This document provides an overview of CNC rapid prototyping, a manufacturing process that utilizes computer numerical control (CNC) machines to quickly and accurately produce high-quality parts and components. The advantages, applications, and disadvantages of CNC rapid prototyping are discussed, as well as the reasons why it is an ideal choice for rapid prototyping projects.

Is CNC Rapid Prototyping?

CNC is a manufacturing process that involves the use of pre-programmed computer software to control the movement of factory tools and machinery. CNC machines are widely used in manufacturing industries to produce high-quality, precision parts and components.

While CNC can be used for rapid prototyping, it is not considered a rapid prototyping technology. Rapid prototyping typically involves the use of 3D printing or other additive manufacturing techniques to quickly produce physical models of a design.

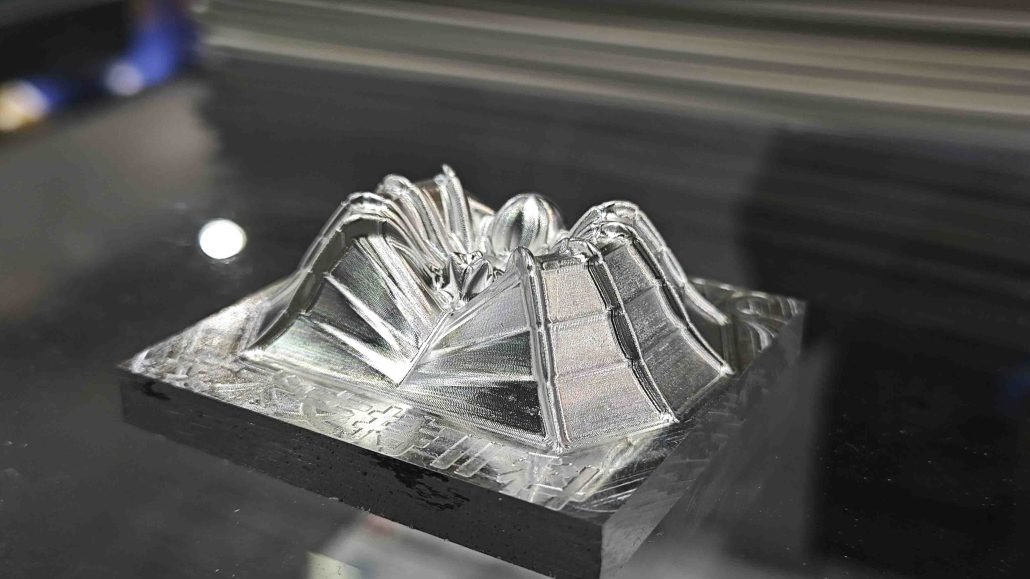

CNC, on the other hand, is a subtractive manufacturing process that involves the removal of material from a block or sheet of material to create a part or component. This process is typically slower than rapid prototyping and can be more expensive.

In conclusion, while CNC can be used for prototyping, it is not considered a rapid prototyping technology.

Advantages of CNC Rapid Prototyping

CNC rapid prototyping offers a number of advantages over traditional manufacturing processes. These include:

- Faster production times: CNC machines can produce parts and components much faster than traditional manufacturing processes, which can help to reduce lead times and increase productivity.

- Greater accuracy and precision: CNC machines are highly accurate and can produce parts and components with a high degree of precision, which is critical for many applications.

- Customization: CNC machines can be programmed to produce a wide range of parts and components, which makes them ideal for customized applications.

- Reduced costs: CNC machines can help to reduce costs associated with traditional manufacturing processes, such as tooling costs and labor costs.

- Flexibility: CNC machines can be programmed to produce a wide range of parts and components, which makes them ideal for small-batch production and specialized applications.

Overall, CNC rapid prototyping is an important technology that offers numerous advantages over traditional manufacturing processes. It is a versatile and effective way to produce high-quality parts and components quickly and efficiently, making it an ideal choice for many applications.

5 Reasons to Use CNC for Rapid Prototyping

CNC machines are a versatile and effective manufacturing technology that offer a number of advantages for rapid prototyping. Here are five reasons to consider using CNC for your next rapid prototyping project:

- Accuracy: CNC machines are highly accurate and can produce parts and components with a high degree of precision. This is critical for many rapid prototyping applications, where accuracy and precision are key factors.

- Flexibility: CNC machines can be programmed to produce a wide range of parts and components, which makes them ideal for rapid prototyping applications. They can be used to produce everything from small, intricate parts to large, complex assemblies.

- Speed: While CNC is not considered a rapid prototyping technology, it can be used to produce prototypes quickly and efficiently. CNC machines can produce parts and components much faster than traditional manufacturing processes, which can help to reduce lead times and increase productivity.

- Cost-Effective: CNC machines can help to reduce costs associated with rapid prototyping, such as tooling costs and labor costs. They can also be used to produce small batches of parts, which can be particularly useful for companies that need to produce parts on-demand or in small quantities.

- Customization: CNC machines can be programmed to produce a wide range of customized parts and components, which makes them ideal for rapid prototyping applications. They can be used to produce parts that are tailored to a company’s specific needs and requirements.

Overall, CNC is an important technology for rapid prototyping that offers numerous advantages over traditional manufacturing processes. By selecting the right manufacturing process for each application, companies can take advantage of the benefits of CNC rapid prototyping while minimizing its drawbacks.

Applications of CNC Rapid Prototyping

CNC rapid prototyping is a manufacturing process that allows for the quick and precise production of high-quality parts and components. This makes it an ideal technology for applications where accuracy and speed are key factors.

One of the most common applications of CNC rapid prototyping is the design and production of custom parts and components. Companies can use CNC machines to create parts and components that are tailored to their specific needs and requirements. This can be particularly useful for small businesses that need to produce unique parts that are not readily available on the market.

CNC rapid prototyping is also commonly used for the creation of prototypes for testing and validation. By using CNC machines to produce physical models of designs, companies can quickly assess the feasibility of a concept and make necessary changes before moving into full-scale production. This can help to save time and money in the long run.

Another application of CNC rapid prototyping is the production of small batches of parts for specialized applications. CNC machines can be programmed to produce a limited number of parts, which can be particularly useful for companies that need to produce parts on-demand or in small quantities.

CNC rapid prototyping can also be used for rapid tooling for injection molding and other manufacturing processes. By using CNC turning machining to produce molds and other tooling components, companies can speed up the manufacturing process and reduce costs associated with traditional tooling methods.

Overall, CNC rapid prototyping is a versatile and effective manufacturing technology that has a wide range of applications in various industries. It offers numerous advantages over traditional manufacturing processes, including faster production times, greater accuracy and precision, and the ability to produce customized parts and components. As such, it is an important technology for companies that are looking to stay competitive in today’s fast-paced business environment.

Disadvantages of CNC Rapid Prototyping

While CNC rapid prototyping offers many advantages over traditional manufacturing processes, there are also some disadvantages that should be considered. These include:

- Higher costs: CNC machines can be expensive to purchase and maintain, which can make them less cost-effective than other manufacturing processes for certain applications.

- Limitations in material selection: CNC machines are typically limited in the types of materials that can be used, which can make them less suitable for certain applications.

- Less suitable for complex geometries: CNC machines are better suited for simple geometries and may not be the best choice for producing parts with complex shapes and contours.

- Less suitable for rapid prototyping: While CNC machines can be used for prototyping, they are not considered a rapid prototyping technology and may not be the best choice for producing physical models quickly.

Despite these disadvantages, CNC rapid prototyping remains a versatile and effective manufacturing technology that has a wide range of applications in various industries. By understanding the limitations of CNC machines and selecting the right manufacturing process for each application, companies can take advantage of the benefits of CNC rapid prototyping while minimizing its drawbacks.

Longsheng: Precision CNC Rapid Prototyping Machining Services

Longsheng is a leading provider of precision CNC rapid prototyping machining services. We specialize in producing high-quality custom parts and components with quick turnaround times. Our state-of-the-art CNC machines are highly accurate and efficient, allowing us to produce complex parts and components with a high degree of precision.

Our CNC Rapid Prototyping Machining Services

At Longsheng, we offer a wide range of CNC rapid prototyping machining services to meet the needs of our clients. Our services include:

- CNC Milling: Our CNC milling services allow us to produce complex parts and components with a high degree of precision. We can machine a wide range of materials, including metals, plastics, and composites.

- CNC Turning: Our CNC turning services allow us to produce cylindrical parts with a high degree of accuracy and precision. We can machine a wide range of materials, including metals, plastics, and composites.

- CNC Routing: Our CNC routing services allow us to produce parts and components with complex shapes and contours. We can machine a wide range of materials, including metals, plastics, and composites.

- CNC EDM: Our CNC EDM services allow us to produce parts and components with complex shapes and contours. We can machine a wide range of materials, including metals, plastics, and composites.

- CNC Grinding: Our CNC grinding services allow us to produce parts and components with a high degree of accuracy and precision. We can machine a wide range of materials, including metals, plastics, and composites.

Advantages of Our CNC Rapid Prototyping Machining Services

At Longsheng, we understand that time is money. That’s why we offer rapid prototyping machining services that are designed to meet the needs of our clients. Our services offer a wide range of advantages, including:

- Quick Turnaround Times: Our CNC machining services are designed to deliver high-quality parts and components with quick turnaround times. We understand the importance of getting your project completed on time, and we work hard to meet your deadlines.

- High-Quality Parts and Components: Our CNC machines are highly accurate and efficient, allowing us to produce high-quality parts and components with a high degree of precision. We use only the highest quality materials to ensure that our products meet or exceed your expectations.

- Customized Solutions: We understand that every project is unique. That’s why we offer customized solutions that are designed to meet the specific needs of our clients. Whether you need a single part or a complex assembly, we can provide the solutions you need to get the job done right.

- Competitive Pricing: We understand the importance of staying competitive in today’s marketplace. That’s why we offer our CNC rapid prototyping machining services at competitive prices. We work hard to keep our costs low, so that we can pass those savings on to you.

Contact Us Today

At Longsheng, we are committed to providing our clients with the highest quality CNC rapid prototyping machining services. If you have a project that requires precision parts and components, contact us today to learn more about our services. We look forward to working with you to bring your project to life.

FAQ

CNC rapid prototyping is a manufacturing process that uses computer numerical control (CNC) machines to quickly and accurately produce high-quality parts and components.

CNC rapid prototyping is different from traditional manufacturing processes in that it uses subtractive manufacturing techniques to remove material from a block or sheet of material to create a part or component, while traditional manufacturing processes typically involve additive manufacturing techniques to build up a part or component layer by layer.

Some of the advantages of CNC rapid prototyping include faster production times, greater accuracy and precision, customization, reduced costs, and flexibility.

CNC rapid prototyping has a wide range of applications in various industries, including the design and production of custom parts and components, the creation of prototypes for testing and validation, the production of small batches of parts for specialized applications, and rapid tooling for injection molding and other manufacturing processes.

Some of the disadvantages of CNC rapid prototyping include higher costs, limitations in material selection, less suitability for complex geometries, and less suitability for rapid prototyping.

There are several reasons to consider using CNC for rapid prototyping, including its accuracy, flexibility, speed, cost-effectiveness, and customization capabilities.

In conclusion, CNC rapid prototyping is a versatile and effective manufacturing technology that offers numerous advantages over traditional manufacturing processes. It is particularly well-suited for applications where accuracy and speed are key factors, such as the design and production of custom parts and components, rapid tooling for injection molding and other manufacturing processes, and the creation of prototypes for testing and validation. By selecting the right manufacturing process for each application, companies can take advantage of the benefits of CNC rapid prototyping while minimizing its drawbacks.