacrifice in quality.

3. Customized Specialized Tooling:

For large workpieces or oddly shaped structures, there is no fixed equipment. We have developed different sheet metal hemming tools for such instances, for instance, a movable hydraulic hemming module, which perfectly addressed the edge reinforcement problem of a six-meter-long treatment tank for an environmental protection equipment manufacturer.

These flexible application scenarios fully demonstrate LS Manufacturing’s technological expertise and innovative approach, both in its cutting-edge fixed equipment as well as in the manner that it is capable of providing total solutions to all manner of challenging working conditions.

How LS Manufacturing Solved the Edge Cutting Problem for Telecommunications Cabinets

This is a typical LS Manufacturing case study demonstrating how we implement disciplined sheet metal hemming processes to resolve real customer pain points.

1. Customer Pain Point:

After a commissioning order, communications equipment manufacturer server cabinets used to get cable cuts during installation and servicing. Inspection revealed shortcomings in the first sheet metal hemming process, resulting in uneven hemming and minute burrs on the edges that are not visible to the eye, which added to an ongoing threat to the cable insulation and resulted in numerous complaints from customers.

2. LS Manufacturing Systematic Solution:

- Mold Optimization: We created a special, precision-ground hemming mold according to the customer’s specifications in order to deliver an even pressure across the curling process so that it forms an even, smooth arc profile from the ground level.

- Process Reconstruction: We re-calibrated and precisely calculated the hemming allowance to deliver a tight hem with no extrusion of the excess material and also established the optimal pressure and speed levels for the material.

- Accuracy Execution: The solution was implemented in our high-accuracy CNC hemming machines in our workshop. Stable machines accurately replicated the optimized process, which ensured consistency in mass production.

3. Results and Value:

With this systematic upgrade in the sheet metal hemming process, we eliminated the incidence of nicks on cabinet edges altogether. Hemming smoothness and consistency reached 100% compliance with zero customer complaints. Not only did this significantly enhance the market standing of this model cabinet, but it also significantly increased its installation and maintenance speed and return rate.

This LS Manufacturing case study once again demonstrates that what seems to be a trivial process step turns out to be crucial to product dependability.

Hem Quality Inspection And Common Defect Detection – The “Gatekeeper” Of the Process

Optimal sheet metal hemming is not only a product of sophisticated manufacturing but also of intense quality check-up. In LS Manufacturing, we make inspection the “gatekeeper” of the entire process of sheet metal hemming. Through systematic inspection practices and rapid systems of defect detection, we ensure that every product that we produce is perfect. Our quality inspection system is centered on two important aspects:

1. Standardized Inspection Process:

- Visual and Tactile Initial Check: Quality inspectors visually check the smoothness and evenness of the hem contour and feel with their fingers to check for scratch or burrs.

- Precise Measurement Instrument: Using precise measuring instruments such as radius gauges and calipers, we rigidly check against standard samples to confirm the hem size, diameter, and tightness as per process requirements.

2. Rapid Diagnosis and Resolution of Common Defects:

LS Manufacturing has also established an entire defect database for quick identification and troubleshooting of all defects. For example:

- Loose/asymmetrical hem: This is normally a result of insufficient material or misaligned molds, which requires an immediate review of process parameters and mold alignment.

- Tight or cracked hem: This is usually a result of excessive pressure or insufficient material ductility, which requires equipment pressure adjustment and rechecking of material suitability.

- Surface indentations or scratches: This is typically caused by mold wear or foreign trash, which indicates mold cleaning or maintenance.

This rigorous test and comment loop ensures that every sheet metal hem manufactured by LS Manufacturing is not just a reflection of craftsmanship but also of dependability.

FAQs

1. Is hemming significantly easier for sheet metal of different thicknesses?

The difference actually is quite significant. Thin sheet metal (e.g., 0.5-1.0mm) has a tendency to deform but requires precise control to prevent crushing. Medium-thick sheet metal (1.5-3.0mm) requires increased pressure and precise stock. Thick sheet metal (>3.0mm) provides very high equipment capacity, mold, and calculation process requirements. By utilizing a comprehensive range of high-tonnage CNC machines as well as a comprehensive process database, LS Manufacturing can custom fit the most reliable hemming solutions to sheet metal of various thicknesses with uniform quality.

2. What are the differences between stainless steel and aluminum hemming processes?

The two processes are very different. Stainless steel is very hard and has high springback, where special pressure control and bending design are required to offset springback. Aluminum is soft and of high ductility, where pressure and speed need to be carefully controlled so as not to crush or scratch the surface. LS Manufacturing has created a comprehensive material and process parameter library, optimizing process strategy for different material properties in order to create perfect hemming for each material.

3. Is professional hemming quality guaranteed for small batches?

Yes. LS Manufacturing’s variable production system and consistent process control ensure that the same high process quality and inspection procedures are adhered to for any batch size. With precise parameter adjustment of CNC equipment and rapid changeover of dedicated tooling, we offer sheet metal hemming quality equivalent to mass production while ensuring the accuracy and reliability of each batch.

4. If my design is unconventional, can hemming be performed?

We eagerly await your design requirements! LS Manufacturing’s engineering team is skilled at resolving non-standard challenges. For specialty structure designs, irregular profile, or space-constrained applications, we can create superior hemming by modifying specialty molds, developing specialty tooling, or simplifying process sequences. LS Manufacturing have successfully manufactured numerous complex custom programs and are committed to bringing innovative designs to reliable products.

What will you gain by placing your professional hemming work in the hands of LS Manufacturing?

When you choose LS Manufacturing, you gain so much more than competent, professional sheet metal service. You gain a manufacturing partner who inherently creates value and diminishes risk.

Partnering with us will avoid direct costly trial and error expenses and quality threats, guaranteeing stable, long-term, and quality output of your product. This not only guarantees your supply chain reliability but also greatly enhances your final product’s strength and appearance, making your final product more competitive in the market. Above all else, you’ll have the technical knowledge of LS Manufacturing’s entire engineering department at your fingertips.

We’re not just a supplier; we’re your one-stop technical advisor, committed to making your product a success with our quality sheet metal work.

Conclusion

Understanding these seven core technologies, from pre-determination of materials to closed-loop verification, is a systematic approach to perfect sheet metal hemming. Not only is this technologically ahead, but it’s also a commitment to excellence.

LS Manufacturing truly invites you to take this critical step: Contact our team of experts now today for a free, expert sheet metal hemming process analysis report tailored to your product. Allow us to empower your product quality through our professional insight.

Contact LS Manufacturing and upload your design drawings now and get an instant sheet metal fabrication quote ( sheet metal fabrication price), let LS Manufacturing be your strong backing in pursuit of ultimate overmolding precision!

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.