Are you new to the world of CNC machining? Do you want to learn about CNC machine parts and their functions? In this article, we will dive into the basics of CNC machine parts and how they contribute to the entire machining process.

CNC machines have revolutionized the manufacturing industry, making it possible to produce complex components with incredible accuracy and speed. These machines have several parts that work together to deliver a highly precise and efficient performance.

What are CNC Machine Parts?

If you’re interested in CNC machining, you’re probably aware that it’s a highly versatile and precise manufacturing process. But what exactly are CNC machine parts, and how do they work?

CNC stands for “Computer Numerical Control”—and as the name implies, it involves using computer software to automate a variety of machine tools. That way, you can easily produce complex geometries with high accuracy and repeatability. A CNC machine typically consists of three main components: the control system, the machine itself, and the tooling. Each of these parts plays a critical role in the CNC process.

CNC machines are used in a variety of industries, including aerospace, automotive, medical and jewelry making. They are capable of producing parts with a high degree of accuracy and complexity, which makes them ideal for making intricate parts.

What are the basic components of CNC machine?

The world of manufacturing has come a long way, and one of the most significant advancements has undoubtedly been the introduction of CNC machines. These machines have revolutionized manufacturing processes across industries, allowing for greater accuracy, efficiency, and speed in the production of a wide range of objects. However, to get the most out of these machines, you need to have a proper understanding of their basic components. In this post, we will explore what the basic components of a CNC machine are and what makes them so essential.

A CNC machine is essentially a computer-controlled machine that uses programs to guide its movements. The process involves a computer that retrieves information from a design program and translates it into a sequence of motions and commands that are executed by the machine. However, without the following fundamental components, the CNC machine would be rendered useless:

Control Panel

The control panel is the nerve center of a CNC machine, where all the programming and operational parameters are set. This panel is where the operator enters the commands to indicate what the machine should do, how fast it should do it, and how it should move. The control panel also allows the operator to monitor the operations of the machine and make any necessary adjustments during the manufacturing process.

Spindle

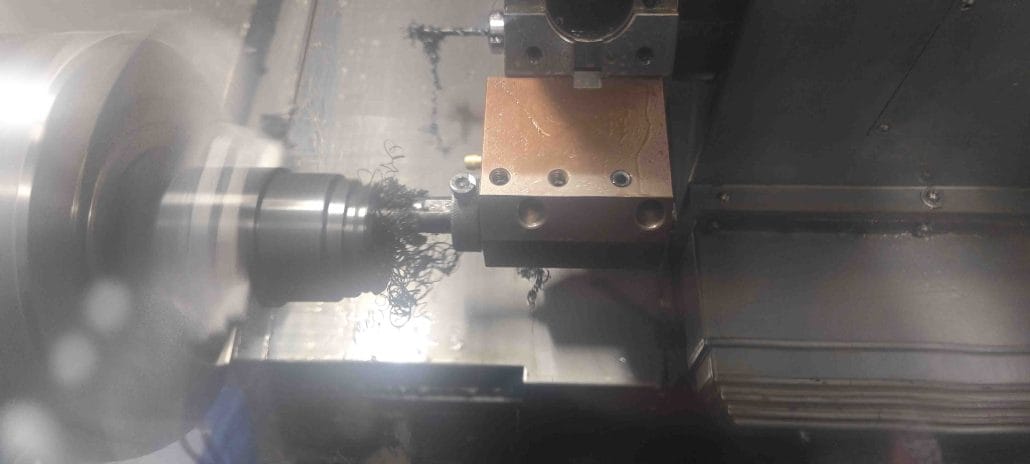

The spindle is the rotating component that holds the cutting tool. CNC machines use different types of spindles depending on the material being cut and the depth of the cut that is required. The spindle’s speed and direction are controlled by the programming in the control panel, with different speeds used for different materials and cutting tools.

Cutting Tool

The cutting tools used in CNC machining are typically made from high-speed steel or carbide. These cutting tools come in different shapes and sizes to accommodate different materials and cutting depths. The cutting tool’s specific operations are determined by the programming in the control panel, which controls the speed, direction, and depth of each cut.

Worktable

The worktable is where the material being cut is held in place during the manufacturing process. The material is secured firmly to the worktable to ensure accurate and consistent cuts. The worktable can move in different directions, depending on the programming in the control panel, allowing for precision cuts to be made at different angles.

Motors

CNC machines use motors to move the spindle, worktable, and cutting tools in different directions. These motors are controlled by the programming in the control panel, allowing for accurate and consistent movements that result in precise cuts. The motors used in CNC machines are typically high-torque, high-precision motors that can operate at high speeds without sacrificing accuracy.

In conclusion, to get the most out of a CNC machine, it is essential to have a proper understanding of its basic components. Understanding the control panel, spindle, cutting tool, worktable, and motors allows for greater accuracy, precision, and consistency in the manufacturing process. With this knowledge, you can take full advantage of the capabilities of a CNC machine, allowing you to manufacture high-quality products at greater speed and lower costs.

Examples of CNC Machined Parts

CNC (Computer Numerical Control) machining is a manufacturing process that uses computer software to control the movement of machinery and tools to create precise parts. This process has revolutionized the manufacturing industry by providing a more efficient and accurate method of creating parts.

Here are some examples of CNC machined parts:

- Engine components: CNC machining is commonly used to create parts for engines, such as cylinder heads and blocks, pistons, and connecting rods. These parts require a high degree of precision to function correctly and CNC machining ensures that the parts are made to exact specifications.

- Aerospace components: CNC machining is used to create parts for aircraft, such as turbine blades and engine mounts. These parts need to be extremely durable and reliable, and CNC machining helps to achieve this level of precision.

- Medical implants: CNC machining is commonly used to create precision parts for medical implants, such as hip and knee replacements, dental implants, and spinal implants. These parts need to be made to exact specifications to ensure that they are safe and effective, and CNC machining allows for this level of precision.

- Electronic components: CNC machining is used to create parts for electronic devices, such as computer parts, smartphone components, and circuit boards. These parts need to be made with extreme precision to ensure that they function correctly, and CNC machining provides this level of accuracy.

- Automotive components: CNC machining is used to create parts for vehicles, such as transmission parts, suspension components, and braking systems. These parts need to be made to exact specifications to ensure that they are safe and reliable, and CNC machining allows for this level of precision.

- Industrial machinery: CNC machining is used to create parts for industrial machinery, such as gears, bearings, and shafts. These parts need to be made with extreme precision to ensure that the machinery operates efficiently and safely, and CNC machining provides this level of accuracy.

These are just a few examples of the many different types of parts that can be created using CNC machining. CNC machining is a versatile process that has revolutionized the manufacturing industry by providing a more efficient and accurate method of creating parts. As technology continues to advance, we can expect to see even more innovative uses for CNC machining in the future.

How to Choose the Right Material for Your CNC Machined Parts

When it comes to CNC machining, selecting the right material is crucial for the success of your project. The material you choose will determine the durability, strength, and overall performance of your parts. Here are some factors to consider when selecting the right material for your CNC machined parts.

Material Properties

The properties of the material are important to consider when selecting the right material for your CNC machined parts. For example, if you need a part that is strong and durable, you may want to consider materials such as aluminum, stainless steel, or titanium. If you need a part that is lightweight, materials such as plastics or composites may be a better choice.

Application

The application of your CNC machined parts is another important factor to consider. If your parts will be used in harsh environments or will be exposed to corrosive substances, you will need to select a material that can withstand these conditions. On the other hand, if your parts will be used in a more controlled environment, you may have more flexibility in selecting a material.

Cost

Cost is another important factor to consider when selecting the right material for your CNC machined parts. Some materials may be more expensive than others, so you will need to determine the best balance between cost and performance for your specific project.

Machinability

The machinability of the material is also an important factor to consider. Some materials may be more difficult to machine than others, which can impact the time and cost required to produce your parts. Make sure to consider the machinability of the material when selecting the right material for your CNC machined parts.

Overall, selecting the right material for your CNC machined parts requires careful consideration of a variety of factors. By taking into account the material properties, application, cost, and machinability, you can choose the material that will provide the best performance for your project.

Why CNC Machine Parts are Important

So why are all these components so important? Put simply, they enable manufacturers to produce complex, highly precise shapes and components with great efficiency. Without a high-precision control system, it would be virtually impossible to create these shapes with any degree of accuracy or consistency. Without the right machine components, the machine would be unable to move reliably or at the required speeds. And without high-quality tooling, the machine would be unable to do its job effectively.

Because of its precision, efficiency, and versatility, CNC machining has become one of the most popular manufacturing processes around the world. And understanding the various components that make it possible is key to unlocking its full potential.

FAQ

The control system is the brain of the CNC machine. It receives instructions from the operator or computer and translates them into movements of the machine’s components. The control system also monitors the machine’s performance and alerts the operator if there are any issues.

The enclosure is a protective covering that surrounds the machine to prevent debris and other materials from getting inside and causing damage. It also helps to reduce noise and protect the operator from any flying debris.