When it comes to manufacturing, precision is key. Whether you’re creating parts for aerospace or medical industries, or producing products for consumers, you need your machines to be accurate. That’s where milling machines come in. CNC milling is a method of using computer-programmed codes to control the movement of the machines, creating precise and complex parts with ease.

If you’re in the market for a milling machine, accuracy is likely one of your top priorities. And with good reason! Precision is essential in today’s competitive marketplace. Here are just a few of the benefits of investing in an accurate CNC milling machine:

Decreased Waste:

When your milling machine is accurate, you can produce parts with minimal waste. This not only saves you money, but it also reduces your environmental impact by minimizing the amount of material that ends up in landfills.

Improved Quality:

An accurate milling machine produces parts that meet your specifications exactly, every time. This ensures that your final products are of the highest quality, which is crucial for maintaining customer satisfaction and protecting your brand’s reputation.

Faster Production Times:

When you’re confident in the accuracy of your milling machine, you can speed up production times without sacrificing quality. This allows you to get your products to market faster, giving you a competitive edge.

What Factors Affect CNC Milling Accuracy?

CNC milling relies on precision to create quality parts. To achieve this, various factors need to be taken into account in the milling process. We’ll go over some of the most critical factors below.

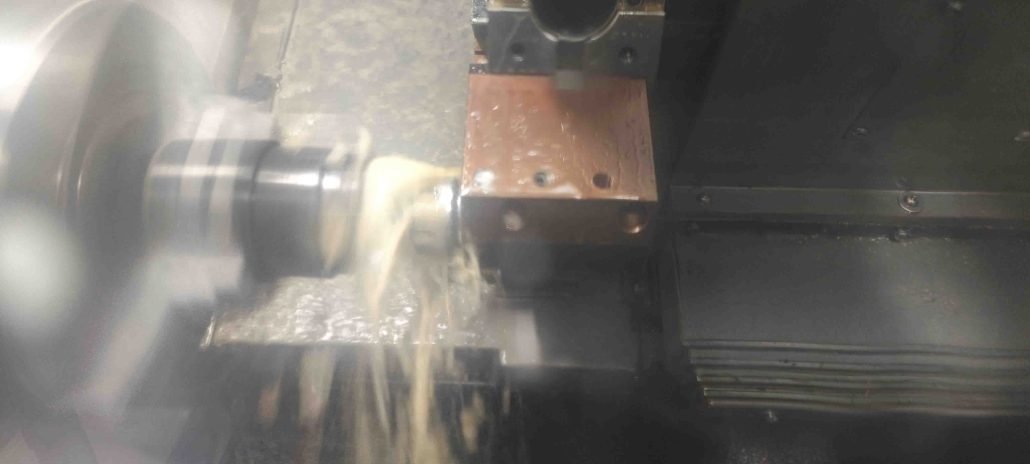

Machine Stability

One of the primary factors affecting CNC milling accuracy is the machine stability. It’s essential to ensure that the machine is stable enough to handle the cutting tool’s vibration during milling. A stable milling machine will ensure consistent results, higher accuracy, and smoother finishes.

Material Properties

The material properties also play a significant role in the milling process. Materials vary in their hardness, malleability, and ductility, and each characteristic demands a unique approach to achieve the desired accuracy. The properties of the material also affect the tool wear, cutting temperature, and chip evacuation, which can all impact the accuracy of the finished product.

Cutting Tool Quality

Choosing the right cutting tool is vital in achieving milling accuracy. The tool’s quality, geometry, and proper usage can influence the precision of the cutting process. High-quality cutting tools can enhance machining performance, improve accuracy, and extend tool life.

Cutting Parameters

The cutting parameters also impact CNC milling accuracy. These include the spindle speed, feed rate, depth of cut, and the tool path. Each of these parameters needs to be optimized carefully to create high-quality parts. Deviating from the optimal set of parameters can result in lower accuracy, surface roughness, and even tool breakage.

Operator Expertise

Lastly, the operator’s expertise can affect CNC milling accuracy. An experienced and highly-trained operator can understand the fundamentals of CNC milling and the intricacies of the machine. They can adjust the machine’s components, such as calibration, tolerances, and cutting parameters, to produce highly accurate machined parts.

To ensure the highest CNC milling accuracy possible, it’s essential to pay attention to the machine’s stability, material properties, cutting tool quality, cutting parameters, and operator expertise. These factors work together to determine the accuracy of the finished product.

How to Choose an Accurate CNC Milling Machine

Now that you understand the importance of accuracy in milling, it’s time to choose the right machine for your needs. Here are a few tips to help you get started:

Consider Your Materials:

Different materials require different machining processes. Make sure you choose a machine that can handle the materials you’ll be working with.

Evaluate the Machine’s Accuracy Rating:

Most CNC milling machines have an accuracy rating that measures how close the machine can get to your desired measurements. Look for a machine with a high accuracy rating to ensure you get the precision you need.

Research the Brand:

Make sure you choose a reputable brand with a history of producing quality machines. Look for reviews from other customers to get an idea of the machine’s performance.

Investing in a CNC machined is a big decision, but it can pay off in a big way for your business. By choosing an accurate machine, you’ll enjoy decreased waste, improved quality, and faster production times, all of which can help keep you competitive in today’s marketplace. Take the time to research your options and choose a machine that meets your needs and budget. With the right machine by your side, you’ll be able to take your manufacturing to the next level.

Achieving Uncompromising Accuracy with CNC Milling

Are you tired of inaccurate and unreliable results from your CNC milling process? Look no further, we have the solution for you. At Longsheng Technology, we understand the importance of precision and consistency in manufacturing. CNC milling is a cost-effective and efficient way to produce complex parts with the utmost accuracy, but only if done correctly.

Many factors contribute to achieving accurate results with CNC milling, including machine selection, tool quality, programming, and operator expertise. Investing in high-quality machines and tools is essential, but without skilled and knowledgeable operators, even the best equipment will fall short of expectations.

At Longsheng Technology, we prioritize extensive training and education for our operators to ensure precise and efficient results. Our team is experienced in programming complex geometries, minimizing setup times, and optimizing tool paths for maximum productivity.

Moreover, we use cutting-edge technology to monitor and adjust the milling process in real-time, reducing the risk of errors and defects. Our quality control measures guarantee that every part produced meets or exceeds our clients’ expectations.

In conclusion, achieving uncompromising accuracy with CNC milling is possible with the right combination of equipment, expertise, and technology. At Longsheng Technology, we strive to exceed our clients’ expectations and deliver exceptional results every time. Contact us today to learn more about our CNC milling services and how we can help you achieve your manufacturing goals.

FAQ

CNC milling accuracy is the ability of a CNC milling machine to create precise and accurate parts repeatedly. The accuracy of CNC milling depends on a machine’s ability to interpret the design data, the precision of the spindle motor, and the control system’s accuracy.

There are some limitations to CNC milling accuracy. Some of the limitations include:

Material hardness: If the material being milled is too dense or hard, it can cause tool damage, reducing the milling’s accuracy.

Tool changes: Frequent tool changes can affect the milling’s accuracy.

Workpiece size: The larger the workpiece, the more challenging it is to maintain CNC milling accuracy.