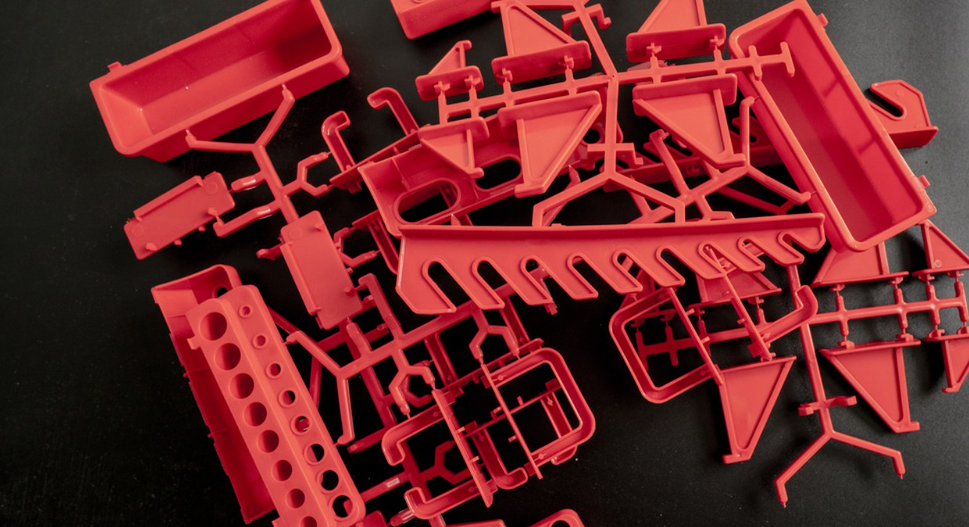

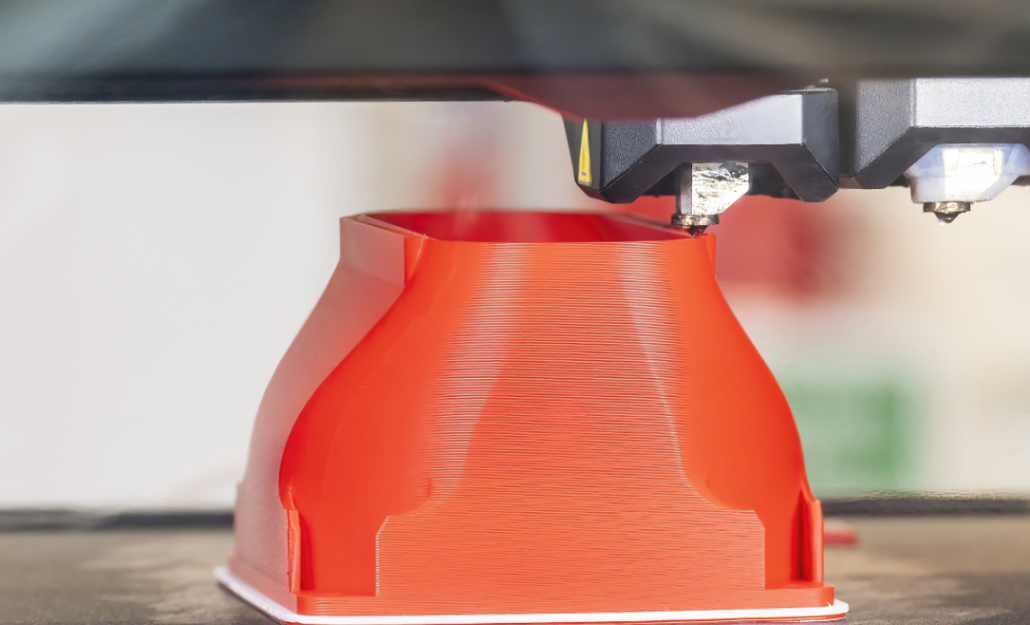

Pioneers of Plastic Injection Molding: Tracing Back to its Roots

Have you ever wondered when plastic injection molding started? It was in the 19th century when plastic injection molding technology began. Our team of researchers has discovered that the first injection molding machine was developed by John Wesley Hyatt, an American inventor, in 1872. Hyatt’s creation was a significant milestone in the history of plastic molding and served as a foundation for today’s technology.

Pioneers of Plastic Injection Molding: Tracing Back to its Roots Read More »