If you work in manufacturing or product development, you’ve likely heard of injection molding. But have you considered using injection molding services for your next project? In this ultimate guide, we’ll explore the benefits of injection molding, the process itself, and how to choose the right injection molding service for your needs.

What is Injection Molding?

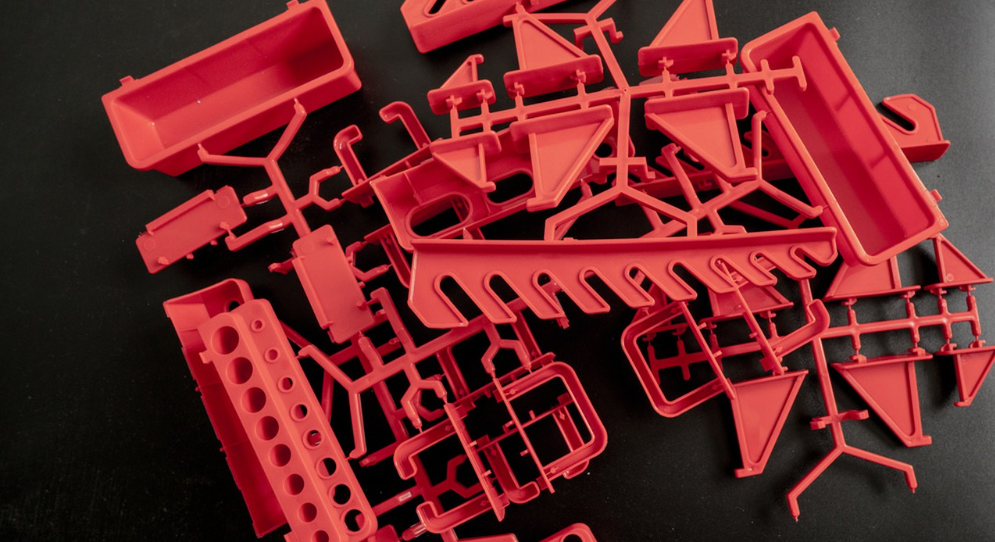

What is injection molding?Injection molding is a manufacturing process where molten thermoplastic or thermosetting polymer is injected into a mold cavity. The plastic then cools and solidifies into the desired shape. Injection molding is capable of producing high volumes of complex parts with a high degree of accuracy and consistency.

Why Use Injection Molding Services?

Injection molding is a versatile and cost-effective manufacturing technique that can produce complex and precise parts at high volumes with minimal waste, making it the go-to method for many industries. From automotive to medical, the construction industry to consumer goods, injection molding has a wide range of applications and benefits. In this article, we explore why you should consider injection molding services for your next manufacturing project.

Quality and Precision

One of the primary benefits of injection molding is the high precision and consistency in manufacturing. The technique allows you to achieve greater accuracy when molding parts with intricate designs and geometries, as well as intricate details. Injection molding provides an excellent way to manufacture intricate and detailed parts accurately and efficiently.

Cost-Effective

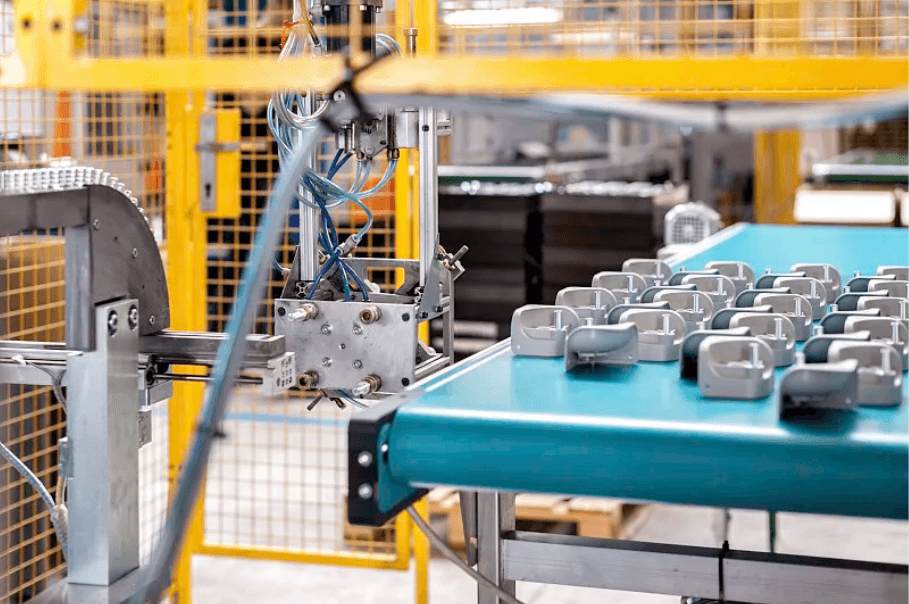

Injection molding services are a cost-effective option for mass-producing parts. The cost per unit decreases as production volumes increase, making it a suitable solution for businesses that require high-volume output. With the increased automation and efficiency that injection molding provides, you can keep your production costs low while still producing top-quality parts.

Speed

Another significant advantage of injection molding is its speed. It is a highly automated process that can produce parts at a faster rate than other manufacturing processes, reducing production lead times and increasing your production capacity. Injection molding can significantly speed up your production process, allowing you to get your products to market quickly and efficiently.

Versatility

Injection molding services are versatile and can produce parts of different sizes, shapes, and complexities. The technique allows for the use of different materials and color options, making it a perfect solution for industries that require product differentiation in a variety of sizes and textures.

Minimal Waste

Injection molding is a highly efficient and precise manufacturing technique that generates minimal waste. The technique requires the use of precisely measured amounts of material, resulting in fewer defects and less material waste. This cost-saving benefit is particularly critical for businesses that are conscious of their environmental impact and sustainable practices.

High Volume Production

Injection molding is the ideal manufacturing technique for businesses looking to produce high volumes of products. The technique ensures precise and consistent results every time, making it perfect for mass production.

Smooth Surface Finish

The surface finish of injection-molded products is usually smooth and can be made even smoother with additional processes such as polishing. This makes them perfect for products that require a polished finish.

Wide Range of Materials

Injection molding allows businesses to choose from a wide range of materials, including metal, glass, and composites. This provides an opportunity to create products for various industries.

Design Flexibility

Injection molding design offers great design flexibility. This means that businesses can create complex products with intricate designs using injection molding.

The Injection Molding Process

The injection molding process consists of four key stages: clamping, injection, cooling, and ejection.

Clamping: The two halves of the mold are closed and held together with high pressure to prevent the plastic from escaping.

Injection: The material is injected into the mold cavity under high pressure, filling the space and taking on the shape of the mold.

Cooling: The plastic is allowed to cool and solidify in the mold.

Ejection: The mold is opened, and the solidified part is ejected.

Choosing the Right Injection Molding Service

Not all injection molding services are created equal. Here are some factors to consider when choosing a service provider:

Experience: Look for a service provider with extensive experience in injection molding.

Quality: Make sure your service provider has a quality management system in place to ensure consistent production.

Capacity: Consider the capacity of the service provider. Do they have the resources to meet your production needs?

Materials: Make sure the service provider has experience working with the materials you need for your project.

Cost: Injection molding can be expensive, so make sure you get a clear and accurate quote from your service provider upfront.

Injection molding offers numerous benefits over other manufacturing processes, including cost-effectiveness, versatility, consistency, speed, and material selection. When choosing an injection molding service provider, look for experience, quality, capacity, materials, and cost. With the right service provider, injection molding can help you achieve your manufacturing goals quickly and efficiently.