Compared with traditional metal materials, aluminum alloy has lower density, higher strength and stiffness, good corrosion resistance and conductivity. This material can achieve high-precision, high-efficiency, and high-quality machining and production in CNC machining technology, and the machining aluminum alloy can be easily recycled and reused.

So, how should aluminum alloys be machining in CNC machining? What is the principle of application? Next, Longsheng Technology will answer these questions one by one and provide a detailed introduction to the advantages of aluminum alloys in CNC machining

Aluminum alloy: Overview

Aluminum alloy is an alloy made by mixing aluminum with other metal or non-metallic elements. Usually used to manufacture structural materials, aluminum alloys are much lighter than ordinary steel and can be machining through various methods such as casting, forging, and cold working.

There are many types of aluminum alloys, including hard aluminum alloys, deformed aluminum alloys, lightweight aluminum alloys, etc. Each aluminum alloy has its own unique application field. Hard aluminum alloys are commonly used in the manufacturing of molds and cutting tools. Deformed aluminum alloys are commonly used in the manufacturing of car bodies and aircraft casings. Lightweight aluminum alloys are used in the manufacturing of aircraft and high-speed railways.

CNC machining principle of aluminum alloy

Aluminum alloy machining is mainly divided into three types: turning, milling, and turning milling composite. The following will introduce their principles separately.

turning

CNC turning refers to placing an aluminum alloy workpiece on a lathe and cutting it into the desired shape by rotating the workpiece. In turning, the workpiece is fixed on the spindle and rotates, while the cutting tool moves on the workpiece and cuts the material.

By controlling the feed and position of the tool, the desired shape and size can be achieved. In the turning of aluminum alloys, hard alloy cutting tools are usually used.

milling

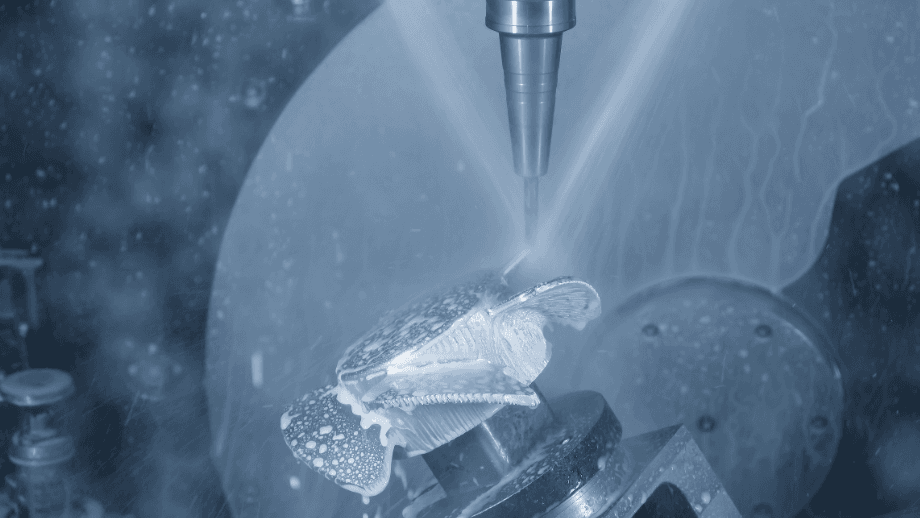

CNC milling is a machining method that removes material by placing a rotating tool on a workpiece and moving the tool along the surface of the workpiece. Compared to turning, milling has higher efficiency and is suitable for manufacturing shapes such as planes, surfaces, grooves, etc.

In the milling of aluminum alloys, commonly used tools include end mills, ball end cutters, flat bottomed cutters, etc. By controlling the feed speed, rotational speed, and cutting depth of the cutting tool, precise machining can be achieved.

Turning and milling composite

Turning milling composite is a process that combines turning and milling. By combining turning and milling, both turning and milling tasks can be completed simultaneously to achieve more complex shapes and machining requirements.

By setting appropriate programs and process parameters on CNC machine tools, the switching and combination of turning and milling can be achieved to meet the Vneeds of various complex parts.

conclusion

When using aluminum alloy for CNC machining of parts, regardless of the machining method used, the machining principle of aluminum alloy is similar, that is, cutting the aluminum alloy workpiece into the desired shape through a cutting tool. Cutting tools need to be selected with appropriate cutting speed, cutting depth, and feed rate to ensure machining efficiency and accuracy

However, if there are requirements for the machining shape and size of aluminum alloy parts, it is best to consult the manufacturer to choose a suitable process for machining , which can greatly improve the applicability of the parts

To learn more about other CNC machining processes, please click on the link【9 Different Types Of CNC Machining Processes】

Common aluminum alloy grades

The strength of aluminum alloys depends on the alloying elements added to them. Common aluminum alloy series include 1000 series, 2000 series, 3000 series, 5000 series, 6000 series, 7000 series and 8000 series. Each series has different characteristics and application areas. The following are some common aluminum alloys and their characteristics:

| Aluminum Grades | Aluminum Content | Copper Content | Description |

|---|---|---|---|

| 1000 series | 99% | 0% | Pure aluminum, with good corrosion resistance and conductivity, is commonly used in power transmission lines and food packaging. |

| 2000 series | 90-99% | 2-6% | Aluminum copper alloy, with high strength and excellent thermal conductivity, is commonly used in aerospace and automotive manufacturing. |

| 3000 series | 90-99% | 0.05-0.2% | Aluminum manganese alloy has good corrosion resistance and welding performance, and is commonly used in the manufacturing of pressure vessels and body components. |

| 5000 series | 90-99% | 0.1-0.25% | Aluminum magnesium alloy has good strength and corrosion resistance, and is commonly used in ship construction and marine applications. |

| 6000 series | 90-99% | 0.1-0.8% | Aluminum silicon alloy, with good processability and welding performance, is commonly used in construction, electronic equipment, and automotive components. |

| 7000 series | 90-99% | 1-8% | Aluminum zinc alloy, with extremely high strength and corrosion resistance, is commonly used in aerospace and sports equipment. |

| 8000 series | 90-99% | 1-2% | Aluminum tin alloy, with good welding performance and high strength, is commonly used in aerospace and sports equipment. |

For more information on CNC machining materials, please click on the link 【10 Kinds Of Commonly Used CNC Machining Materials】

benefits of using aluminum alloy CNC machining

Aluminum CNC machining is a high-precision machining method with many advantages, including:

Lightweight

Aluminum alloys have a lower density and are lighter in weight compared to many other metals, such as steel. This makes aluminum alloys an ideal choice for many applications, especially in areas that require weight reduction, such as aerospace, automobiles, and sports equipment.

high efficiency

CNC machining machines have fast machining speed and can automatically and continuously process, greatly improving machining efficiency. Compared with traditional manual machining , CNC machining machines can process products of various shapes and sizes according to customer requirements, and can perform thread, hole machining , etc

Good processability

Aluminum alloy has good machinability and is suitable for various online CNC machining operations, such as turning, milling, etc. They have high cutting performance and thermal conductivity, making it easy to form complex shapes and details.

Recyclability

Aluminum alloy is a recyclable material with good reusability. Abandoned aluminum alloy materials can be recycled and reprocessed, reducing resource waste and adhering to the principle of sustainable development.

Good thermal conductivity

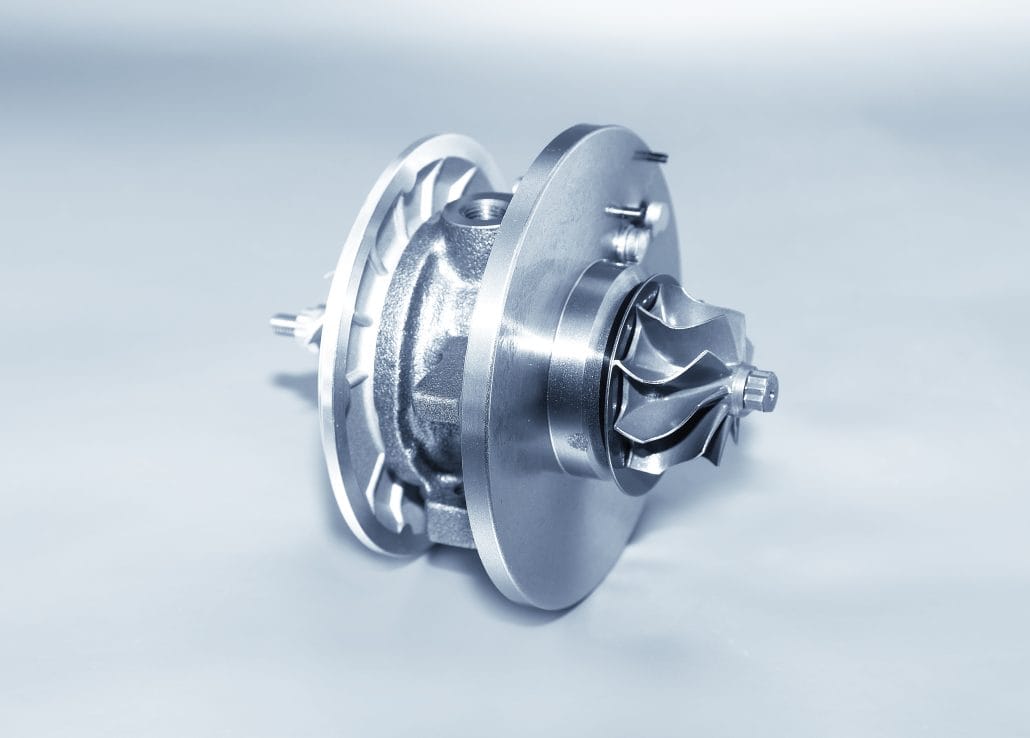

Aluminum alloy has good thermal conductivity and can quickly conduct heat and dissipate heat. This gives aluminum alloys great advantages in applications that require heat dissipation, such as electronic devices, radiators, and engine components.

Comparison of Aluminum Alloy vs. Other Materials

Aluminum alloy has some advantages and disadvantages compared to other materials. The following is a comparison between aluminum alloy and other common materials:

| Materials | Plasticity and machinability | machinability | Thermal conductivity | Processing efficiency |

|---|---|---|---|---|

| Aluminium alloy | high | good | good | high |

| steel | centre | good | same as | centre |

| Stainless steel | centre | same as | same as | centre |

| copper | high | good | excellent | centre |

| brass | high | good | same as | centre |

| Cast iron | low | same as | same as | low |

| plastics | high | same as | range | high |

| Carbon fiber composite materials | centre | good | Average to Excellent | Medium to high |

| titanium alloy | centre | same as | range | centre |

| magnesium alloy | high | good | same as | high |

From the above table, it can be seen that aluminum alloys have high advantages in plasticity and machinability, making them suitable for various machining operations. They have good cutting performance and thermal conductivity, can provide efficient machining processes, and can adapt to various surface treatment methods.

In contrast, steel is slightly inferior to aluminum alloy in terms of plasticity and thermal conductivity, while copper has excellent thermal conductivity, but its plasticity is slightly inferior to aluminum alloy. Plastics perform well in plasticity and machining efficiency, but their cutting performance and thermal conductivity are relatively poor. Synthetic materials have high advantages in thermal conductivity and machining efficiency, but their plasticity and cutting performance are relatively average.

Price Comparison Table of Aluminum Alloy vs. Other Materials

The following is a simple comparison table between aluminum alloy and other common materials in terms of price:

| Materials | Price Range (USD/Pound) |

|---|---|

| Aluminium alloy | 1.00 – 5.00 |

| steel | 0.50 – 2.00 |

| Stainless steel | 2.00 – 5.00 |

| copper | 2.50 – 8.00 |

| brass | 3.00 – 7.00 |

| Glass fiber composite material | 5.00 – 12.00 |

| plastics | 0.10 – 2.00 |

| Carbon fiber composite materials | 15.00 – 30.00 |

| titanium alloy | 10.00 – 20.00 |

| Ultra High Molecular Weight Polyethylene | 2.00 – 5.00 |

Industrial applications of aluminum alloys

Aluminum alloys have a wide range of applications in the industrial field, and the following are some common industrial applications:

Electronics and Electrical Industry

Aluminum alloys are widely used in the manufacturing of shells, heat sinks, wires, and connectors for electronic products and electrical equipment. Aluminum alloy has good conductivity and heat dissipation, which can meet the requirements of electronic equipment for thermal management and electromagnetic shielding.

Aerospace Industry

Aluminum alloys are widely used in the manufacturing of aircraft structures, wings, casings, engine components, and spacecraft components. The lightweight characteristics and excellent strength of aluminum alloys make them important in the aerospace field. Moreover, the corrosion resistance of aluminum alloys can also help prevent aircraft from being damaged by corrosion in harsh environments.

Automobile manufacturing industry

Aluminum alloys can be used to manufacture lightweight components such as car bodies, engines, and suspension systems. The use of aluminum alloy materials can significantly reduce vehicle weight, improve fuel efficiency, and provide better safety performance.

Construction industry

Aluminum alloys are used in the construction industry to manufacture doors and windows, curtain walls, roof structures, bridges, and building materials. It has good weather resistance and corrosion resistance, can resist the impact of outdoor environment, and provides lightweight and aesthetically pleasing design solutions.

Aluminum alloy conditioning, treatment, and finishing

The following is a list of how to choose appropriate treatment processes for aluminum alloy parts in conditioning, treatment, and finishing based on application needs:

| Application Requirement | Conditioning Method | Treatments Method | Finishes Method |

|---|---|---|---|

| Improve strength and hardness | Heat treatment, cold deformation | – | – |

| Improving corrosion resistance | – | Anodizing and electroplating | – |

| Improving wear resistance | – | – | Spraying and coating |

| Enhanced corrosion resistance | – | Chemical oxidation and electroplating | – |

| Improve surface finish | – | – | burnishing |

| Glass fiber composite material | 5.00 – 12.00 | ||

| Implement specific color requirements | Staining | ||

| Improving conductivity | Alloy adjustment | – | – |

| Improve electromagnetic shielding performance | – | – | Electromagnetic shielding coating |

| Enhance decorative effects | – | – | Spraying, polishing, sandblasting |

| Increase high-temperature resistance | – | heat treatment | – |

| Increase weather resistance | – | Painting and oxidation treatment | – |

These application requirements and goals cover some common needs of aluminum alloys in various fields, including performance improvement, corrosion resistance, aesthetic appearance, and functional enhancement. The specific requirements and goals may vary depending on the application field.

Manufacturing aluminum alloy parts through Longsheng CNC machcining services

Our service team has rich machining experience and technical support. When manufacturing aluminum alloy parts, we not only provide high-quality part manufacturing, but also a series of pre-sales and after-sales services. Our services also include the selection and testing of raw materials to ensure that the materials of the parts meet the requirements.

If you need to manufacture aluminum alloy parts, please provide relevant drawings or samples, and we will provide you with a quotation and more detailed information. Please contact our customer service team, we look forward to working with you.

FAQ

The advantages of CNC machining of aluminum alloy include efficiency, accuracy, and repeatability. As aluminum alloy is a light, strong and corrosion resistant metal, it is very suitable for manufacturing various parts and products, such as aerospace, automobile parts, Mobile phone case and electronic equipment.

Yes, aluminum alloys are easy to machine and cut, and have excellent plasticity and machinability. This also makes aluminum alloys very suitable for manufacturing parts and components of various shapes and sizes.