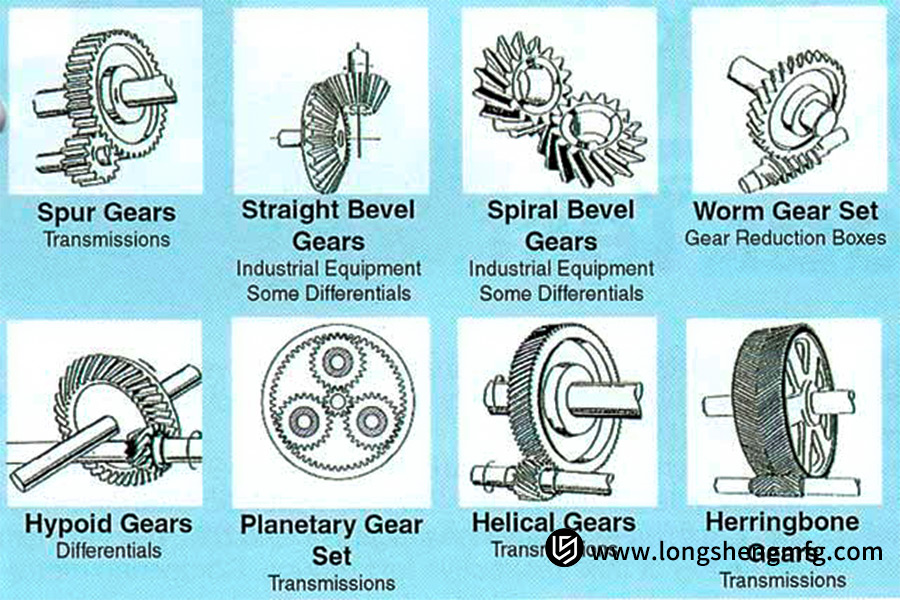

Actually, in the center of industrial transmission, gears are called the “heart of industry.” The precise meshing of gears is the basis of transmitting power. The design and manufacture of gears are not common. From primitive spur gears to sophisticated helical gears, to offset bevel gears and worm gears with large reduction ratios, each type of gear significantly affects the efficiency, noise, and service life of the whole transmission system.

Misalignment of gears or defective workmanship by suppliers can lead directly to unusual equipment wear, excessive noise, excessive energy usage, and even unplanned downtime, resulting in significant maintenance expenses and lost production.

LS Manufacturing is familiar with this challenge from the inside out. Not only are we a precision gear producer, but also a seasoned transmission system engineering partner. From our deep technical expertise, we provide comprehensive solutions from type selection and parameter optimization to precision production and testing.To save you time, here’s a quick overview of the core conclusions.

Gear Selection and Application Core Quick Reference

| Gear Type | Core Features and Advantages | Typical Applications |

| Spur Gears | Simple structure, reduced cost, and simplicity in production but are noisy and unstable. | Spur gears are suited for parallel shaft transmission and light-load, low-speed applications, such as printers and conveyors. |

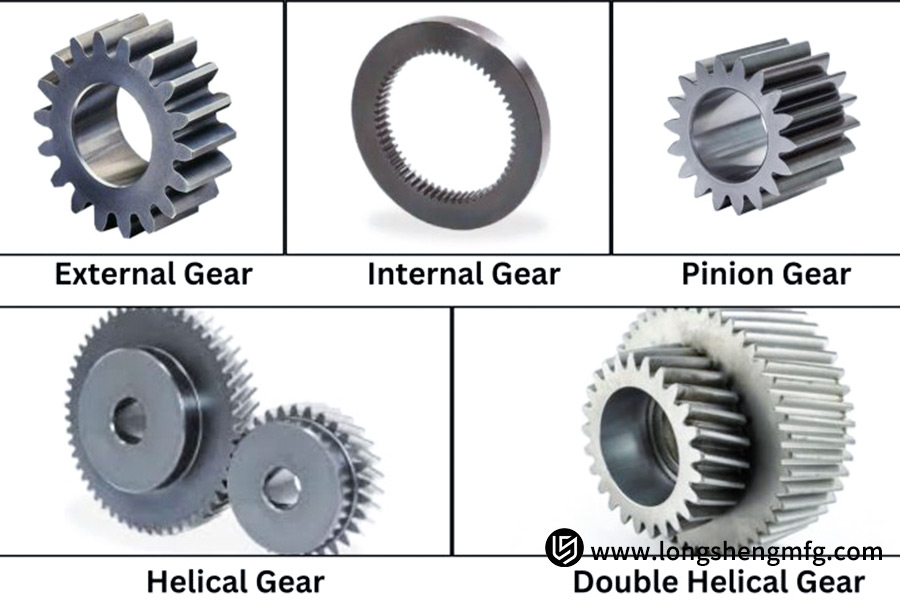

| Helical Gears | Give smooth meshing, low noise, and heavy load; however, they generate axial forces. | Helical gears are suited for heavy-load, high-speed applications, such as car transmissions and industrial reducers. |

| Bevel Gears | Used on intersecting shafts and possess the ability of changing direction | They are harder to manufacture. They are suitable in situations requiring direction changes, such as automotive rear axles and drill vertical machines. |

| Worm Gears | Capable of delivering high single-stage reduction ratio, smoothness of the transmission, and self-locking action; but their efficiency is low. | They are most suitable for applications with high speed ratios and self-locking capacity, such as elevators and indexing devices. |

LS Manufacturing, with its extensive body of engineering know-how, doesn’t merely provide you with precisely manufactured gears to your specifications, but is your technical partner, intervening at the point of selection to direct you into the best selection for your specific application, maximizing efficiency and minimizing cost of ownership.

Choosing the right gear is a critical decision that establishes the performance and reliability of the transmission system. Different types of gears offer compromises in efficiency, noise, load-carrying capacity, and cost.

Why trust this guide? Practical Experience from LS Manufacturing Experts

Every conclusion and recommendation in this guide is the product of over two decades of LS Manufacturing’s rich experience in the gear and transmission industry. We are not armchair talkers but practical innovators. We have been successful in resolving complex problems such as high noise levels, premature tooth wear, and low transmission efficiency for hundreds of clients across industries ranging from high-precision medical devices to heavy mining equipment.

For example, we helped a packaging equipment customer reduce noise levels on equipment from 85 decibels to 68 decibels by replacing their spur gears with special helical gears with greatly extended maintenance intervals. This real-world experience enables us to most accurately project the long-term impact of different selection options.

What you are reading is not merely a compendium of technique; it is the distillation of the countless practical experience and engineering know-how of LS Manufacturing, designed to clear the haze and ensure your project’s success the first time.

Why are spur gears fundamental, but not a panacea?

Because the oldest and most straightforward type of gear, spur gears are the backbone of the transmission industry. But why aren’t they utilized everywhere? The answer lies in its inherent design characteristics.

1. Core Advantages: Simple Structure and High Transmission Efficiency

Spur gears possess teeth parallel to the axis and thus are relatively simple to design, manufacture, and install. They are low-cost gear parts for most light-load, low-speed applications. They have the ability to attain greater-than-99% transmission efficiencies under favorable conditions.

2. Fatal Disadvantages: High Noise and Shock, Limited Applications

Meshing of their teeth involves sudden “line contact” and generates high operating vibration and noise, making them unsuitable for silent operation usage. They are also severely limited to parallel shaft usage and cannot achieve cross-shaft power transmission like bevel gears or worm gears.

LS Manufacturing not only provides superior quality gear parts, but also correctly recommends helical gears and other best-fit gear types based on your specific operating conditions (e.g., load, speed, and noise demands) to give maximum overall system performance.

The detriments of spur gears are experienced in complex applications with high loads, high speeds, or low noise.

In what situations do helical gears significantly outperform spur gears?

If your machinery calls for smooth running, silent running, and heavy loads, the performance advantages of helical gears are self-evident at once. The key to it lies in their distinctive helix angle design.

1. Smooth engagement for low-noise operation:

In contrast to the spur gear’s sudden, full-line tooth engagement, helical gear teeth engage and disengage incrementally. Due to the fact that the meshing is constantly occurring, shock and vibration are significantly reduced, with very smooth and silent operation, making helical gears the top choice for high-speed transmissions such as automobile transmissions and precision industrial pumps.

2. Higher load capacity and durability:

Also due to the design of helix angle, helical gears take up more teeth simultaneously at meshing, distributing the load on a larger contact area. They can thus transmit greater torque and support a longer operating life for the same size, and they provide an excellent combination with heavy-load applications.

3. Axial force management and precision manufacturing:

Granted, helix angle in helical gears brings axial thrust with it, and that is their sole disadvantage. But this is exactly where LS Manufacturing differs—our deep experience with specialty gear manufacturing enables us to not only tightly control helix angles for optimal performance but also deliver end-to-end solutions, including bearing selection matching, to perfectly counter balance axial forces and provide peace of mind.

Although spur gears are fundamental, their smooth running and load limitations make them less than satisfactory under complex conditions of usage. Their smooth operation and high loads make helical gears infinitely superior to them in tough situations.

What transmission challenges do bevel gears, worm gears, and planetary gears solve?

Whenever transmission requirements exceed simple parallel shaft layouts, engineers need more sophisticated gear types. Bevel gears, worm gears, and planetary gears are specialist solutions that address three basic transmission problems.

1. Bevel Gears:

When power must be transmitted between cross-shafts (usually 90 degrees), bevel gears are used. Because they are conical, bevel gears are designed to accommodate reversible change in transmission direction and thus become essential core gear units for machines such as automobile differentials and vertical mixers to efficiently transmit power between cross-shafts.

2. Worm Gears:

Worm gear sets are able to produce extremely high reductions in one stage and run efficiently and quietly. Their characteristic meshing action provides a reverse self-locking quality, which enables them to safely load and prevent reverse rotation in lifting mechanisms and indexing machines, so they are a critical gear type for ensuring equipment safety.

3. Planetary Gears:

Planetary gears are renowned for their design being compact, possessing high power density, and efficient transmission. They distribute loads evenly between different planetary gears to deliver high power output in a compact package. Planetary gears are widely used in robotic joints, wind turbines’ gearboxes, and high-performance transmissions.

LS Manufacturing possesses state-of-the-art gear processing capability and can precision produce all forms of gears ranging from bevel gears to complex planetary gear sets with one-source transmission solutions.

How can we maximize gear life and performance through materials and heat treatment?

In the production of special gears, materials and heat treatment are the most important factors for the ultimate performance of a gear. Proper selection can impart better wear resistance, high strength, and better impact resistance, while improper selection can lead to premature failure.

1. Materials:

Alloy steel (e.g., 20CrMnTi) is preferred in heavy-load, high-speed applications but its inherent advantages require subsequent heat treatment to attain them to the fullest.

Brasses and plastics (nylon and POM) are used in light-load applications with low noise, corrosion, or self-lubrication but no heat treatment.

2. Heat Treatment:

- Carburizing and quenching: It creates a tough and wear-resistant surface on the gear surface without sacrificing the toughness of the core to ensure impact resistance. It is a conventional process for harsh service conditions.

- Nitriding: This increases surface hardness and corrosion resistance with less deformation, and is most appropriate for accurate gears that are difficult to withstand quenching deformation.

- Induction hardening: This achieves immediate, localized hardening of the tooth surface with less deformation and high efficiency. It is commonly used for surface hardening of large-module gears.

At LS Manufacturing, our value is providing you with the best performance-cost solution. For example, for load-bearing gears, we recommend case-hardened steel and carefully control the process of quenching so that every part is of high quality performance and long life it must have for its specific working conditions.

LS Manufacturing not only provides one-piece gear machining, but also complete-process service, ranging from materials science consulting to precision custom gear machining and manufacturing.

What are the key factors that determine gear machining prices?

In procuring online gear machining, one should understand the factors of gear machining prices. An accurate quote is largely based on the following key factors, which combined set the final cost.

| Key Factors | Impacting Price |

| Gear Type and Complexity | Spur and helical gears are relatively inexpensive; bevel, worm, and planetary gears are much more expensive since they possess sophisticated tooth geometries and require longer machining times. |

| Precision Grade | According to AGMA or DIN specification, each step up in precision grade (e.g., from Grade 8 to Grade 6) makes equipment and process requirements grow exponentially and results in a very large price increase. |

| Materials and Heat Treatment | Alloy steel is more expensive than carbon steel, and specialist materials are even more so. Processes of heat treatment such as carburizing and nitriding add energy and time costs but can significantly improve the performance of gears. |

| Batch Size | One-piece or low-volume production has high amortized cost of tooling and commissioning; high-volume production can significantly reduce unit cost using standardization and process optimization. |

At LS Manufacturing, we strive to provide open and competitive cost for machining gears. We reduce the number of machining processes, use standardized modules, and give clear choices through our omline gear machining solutions such that you can make the best decision in your budget.

LS Manufacturing not only provides parts of the best quality but also leverages our extensive experience to advise you on how to achieve maximum cost-effectiveness by changing precision or material selection without compromising performance.

What core processing and testing capabilities does a qualified gear supplier possess?

The value of a competent gear supplier is not only in providing machined gear parts, but also in providing the accuracy and reliability of each part. That is predicated on a complete set of cutting-edge processing and testing equipment.

1. Comprehensive Core Processing Capabilities:

Custom gear production with specialized expertise begins with cutting-edge processing equipment. A competent supplier must have:

- Gear hobbing machines: In order to influence effective rough machining of gears, to act as a foundation for tooth profile

- Gear shaping machines: For machining special structures such as internal gears and shoulder gears

- Gear grinding machines: To influence accurate gear shaping, establishing final accuracy and noise performance

2. Precision Testing and Quality Assurance

Simply owning processing equipment is not enough; a strict testing system is the key to quality:

- Gear measuring center: Provides comprehensive inspection of tooth guide faults and tooth profile to deliver proper meshing.

- Coordinate measuring machines: Precisely checks macro-size and location tolerances of gears.

LS Manufacturing utilizes a complete array of state-of-the-art equipment, ranging from rough machining to finish grinding, combined with a complete test process, to ensure each machined gear component meets design specifications.

LS Manufacturing doesn’t merely manufacture gears but, through data-driven inspection reports, also provides a solid foundation of quality trust for your transmission system.

How does LS Manufacturing help industrial robot manufacturers solve the noise and lifespan challenges of joint gears?

One of the leading makers of industrial robots was faced with a tough challenge: the fine-pitch helical gears used in their joint drive units, subjected to long-term, heavy-load cycles, began to suffer premature pitting corrosion after several months of operation. This caused increased operating noise and gradual loss of positioning accuracy, causing significant damage to the end-product reliability and brand reputation.

1. Customer Dilemma:

The gear components available for their joints, with respect to material choice and heat treatment, were not able to meet the demanding, continuous, and precise operation needs of the robot joints. Therefore, even though the kind of gear used was suitable (helical gears were employed), the overall performance was suboptimal.

2. LS Manufacturing Solution:

On close inspection, LS Manufacturing did not simply substitute a like part. Instead, it provided a very specific gear machining and manufacturing solution:

- The raw material was upgraded from common alloy steel to high-performance case-hardened steel.

- Gear accuracy was significantly improved from AGMA Grade 9 to Grade 11 (via a precision gear grinding process).

- A special phosphating treatment was done on the tooth flanks to increase lubricity and reduce wear.

3. Results and Value:

This optimization increased the new gear’s fatigue life by more than three times, completely prevented premature pitting, and reduced operating noise considerably. Not only did this serve to directly improve the customer’s robot precision and reliability, but it also allowed them to achieve strategic competitive benefits in the high-end market and establish a firm, long-term supply chain alliance with LS Manufacturing.

How to Efficiently Start Your Project with “Online Gear Machining Service”?

The key to starting a project with the online gear machining facility is to provide clear and complete technical details. This not only allows you to get an immediate precise gear machining quote, but also provides you with professional technical advice from our engineers to ensure your project is a success day one.

1. Prepare core parameters to ensure an accurate quote:

Kindly provide the following details clearly in your inquiry, as it is the foundation for gear machining price and lead time quotation:

- Gear type: spur, helical, bevel, etc.

- Major dimensions: module/diametral pitch, number of teeth, pressure angle, face width

- Material and heat treatment: e.g., quenched and tempered 45# steel, carburized 20CrMnTi, etc.

- Precision grade: e.g., GB Grade 7, AGMA Grade 10, etc.

2. Receive an “intelligent quote” with technical advice:

LS Manufacturing’s online gear machining service is backed by experienced engineers. They will see your submitted parameters for the first time and hopefully make optimization suggestions if they spot underlying issues (e.g., incorrect choice of material, over-precision leading to costly wasted resources). In other words, you are not only quoted a price but also given a pre-processed technical solution.

Comprehensive planning will pay off to successfully integrate LS Manufacturing’s engineering capabilities through our web-based gear machining service, enabling single-stop processing from inquiry to technical solution confirmation and enhancing considerably project efficiency.

What benefits will you gain by choosing LS Manufacturing as your gear processing partner?

Choosing LS Manufacturing means so much more than value-added custom gear machining and manufacturing services; it also means a transmission technology team highly integrated into your project workflows. We aim to provide the full value-added services to become your ultimate engineering support.

1. Free, in-depth selection and design consultation:

Before and after submitting your gear processing request using our online gear machining service, LS Manufacturing engineers will provide you with free gear design and selection consultation to help you eliminate design risks and get the best transmission solution.

2. Professional manufacturability analysis and cost optimization:

LS Manufacturing will examine your drawings as part of a detailed manufacturability review to identify design features that can affect price and lead time, and provide suggestions for improvement. What this means is that our precision gear processing and manufacturing capabilities are directed toward optimal cost-effectiveness, not simply to order of production.

3. One-stop, complete solution:

LS Manufacturing has full-service capability covering materials, precision machining, heat treating, to surface finishing. This yields controlled quality and predictable delivery times for the entire chain of manufacture completely free from the frustrations of dealing with many suppliers and questionable responsibility for quality.

4. Strict Quality Traceability and Transparent Management:

LS Manufacturing has established an end-to-end traceability of quality system. On its web-based gear processing service platform, we provide open visibility of order status and critical quality information, creating strong confidence in quality. By choosing us, you are choosing a reliable partner dedicated to the success of your project.

From proper choice of gear type to customized gear machining and manufacture as per cutting-edge equipment and materials science, high performance of gear transmission systems relies on meticulous cooperation at each stage.

FAQs

1. How should I choose the appropriate gear type for my new project?

Choosing a gear type for your project is a methodical analysis of four crucial considerations: First, transmission structure. For concurrent shafts, spur or helical gears are suitable, and for crossing shafts, bevel gears must be employed. Second, performance requirements. Helical gears must be employed in heavy-load situations, and spur gears must be avoided in noise-critical applications. Third, reduction ratio requirements. In high reduction ratio situations, worm or planetary gears must be employed. And finally, space constraints. Planetary gears or low-module gears must be utilized in confined spaces.

2. Is small-batch custom gear processing expensive?

Small-batch customization isn’t necessarily expensive. LS Manufacturing controls costs with three steps: first, using standardized tooling and modularity of process to reduce setup expense; second, proposing most cost-efficient material solutions based on given requirements; and third, optimizing efficiency in small lots with flexible manufacturing processes. We highlight providing the most affordable options for customers with various batch sizes, with the same level of quality and cost control, so even small-batch customizations get to enjoy professional gear processing services.

3. Can you process plastic or powder metallurgy gears?

LS Manufacturing has full material processing capacity. Plastic engineering gears (e.g., nylon and POM) are suitable for light loads, corrosion resistance, and minimal noise; powder metallurgy gears are suitable for complex shapes and medium loads; and metal gears are suitable for high-strength requirements. We will recommend the most appropriate material and process combination for your specific application (e.g., food processing machinery, medical devices, or auto components) to offer the optimum price-performance ratio.

4. How long does it typically take from drawing receipt to sample delivery?

The standard lead time for gear samples is 2-4 weeks. The actual length is a function of three factors: gear design complexity (helical and bevel gears have higher complexity), material lead time to procure (long lead materials take additional time), and existing production schedule. LS Manufacturing promises 24-hour delivery of an entire production schedule on receipt of drawings. We also have the provision to use an expedited process in situations of urgency, with low lead times without compromise on quality.

Conclusion

From simple spur gears to high-accuracy worm gears, every gear type has its unique engineering expertise and delivers distinction in solutions for different transmission requirements. Selecting them appropriately and carefully manufacturing them have a direct influence on the efficiency, smoothness, and working life of the entire machine.

By drawing on its vast technical expertise and overall abilities from material science through precision machining, LS Manufacturing is committed to providing customers superior gear system solutions through unexpected levels of quality, making us your trusted transmission engineering partner.

Don’t allow gears to delay product enhancements or new product designs. Contact LS Manufacturing and forward your initial concept, technical specifications, or detailed drawings to our transmission experts today. You’ll receive a free customized Gear Selection Recommendation, a Manufacturability Analysis Report of areas of potential cost reductions, and an extremely competitive Precision Quote. Contact us now and utilize the skills of LS Manufacturing as the very basis of competitive advantage of your products!

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.