If you are engaged in manufacturing and machining fields, you will not be unfamiliar with CNC machining,CNC machining has become an indispensable part of the manufacturing industry, because it can improve efficiency and accuracy, shorten the production time, now this technology is more and more popular, some people think that this is the future of manufacturing development

So, what are the different types of CNC machining operations in the process of manufacturing precision parts? For more information, please continue reading the important information provided by Longsheng Technology in this blog to better understand the types of CNC machining and the differences between them and the areas in which they are used.

What is CNC machining?

CNC machining mainly relies on computer programs. In CNC machining, the use of CAD (computer aided design) design parts graphics, through CAM (computer aided manufacturing) software graphics into machining program, and then through the CNC control program to load the program on the machine tool for machining . Therefore, CNC machining not only needs a certain knowledge of mechanical manufacturing, but also needs skilled computer programming skills.

Using CNC machining can produce highly accurate parts, greatly saving the machining cost and time. At the same time, it also ensures the consistency of product quality after machining . The technology is also used in the machining of metals, plastics, ceramics and other industrial materials.

CNC machining type and operation process

The core technology of CNC machining is the digital instruction, as the instruction of machine action to complete the favorite parts machining. Below we mainly introduce the types of CNC machining and some operating processes.

CNC lathe

CNC lathe is a machine tool based on computer control, its main function is to rotate the workpiece locked on the spindle, through different cutting tools for machining . CNC lathes can be divided into two types: plate type and vertical type.

Plate CNC lathe

Plate CNC lathe is a special form of CNC lathe, it has its own unique machining mode and machining field. Plate-type CNC lathes are usually used for machining plate-type objects, flat surfaces and simple surfaces. They have the advantages of high precision, high efficiency and high degree of automation.

The operation flow of plate lathe CNC machining.

First, preparation. The operator needs to confirm whether the tool and fixture used is suitable for the workpiece to be processed, and adjust and replace it. Then, the workpiece is fixed on the workbench, and accurate positioning and calibration.

Next, the numerical control programming. Nc program is written by CAD/CAM software, the required machining path and machining mode into the computer can identify machine instructions, and then input the program in the controller.

Pretreat. Before CNC machining, it is necessary to pretreat. Set machining parameters, such as cutting depth, cutting speed, etc., through the controller. At the same time, also need to carry out some preparatory work, such as the coating of the tool, etc.

Start CNC machining. The prepared CNC program is transferred into the controller and began to process. Operators need to monitor the machining process to ensure the quality and efficiency of machining .

Finally, the work is inspected and any necessary trimming and polishing is done.

Vertical CNC lathe

Vertical CNC lathes are widely used in machining industry, especially for the preparation of thread, gear, shaft and other complex shape workpiece. It has the advantages of high machining precision, high machining efficiency, small weight and size limit to the workpiece.

The operation flow of vertical CNC lathe CNC machining

First, preparation. The operator needs to confirm whether the tool and fixture used is suitable for the workpiece to be processed, and adjust and replace it. Then, the workpiece is fixed on the workbench, and accurate positioning and calibration.

Next, the numerical control programming. The NC program is written by CAD/CAM software.

Pretreat. Before CNC machining, it is necessary to pretreat. Set machining parameters, such as cutting depth, cutting speed, etc., through the controller. At the same time, also need to carry out some preparatory work, such as the coating of the tool, etc.

Start NC machining. The prepared NC program is transferred into the controller and began to process. Operators need to monitor the machining process to ensure the quality and efficiency of machining .

Finally, the work is inspected and any necessary trimming and polishing is done.

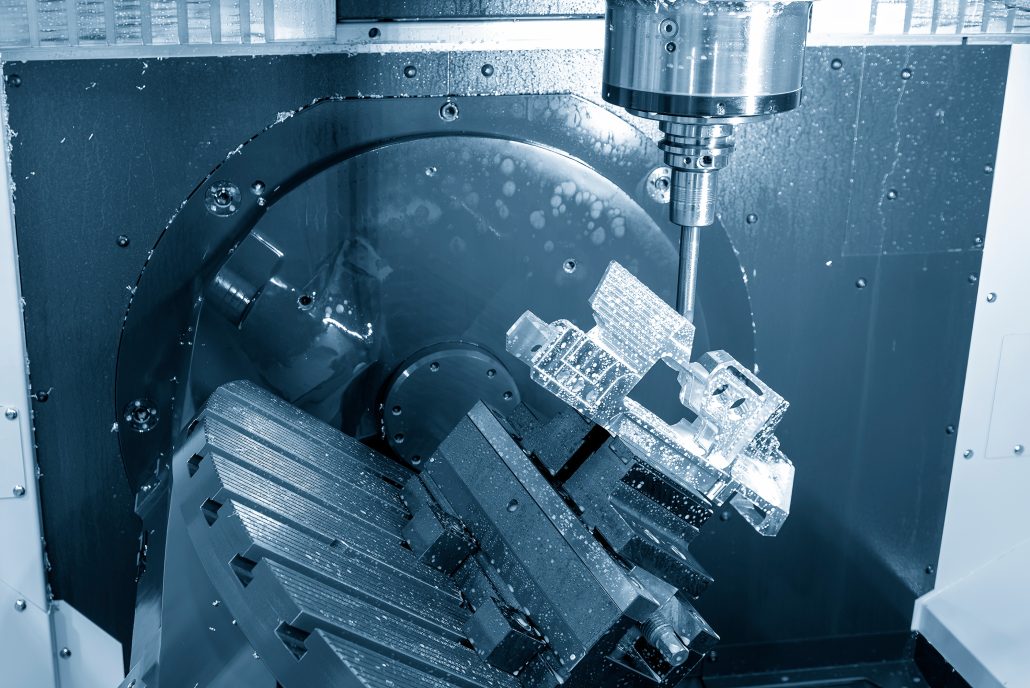

CNC milling machine

CNC milling machines are machine tools that process materials into desired shapes by constantly rotating and moving the cutter. CNC milling machine can be divided into vertical and horizontal two types

Vertical CNC milling machine

Vertical CNC milling machine CNC machining is a method of machining workpiece by computer control of tool movement and material movement. Specifically, it uses a vertical structure, the workpiece is fixed to the workbench, and then the tool is moved through different axial direction to work the workpiece. By controlling the relevant parameters of the CNC machine, such as feed speed, speed, etc., the operator can realize the accurate machining of the workpiece and produce high quality products.

The basic operation flow of vertical CNC milling machine CNC machining:

Install the tool: The operator first installs the tool into the tool sleeve and then into the spindle head. Start the CNC machine, configure the cutting parameters, and let the machine check the tool to ensure the correct tool position and feed speed.

Set the workpiece clamping: put the workpiece on the workbench and fix it. In order to ensure the stability of the workpiece in the process of machining , it is necessary to use the fixture to clamp it.

Set the coordinate axis: according to the drawings and machining requirements of the workpiece, determine the coordinate axis and machining path, and set the relevant parameters in the system.

Programmable control: The use of CNC program input machine tool numerical control system, set a variety of parameters, such as: cutting parameters, feed and feed speed, cutting mode, etc.

Start machining: After debugging, program sequence input, start CNC machining. Control program execution sequence and workpiece motion parameters, and can detect machine tool state at any time.

Inspection of machining effect: after machining is completed, it is necessary to inspect and compare with the set standards to ensure the quality of machining .

Horizontal CNC milling machine

The vertical CNC milling machine works in a similar way to the horizontal CNC milling machine, the difference lies in the direction and position of the workbench swing. When the vertical CNC milling machine is used for machining, the workpiece needs to be placed on the workbench and fixed by the fixture.

Horizontal CNC milling machine CNC machining process:

Preparation: Select the appropriate workpiece and fixture, and confirm the initial position of the machining shaft in all directions.

Programming: according to the machining requirements to write G code, to achieve the adjustment of the machining parameters, such as cutting speed, feed speed and spindle speed.

Alignment: Mechanical alignment ensures perpendicularity between the tool and the workpiece to prevent the tool and groove from being too deep or too shallow.

Processing: the machining parameters will be input into the computer, the horizontal CNC milling machine CNC machining machine according to the preset program to run the relevant parts, develop a predetermined outline, and according to the requirements of the parts machining out.

Finish: after machining , simple maintenance work should be carried out on the machine tool, such as cleaning the suction port and cutting fluid pipeline.

CNC drilling machine

CNC drilling machine is a kind of machine tool that processes materials by rotating the drill bit. It is suitable for drilling and cutting materials. CNC drilling machine can be divided into vertical and horizontal two types

Vertical CNC drilling machine

Vertical CNC drilling machine CNC machining is to place the workpiece under the drill and move the drill down to drill. During this process, the bit usually does not move, but simply rotates while drilling or tapping. One thing to note here is that the depth of the borehole must match the predetermined depth to ensure the quality of the machining.

CNC machining process of vertical CNC drilling machine:

Design parts: Use CAD software to design parts and obtain accurate three-dimensional model.

Set the machine: place the parts on the working table of the vertical CNC drilling machine, and set the machining parameters.

Start the equipment: Use the control system to start the equipment and automatically process according to the program.

Finish the machining : after the machining is completed, the mechanical arm will be used to take out the parts for quality testing.

Horizontal CNC drilling machine

CNC machining of horizontal CNC drilling machine is a common CNC machining method, which is characterized by simple operation, high efficiency, high precision and good stability. CNC machining of horizontal CNC drilling machine is almost the same in function as CNC machining of vertical CNC drilling machine. The main difference between them is the Angle of machining . Transverse CNC drilling machine CNC machining is usually used to process large and heavy parts, such as machine tools, automotive engines, etc

Transverse CNC drilling machine CNC machining process:

Writing numerical control program: same as CNC machining of vertical CNC drilling machine, CNC machining of horizontal CNC drilling machine also need to write numerical control program.

Adjust machine parameters: same as CNC machining of vertical CNC drilling machine, adjust machine parameters according to machining requirements and material properties.

Fixed workpiece: The workpiece to be processed is fixed on the workbench to ensure its stability and smoothness.

Machining: Input the programmed NC program into the NC system, start the CNC machining of the horizontal NC drilling machine, and carry out the machining process automatically.

Automatic tool change: In the process of machining, if the tool needs to be replaced, the transverse CNC drilling machine CNC machining machine will automatically select and replace the appropriate tool through the tool library.

Inspection: After the machining is completed, it is also necessary to conduct quality inspection to ensure that the machining quality meets the requirements.

Custom CNC machining parts service

By now, you’ve probably developed an in-depth understanding of the different types of CNC machining processes and found their advantages. Need to customize parts with complex geometric shapes in the shortest possible time? Then, Longsheng Technology is your ideal manufacturing partner.

We Longsheng provide customized CNC machining parts services, to provide customers with high quality parts machining solutions. Our service process includes:

Communicate with customers to understand their needs and technical requirements;

Design and program parts according to drawings or samples provided by customers;

Arrange machining equipment for parts machining and inspection;

Strict inspection and testing of finished products to ensure the quality of parts meet customer requirements;

Carry out packaging and logistics distribution of finished products as required.

Our CNC lathes and milling machines are equipped with advanced control systems and precise cutting tools to ensure accurate machining of various materials. Whether plastic, metal, aluminum, copper, iron, steel or other materials, we are able to perform precision machining according to your specifications and drawing requirements.

Our professional team has many years of experience and always adheres to strict quality standards in the process to ensure precision at all stages. We also offer a variety of machining processes such as drilling, milling, turning, cutting, bending and forging to meet your various needs.

In addition to custom machining , we also provide a rapid sample making service so that you can confirm that your requirements are met. We will work hard to ensure that you get the best service and the products you need in the shortest time.

If you need customized CNC machining parts service, Longsheng will be your best choice. We are the leader in online CNC machining services, providing high quality machining services to meet your various needs. Please feel free to contact us, we will serve you wholeheartedly.

cnc turning, cnc milling different applications

In the use of CNC machines, CNC turning and CNC milling these two kinds of technology in the process of machining have different applications, let’s talk about their differences and applications in detail.

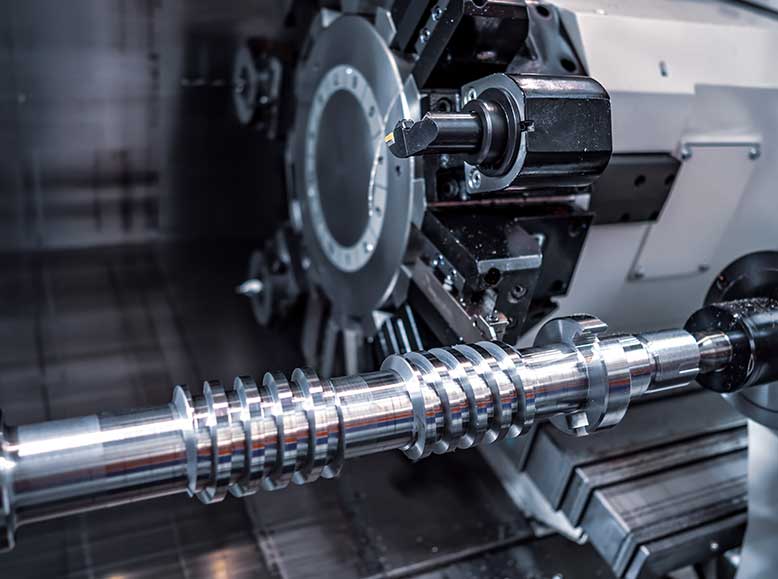

CNC turning

CNC turning is a kind of machining method which uses the rotating tool to remove the material on the workpiece in order to achieve the machining effect. A CNC lathe moves the tool and the workpiece, rotating the tool back and forth across the surface of the workpiece.

CNC turning is mainly used in the manufacture of rotating symmetrical parts, such as shaft parts, connectors, valves, etc. CNC lathes can process a workpiece by controlling the relative motion between the tool and the workpiece. The advantage of CNC turning is that it can produce parts with high precision and good surface quality. It can also be used to make high-volume products because the relative position between the tool and the workpiece is controlled by the computer.

CNC milling

CNC milling works by intersecting the rotating tool with the workpiece surface, allowing the tool to continuously remove material from the workpiece. Unlike CNC turning, CNC milling is often used to cut more complex shapes such as squares, grooves, and circles. In the process of CNC milling machine, the workpiece usually does not move, but the machine controls the position and direction of the cutting tool.

CNC milling is mainly used to manufacture flat and curved parts, such as thin-walled structural parts, parts facets, horizontal and vertical three-dimensional parts, etc. CNC milling machines can process the workpiece by controlling the relative motion of the tool in multiple directions. Compared with CNC lathes, CNC milling machines can perform complex cutting and forming operations. It can also use different types of cutting tools to complete a variety of processes such as drilling, boring and broaching.

In the manufacturing process, different machine tools should be selected for different parts to achieve the best machining results. Only in the selection of the right tools and equipment, we can better achieve high quality and efficient manufacturing of products