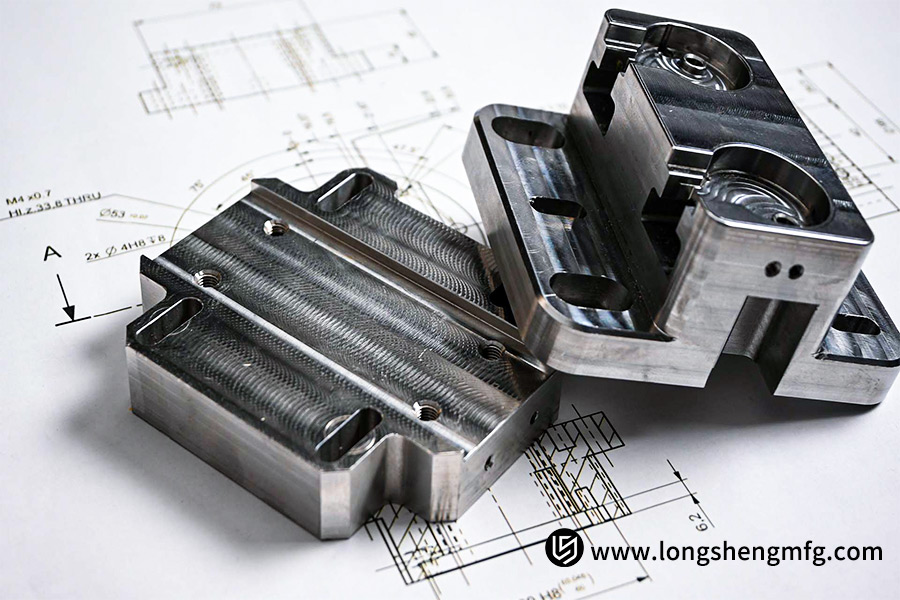

In precision manufacturing, acrylic CNC machining is also commonplace to fabricate high-transparency parts with complex shapes and strict dimensional accuracy. However, the nature of the material itself also imposes unique challenges on machining. Cracking and melting of acrylic must be avoided at all costs in order to ensure quality finished products. Otherwise, it will lead to defects, loss of strength, or even scrap, greatly affecting production efficiency and cost.

LS Manufacturing understands that the beginning of all excellent acrylic products lies in meticulous attention to detail. In this article, five points of process will be revealed to minimize your risk of machining and enhance yield rates.

If you are having the following issues, don’t hesitate to contact LS Manufacturing. Our specialists will provide full service solutions, from consultation to delivery, to bring optimum results to your project. To save you time, here’s a quick overview of the core conclusions.

Quick Reference Table for Prevention of Cracks and Melting of Acrylic CNC Machining

| Key Points | Main Objectives | Key Methods and Reasons |

| Tool Selection | Avoid melting and improve finish. | Use sharp, multi-edged, high-quality acrylic cutting tools with long chip flutes for fast, smooth cutting and rapid heat removal. |

| Cutting Parameters | A balance between efficiency and thermal effects is to be established. | Moderate feed and high speed are to be employed. This high parameter values will tend to get melted easily, while a low parameter will tend to cause frictional heating. Optimization will be needed to obtain the optimum compromise. |

| Cooling Method | Effective machining temperature control. | Air cooling (compressed air) is preferable to disperse chips and reduce temperature; liquid cooling should be applied cautiously not to introduce stress cracking to the material. |

| Workpiece Fixturing | Prevent vibration and cracking. | Use special fixtures for even support and precise distribution of force to avoid internal stress cracking caused by non-uniform clamping force or vibration. |

| Machining Path | Reduce internal stress. | Utilize a multi-cut, staged cutting to avoid excessive depth of cut at the same time; tool path optimization for fewer sharp turns and low stress concentrations. |

The key to success in acrylic CNC machining is “heat control” and “stress reduction.” By fully adopting the above five points, you can crack and melt issues professionally during machining and can achieve high-precision, high-quality, high-finish parts every time.

In case you are in search of uncompromising machining, LS Manufacturing, with its great knowledge of machining and material properties, can provide you with expert solutions. Do not hesitate to contact our experienced team to assist you with your project.

Why Trust This Guide? Practical Experience of LS Manufacturing Experts

LS Manufacturing has decades of hands-on experience in precision acrylic CNC machining. We have machined tens of thousands of acrylic parts for medical, optical, display, and high-end consumer product markets and have an intimate appreciation of the subtle impact of material batch variation and workshop temperature and humidity on machining results.

LS Manufacturing has helped a customer eliminate the prevalent micro-cracking problem in his highly transparent acrylic protective covers while machining. We diagnosed through our in-house diagnostic technology that the root cause was the resonance between cutting stress and clamping stress. We specially designed a customized flexible fixture and optimized layered cutting path for ideal cutting, which ultimately improved the yield rate from 65% to over 98%.

From experience of working with many real-life cases like this, LS Manufacturing understands how to get to the point so that any recommendation you get is tested and true.

Why is acrylic prone to cracking during CNC machining?

Machining acrylic on a CNC machine, cracking is among the leading causes of part rejection. Cracking is mainly due to the physical properties of acrylic and the related mechanical stresses of machining.

1. Material Brittleness and Internal Stress:

Acrylic (PMMA) is a thermoplastic. Although extremely clear, it is not impact-resistant and is highly brittle. There is residual internal stress in the sheet during manufacturing or heat treatment. Cutting forces and internal stresses are added during machining. Cracking will result if stresses are greater than material strength. This is the first issue to avoid in minimizing acrylic cracking.

2. Stress Concentration Effects:

Sharp corners, close clearances, or sudden changes in cross-section in CNC milling can all be stress concentration points. As the tool passes through such areas, stress cannot be relieved adequately and cracks are very likely to initiate at such points of weakness. LS Manufacturing’s experience suggests that part design optimization (for example, rounded corners) can minimize this risk significantly.

3. Processing Thermal Stress and Clamping Force:

The heat generated by friction in machining causes the acrylic to locally heat up and expand and subsequently cool and contract. This heating and cooling introduces stress in the material. Poor fixture design and excessive clamping also cause the possibility of cracking ahead of machining, as in “pre-stressing.”

Leaning on our extensive experience in acrylic CNC machining, LS Manufacturing is able to measure the material’s internal state of stress with accuracy and relieve and reduce stress in an orderly fashion by optimizing cutting parameters, tool paths, and clamping methods, thereby preventing acrylic cracking.

If your application requires stringent part yield specifications, please contact LS Manufacturing’s engineering staff for a custom, reliable solution.

How to prevent melting acrylic by adjusting cutting parameters?

In the machining of acrylic using CNC, melting will lead to the diminishment of the machined surface gloss and to the generation of burrs, severely influencing the quality of the end product. Optimally adjusting acrylic cutting parameters is the most straightforward and efficient method to avoid acrylic melting. These are methods for modifying major parameters:

1. Maintain a high spindle speed:

A minimum of 18,000 RPM is recommended. The higher speed will have the cutting edge move fast over the material and reduce the time the material has to allow heat to build in a single location, thereby giving “cutting” rather than “melting” of the material.

2. Proper feed rate:

An excessive feed rate will generate too much tool-material friction leading to be greater heating; too low a feed rate will likely cause chatter. A rule of thumb is to use high speed with a moderate-to-high rate of feed to have adequate cutting forces to form and throw chips, not to dissipate as heat.

3. Adopt a layered cutting strategy:

Don’t cut too deep in a single pass. Use several layered cuts for thicker stocks, but keep each cut depth at 1/2 the tool diameter. This effectively controls the load and heat generation per cut and enables smooth removal of chips.

4. Ensure chip evacuation and cooling:

With compressed air, chips can be easily expelled right away and are not prone to coming back to the workpiece surface or grooves. This is a crucial aid to preventing melting of acrylic.

We customize acrylic cutting parameters for each project in LS Manufacturing. We consider material brand, thickness, type of tool, and final surface requirement, and come up with the best solution after careful testing.

If you want a guaranteed, tailored parameter solution for your material, you can contact us today and LS Manufacturing will be happy to guide you with expert assistance.

How to Determine the Optimal Feed Rate for Acrylic CNC Machine Tools?

Acrylic CNC machining optimization of feed rate is an important process in efficient, high-accuracy machining. Feed rate is related to material removal rate, cutting heat, and surface finishing linearly and must be optimized in terms of material and machining conditions.

1. Understand the Relationship between Feed Rate and Material Removal:

Feed rate, along with spindle speed and depth of cut, affects material removal rate. In acrylic CNC machining, the removal rate should be maximized while ensuring that cutting forces are used in “cutting” rather than “rubbing.” The feed rate must not be very low because this will cause excessive friction between the tool and the material such that built-up heat is not dissipated fast enough by the chips, hence causing melting.

2. Differentiating Material Types:

Machining performance varies significantly among different materials:

- Cast acrylic: Due to its smooth texture and low internal stress, it will usually accommodate higher feed rates. Initial trials can be in the range of 800-1500 mm/min.

- Extruded acrylic: Due to its relatively soft texture and internal stress, very high feed rates can easily cause cracking or tool sticking. Start with a conservative feed rate of 500-1000 mm/min.

3. Using a formula for preliminary calculations and on-site testing:

A functional starting point is the formula: Feed rate = rotational speed × number of flutes × feed per flute. By way of example, at 18,000 rpm with a two-flute cutter and 0.08 mm per flute feed rate, the calculated feed rate comes to approximately 2,880 mm/min. This is strictly a figure of calculation. The optimal feed rate for acrylic CNC machining must be discovered through trial machining, observing the chip morphology (which should be continuous coils, not powdery or molten) and the machined surface.

In our shop, LS Manufacturing, we have a patented testing protocol that allows us to quickly identify the optimal feed rate for specific brands and lots of material, which should save you your trial-and-error cost and material blemishes.

If you are experiencing difficulties with parameter settings, please look to LS Manufacturing for a tailored-to-your-needs acrylic CNC machining parameter solution.

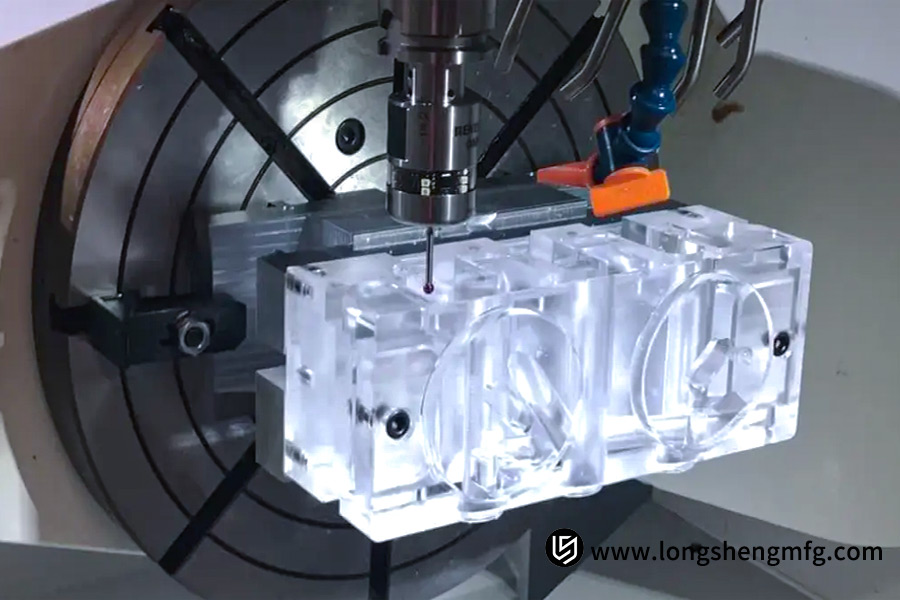

How does LS Manufacturing address the machining challenges of complex acrylic parts?

In medical device manufacturing precision, transparent acrylic parts are in large demand because of their biocompatibility and high transparency, but cracking and melting while being machined is a nagging problem. The next real medical case demonstrates how the capabilities of LS Manufacturing solve that problem.

1. Customer Pain Points:

Specialty medical device manufacturer needed production of a batch of complex clear acrylic housings for diagnostic tools. These encasements possessed a thin wall and precise snap fasteners. Their previous vendor had a 30% chipping rate when they were milling the inner threads, and the transparent surface often exhibited fogging and melting marks, which greatly influenced device assembly efficiency and appearance. The customer was under the dual pressures of tight lead times and low yields.

2. LS Manufacturing’s Customized Solution:

To satisfy the client’s specific needs, LS Manufacturing provided a professional, customized acrylic CNC machining service. Actions included:

- Tool Path and Cutting Parameter Optimization:

To avoid stress concentration at abrupt corners, smooth corner processing technology was applied, which translated straight corners in the tool path into arc transitions, thus preventing considerably the possibility of microcracking.

For thin sections, cut technique in layer was employed. By controlling the cut depth, the cutting force was controlled such that chipping or tool deformation was prevented due to excessive depth of cut.

- Upgraded Cooling and Chip Removal System:

During the machining operation, a concentrated air cooling system is used for maintaining the cutting temperature lower than 60°C. Its pressure is consistent with a value greater than 0.3 MPa, and hence material softening was prevented successfully.

Furthermore, a highly successful dust extraction module removes chips near the tool in real-time, preventing molten chips from reattaching to the workpiece surface and causing secondary burns, providing optical clarity.

3. Achievements and Value:

Through the integration of these cutting-edge solutions, LS Manufacturing has been able to successfully attain:

- Quality Breakthrough: The medical housings machining yield has risen to 99.8%, with zero cracking and zero melt marks, meeting all medical-grade appearance specifications.

- Efficiency Improvement: The entire production cycle has been reduced by 20%, allowing customers to get their products to market quicker.

This achievement unequivocally validates LS Manufacturing’s rich technical expertise in acrylic CNC machining operations. In case you are faced with the same challenges in machining complex acrylic CNC parts, please contact us for custom services.

What details should be considered during custom acrylic CNC machining?

Successful custom acrylic CNC machining goes far beyond programming and cutting; it begins with meticulous detail. At LS Manufacturing, we are aware that each step can influence the end part’s performance and look. The following details are crucial in ensuring the project’s success:

1. Manufacturability Review during the Design Phase:

At the initial design phase, LS Manufacturing engineers actively examine the drawings for stress concentrations due to sharp corners, uncallouted draft angles, and non-uniform wall thickness. This actually avoids risk of cracking and deformation upon subsequent machining and is the first promise of high-quality custom acrylic CNC machining.

2. Application-Specific Material Selection:

Various acrylic CNC machining firms employ different material specifications. LS Manufacturing will accurately recommend casting-grade or extrusion-grade acrylic based on the end use of the part (i.e., whether ultra-high weather resistance, optical transparency, or impact toughness is required), such that material characteristics exactly match product specifications.

3. Precision Tolerance and Surface Control:

LS Manufacturing maintains tight tolerance levels for key dimensions and surface finishes with strict control. Through optimized machining practices and skilled polishing processes, a variety of matte through optical mirror finishes can be achieved, parts fulfilling high-end appearance standards without sacrificing functionality.

At LS Manufacturing, we provide single-source acrylic CNC machining services, including technical advice and material selection, accurate machining, and post-processing. We believe that quality custom parts are built on rigorous attention to detail.

If you have a project requirement, please provide your drawings and we will provide a no-cost professional evaluation and feasibility study.

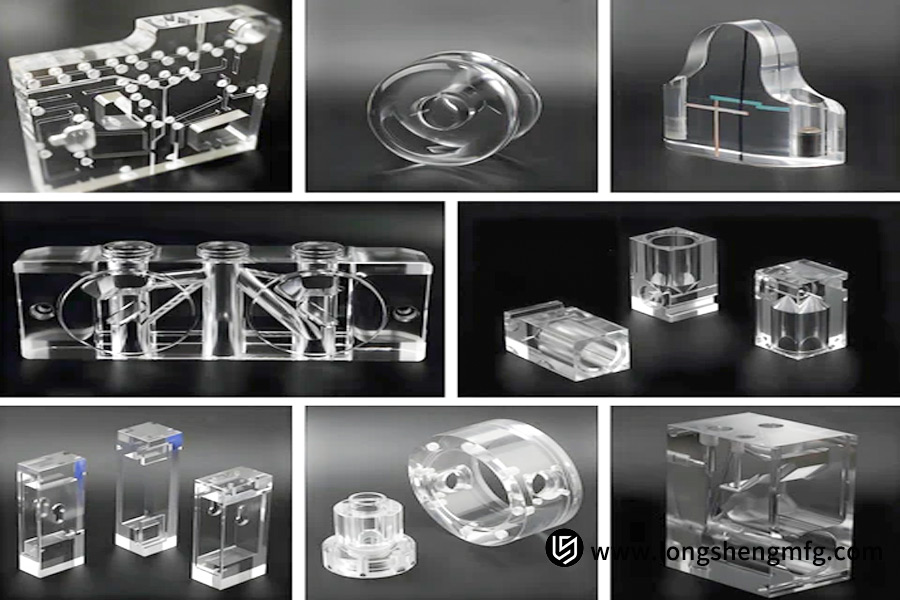

What value-added options are included in our acrylic CNC machining services?

In acrylic CNC machining services, basic cutting is only half the story. To prevent cracking and melting in acrylic CNC machined parts and achieve maximum optical performance and working life, a host of value-added services are essential. LS Manufacturing offers the following significant value-added options to completely secure your part quality:

1. Professional Post-Processing and Strengthening:

LS Manufacturing offers surface finishing ranging from special polishing services for acrylic to high gloss or even optical mirror quality levels; and sandblasting for an even matte finish. Additionally, on special requirement parts, we are able to coat (e.g., clear protective films) surfaces to increase surface wear resistance and internalize stress to avoid environmental cracking.

2. Precision Quality Inspection and Tolerance Control:

We have strict tolerances on key dimensions and aesthetic surfaces. Optimized machining practices combined with specialized polishing processes allow LS Manufacturing to achieve a variety of finishes from matte to optical mirror, making parts both functional and attractive. This rigorously checks every detail, avoiding potential failures due to dimensional differences or microcracking.

3. Rapid Prototyping and Manufacturability Review:

LS Manufacturing’s rapid prototyping technology allows you to visualize real parts for preliminary verification before proceeding with mass production. Our engineers further conduct manufacturability review, checking the design for sharp edges which can cause stress concentrations, undefinable draft angles, and even wall thickness. This essentially prevents cracking and warping on subsequent processing and is the primary guarantee for superior quality custom acrylic CNC machining.

These value-added services form the basis of LS Manufacturing’s highly dependable acrylic CNC machining services. We strongly recommend a package service and have our qualified experts take responsibility for the entire process from design to delivery so that every acrylic CNC machined part you receive delivers top performance as well as impeccable quality.

Why does the quality of acrylic CNC machined parts depend on tool selection?

In acrylic CNC turning, the tool is the most critical parameter that directly interacts with the material. Its choice has a direct influence on cutting forces, chip evacuation efficiency, and heat generation and thus essentially governs the dimensional accuracy, edge integrity, and surface finish of the acrylic CNC turned product.

| Tool Type | Applicable Applications | Core Advantages and Considerations |

| Single-edge specialist shears | They are used for high-transparency thick cast acrylic. | Low cutting resistance and good heat extraction form melt-mark-free, smooth-cut surfaces and are the tool of first choice for creating optical-grade surfaces. |

| Double-edge spiral milling cutters | Profile cutting and machining efficiency at high levels. | They have good chip evacuation and high efficiency but require extremely sharp cutting edges to prevent frictional overheating and material melting. |

With the exception of tool choice, the following are of primary concern:

- Cutting edge sharpness is paramount: Single-edged or multi-edged, the cutting edge will have to be carefully ground to cut acrylic and maintained to a very fine edge. Even slight dullness will shift from “cutting” to “pressing,” generating heat from friction that will cause edge melting or develop a white haze-like imperfection.

- Chip flute design affects heat dissipation: The tool must have big and smooth chip flutes to allow for quick and smooth extraction of chips. Chip trapping, which acts against the workpiece and the tool continually, is one main cause of point overheating and surface scoring.

- Optimized Tool Geometry: Experienced rake and relief angle design optimizes chip flow and reduces cutting resistance. An optimized angle enhances the machining operation to be smoother and greatly reduces the danger of material cracking.

We have at LS Manufacturing a catalog of specialized tools optimized for application with polymer materials and can accurately recommend or tailor the optimum tools based on your specific acrylic CNC machining requirements.

How can the cooling system control acrylic machining temperatures?

Acrylic CNC machining’s biggest source of material melting is high temperature. There is fast cutting heat dissipation with the help of adequate cooling, that is, temperature inside the machining zone is lower than the softening point of acrylic (approximately 60°C), and is essential to provide high-precision, stress-free components.

1. Precisely Control Air Cooling Parameters:

Using a steady air pressure of at least 0.3 MPa in cooling, not only is the cutting region cooled effectively but also molten chips are rejected effectively in real-time so that they won’t stick back to the machined surface.

2. Precise Temperature Control of the Liquid Cooling System:

In constant long-term machining, the liquid cooling system can keep the cutting zone temperature at a constant level below 60°C. Accurate temperature control prevents overheating the material and softening or deforming it.

3. Customized Cooling Solutions:

LS Manufacturing develops cooling nozzle angles and airflow patterns tailored to part geometry and machining requirements for efficient heat dissipation and to minimize the risk of machining considerably.

By creating a scientific cooling system and parameters adjusted, the melting problem of acrylic can be ruled out automatically. If you consider that it is complicated to control temperature in performing acrylic CNC machining, please call our technical engineers for professional assistance.

What are some common operational errors in acrylic CNC machining?

In machining acrylic CNC, some operational errors have a direct impact on machining quality and lead to melting or cracking of the part. These errors must be sensed and addressed to prevent acrylic cracking and boost yield.

1. Feed Rate and Speed Mismatch:

- Error: Mechanically applying high feed rates with low speeds generates high friction and heat formation between tool and material.

- Correction: Use the “high speed, moderate feed” principle in order to use cutting force for material separation rather than heat formation. LS Manufacturing provides customers with precise parameter combinations through process optimization.

2. Neglecting Material Pretreatment:

- Error: Direct processing of insufficiently stored sheets regardless of the impact of ambient humidity on acrylic characteristics.

- Correction: Let the acrylic sit in a controlled environment of temperature and humidity for 24 hours before processing. We provide material handling recommendations in an attempt to preclude acrylic cracking at its origin.

3. Improper Clamping:

- Error: Over-clamping or poor support results in a buildup of internal stresses in the material.

- Correction: Use special clamps with ideally supported points of support. We can design clamping solutions to part structure to render the clamping stress unnecessary.

4. Failure to Maintain Tools:

- Error: The use of old tools causes lower cutting quality.

- Correction: Put in place an aggressive tool replacement cycle. We believe in utilizing high-precision acrylic tools and ongoing inspection of the cutting edge.

Our technical experts at LS Manufacturing can provide on-site consulting or remote support, saving you unnecessary expense and establishing a long-term stable relationship. Obtain tailored machining optimization from our technical experts.

What are the unique advantages of choosing LS Manufacturing for acrylic CNC machining?

In the extremely competitive market of precision manufacturing, choosing LS Manufacturing as your company to associate with for acrylic CNC machining guarantees you receive more than basic services of machining in technical assistance and working relationship. Our strengths come from three primary dimensions: technology, quality, and service.

| Dimensions of Advantages | Specific Demonstration | Benefits |

| Advanced Machining Capacity | We possess multi-axis CNC machines, five-axis CNC machining capacity, and a variety of sophisticated tools that are engineered to be optimized for polymer material. | We are able to provide precision and effective custom acrylic CNC machining of complex geometries, with effective prevention of material cracking and melting. |

| Strict Quality System | We follow international quality certifications such as ISO 9001 and IATF 16949 and carry strict quality control measures. | We guarantee that every acrylic CNC machined piece of equipment has optimal performance and immaculate quality with uniformity and reliability in series production. |

| Customer-Centric Service | It provides one-stop-shop services ranging from design review, material selection, to post-processing, and possesses a quick-responding technical service team. | We can understand your requirements at a fast rate, provide professional guidance, shorten production cycles, and possess effective project deployment. |

In addition to these advantages, LS Manufacturing is committed to being your strategic partner. We understand that a successful machining job begins by matching requirements precisely. Therefore, our engineers closely collaborate with your product design process, performing expert manufacturability checks, designing for optimization from the beginning, and preventing machining hazards, realizing your concepts into reality at the minimum cost possible and maximum efficiency.

We are sure that professional acrylic CNC machining services are the key to your product’s high quality. Contact LS Manufacturing’s technical consultants today and receive special discounts and technical advice.

FAQs

1. What precautions should I take when machining thick acrylic sheets?

When cutting thick acrylic sheets, there is a need for a layer-by-layer cutting process. The single-pass depth of cut should be kept within 1/2 the diameter of the tool, and high-pressure air cooling should be used to provide for quick cooling. Properly reducing the feed rate and utilizing specialty multi-edge tools assist in the efficient dispersion of cutting forces and heat without overheating-induced localized melting or stress cracking of the material, and yield a smooth, distortion-free cross-section.

2. How to determine if acrylic machining parameters are appropriate?

Acrylic machining conditions can be obtained by combining chip morphology and machined surface. Ideal chips are continuous and continuous strands, with transparent edges and without white marks. Powdery or molten chips, increase speed or feed rate; atomized edges, increase cooling. A step-by-step trial cutting process is recommended to gradually optimize and locate the optimum parameter combination.

3. What is the degree of accuracy achievable for custom small-volume acrylic pieces?

With workshop temperature control and professional process guarantee, LS Manufacturing can reproducibly hold a ±0.05mm dimensional tolerance on small lots of acrylic parts, and key positioning holes can be held to ±0.02mm. With stress relief and properly compensated tools, we ensure every batch of parts is precision assembly ready. For further information on part processing, call LS Manufacturing today. Free consultation available.

4. How can optical clarity be restored after processing transparent acrylic?

To rectify the issue of hazed cut surfaces, micro-flame polishing or high-grade chemical polishing fluids can be utilized. Flame temperature and immersion time control is critical to avoid surface flow marks and second stress. LS Manufacturing has a customized polishing technique to restore light transmittance to over 92% without sacrificing part structure integrity. Our elite personnel and high-grade service guarantee one-stop service.

Conclusion

Preventing melting and cracking of acrylic successfully requires not only understanding of material characteristics and principles of process, but years of hands-on know-how, dedicated equipment and hardware, and meticulous control from beginning to end in manufacturing process.

That is the purpose of LS Manufacturing as your precision manufacturing partner—through our extensive technical know-how and complete solutions, your design intention is exactly accomplished as a zero-defect, high-performance finished product.

LS Manufacturing is not merely a count of quality acrylic parts; it is a solid guarantee of precision, efficiency, and project excellence. Let us be your go-to option for the most reliable assistance to your creative ideas.

Contact LS Manufacturing today for a personalized solution to your next project. Upload your design drawings now and get an instant CNC machining quote ( CNC machining price), let LS Manufacturing be your strong backing in pursuit of ultimate CNC machining precision!

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.