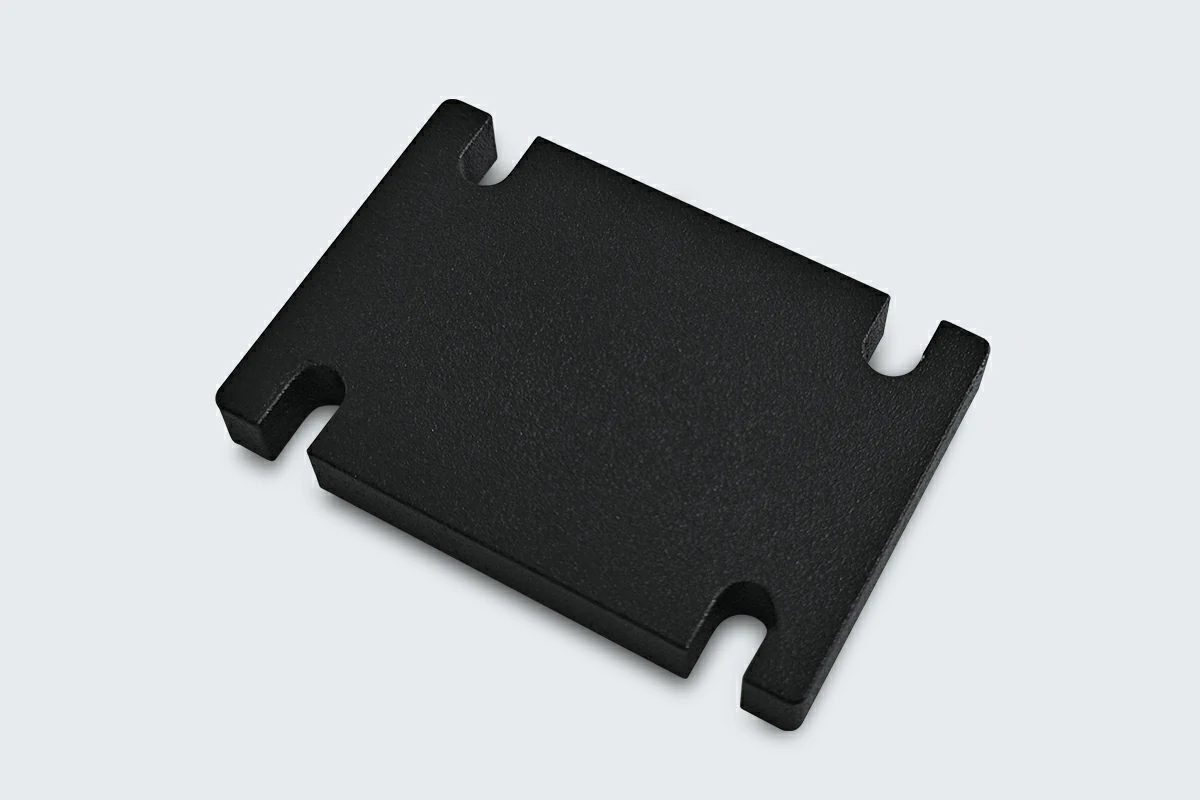

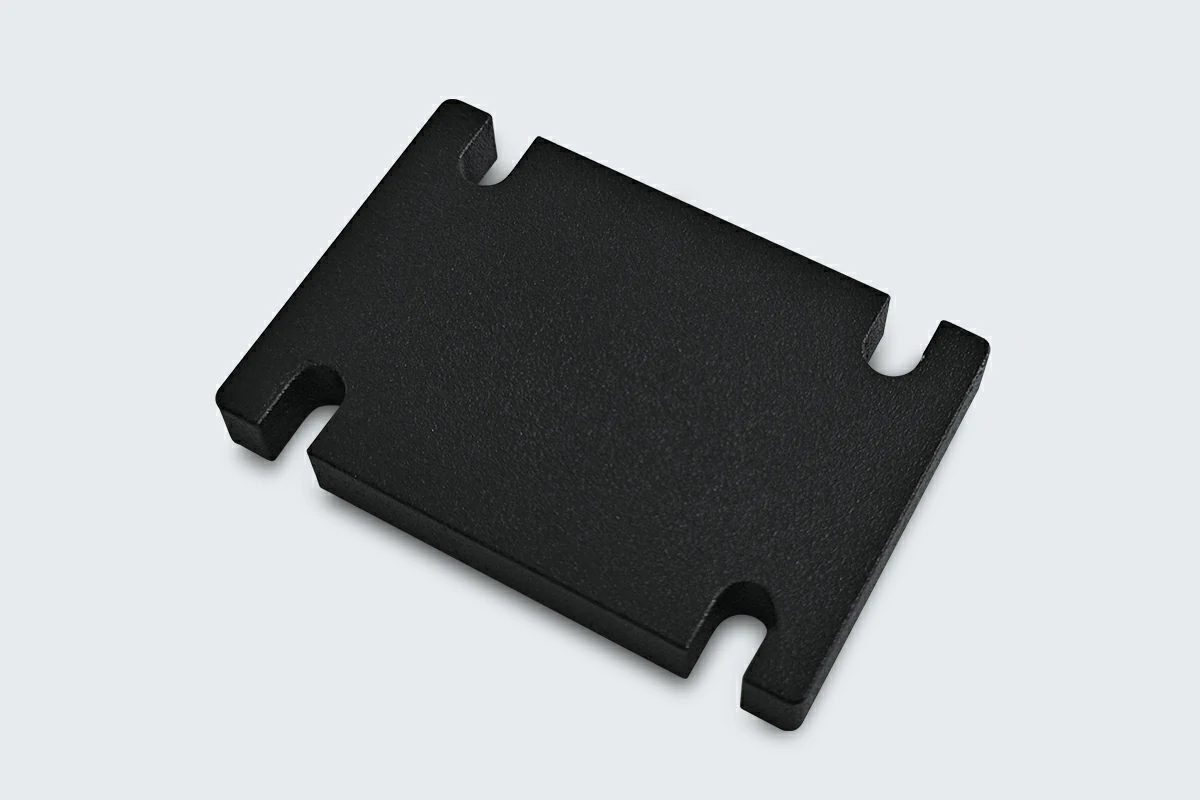

Black Sandblasting & Anodizing Service

This process combines anodizing and sandblasting to give aluminum parts a unique matte, rough or matte black appearance, improving their corrosion resistance and wear resistance.

Black Sandblasting + Anodizing Specifications

| Project | Info |

|---|---|

| Applicable materials | Aluminium |

| Anodizing type | Type II anodizing and type III anodizing |

| Thickness | 5-25 μm |

| Colors | Black |

| Texture | Matte, rough or matte black |

| Part masking | Indicate masking requirements in technical drawing |

| Application | Automotive, architecture, consumer electronics, aerospace, etc. |

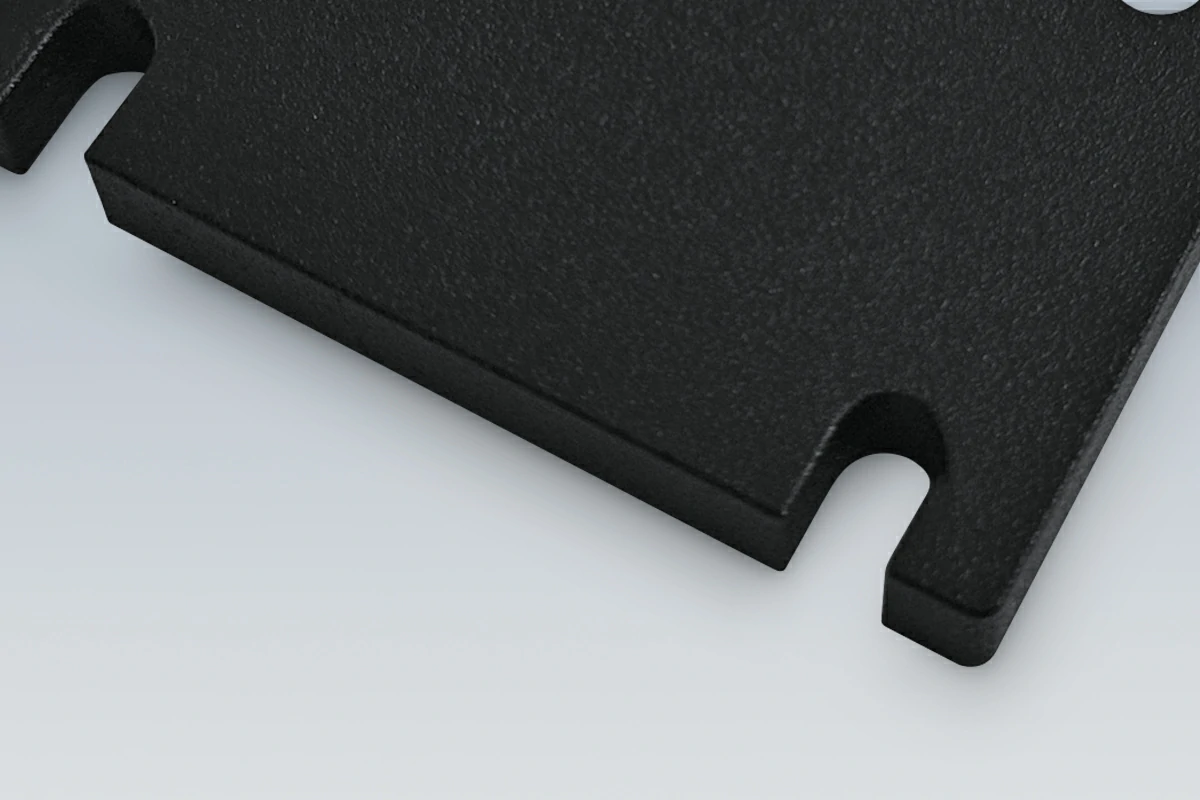

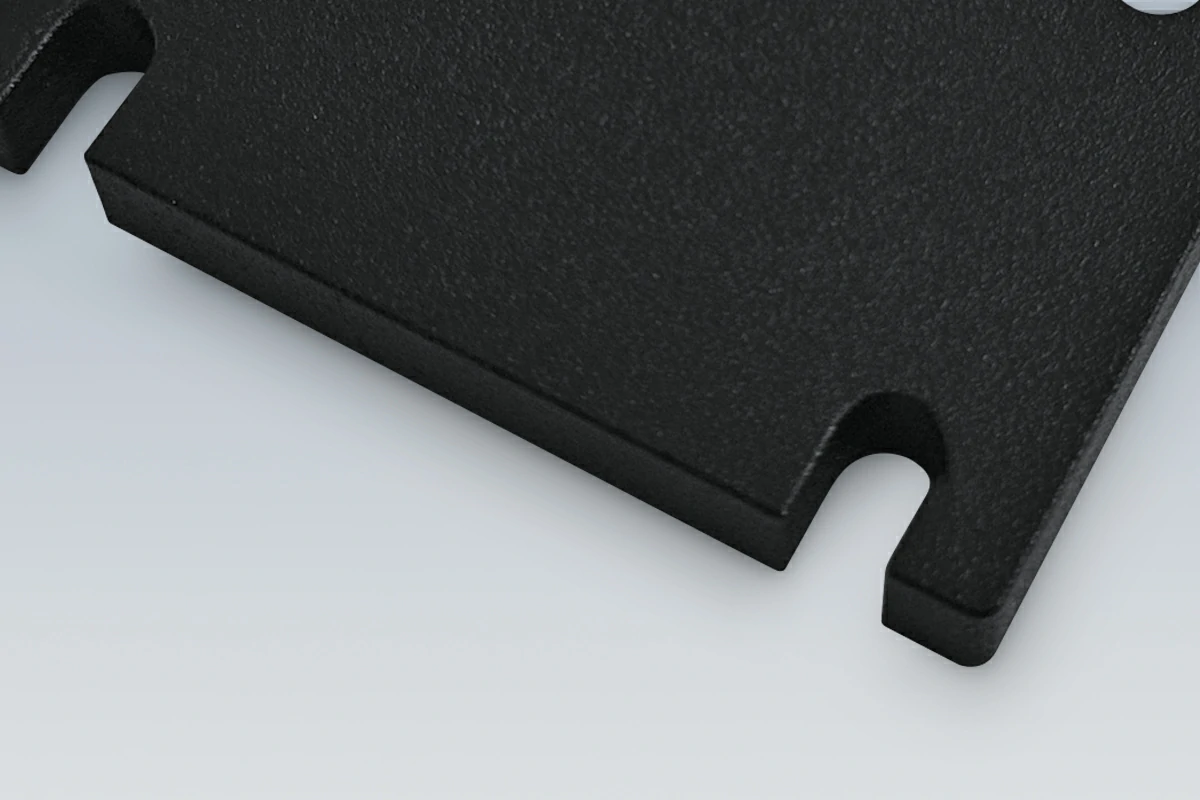

Example of Black Sandblasting + Anodizing Parts

About Black Sandblasting Anodizing

Black sandblasting + anodizing is often used to create a sleek, matte black finish on aluminum components.

Sandblasting: Abrasive is used to roughen the aluminum surface to produce a matte or matte appearance.

Anodizing: Forming a protective oxide layer on the aluminum surface to improve corrosion resistance.

Black sandblasted anodizing can be used to achieve durable and aesthetically pleasing black finish metal parts. It is commonly used in industries that require both corrosion resistance and aesthetics, such as the manufacturing of aerospace components, building components, and consumer goods.

Put your parts into production today

- All information and uploads are secure and confidential.