There are no limits to creativity. All masterpieces begin with the stroke of an idea, and an accurate 3D model is the primary instrument for this idea. However, turning a computer model into a high-capacity, reliable, and ready-for-use physical piece of equipment is a challenging path.

For the typical hobbyist, freely available “free models” on the web are a starting point, but there is a huge difference between them and the demanding criteria of industrial-strength applications—criteria that require basic material science, micron-level precision, and specialized post-processing technology.

LS Manufacturing not only provides a wealth of free beginner 3D printing models as a great starting point for your creative projects, but bridges creativity and reality through our in-depth knowledge, from fast prototyping to low-volume custom manufacturing. To save you time, here

’s a quick overview of the core conclusions.

3D Printing Service Core Quick Reference

| Service Dimensions | Key Content | Key Values |

| Core Services | Rapid prototyping, batch-sized custom production, functional parts manufacturing, design optimization and verification. | Shorten innovation cycles, reduce mold development risks, and achieve complex structures. |

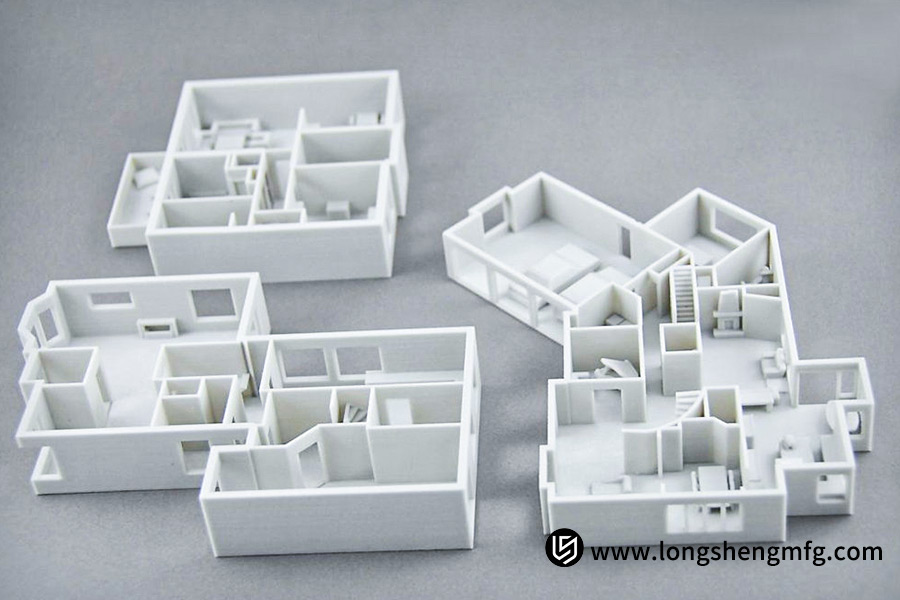

| Applications | Product development prototypes, jigs and fixtures, customized gifts, spare parts, architectural models, and medical models. | Meet different needs from R&D to production with special focus on personalized and complex structures. |

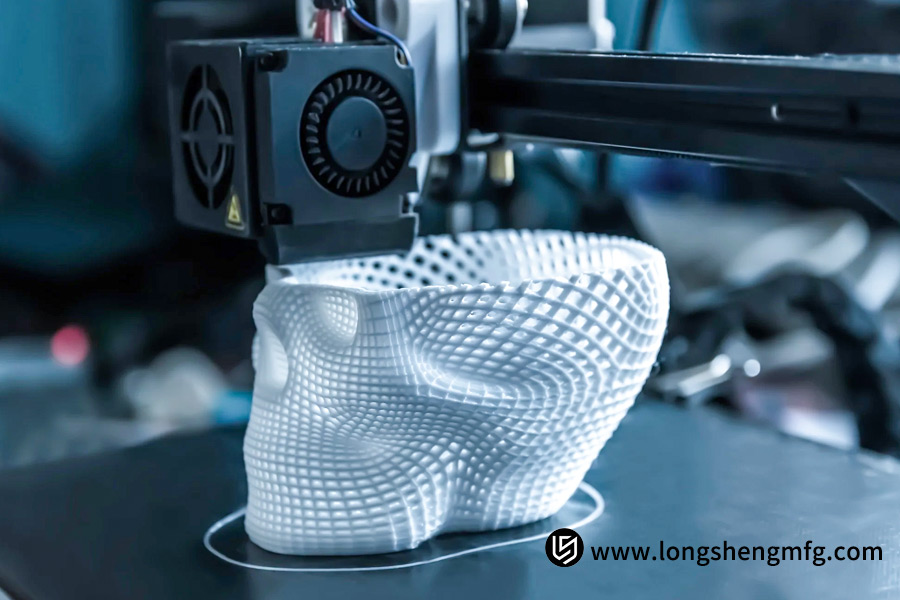

| Key Technologies | SLA, SLS, FDM. | Select optimum technology solution for different requirements (appearance, strength, price). |

| Standard Materials | Resins: High-definition, ABS-imitation. Engineering Plastics: Nylon (strong), ABS (hard), PLA (biodegradable). Metals: Stainless steel, titanium alloy, aluminum alloy (for finished parts). |

Entire range of materials is ready, from demonstration to final application, to ensure performance to specifications. |

| Key Strengths | Faster: Delivery within hours to days. Lower Cost: No mold cost, significant cost advantages for small-volume production. Greater Flexibility: Can produce nearly any complex geometry. |

3D printing enables disruptive advantages over traditional manufacturing in terms of iteration rate and design freedom. |

3D printing services have evolved from simple prototyping to a robust on-demand manufacturing and innovation capability. They are overcoming the speed and cost issues of “from design to reality” and are hence perfect for product development, customized manufacture, and small batch production.

Choosing a one-stop-shop partner like LS Manufacturing provides not only expert printing technology but also a single-source solution, from conceptual assistance based on a free model library through material science, process choice, and post-processing.

Why Trust This Guide? Practical Experience from LS Manufacturing Experts

All advice and observations contained within this guide are based on LS Manufacturing’s considerable hands-on experience with 3D printing. We do not offer abstract knowledge but also proven solutions backed by over 2,000 successful projects.

LS Manufacturing has helped customers overcome challenges in transforming “free models” to “durable, functional parts.” Examples include choosing the right nylon material for a small-volume robotic arm component to withstand long-term friction and impacts, or precisely adjusting process parameters to eliminate internal stress in a high-complexity structural part to prevent cracking under use, have all been crucial.

They have given us a deep understanding of how every aspect, from materials science and control of precision to post-processing, all contribute to determining whether a printed part succeeded or not.

LS Manufacturing does more than offer service; it offers expert experience, gained with tens of thousands of successes and failures, to help you not get caught out and achieve your goals.

Why Can’t the Free 3D Printing Models You Download Be Directly Used in Industrial Production?

When you excitedly find a free 3D print model that you like and are prepared to forward it to production, you typically find that the print yields are disappointing. This is not an error in the model but a big difference between fun models downloaded for free and industrial-grade 3D printed parts. The critical differences may be in the following points:

1. Structural Rationality:

Industrial designs adhere to “Design for Manufacturability” principles rigidly. For example, uniform wall thickness is ensured to prevent shrinkage and distortion; support structures are preoptimized rather than automatic software generation so as to avoid contact point scarring and material wastage.

2. Precision and Assembly Requirements:

Industrial production components are typically printed 3D to mate with other components. Models therefore need to include realistic assembly tolerances, and free models do not include this and therefore are unassembly parts.

3. File Format Differences:

Normal STL files consist of triangular facets and contain one unit of information. The commercial world, though, employs parametric formats such as STEP, which retain modeling history and attributes, allowing for easier modification and accuracy adjustments down the line.

Free 3D printable models provided by LS Manufacturing are all optimized for manufacturability. Most importantly, we provide expert-level DFM (Device for Manufacturing) analysis for whatever custom design you are working with to enable smooth transition from computer files to high-performance physical products.

How do you choose the most suitable 3D printing process and material for your project?

Choosing the most suitable 3D printing process and material is needed to determine product functionality and price. Faced with many technologies, bespoke 3D printing production by expert does not take a one-size-fits-all approach. There is a summary of common industrial processes below:

- SLA (photopolymer lamination): With good precision and a high surface finish, it’s utilized for proof-of-concepts and demonstration models, but the strength and temperature resistance are usually low.

- SLS (nylon powder lamination): The printed parts possess good mechanical strength and heat resistance, no support structure required, best suited for complex internal details, functional parts, and low-part numbers end-use parts.

- FDM (engineered plastics): Based on materials such as ABS, nylon, or PC, it offers a blend of strength, toughness, and price, and is suitable for tooling fixtures, housings, and harsh prototypes.

- Metal SLM: It can directly manufacture metal parts with mechanical properties equal to traditional castings. It is used in high-performance, high-temperature-resistant end-use parts in the aerospace, medical, and automotive sectors.

The key to choosing the right process is to balance strength, temperature resistance, accuracy, surface finish, and price.

LS Manufacturing has an enormous library of processes and materials. Our strength lies in our capability to provide data-driven, expert recommendation proposals based on your exact functional needs so you receive the optimal solution for your custom 3D printing job.

Why is “free G-code” not used in professional 3D printing services?

Free G-code files for 3D printing models are found online, offering the “print-and-use” convenience. But in industrial-level 3D printing services, direct usage of imported G-code is completely bypassed as it is a top priority and major product quality risk.The underlying reasons are:

1. Machine Specificity and Instability:

G-code is a set of commands that tells a specific printer to do something. It is directly associated with the model machine, nozzle, hotbed, and even firmware revision. G-code generated on one manufacturer’s printer may lead to crashes, extrusion errors, or even print failure in another.

2. Missing Process Parameters and Risks:

Quality print depends on precise control of dozens of invisible variables, such as extrusion pressure, cooling rate, and interlayer bonding. Standard G-code cannot guarantee these variables are correctly optimized for your equipment and material, causing invisible defects such as internal stress, insufficient interlayer bonding, or size errors in parts.

3. Guaranteed Performance Consistency:

The backbone of industrial-grade production is reliability and repeatability. Industrial-strength service companies like LS Manufacturing use a proven, proprietary library of process parameters to guarantee that every printed layer is optimized for optimum mechanical properties and dimensional integrity. This is a level of quality control that no G-code 3D printed models with no cost can offer.

That is why professional 3D print service will not use off-the-shelf G-code, simply in order to be able to ship every part you order with higher and more consistent performance from the very beginning.

How can professional post-processing elevate 3D printed parts?

From the build platform, 3D printed parts tend to have rough attributes such as support marks and layer lines. It is here where expert post-processing comes to the rescue. Expert post-processing in custom 3D printing is more than a “touch-up”; it is a critical process that adds functionality, aesthetics, and commercial viability to parts. Expert post-processing introduces a qualitative improvement through the use of a variety of processes:

- Surface Finishing: Sandblasting and grinding considerably improve the feel of parts, achieving a uniform matte finish and establishing a good foundation for subsequent painting.

- Aesthetic and Protective Enhancements: Electroplating and painting not only impart any desired brand color or metallic sheen to parts, but also form a protective coating, adding chemical and scratch resistance.

- Performance Enhancement: For resin components, UV curing ensures complete material stability, whereas a proprietary penetration treatment closes pores efficiently, significantly improving water and moisture resistance.

LS Manufacturing’s bundled post-processing solutions ensure every 3D-printed component that meets end-use requirements for visual, tactile, as well as performance, unlocking the full potential of custom 3D printing.

The difference between a crude “prototype” and a production-ready “commercial-grade product” is in a sequence of expert post-processing operations.

What factors truly influence your 3D-printed part price?

When asking for 3D printing services, most customers are perplexed by the extremely variable 3D printing costs. In fact, an expert estimate depends on an open cost model and is much more than just “material utilization times unit price.” Critical factors influencing the cost of 3D printing are:

| Cost Structure | Specific Factors of Influence |

| Material Cost | Metal powders, resins, or high-performance engineering plastics are inherently costly, and the quote price includes waste and support material. |

| Print Time | It is linearly correlated with the machine type, part height, and fill density. Increased print time increases equipment utilization and energy costs. |

| Post-Processing Complexity | The material and labor expense of simple support removal versus full-scale spraying, punching, and infiltration treatment are radically different. |

| Operations and Management | Inequisible expenses such as professional process optimization, quality inspection, and order management are the key to quality assurance. |

LS Manufacturing is committed to delivering to you a clear cost split so that you can realize the value of each investment without succumbing to meaningless comparing numbers while ignoring the end part quality and reliability. The value of a professional 3D printing service is to obtain high-quality parts meeting all your requirements at an equitable total cost.

The rationale behind the quotations by LS Manufacturing is the overall cost advantage we realize by virtue of streamlined layout, efficient processes, and mass production.

How does 3D printing seamlessly transition from prototyping to small-batch production?

During the process of product development, the transition from prototype testing to small-batch market introduction generally creates a gap due to the change in manufacturing process. The most effective bridge for this gap is expert 3D printing services, which enable smooth idea-to-product conversion. Expert 3D printing has unique advantages in achieving that:

1. Seamless iteration accelerates innovation:

Design iterations only consist of digital model modification, not re-molding or production line modification. This accelerates product optimization cycles from days or weeks to hours, significantly accelerating the R&D process.

2. Guaranteed consistency and manageable risk:

LS Manufacturing uses master digital files and a highly automated print farm to deliver high consistency in dimensions, performance, and material from first prototype through to tiny runs of hundreds of products, effectively eliminating risk of inconsistency between trial and mass production outcomes.

3. Agile response to seize business opportunities:

In instances where early rollouts or market testing are necessary, this digital manufacturing platform supports “on-demand production,” quickly making hundreds of high-quality products, effectively enabling customers to establish market demand without subjecting them to substantial initial inventory costs.

By integrating design and manufacturing, custom 3D printing provides innovators with an agile pathway from prototype to low-volume production.

LS Manufacturing’s 3D printing technologies are your trusted ally, helping you take the all-critical leap from zero to one product with low risk and high efficiency.

How did LS Manufacturing help a robotics startup transform a free prototype into a competition-winning part?

In innovation competitions, a good concept can begin as an open-source 3D printable model from the web, but making it an actual competition-worthy 3D printed component is where the magic begins. This is the story of our collaboration with a university robotics team.

1. Client’s Dilemma:

The team built a light robot arm joint using a free 3D printable design. Although their printed component was defective, the primary load-carrying component kept on breaking repeatedly when tested, and the unpainted finish created too much friction, significantly affecting the robot’s performance.

2. LS Manufacturing’s Solution:

Confronted with this task, LS Manufacturing’s engineering team demonstrated the quality of their experience in custom 3D printing:

- They had a finite element analysis done to the original part to carry out a rigorous structural analysis, and ribs were then introduced on carefully selected stress concentration points.

- SLS printing in carbon fiber-reinforced nylon was then proposed for maximum strength-to-weight ratio.

- Finally, important bearing seat surfaces were precisely precision machined to ensure assembly accuracy and smooth movement.

3. Results and Value:

The professionally optimized 3D-printed part achieved a massive 15% weight reduction with 300% increased strength. The competition-grade high-performance part was a winner, which won the competition for the team. Professional custom 3D printing services can here take a standard free model and optimize it into a competition-winning, competition-grade part, providing innovators end-to-end technical support from concept to win.

Professional custom 3D printing services can transform an ordinary free model into a competition-quality, winning component, providing innovative teams with comprehensive technical support from concept to success.

Beyond providing models, what else can a professional 3D printing service provider do for you?

Most individuals have the impression that 3D print services are just “printing to a drawing,” yet a seasoned partner can provide so much more. Utilizing LS Manufacturing for your custom 3D printing provides access to an engineering group that is dedicated to realizing your product’s greatest value. Our value-added services include:

- Design and Manufacturing Feasibility Analysis: Once you submit your design, our engineers will give you a complimentary Design for Manufacturing (DFM) analysis, complete with optimization recommendations for critical factors such as wall thickness and assembly tolerances, removing production risks right from the start.

- Material and Process Selection Consultation: From your part’s functional requirements, we provide fact-based material and process pairings, rather than trying to sell you a product, so you get optimum performance per dollar.

- Expert Control Throughout the Entire Process: From rapid and accurate quote turnaround, to rigorous quality control throughout the print process, to single-source post-processing and simple assembly, our process gives you control and visibility at each stage.

- Continuous Technical Support: We’re your virtual R&D department, providing ongoing technical support throughout the product development process, helping you work through the hurdles of prototyping and low-volume production.

By choosing LS Manufacturing, you’re not just buying a manufacturer; you’re buying an engineering partner dedicated to making your products competitive. Let us help you turn your concepts into genuinely dependable, high-performance product solutions.

How to Start Your First Professional 3D Printing Project?

It is easy to start your first professional 3D print project. Whether you start with a free 3D printable design from our extensive range or if you already have an existing design, LS Manufacturing provides an easy and transparent partnering process. Simply follow these four straightforward steps:

- Step 1: Get Resources or Upload Your Design: Either upload your design files directly (compatible with a variety of formats like STP and STEP) or download free manufacturability-optimized 3D printable models from our website.

- Step 2: Communicate Your Needs with an Expert: Our application engineers will reach out to you proactively for a speedy and agile conversation to learn about your performance requirements, budget, and timelines to gain a clear picture of your project goals.

- Step 3: Get a Professional Quote and Design for Manufacturing (DFM) Analysis: We’ll send you an open and honest quote, and our professional Design for Manufacturing (DFM) analysis report, complete with optimization recommendations and potential risks noted.

- Step 4: Confirm and Enter Production: After confirmation, your project will be directly entered into our high-quality production process, offering a one-stop 3D printing service from printing to post-processing.

Choose LS Manufacturing as your trusted manufacturing partner. Experience the quality guarantee and peace of mind professional 3D printing services bring you, from your very first project.

FAQs

1. Can I really get some 3D printable models for free?

Yes, you may also download free manufacturability-optimized 3D printable models from the official LS Manufacturing website’s resource library. The wall thickness and support structures of the models, which are critical parameters, are pre-adjusted. They are either an excellent starting point for your concepts or otherwise a direct testbed to verify so that you feel the amazing difference between professional models and online models.

2. Why is the price of 3D printing higher than I expected?

The cost profile of industrial 3D printing is more complex than you may think. On top of raw material, the largest cost is depreciation of industrial equipment, investment in process R&D, a rigorous quality inspection regime, and skilled post-processing. These investments enable the precision, durability, and reliability of every part that is required for industrial application and not merely quoted per gram.

3. Can you print any free STL files I find?

LS Manufacturing can print nearly any STL file, but we strongly suggest you utilize our complimentary Design for Manufacturing (DFM) analysis service beforehand. Free models are filled with design flaws such as variable wall thickness and poor draft angles. Our engineers will render them manufacturable, significantly improving print success rates and part functionality, and reducing time and cost.

4. Are 3D-printed small-batch parts strong enough?

Yes. By using engineering materials like nylon, carbon fiber composites, or metals with commercial print technologies like SLS and SLM, the components can be produced as strong as injection molded components with the added advantage of light weighting. The components have found extensive usage in functional testing, fixtures, and end products, meeting the strength requirements of most industrial applications.

Conclusion

To successfully turn online free 3D models into real-world high-performance components is not a matter of owning a printer but of the ordered assimilation and adept mastery of materials science, precision engineering, design for manufacturability, and adept post-processing.

LS Manufacturing, through our full-spectrum engineering capability, provides a reliable bridge from electronic design to outstanding physical product. We ensure that all designs you create are not only accurately duplicated but also possess improved mechanical properties, ready to stand up to the rigors of real-world applications.

Your next masterpiece project warrants a beginning of excellence by professionals. Contact LS Manufacturing today and download our best-in-class industrially graded range of 3D models absolutely free, as a testbed for your ideas. Upload your design files and receive an exclusive Manufacturability Analysis and Quotation Report.

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.