Have you ever encountered a situation where you need to create a CNC part, but you don’t know what tools to use for design. Yes, this issue has been troubling many people because everyone doesn’t know which tool to use to complete this task. However, now you can rest assured that CAD software can help you complete this task.

In this blog post of Longsheng Technology, we will guide you step by step on how to prepare CAD files for CNC machining, in order to quickly and accurately quote before manufacturing, and then allow the manufacturing process to occur. Continue reading below and learn more about this process through our step-by-step guide.

What is CAD?

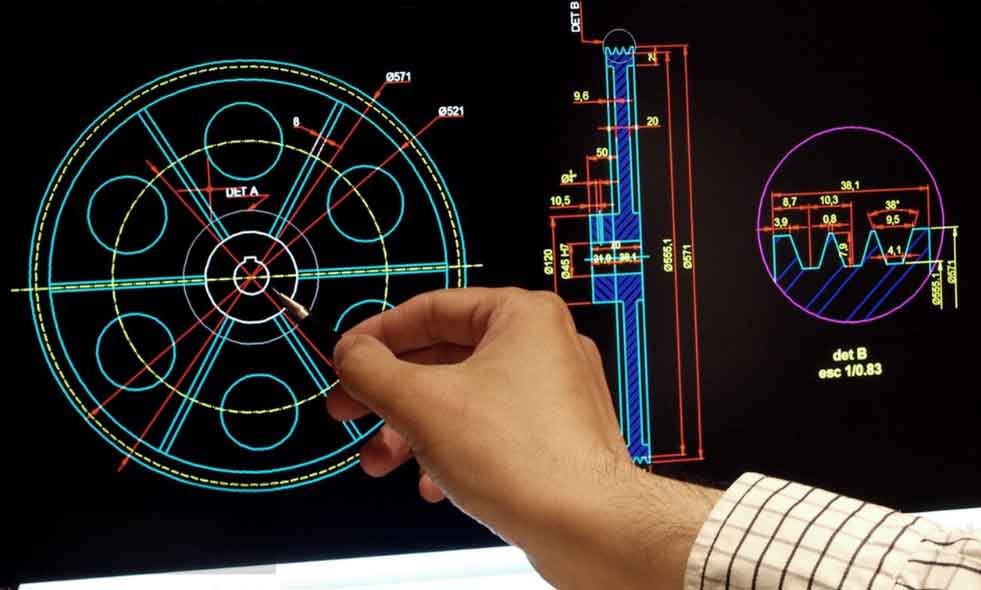

CAD is the English abbreviation of Computer-aided design, which is a computer aided tool widely used in the field of manufacturing and engineering design. Using CAD software, designers can complete 3D modeling of parts in CAD software, including detailed design, sketch making and definition of various necessary structures, and can easily and quickly edit and improve design in design drawings.

After 3D modeling is completed, CAM software (Computer-aided manufacturing) is needed to start the programming of processing program, and various parameters are defined in CAM software, including tool selection, processing path, processing speed, etc.

Finally, by uploading the compiled program code to the control system of the CNC machine tool using a USB flash drive or network, the CNC machining of the parts can begin.

Components of CAD software

Let’s introduce the components of CAD software. CAD software typically consists of three main components:

1.User interface

2.Drawing and modeling tools

3.Analysis and simulation tools

After these parts are added, CAD software becomes powerful and easy to use in modern industrial design processes.

user interface

The user interface of CAD software will include graphics, menus, and toolbars. We can achieve different operations through the user interface. For example, we can create geometric elements through the “drawing tool”. We can make changes to these geometric elements through the ‘Modify Tool’. We can use ‘analysis tools’ to evaluate whether geometric elements meet design requirements.

Drawing and modeling tools

The most common drawing and modeling tools include geometric modeling, surface modeling, sketching tools, and file repair tools. Geometric modeling is a method of creating three-dimensional geometric shapes. Surface modeling is typically used for object design with complex shapes.

Sketching tools are used to quickly draw 2D shapes in order to establish 3D models on them. The file repair tool is a software module used to identify and repair solid meshes and STL triangle models.

Analysis and simulation tools

Analysis and simulation tools are modules used to validate designs and solve potential problems. The purpose of this module is to analyze the design and conduct virtual testing to determine its quality and performance. This can reduce error rates and costs during the production process.

Widely used CAD software

To create CAD drawings, you need to use professional CAD drawing software. The following are several widely used software:

| CDA Software | Description | Download Address |

|---|---|---|

| AutoCAD | Widely used CAD software that provides powerful drawing and editing functions | https://www.autodesk.com/products/autocad |

| SolidWorks | 3D modeling software with integrated simulation and analysis functions | https://www.solidworks.com/ |

| Siemens NX | Comprehensive CAD/CAM/CAE software, providing full process solutions | https://plm.sw.siemens.com/en-US/nx/ |

| Mastercam | Professional CNC programming software, providing a wide range of machining strategies and tools | https://www.mastercam.com/ |

| GibbsCAM | Comprehensive CNC programming software that supports multi axis machining and multiple machine tool types | https://www.3dsystems.com/software/gibbscam |

| AlphaCAM | Comprehensive CNC programming software that supports various machining operations and materials | https://www.hexagonmi.com/products/cad-cam-software/alphacam |

Prepare CAD files for online CNC part pricing

CAD files contain detailed information about part dimensions, shapes, materials, and manufacturing processes. By analyzing this information, you can determine the manufacturing cost of the parts and develop feasible prices.

Here are some steps to prepare CAD files for online CNC part pricing:

1.Using CAD to establish a machinable design scheme

There are many methods for establishing CNC part design using CAD software.

In the design scheme of CNC machining, one method is to redesign the scheme by transferring geometric data to CAD software to create shapes or shape networks.

There are other ways to create CAD files suitable for CNC machining.

Some CAD software platforms can detect 2D images (such as PDF file formats) and convert them into 3D design drawings. This is ideal for Reverse engineering because it allows engineers to create blueprints from objects, rather than vice versa.

Other platforms can allow users to track images using vector cutting paths, or manually define the features of 2D images to convert them into 3D files. 3D scanners can also be used for this purpose.

After completing the CAD design scheme, you need to export it to a machinable file format, such as STL or G-Code, and transfer it to the processing site for production. The formats supported by various CAD software may vary, but you should choose a format that is compatible with your processing equipment.

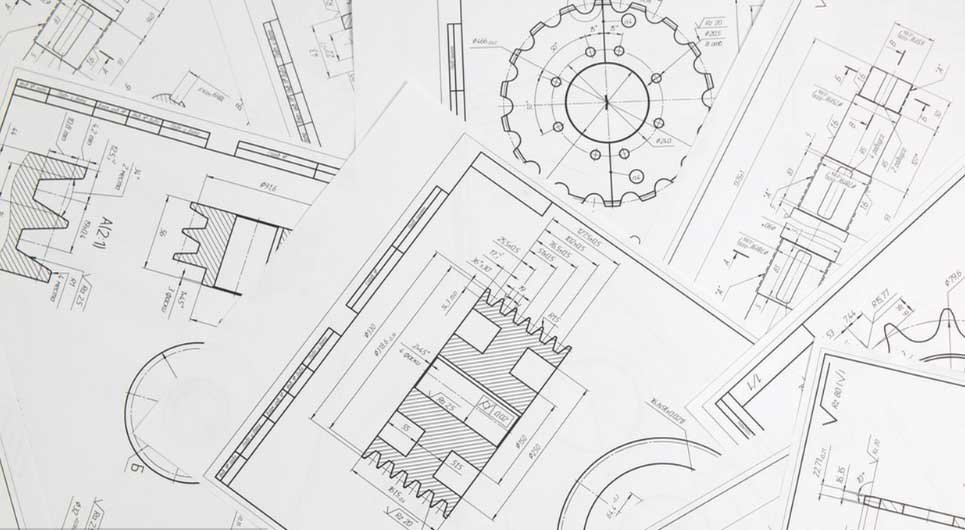

2.Prepare technical drawings

During the process of creating CAD files, you need to follow the following steps to ensure the quality and usability of the final file:

1.Based on the geometric features, appearance, and dimensions of the product, CAD software is used to design sketches and models.

2.Reconstruct and combine the created model to turn it into the final product you want.

3.To ensure that your CAD file can inform the processor how to accurately manufacture CNC parts, you need to add annotations and dimensional parameters.

4.To ensure that manufacturers can smoothly use CAD files for production and processing, we need to promptly resolve any errors or potential issues.

Here are some basic steps for preparing CAD files:

Step 1: Select CAD software. There are many different types of CAD software in the market, and choosing the software that is suitable for personal use is crucial. For example: SolidWorks, AutoCAD, CATIA, and so on.

Step 2: Create a 3D model of the part. Use CAD software to construct a 3D model that includes detailed information such as part shape, size, and material.

Step 3: Generate CAD files. 3D models can be saved in CAD file formats for processing, such as STEP or IGES formats.

When you place a CNC machining order, the dimensions of the CNC parts have been communicated in the 3DCAD file. To save time, you can only indicate the most important dimensions on the technical drawings, as well as elements such as threads, tolerances, or surface finish that require verification by CNC machining manufacturers.

3.Obtain CNC machining quotes online

With accurate CAD files, pricing will become easier. Many online CNC machining parts suppliers provide online pricing tools where customers can upload CAD files and obtain corresponding quotes.

At Longsheng Technology, you can upload your CAD files in a few simple steps to quickly obtain solutions and quotes. Online CNC machining services not only make the process faster and more convenient, but also offer relatively reasonable prices.

conclusion

From the above content, we can conclude that CAD software can indeed produce CNC parts and greatly promote the processing of CNC parts. If you want more specialized CNC machining services, it is recommended to cooperate with professional CNC machining manufacturers to ensure machining efficiency and quality, as well as save time and costs.

Whether you are a novice or experienced user, we believe that this article will be helpful to you.

For more CAD technical information, please refer to this article【LONGSHENG: CNC Manufacturing, CAD Design Scheme】

Making CNC parts: Choose Longsheng to start your next project

No matter which software you use, even the best designs will benefit from expert DFM feedback and production partners, who can turn these designs into reality. Longsheng can meet your needs for all CNC machining and precision machining.

Before you can use our services, you need to consider the following aspects:

1.Your requirement: Determine the type of parts you need, including dimensions, materials, and manufacturing requirements.

2.Design file: Provide your CAD file or manuscript and discuss design issues and improvement suggestions.

3.Delivery time: Our production process usually takes 3-5 working days. If you need to expedite manufacturing or increase quantity, please let us know in advance.

4.Part quantity: We can manufacture 1 or thousands of parts, depending on your project requirements.

After determining these details, you can confidently hand over the manufacturing of CNC parts to us. Starting from your interests, we will provide you with quality assurance to ensure that you receive the best results.

We look forward to working with you and providing you with the best service. If you have any questions about our services, you can contact us at any time through the following methods, and we will reply to you as soon as possible.

Call+8619551067050 or send an email to info@longshengmfg.com

FAQ

CAD software allows users to design and modify in a digital environment, which can save a lot of time and cost. It can also accurately capture every detail, thus producing high-precision and high-quality parts.

There are currently many CAD software options available in the market, such as AutoCAD, SolidWorks, CATIA, etc. Each software has its own specialized application areas and characteristics. When selecting CAD software, appropriate software should be selected based on the required processing type and industry.

What CAD software is required for making CNC parts?