For product developers, are prototyping and small-batch trial production always accompanied by high mold costs, lengthy wait times, and significant investment risks? These pain points of traditional manufacturing methods are severely hindering innovation efficiency.

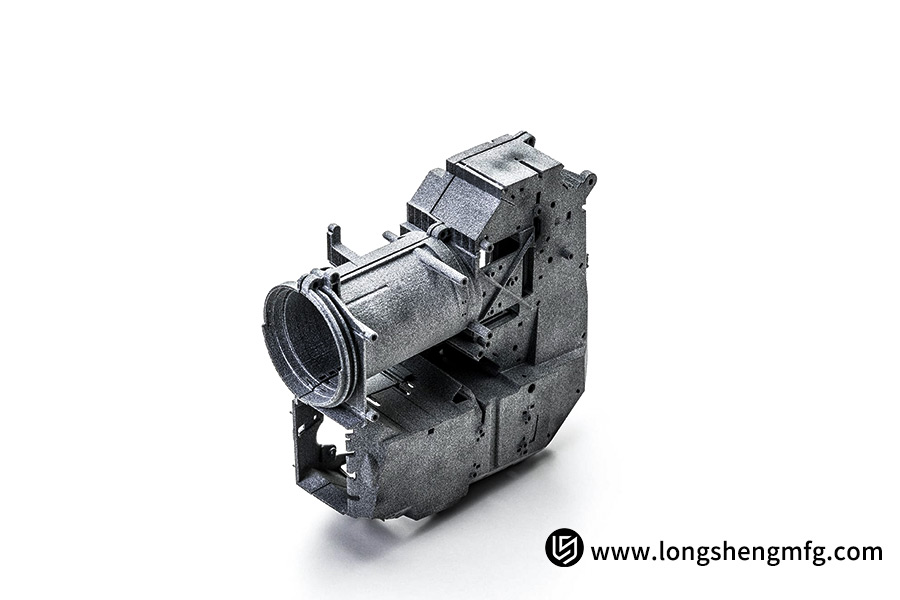

LS Manufacturing’s on-demand 3D printing service is the ideal solution to escape this predicament. Bid farewell to the limitations of one-off molds and say goodbye to the intense financial and time pressures of low-volume production. By utilizing our long experience in additive manufacturing, LS Manufacturing is also equipped with industrial-grade professional 3D printing machines and an in-house technical team, who take full control of all procedures, from design to finished product, with utmost precision and efficiency.

Help your ideas come to life fast with us. Reach out to us today and experience a new era of fast, flexible small-batch development. To save you time, here’s a quick overview of the core conclusions.

On-Demand 3D Printing Core Quick Reference Guide

| Core Dimensions | Main Points |

| Pain of Conventional Approaches | Excessive mold expenses, long cycle times, and high risk of modification make them incompatible for small-batch development, costing budgets and time heavily. |

| LS Manufacturing Core Solutions | No molds, on-demand 3D printing. Direct manufacturing from computer files allows for “print-on-demand” and thus eliminates cost and time of mold. |

| Technical Support | Offers high-precision functional parts in different materials. Assembled products could directly go for test and verification of functions, close to final product performance. |

| Scenarios of Application | Product prototypes, small-volume piloting production, custom parts, intricate structural parts, market verification production, as well as various agile development methods. |

| How to Get Started | Extremely simple process: Online consultation/upload 3D files → Quick quote and process recommendations → Order confirmation → Fast printing and delivery. |

| LS Manufacturing’s Distinctive Strengths | As a service provider, LS Manufacturing exceeds ordinary “printing” by the full range of precision manufacturing from design optimization through production, with reliable precision of quality, expert service, and rapid turnaround. |

On-demand 3D printing precisely addresses the pain points of traditional manufacturing. Through a moldless, digital, and rapid manufacturing approach, it not only achieves up to 50% cost and time savings, but more importantly, empowers developers with unparalleled agility and flexibility, enabling bold innovation, rapid trial and error, and ultimately, a head start in a fiercely competitive market.

LS Manufacturing’s on-demand 3D printing service essentially provides a “golden key” for product development.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Every insight and data in this guide is the product of LS Manufacturing’s twenty years of practical experience in additive manufacturing. We not only possess industrial-grade stereolithography and selective laser sintering equipment, but more importantly, we have successfully delivered over 3,000 small-batch development projects for over 200 clients in the drone, smart wearable, and medical device sectors. We understand that simply “printing” is far from enough to solve development challenges.

For example, a smart home client’s complex housing prototypes repeatedly failed to meet standard printing requirements. Our engineers, leveraging a deep understanding of material shrinkage and support design, adjusted parameters and optimized the structure, ultimately delivering a functional part ready for assembly and testing, saving over 60% in mold trial costs.

This is precisely what sets LS Manufacturing apart from ordinary service providers—we offer more than a simple print run, but a comprehensive manufacturing solution based on extensive project experience.

Why Are Traditional Small Batches Eating Up Your Development Budget?

When you launch a new product project and need a small trial run of only 50-500 pieces, are you ever shocked by the tens or even hundreds of thousands of yuan in traditional mold costs? This is just the beginning of the visible costs. Traditional manufacturing models have inherent cost disadvantages in small batches, quietly eating into your precious development budget.

Let’s use a specific comparison to illustrate the significant differences. Suppose you need to produce 500 plastic parts:

| Cost Items | Traditional injection molding | LS Manufacturing on-demand 3D printing services |

| Upfront mold cost | 30,000-80,000 RMB (one-time investment, high sunk costs) | 0 RMB (no mold opening required, direct manufacturing from digital files) |

| Production cost per part | 5-15 RMB (but high mold fees apply, significantly increasing actual unit cost) | 15-40 RMB (without mold fees, total cost still significantly lower than traditional production) |

| Turnaround | 3-6 weeks (including mold design, machining, mold trials, and modifications) | 1-3 days (production can begin as soon as files are in place) |

| Design modification cost | 2,000-10,000 RMB per modification and 1-2 weeks of waiting time | Nearly zero cost (only 3D file modifications, no physical mold restrictions) |

Even more significant are the hidden costs that are easily overlooked:

- A single mold modification can mean tens of thousands of RMB in additional expenses and weeks of project delay.

- The market opportunity cost of a long wait is even more staggering—a month’s delay to market launch could mean missing the optimal market window, allowing competitors to seize the initiative.

Through low-cost, on-demand 3D printing, they fundamentally restructure your cost structure, allowing you to focus your budget on true innovation and market validation rather than on the burden of heavy molds.

How Does LS Manufacturing’s On-Demand Manufacturing Achieve 50% Cost Savings?

“50% savings” isn’t an empty buzzword; it’s the actual value that LS Manufacturing brings along each step of its revolutionary manufacturing paradigm. Our on-demand 3D printing capabilities make cost-effective hurdles for you in the following three basic areas, indeed saving you time and funds.

1. No mold investment:

In traditional manufacturing, mold costs, often tens to hundreds of thousands of yuan, are the largest sunk cost. LS Manufacturing eliminates this cost entirely, taking the burden of heavy mold amortization away from low-volume orders. This frees your development capital to be invested only in product development and not squandered on expensive “entry tickets.”

2. Intelligent Optimization of Materials and Processes:

LS Manufacturing leverages its vast material database and intelligent algorithms to accurately recommend the most efficient and cost-effective printing materials and process parameters for your design. This not only ensures part performance but also prevents hidden waste in the shape of print failure and excess strength through misguided material selection or improper processing, reaching maximum value of every dollar spent.

3. Ultimate Time Efficiency:

Time is money. LS Manufacturing takes weeks-long production time and condenses it into mere days. From conceptualization to finished product, it is very quick. Not only does this suggest streamlined design iterations, but to have your product out first to market.

Let LS Manufacturing be your partner to allow you to seize transitory market windows. The commercial payback on this time value is necessarily valuable savings.

What Is The Value Of Product Development Using LS Manufacturing’s High-Precision 3D Printing?

When the discussion shifts from “cost” to “value,” the reach of high-precision 3D printing transcends mere manufacturing and is revolutionizing the very building blocks of product development. LS Manufacturing’s precision in additive manufacturing offers you more than just parts; it provides competitive edge and design liberty throughout the entire development process.

1. Accurate Verification, Significantly Reduced Late-Stage Risk:

LS Manufacturing’s accurate manufacturing confirms that prototypes are very consistent with final design intent. You not only have a visual model but a functioning prototype available for rigorous testing. From inspecting assembly clearances to testing mechanically under actual loads, accurate prototypes expose problems early in development, cancelling costly late-stage design modifications and basically assuring product launch success.

2. Freedom from Design Constraints, Facilitating Product Innovation and Breakthroughs in Innovation:

Highly advanced processes linked to molds and tooling often force designs to trade off manufacturability. LS Manufacturing’s accuracy 3D printing technology completely frees this yoke. From latticed weight-saving constructions to complex one-piece flow channels or free-flowing organic forms, you can pursue your creative visions without constraint.

LS Manufacturing extensively expands the design boundaries of product development so you can design breakthrough products with improved performance and improved user experience.

LS Manufacturing Case Study: Smart Wearable Startup Iterates In 2 Weeks, Saving 60%

This real-world 3D printing case vividly demonstrates how LS Manufacturing can help companies achieve real savings in product development time and money. Our efficient manufacturing process resulted in a 60% cost reduction.

1. Customer Dilemma:

A smart wearable startup at a critical stage of development urgently needed 100 sets of precision-engineered device housings for crucial clinical testing and initial market rollout. However, traditional mold-making solutions resulted in a high price tag exceeding 100,000 yuan and a production cycle lasting up to 5 weeks. This cost and time commitment was beyond the startup team’s means, severely hindering product advancement.

2. LS Manufacturing Solution:

After learning about LS Manufacturing’s on-demand manufacturing services, the team submitted their design drawings online. Our system generated a transparent online quote within an hour. After confirming the order, we quickly initiated the high-precision SLA photosensitive resin printing process, completing printing, post-processing, and quality inspection for all 100 housings within five days, delivering the high-quality finished product to the customer.

3. Achievements and Value:

The total cost of this collaboration was only 40% of a traditional mold-making solution, directly saving the customer over 60% in costs. More importantly, the incredibly fast turnaround time of less than a week from order placement to delivery gave the team a valuable window for clinical testing and financing.

This successful product development collaboration not only saved time and money but also became a key enabler for rapid product iteration and market dominance.

What Scenarios Are Best Suited For LS Manufacturing’s On-Demand 3D Printing?

LS Manufacturing’s on-demand 3D printing service isn’t a panacea, but it can deliver disruptive efficiency and cost optimization to your product development process in the following key scenarios. If you’re facing any of the following scenarios, our service is an ideal choice:

1. Rapid Concept Verification and Design Iteration:

In the early stages of creative development, you need to quickly transform your ideas into tangible, physical objects for internal evaluation or presentation to your team or investors. With on-demand 3D printing, you can produce high-quality concept models within days, significantly accelerating decision-making and design refinement.

2. Functional Testing and Assembly Verification:

This is a crucial step in product development. LS Manufacturing’s high-precision parts can simulate the performance of the final product and can be used directly for strength testing, assembly checks, and even small-batch clinical trials, ensuring that all design issues are identified and resolved before molds are even created.

3. Small-batch Trial Production and Market Validation:

When you need 50-500 units for market launch testing, crowdfunding, or early user feedback, LS Manufacturing’s services are the perfect choice. It allows you to produce small batches of products with minimal risk and cost, verify market response, and avoid blindly investing in large-scale production.

4. Customized Equipment and Production Auxiliary Tools:

Traditionally, customizing jigs, fixtures, or inspection tools for specific production lines is costly and time-consuming. Using 3D printing, lightweight, highly complex custom tools can be quickly and economically produced, directly improving production efficiency.

5. Direct Digital Manufacturing of End-Parts:

For customized products (such as medical orthotics and personalized headphones) or parts with complex internal structures, 3D printing enables integrated manufacturing, where traditional processes are inadequate, directly producing functional end-parts.

From consumer electronics and medical devices to automotive parts, LS Manufacturing’s flexibility is meeting the agile product development needs of various industries.

How Does LS Manufacturing Ensure That Parts Are Ready For Functional Testing?

You may be wondering: Are 3D-printed parts just “showpieces”? Can they withstand real-world functional testing? This is precisely the core advantage of LS Manufacturing. Our specialized material systems and precision processes ensure you receive not just mockups, but reliable test parts, a level of performance far beyond that of standard desktop printing.

1. Engineering-Grade Material Selection:

We offer a wide range of materials with performance comparable to or even exceeding that of traditional engineering plastics. For example, ABS-like resins offer excellent strength and temperature resistance; PA nylon (including glass fiber reinforced materials) offer superior toughness, wear resistance, and mechanical strength; and TPU offers exceptional elasticity and tear resistance. This wide selection enables parts to withstand most functional testing scenarios, including structural stresses, temporary friction assembly, and environmental weathering.

2. Stable, High-Precision Printing Process:

Functional testing requires precise part dimensions and consistent quality. Our industrial-grade, high-precision 3D printing equipment, under full closed-loop control, rigorously replicates design details, ensuring dimensional tolerances in critical assembly locations are consistently controlled within ±0.1mm. This high degree of dimensional consistency and surface finish quality is the foundation for precise assembly and testing.

3. Professional Post-Processing and Quality Inspection:

Printing is only the first step. We perform targeted post-processing steps, including support removal, grinding, sandblasting, painting, and even heat treatment, depending on the material and application. Each batch of parts undergoes rigorous quality inspection before shipment to ensure both appearance and core performance meet standards, allowing you to enter the testing process directly upon receipt without the need for secondary processing.

LS Manufacturing utilizes three key processes to ensure that the parts we deliver are not just mockups, but functional components ready for rigorous testing.

How To Get Started With LS Manufacturing’s On-Demand 3D Printing Services?

Starting your journey to efficient and flexible low-volume manufacturing is easier than you think. LS Manufacturing is committed to simplifying complex production processes. In just three steps, you can easily enjoy professional on-demand 3D printing services and quickly turn your ideas into reality.

1. Upload 3D Files Online:

Simply visit our website or contact your account manager to upload your 3D design files (we fully support all major formats, including .stl, .step, and .obj). Our system will automatically perform a preliminary manufacturability analysis. The entire process starts with a single click, eliminating lengthy email exchanges and manual confirmations.

2. Get an Instant, Transparent Online Quote:

After uploading your file, our intelligent quoting system generates a clear online quote within 1 minute based on material usage, printing process, and labor time. The price structure is clear at a glance, with no hidden fees, giving you complete control over your development costs before making a decision.

3. Fast Production and Professional Delivery:

After confirming your quote, your order will be directly processed into our digital production schedule. Sit back and relax as we efficiently coordinate printing, post-processing, and quality inspection, and deliver high-quality parts quickly through our professional logistics network.

From file to physical part, LS Manufacturing’s on-demand 3D printing process is seamless. Our online quoting and digital process eliminate the uncertainty and communication costs associated with traditional manufacturing, allowing you to focus on core product development and innovation.

What Sets LS Manufacturing Apart From Other “On-Demand 3D Printing Near You” Service Providers?

When you search for “on-demand 3D printing near you,” you may find many options offering fast service. However, what sets LS Manufacturing apart is that we offer far more than just a printer—we provide comprehensive, professional support to ensure the success of your product development.

1. Industrial-grade, high-precision 3D printing equipment:

Unlike common desktop equipment, LS Manufacturing fully utilizes industrial-grade, high-precision 3D printing systems. This means your parts achieve a quantum leap in dimensional stability, detail, and batch consistency, providing a solid foundation for functional verification and precision assembly, rather than simply achieving visual quality.

2. Full Review and Technical Support from Professional Engineers:

After receiving a convenient online quote, your project will be fully supported by a team of LS Manufacturing engineers. They will review the design files for process feasibility and proactively provide optimization suggestions where necessary, such as adjusting the orientation to enhance strength or modifying wall thickness to save costs. This eliminates the risk of print failures from the very beginning—a value that cannot be replaced by automated systems.

3. Strict Quality Control System Throughout:

From material storage, printing parameter setting, to post-processing, LS Manufacturing implements standardized quality control processes. Every delivered part undergoes rigorous testing to ensure its mechanical performance and aesthetic quality meet your expectations, ensuring true “out-of-the-box” performance.

4. Deep Foundation in Precision Manufacturing:

The core team at LS Manufacturing has extensive experience in precision manufacturing and deeply understands the challenges of the entire process, from prototyping to mass production. Therefore, we provide more than just printing services; we offer integrated design and manufacturing solutions based on our extensive experience, proactively helping you avoid development pitfalls.

When you choose LS Manufacturing, you’re not simply choosing a “nearby on-demand 3D printing” provider; you’re choosing a strategic partner committed to becoming an extension of your product development team.

FAQs

1. Does my design file need to be final?

Absolutely not. This is the core advantage of on-demand 3D printing, which enables rapid iteration. You can submit files for physical production at any stage of the design process for early visual evaluation or functional testing. Even if adjustments are needed later, simply update the file and print again. This flexibility saves valuable time and cost during product development and makes idea validation more efficient.

2. What is a small batch size? Is there a minimum order quantity?

LS Manufacturing’s on-demand 3D printing service offers ultimate flexibility, enabling a “minimum order of one piece.” We efficiently handle small batches ranging from one to thousands. This eliminates the high barriers to entry associated with traditional manufacturing, making it possible to produce single prototypes or conduct market testing in very small batches. This perfectly meets the flexible needs of the early stages and beyond of product development.

3. What post-processing options are available?

LS Manufacturing offers professional, full-process post-processing services, including fine sanding and sandblasting to enhance the tactile feel, precise painting (supporting Pantone color matching), impregnation, and assembly. When you request an online quote, simply select the options you need, and we’ll process them accordingly, ultimately delivering ready-to-assemble finished parts that meet your needs from testing to display.

4. How is my design data secure?

Protecting our customers’ intellectual property is our top priority. LS Manufacturing utilizes bank-grade encryption for file transfer and storage, and signs a legally binding non-disclosure agreement (NDA) with each customer. Your design files are used solely for the production of your order and will never be disclosed or used for other purposes. We safeguard your every innovation with professionalism and integrity.

Conclusion

LS Manufacturing’s on-demand 3D printing services are the key to solving this dilemma. Not only do we maximize cost and time savings through our “zero mold” model and intelligent processes, but more importantly, our industrial-grade high-precision printing and engineering materials ensure that your parts can be directly used for rigorous functional testing and validation, fundamentally guaranteeing product development success.

From concept prototyping to small-batch pilot production, LS Manufacturing is your reliable partner throughout the entire agile development process.

Don’t let traditional manufacturing methods slow you down. Upload your 3D file and receive a comprehensive quote on your project’s cost and timeline in minutes. Let us accelerate your creativity with professional on-demand 3D printing services and contact LS Manufacturing, turning your blueprint into reality and seizing market opportunities together!

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.