Quality control process for

producing custom parts

Learn about LS Manufacturing’s advanced manufacturing processes, our strict implementation of ISO quality standards and ISO 90001:2015 certification guarantee the consistent quality, accuracy and durability of your custom parts and prototypes.

- Guaranteed consistent quality

- ISO 9001:2015 certified

- First article inspection

Make quick solutions to quality problems

To ensure that each custom part you order meets the highest manufacturing standards, we can rework or refund if the order does not meet your specifications. You only need to inform us of the problem within 5 working days after receiving the goods, and we will solve it within 3 working days.

Conditions for Refund

After confirming product issues, we will promptly process refunds and handle returns to ensure customer satisfaction and swift issue resolution.

- Damaged or Lost Goods

- Parts cannot be machined

- Unsatisfactory Product Quality

- Other reasons

Conditions for Rework

After raising an issue, we will review the design and samples to check for any inconsistencies. We will then promptly address the complaint and send replacement parts immediately.

- Specification mismatch

- Defects or flaws

- Inaccurate dimensions

- Other reasons

Rigorous Quality Control

We provide high quality manufacturing solutions for complex and precision parts such as optical parts, automotive parts, medical devices or aerospace parts, and in order to demonstrate our commitment to quality and excellence, we actively seek and obtain accreditation from reputable organizations.

- ISO 9001:2015

- IATF 16949:2016

- IS0 14001

- As9100D Certification

Make Quick Solutions To Quality Problems

To ensure that each custom part you order meets the highest manufacturing standards, we can rework or refund if the order does not meet your specifications. You only need to inform us of the problem within 5 working days after receiving the goods, and we will solve it within 3 working days.

CMM Inspection Report

Availability: CNC machining

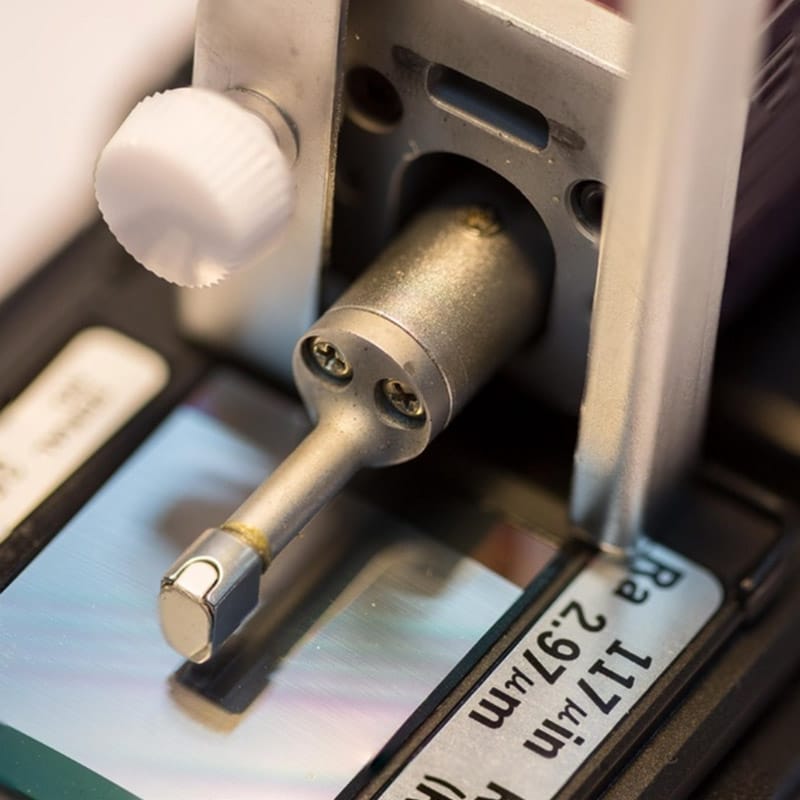

Dimensional Inspection Report

Availability: CNC machining, 3D printing, sheet metal fabrication

Material Test Report

Availability: CNC machining, sheet metal fabrication

First Article Inspection (FAI)

Availability: CNC machining

most advanced testing equipment

Experience our unmatched precision and superior quality control, using cutting-edge inspection equipment to ensure that every part meets stringent industry standards and exceeds customer expectations.

Frequently Asked Questions About

Frequently Asked Questions about Quality Control

We provide new product developers with engine processing parts suitable for functional testing or final use of engineering -level materials. Get your required custom metal parts service support by reading FAQ.

How do you ensure the dimensional accuracy and tolerance of machined parts meet requirements?

We utilize precision equipment like Coordinate Measuring Machines (CMMs) to perform first-article, in-process, and final inspections, strictly adhering to drawing tolerances to ensure perfect fit and function in your assembly.

How is material performance verified?

We source raw materials with certified material test reports and can perform spectral analysis and mechanical property testing to verify composition and ensure key performance metrics are met.

How are internal defects in injection molded/cast parts monitored?

We optimize processes using Mold Flow Analysis and employ non-destructive testing like Industrial CT or X-ray scanning to accurately detect internal voids or shrinkage, ensuring structural integrity.

What specific quality controls are in place for 3D-printed parts?

Beyond dimensional checks, we inspect for layer lines and warping, and can perform density analysis to ensure the performance of both prototypes and end-use parts.

How do you guarantee consistency in surface treatment quality?

We enforce consistency through standardized tests including coating thickness measurement, cross-cut adhesion tests, salt spray testing, and colorimeter checks for durability and appearance.

What is the corrective action process when a quality deviation is found?

We immediately initiate the 8D problem-solving methodology: containing the issue, performing root cause analysis, and implementing corrective and preventive actions for permanent resolution.

How do you perform accurate inspection on complex free-form surface parts?

We use high-precision 3D laser or blue light scanners to compare scan data with the original CAD model, generating a comprehensive color deviation report for complex geometry assurance.

How are quality fluctuations avoided across different production batches?

We standardize operating procedures, strictly monitor process parameters, and perform regular equipment maintenance and calibration to ensure process stability and repeatability.

Which quality management system does the company adhere to overall?

We implement and maintain robust international quality management systems, such as ISO 9001, supported by internal audits and continuous improvement to ensure system effectiveness.

Is product quality data traceable?

Yes. Each batch has a unique lot traceability number, linking complete records for materials, production, and inspection, enabling full traceability from raw material to finished product.

Precision Manufacturing Capabilities

Download Our Brochure to Get a Full

Overview of Our Manufacturing Capabilities

Access our technical documentation, covering all core processes, tolerance standards, material options, and industry case studies, to help you quickly evaluate project feasibility.

What's in the manual?

·High-definition product images and 3D cross-sections.

·Detailed process capabilities and tolerance standards, e.g., 5-axis CNC accuracy, injection mold lifespan.

·Comprehensive material options and surface finishes, e.g., titanium, PEEK, anodizing, sandblasting.

·Quality system certifications (ISO 9001) and industry case studies.

·A complete guide to our process from rapid prototyping to mass production.

Lead Capture Form

Simply enter your email to get the download link instantly

News & Blog

Deep understanding of industry knowledge and real-time updates at any time.

The Ultimate Guide to CNC Milling: Advantages, Limitations & Applications

Design for Manufacturing (DFM): Principles, Process, and Application Explained

CNC Turning Parts:Everything You Need to Know| LS Manufacturing

CNC Machining: The Ultimate Guide to Processes, Materials, and Applications

What Are The Parts Of A Plasma Cutter Gun?

What Are Taps In Machining?

How to Cost a Xiaomi YU7 Auto Part?

What Is The Difference Between Sheet Metal And Machining?

Put your parts into production today

- All information and uploads are secure and confidential.