The loose knife is a new type of knife with a unique design, suitable for various industrial fields. It is made of high-tech materials, and has excellent hardness, wear resistance, durability and other characteristics, so in a variety of occasions can play a remarkable effect. With loose knives, industries can become more efficient, reliable, and flexible, in addition to dramatically reducing costs.

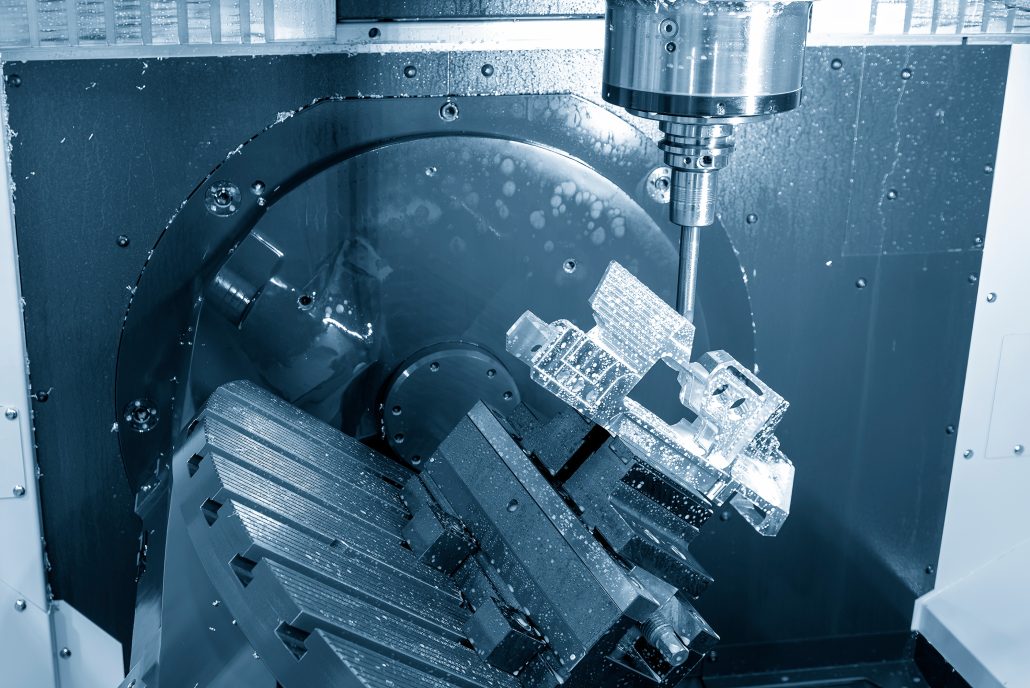

As the core part of CNC machining center, the loose knife plays a vital role in the machining process. Next, this blog of Longsheng technology website will explain CNC machining loose knife in detail, including its principle, advantages and application fields

CNC machining loose knife concept

A loose knife is a tool used on CNC machine tools. It is a rotary knife, online CNC machining loose knives are usually made of tungsten steel or tungsten carbide, with extremely high hardness and strength, so that a high efficiency process can be achieved. Loose knife in CNC machining process, through the computer program automatic control of rotation and movement, to achieve efficient cutting and processing.

What is a loose knife?

CNC pine knife is a tool that can accurately carve out patterns and patterns on pine. It is refined by CNC technology, with high speed and high precision. CNC machining loose knives are able to produce scrapers in different sizes and shapes compared to traditional tools, making it ideal for novel, personalized works.

As a woodworking tool, CNC machining loose knife has many unique characteristics. First, it has high speed and precision to create perfect patterns and patterns that traditional tools cannot achieve. At the same time, CNC machining loose knife also has the advantages of durability and repeated production. As a result, you can produce wood products that have a unique look and are amazing.

In the process, CNC machining loose knife is also a very prominent tool. It utilizes machining technology to easily achieve a degree of accuracy and control similar to traditional tools, while automatically adjusting position and speed during production. Because it does not require much human mastery and manual control, CNC machining loose knife can improve production efficiency, reduce labor intensity, and improve product quality and consistency.

The use of CNC machining loose knives can be used not only in production aspects such as home decor, handicrafts and art, but also in other areas such as construction, furniture and kitchen supplies. Because of its ability to outperform manual manufacturing in terms of accuracy and durability, CNC machining loose knives have become ideal tools for producing all kinds of wood products.

The principle of a loose knife

The principle of the loose knife is to control the rotation and movement of the loose knife through the motor or cylinder and other devices. In the CNC machining process, the computer program will control the rotation speed of the loose knife, feed speed and other parameters, in order to achieve more accurate and efficient cutting and machining. In addition, the loose knife can also be used for a variety of high precision machining operations, such as hole machining, thread machining, etc.

Types of loose knives

According to different designs and uses of loose knives, they can generally be divided into the following types:

1) Straight handle type loose knife: Straight handle type loose knife is a spindle component, directly connected with the spindle. It is suitable for cutting and processing various materials, with high strength and rigidity.

2) Lock claw clip type loose knife: lock claw clip type loose knife is a more common type of loose knife, it clamping tool through the lock claw, can be used to process a variety of shapes and sizes of the workpiece.

3) Quick change loose knife: quick change loose knife can quickly change different tools, improve production efficiency and processing accuracy. It generally through chuck and quick change interface to achieve quick tool change.

4) Independent head loose knife: independent head loose knife is suitable for all kinds of special-shaped workpiece processing, because you can freely adjust the deflection Angle and cutting depth of the tool, can realize a variety of complex shape processing.

The processing process of the loose knife

With the development of CNC machining technology, we can control the machining process of the loose knife through the computer. This allows us to mass-produce loose knives with the same properties and achieve greater precision and efficiency during processing.

Specifically, CNC machining loose knife needs to go through the following steps:

Loose knife design

First, we need to design the right loose knife model. The design process is usually done on a computer, and design software can help us with complex geometric modeling and motion planning.

Material selection

After determining the model of the loose knife, we need to choose the appropriate material for processing. Generally, high speed steel, hard alloy and other materials are widely used in the production of loose knife.

CNC machining

After determining the material, we can process it through CNC machine. CNC machining technology can help us achieve very high accuracy and efficiency, while ensuring that the performance of each loose knife is very similar.

Loose tool detection

After finishing, we need to test the loose knife. This includes static characteristic test and dynamic cutting test. Through these tests, we can determine whether the performance of each loose knife is as expected.

Application of CNC machining loose knife

The application of pine knife is very wide, including metal, plastic, wood, glass and other materials.

In the field of metal processing, loose cutter can quickly and accurately complete various processing work, such as milling, cutting, punching and so on. Its sharp edges can easily cut metal, reducing waste and improving production efficiency.

In the field of plastic processing, the surface of the loose cutter is smooth, which can ensure the precision and quality of processing. When using a loose knife to process plastics, it can not only reduce the extrusion force in the process of processing, but also improve the processing speed, so that the product is more high-quality.

In the field of wood processing, the cutting effect of the loose knife is very good. Pine knife can easily cut a variety of wood, such as hardwood, softwood, etc., cutting efficiency is high, and the surface quality of wood products is better.

In the field of glass processing, loose knives can be used for tasks such as cutting, drilling and grinding. The cutting Angle design and surface treatment of the loose cutter ensure high cut quality while reducing the formation of glass fragments.

Causes of CNC machining center loose knife

As the core part of CNC machining center, the loose cutter plays a vital role in the machining process. However, many users found their CNC machining center loose knife in the process of use, because it will bring serious consequences, such as machine damage, product quality reduction, and even the injury of workers

Cause CNC machining center loose knife loose reasons, may be related to the following aspects:

Cutting vibration

in the process of high-speed machining, high-precision machining and other high requirements of the machining process, the tool will often be subjected to large cutting force and cutting vibration. If the stability of the spindle, tool head and other components is not good, it will also lead to the loosening of the tool.

Machining parameter error

in the process of machining, if the machining parameters are too radical, it will lead to too much cutting force, so that the phenomenon of loose cutting occurs.

Tool wear

In the process of use, the tool will wear, especially the tool working for a long time, wear is more serious, these wear will lead to loose tool.

Poor surface condition leading to loosening

the fixing of CNC machining center loose cutter is related to the surface condition. If the surface condition is poor, it may lead to loose cutter. Therefore, before use should check whether the processing surface is smooth and flat, and timely treatment of poor surface conditions.

Material problems

If you need to process the workpiece material strength is high or other poor performance, it will lead to greater pressure when cutting, which will also lead to loose tool.

Gap between the handle and the knife

When clamping the tool, the chuck and the handle need to leave a certain gap, so that the chuck can clamp the tool. However, during machining, this gap may increase due to the wear of the tool handle surface or the deformation of the chuck, resulting in the loosening of the tool.

Tool too thick or heavy to loosen

If the tool is too thick or heavy, prolonged use may lead to loose knife.

Bad handle quality

If the quality of the handle is not good, it is easy to lead to deformation, cracking and other problems, affecting the stability of the tool, resulting in loose tool.

Processing load

in the processing of large hard materials, the tool and the handle of the load is very large, if the clamping force is not enough, the tool will be loose.

Equipment aging leads to loosening

the normal use of CNC machining center equipment for a long time, often prone to aging leads to loosening. Equipment aging may be due to parts wear, vibration during processing and other factors.

Program error leads to loosening

in the process of CNC machining center, if the program error, may lead to loose knife. Therefore, before using CNC machining center, we must make sure that the early work (such as setting parameters, maintaining equipment, writing programs, etc.) is no problem, in order to avoid the impact of program errors.

CNC machining center reason

CNC machining center itself is also easy to lead to loose knife, such as the frame structure of the machine tool precision is insufficient, tool rod wear resulting in contact is not close, etc. At this time, we need to maintain the machine tool, check the wear of the tool rod in time, and adjust and replace it in time.

The loosening between the chuck and the spindle

in the machining process of CNC machining center, the chuck needs to rotate through the spindle, therefore, the match between the chuck and the spindle is very important. If the accuracy of the chuck is not high or the spindle mating surface is worn, it will lead to the loosening of the chuck, resulting in the loosening of the tool.

Prevent CNC machining center loose tool method

To prevent loose knife problems, you need to take some precautions. Here are some common methods:

Strong discharge knife, installation tool inspection

discharge knife, installation tool should be carefully checked to ensure that the tool, knife holder, knife handle match, clamping is firm, so as to avoid the formation of loose knife.

Periodically check the tool

regularly check the tool wear, handle deformation, fatigue fracture and other problems, timely replacement or repair, to ensure the quality and stability of the tool.

Strengthen maintenance of machine tools and tools

Keep machine tools and tools clean and dry, avoid tool contact with corrosive liquids and gases, so that the life of the tool is extended, also help to reduce the occurrence of loose knives.

Ensure the accuracy of the chuck

In order to prevent the gap between the chuck and the shank from being too large, we need to ensure the accuracy of the chuck. Selecting high quality chuck and maintaining regular chuck maintenance can effectively reduce the deformation of the chuck and reduce the loosening rate of the tool.

Follow the procedures when installing the tool

When installing the tool, follow the procedures and procedures to ensure that the tool is installed correctly and securely.

Select the right machining conditions

Select the right machining conditions, can reduce the loss of tools and vibration.

Increase tool support

If tool support is insufficient, you can reduce tool vibration and loosening by increasing tool support.

Correct setting of processing parameters

in processing, according to the nature of the material and the shape and size of the workpiece, the correct setting of processing parameters, so as to ensure the quality of processing and reduce the occurrence of loose knife phenomenon.

How to choose the right loose knife

In addition to CNC machine tools, there are other tools available using loose knives. For example, manual loose knife, traditional machine or use of power tools for processing and so on. Each option has its advantages and disadvantages, so choosing the right loose knife tool requires careful thought.

Buy CNC machining loose knife points

When choosing CNC machining loose knife, in order to pick out a suitable loose knife for you, you need to consider the following points:

Size: The size of the pine knife should take into account the size of the pine wood cut. If you choose a tool that is really too thin or too thick, you will not get the best results.

Shape: Choosing the right shape will help you have more control over the cutting tool. It should be selected according to the shape and Angle you need to cut.

Sharpness: The sharpness of a loose knife will affect the result of cutting. Avoid cutting tools that are too blunt, or they may damage the pine.

Standards: The standards used for the size of the loose cutter should be considered so that correct codes and standards are followed during the manufacturing process.

Using CNC machining loose tool skills

Once you have purchased a CNC machining loose cutter, the next step is to understand how to use them properly. Here are some tips for machining loose knives using CNC:

Use the right tools: Different materials require different types of tools. Choosing the right tool will ensure the best cutting results and avoid wasting material.

Understand cutting speed: The higher the cutting speed of the loose cutter, the higher the production efficiency. But be careful not to let the cutting speed be so high that it damages the loose cutter or the material.

Do regular maintenance: As with any high-precision machine, regular maintenance will help keep your CNC machine and loose cutter in top performance.